Top 10 Global Horizontal Form Fill Seal Machine Manufacturers: The Definite Guide In 2025

Top 10 Global Horizontal Form Fill Seal Machine Manufacturers: The Definite Guide In 2025

Do you want to be familiar with top 10 global horizontal form fill seal machine manufacturers? Or are you interested in buying the best horizontal form fill seal machine for your system?

If your answer is yes, then you are on the right forum. We are here to guide you more about the global leading manufacturers of HFFS machine and their customer related dedications. This guide will help you in going through their best collection of HFFS machines and all product related information.

Here is the list of top 10global horizontal form fill seal machine manufacturers

| S.NO | MANUFACTURES OF HORIZONTAL FORM FILL SEAL MACHINE | HEADQUARTER |

| 1 | Syntegon Technology | Germany |

| 2 | IMA Group | Italy |

| 3 | ULMA Packaging | Spain |

| 4 | ALLPACK | China |

| 5 | PFM Packaging | Italy |

| 6 | BW Flexible Systems | US |

| 7 | LENIS | Canada |

| 8 | OPACK Machine | Turkey |

| 9 | Bossar Packaging | Spain |

| 10 | Imanpack | Italy |

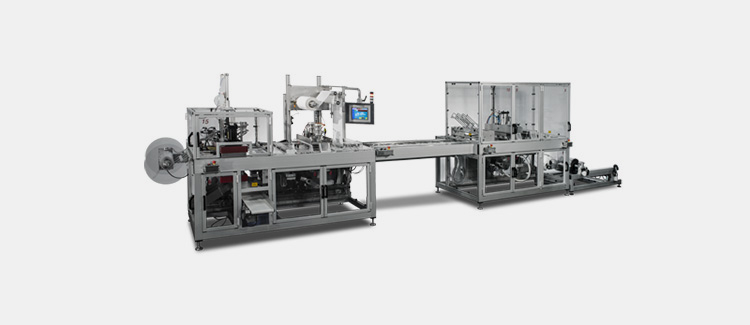

1. SYNTEGON

Company Background & Information

Syntegon is one of the leading process and packaging machine manufacturers with over 160 years of experience in this field. They have a large working force of around 5,800 individuals that are busy growing Syntegon to its ultimate level. They have installed 6 thousand machines globally, producing machines for pharmaceutical, food, and chemical industries.

Key Products

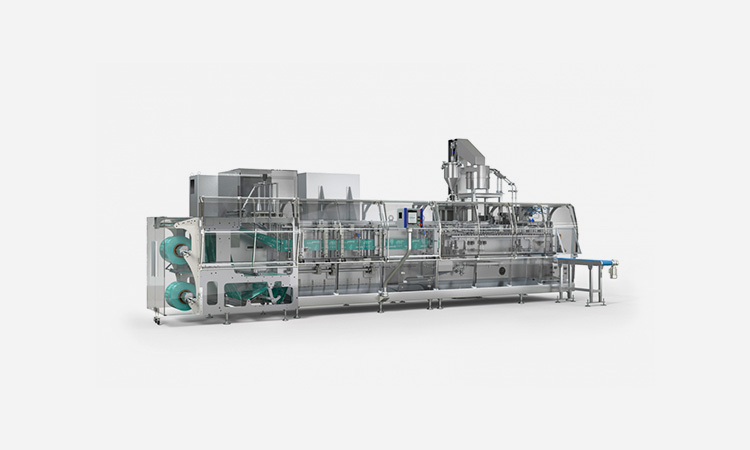

Syntegon Pack 102 Horizontal Flow Wrapper

Syntegon SigPack Horizontal Flow Wrapper

Recommend Reason

- Syntegon holds vast experience in producing highly innovative and productive ideas related to packaging machines.

- Syntegon holds plenty of resources for detailed knowledge as it holds over 1800 registered patents.

- Syntegon HFFS machine has the perfect combination of pressure, temperature and sealing duration that gives airtight solutions.

- The packaging gives hygienic solutions and avoids entrance to any type of environmental factor.

- Packaging style flexibility can be gained through highly automated machines of syntegon.

2. IMA Group

Company Background & Information

IMA Group is an expert in producing packaging lines and machines. They have a wide experience of over 50 years and are involved in producing modified atmospheric packaging machines that ease the process and provide high-quality packaging. IMA is also an expert in the manufacturing of wrap machines like horizontal form fill and seal machines and vertical form fill and seal machines.

Key Products

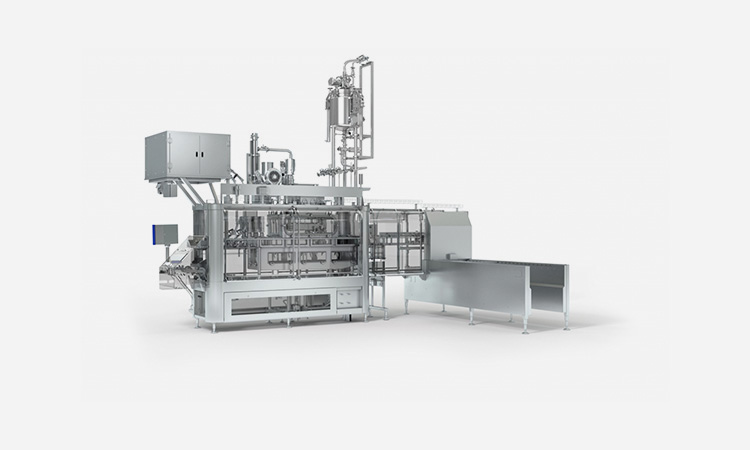

CARRERA I-500

CARRERA 1500

DELTA 3000

Recommend Reason

- IMA groups are well selected because of their high-quality customer care services and assistance.

