I Bar Sealer: The Complete Buying Guide In 2025

I-bar sealers are becoming increasingly popular among businesses and manufacturers. These devices provide an efficient way to extend the shelf life of products. Not only do they provide a great, economical solution for keeping products fresh and safe but they are also incredibly easy to use and perfect for small businesses with limited space.

In this blog post, we will discuss all you may want to know about an I bar sealer from how it works, its components, applications and the different types of I bar sealer available on the market so as to help you make an informed decision on the model that suits your needs. Keep reading to learn more!

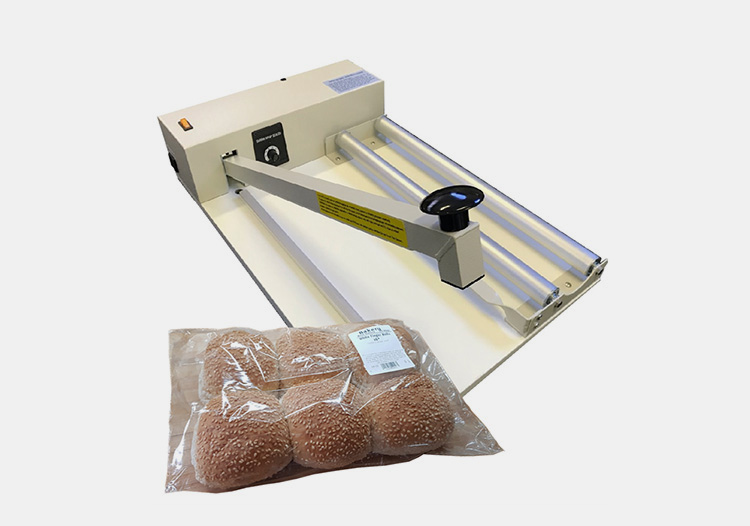

1.What Is An I Bar Sealer?

An I bar sealer is a type of packaging equipment used for sealing plastic and polyethylene bags. This sealer makes an airtight and tamper-proof seal that is simple to open with a pair of scissors or a knife using an I-bar mechanism. The food business, as well as the medical, pharmaceutical, and cosmetic sectors, frequently employ this kind of packaging.

By establishing a barrier between the product and the outside environment, the I bar sealer aids in preventing product contamination and spoiling. Additionally, it adds another line of defense against theft or tampering. The finished product is a packaging that is not only impervious to tampering but also attractive

In addition to its packaging capabilities, the I bar sealer can also be used to label products or print logos and other information on plastic bags. This makes it an invaluable tool for businesses that rely heavily on branding and customer loyalty. All in all, the I bar sealer is a versatile and reliable packaging machine that can be used for a variety of different applications.

2.What Are The Components Of An I Bar Sealer?

An I bar sealer consists of the following components:

Heating Element

This is a metal wire or ribbon that runs between the top and bottom jaws of the sealer. It generates heat to melt plastic film when it passes through the gap.

Timer

The timer allows you to set the sealing time for different types of plastic film thicknesses. This ensures a consistent heat seal quality every time.

Adjustable Temperature Control

The temperature control system allows you to adjust the heat levels to match the plastic film that is being used. This provides optimal sealing results for different types of films and thicknesses.

Pressure Plate

The pressure plate is located above the sealing jaws and it helps to keep a strong, even seal on plastic film or other materials.

Sealing Blade

The sealing blade is the component of the I bar sealer which cut through plastic film and creates a neat and even seal. It is usually made of stainless steel and can come in various shapes such as flat, round or v-shaped.

Jaw Bar

This is a bar that runs along the top of the sealing jaws and helps control their movement when sealing.

Cutting Blades

Cutting blades are located on either side of the sealing jaws and help trim excess plastic film or material.

Stand

This is a sturdy base that supports the entire I bar sealer and keeps it stable when in use.

Footswitch

A footswitch allows for hands-free operation of the I bar sealer, allowing users to move away from the machine while still controlling it.

Cooling Fan

This element helps to cool down the sealer after each use and prevents overheating of the heating element.

Safety Switch

This is an additional safety feature that shuts off the machine when it’s not in use, preventing accidents or injury to users.

3.What Are The Merits Of An I Bar Sealer?

Minimizes waste

By creating an airtight seal around the product, an I bar sealer prevents oxygen and other contaminants from entering and damaging the product, reducing waste.

Cost-effective

An I bar sealer is a cost-effective solution for packaging products since it does not require manual labor or specialized equipment to operate.

Versatility

I bar sealers are versatile and can be used with various types of materials including polyethylene, polypropylene and cellophane. This makes them suitable for almost any product packaging requirement.

Saves Time and Money

An I bar sealer is a faster solution for sealing products compared to manual packaging methods, allowing businesses to save time and money when packaging their products.

Occupies Less Space

An I bar sealer has a compact design which allow it to occupy very little space making it a great option for small business with limited storage or workspace.

Precision

I bar sealers offer precision sealing, ensuring that the product remains secure and properly sealed. This ensures that products reach their destination without any damage or contamination.

4.What Are The Applications Of An I Bar Sealer?

An I bar sealer can be used in many different industries. Here are some key applications of an I bar sealer:

Food Processing

I bar sealers are used to package and preserve food items, such as pre-cooked meals, snacks, and other perishables. The heat sealing process provides an airtight seal that prevents oxygen and bacteria from entering the packaging thus keeping the food fresh for longer periods of time.

Cosmetic Industry

When it comes to the cosmetic industry, I bar sealers are commonly used for packaging cosmetics, such as lip balms and eyeliners. They provide a strong and aesthetically pleasing seal that keeps the contents safe from contamination.

Pharmaceutical Industry

An I bar sealer can be used to seal bags containing medication and other medical supplies. The high quality seals provided by the machine helps ensure that the contents remain safe and secure for transport or storage.

Retail Packaging

In the retail industry, I bar sealers are often used to package items such as stationery, clothing and footwear due to their ability to provide a secure and tamper-proof seal.

Agricultural industry

An I bar sealer is useful for sealing packages containing agricultural goods such as grains and fertilizers. This sealer can provide a secure seal on the packages which will help protect the contents from damage or contamination during transport.

5.What Are The Working Principles Of An I Bar Sealer?

The working principles behind an I bar sealer are relatively simple. First, the material to be sealed is placed between the two heated bars and clamped together. The heat from the bars melts the edges of the bag or material, welding them together and creating an air-tight seal.

Depending on the type of sealer, the heat may be delivered through a continuous welding process, or with a single pulse. Once the bag is sealed, the I bar sealer can then be used to emboss product information into it, such as expiration dates and lot numbers.

6.What Are The Different Types Of I Bar Sealers Available On The Market?

a) Manual I Bar Sealer

Manual I bar sealers are ideal for small-scale operations that require a simple and cost effective sealing solutions. These machines are lightweight, easy to use, and can be used for sealing packages of various shapes and sizes.

b) Automatic I Bar Sealer

These are more advanced I bar sealers and are perfect for large-scale operations. They use heat and pressure to create an even stronger seal than the manual impulse sealer. Some automated models also come with a cutting system, allowing you to quickly cut through tough materials without compromising the integrity of the seal.

c) Impulse Sealers

These are manual sealers and are one of the most popular I bar sealers on the market. They utilize a heated metal clamp to make a tight, air-tight seal on poly bags or plastic film. The heat is generated by an electrical pulse which allows for quick, precise seals with minimal effort.

d) Foot Operated Sealers

These are similar to manual impulse sealers, but require the user to physically step on a pedal to activate the heat clamp. This type of sealer is perfect for high-volume operations, as it can quickly produce multiple seals without having to sacrifice accuracy or precision.

e) Continuous I Bar Sealer

These larger, industrial sealers are used for high-volume production processes, such as packaging large amounts of products. They feature multiple heating elements that move along a track, allowing them to quickly and efficiently seal plastic materials.

f) Vacuum I Bar Sealer

This type of machine is designed specifically for sealing vacuum-sensitive packages, such as those containing food or medical products. It features an airtight seal that helps maintain the product’s freshness and safety.

7.What Is The Difference Between Manual I Bar Sealers And Automatic I Bar Sealers?

Manual I bar sealers are typically designed for smaller runs and lower production rates. With this type of machine, the operator must manually place and secure the plastic bag in the sealing jaws before activating the heat element to close and seal it. Manual I bar sealers offer greater flexibility than automatic versions but require more attention from an operator.

Automatic I bar sealers take much of the manual labor out of the process. The operator places the plastic bag in a designated area and an automated system will move and secure it within the sealing jaws before activating the heat element to close and seal it. This type of machine is ideal for larger runs and higher production rates, but does require a greater up front cost.

Automatic I bar sealers also offer more consistent results than manual I bar sealers because they are not subject to the same variations that can be caused by human error.

8.What Is The Difference Between I Bar Sealers And L Bar Sealers?

The major difference between I bar sealers and L bar sealers is the size of their respective sealing heads and the items for which they are used. I bar sealers are primarily used for sealing plastic bags and have a long, narrow sealing head that is designed to create air-tight seals. This type of sealer will typically be able to accommodate thicker materials like polyethylene as well as lighter weight packaging films or fabrics.

L bar sealers are also designed to create air-tight seals; however, they are used mainly for sealing boxes or cartons. This type sealer has a wider sealing head and is equipped with an adjustable heat plate that is used to adjust the amount of pressure applied during sealing. Additionally, L bar sealers can be fitted with a cutter blade that will trim excess material while simultaneously heat sealing the box or carton.

9.What Type Of Materials Can Be Used With An I Bar Sealer?

An I bar sealer can be used with many different types of materials, including:

Polyethylene (PE)

This is the most commonly used material for I bar sealers and offers good heat, chemical and moisture resistance. It is suitable for use with food, medical supplies, and other products that require a sealed package.

Polypropylene (PP)

PP is similar to PE in terms of its properties, but is slightly harder and more durable. It is suitable for use with heavier items and provides a stronger seal than PE.