- The supply of machines equipment and spare parts is done globally without any restrictions.

- Machines are manufactured starting from entry-level to any highly automated process line.

- Their machines are highly reliable and also do not produce any harm to the atmosphere.

- Machines are easy to control and no expertise is required.

3. ULMA Packaging

Company Background & Information

ULMA Packaging started its business in 1961 and since then they are been involved in designing and developing packaging machines and their solutions. Their highly experienced research and development department is working day and night to achieve their benchmark. With 7 sub-offices and 20 subsidiaries, ULMA packaging has a network now in more than 120 countries. They are experts in producing HFFS, VFFS, Thermoforming, and shrink-wrap machines.

Key Products

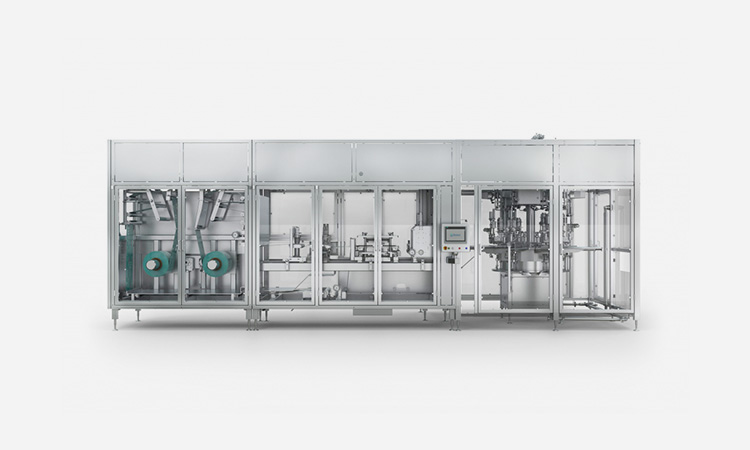

FR 100

FR 305

FM 300

Recommend Reason

- ULMA Packaging is an expert in producing machines from standalone to fully automated lines.

- High-quality food, cosmetics, pharmaceutical, and chemical packaging can be performed through HFFS machines.

- They support their customers from installation to commissioning and in every area.

- Machines are equipped with safety features and human life is considered as the foremost priority.

- HFFS machines of ULMA packaging are highly automated and adjusted with different package sizes.

4. ALLPACK

Company Background & Information

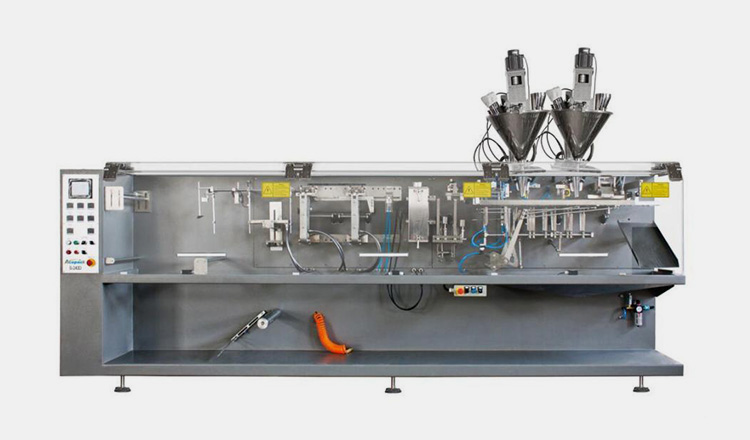

ALLPACK is a leading industry for manufacturing packaging machines that can be used in both the pharmaceutical and food industries. With a greater experience and focus, they have been involved in manufacturing various carton sealers, solid preparation lines, vacuum packaging machines, shrink packaging machines, capsule filling machines, tablet press machines, and other packaging machines. They completely focus on the priorities of their customers and live to grow each day.

Key Products

Automatic Horizontal Packaging Machine / DXDZ-350W/450W/630W

Automatic Horizontal Packaging Machine/ DXDZ-450B

Down-Paper type Horizontal Packaging Machine / DXDZ-350X

Recommend Reason

- With 12 years of experience, Allpack China has a variety of technologies that ease human efforts with perfection and performance.

- They deliver their machines in a fast method and also check their machines before sending them to their customers.

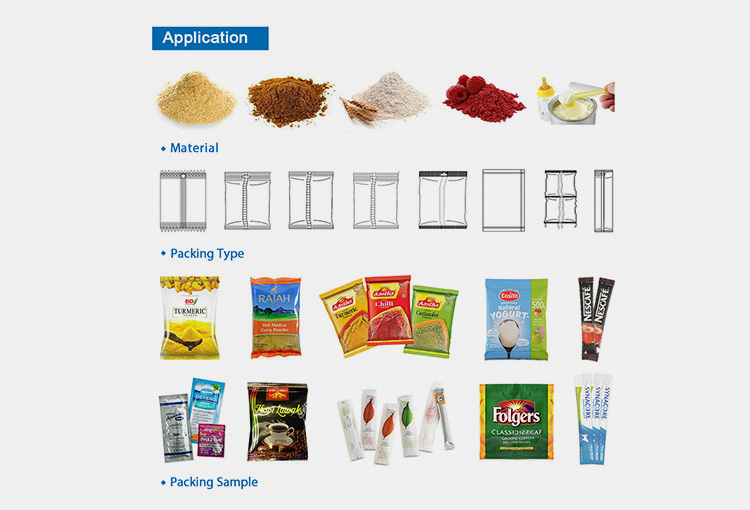

- HFFS machines can easily be used for packaging dry products, solid products, and liquid products.

- Cookies, bread, crumbs, different types of candies, toffees, and bubble gums can easily be packaged and sealed using HFFS machines

- Allpack produces high-definition machines that can be used in food, cosmetics, agriculture, pharmaceutical, and other industries.