Vinyl

Vinyl is a flexible material that can be used to seal products requiring a more pliable package. It is resistance to water, grease, and oils.

Laminated Films

Laminated films are composed of multiple layers of different materials and provide an enhanced seal, making them suitable for medical or hazardous applications.

Aluminum Foil

An I bar sealer can be used to heat seal aluminum foil. This is often used for packaging food items, where the sealing process helps to keep the contents fresh and protected from contamination.

Paper

An I bar sealer can also be used to seal paper, allowing for airtight packages that protect their contents. This is particularly useful for items such as documents, which need to stay secure and protected from external elements.

Fiberboard

Fiberboard is made from recycled paper and cardboard and provides a strong seal for packaging heavier items. It is not recommended for use in extreme temperatures or with liquid products.

10.What Are The Maintenance Procedures Of An I Bar Sealer?

The maintenance of an I bar sealer is important for ensuring it operates correctly and efficiently. Here are some tips on the maintenance procedures you should follow:

First, inspect the unit regularly. Make sure that all seals and connections are properly connected and sealed. Check if there are any cracks or damage to the I bar sealer itself. Replace any defective parts as soon as possible.

Second, clean your I bar sealer regularly. Remove any residue from the sealing surfaces to ensure a good seal closure every time.

Third, lubricate the seals and moving parts of the machine. This helps prevent wear and tear on these components, and it also helps keep them from becoming stuck or clogged with dust or other particles.

Fourth, check the temperature settings to ensure that your I bar sealer is functioning properly. Overheating can cause damage to the seals and other components, so it's important to make sure they are set correctly.

Fifth, inspect all safety devices on the I bar sealer regularly. Make sure they are functioning properly and that all guards are in place. Also test any emergency shut-off systems that may be present.

Finally, check the electrical system to ensure that all wires and connections are secure. Inspect for corrosion, too. If any problems are found, replace them immediately.

11.What Are Some Of The Common Problems Associated With I Bar Sealers And Their Possible Solutions?

Jammed Sealing Bars

This occurs when there is an obstruction in the way of the sealing bars, preventing them from closing properly and resulting in a poor seal.

Possible Solutions

Increasing air pressure, using different sizing tape, or changing the packaging material being used.

Poor Film Tracking

Unstable film tracking is often caused by incorrect settings on the machine, such as incorrect speed or tension.

Possible Solution

Adjusting the settings can help improve the film tracking and produce better seals.

Overheating

Overheating is a common issue when using an I bar sealer. This can be caused by a number of factors, such as the speed at which the machine is running, the type of material being sealed, or incorrect settings on the machine.

Possible Solution

Decrease the speed at which the machine runs and ensure that the temperatures are correct.

Corrosion

Corrosion of the machine’s components can be caused by moisture or other particles entering the sealing chamber. This can lead to the machine having difficulty in sealing correctly and efficiently.

Possible Solution

To help prevent corrosion, it is important to ensure that all parts are kept dry and free from any corrosive materials.

Clogging

Clogging of the seals can happen when there is an accumulation of particles, such as dust or powder. This can cause the seals to be blocked and unable to seal correctly.

Possible Solution

Make sure the seals are always clean and unobstructed by anything by regularly inspecting them.

12.How Can You Choose The Right I Bar Sealer For Your Needs?

Choosing the right, I bar sealer for your needs can be a daunting task. However, the following considerations can help you to select the best one for your needs.

Consider the size and thickness of the material you plan on sealing

Different I bar sealers can accommodate materials of varying sizes, so it is important to make sure that your chosen machine fits within the desired parameters. Additionally, depending on what type of material you are using, different machines may require differing levels of heat for effective sealing.

Think about the speed of your sealing process

Different I bar sealers can offer various speeds, and selecting an appropriate machine will depend on the number of products you are planning to produce over a given period of time.

Look into features such as temperature and pressure control

Depending on the type of material you plan to seal, it may be beneficial to look for a machine that offers temperature and pressure control features. This will ensure that you achieve the desired effect from your I bar sealer.

Think about the overall cost of the machine

Price tags for various machines vary, so be careful to shop around before making a purchase. Also, keep in mind the price of any accessories or replacement parts that you might need to buy later on.

Research customer reviews and ratings

You may get a better understanding of how well a certain machine operates by reading customer reviews, so make sure to use this information before making a choice of your I bar sealer.

CONCLUSION

When it comes to sealing applications, properly sealing a package and product are key areas that can determine the outcome of an entire shipment. Choosing an I bar sealer from Allpack demonstrates your commitment towards providing safe and secure packaging solutions for all products involved. This highly efficient and effective sealer is just what you need for any packaging application. Not only will this provide optimal protection for your products during shipping, but it also saves time and effort on the packing line due to its highly durable construction. Plus, with its many features like adjustable timer settings and adjustable feet, no packaging challenge is too big or too small for the I bar sealer. If you’re ready to experience the power of an I bar sealer, don’t hesitate to contact Allpack today!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide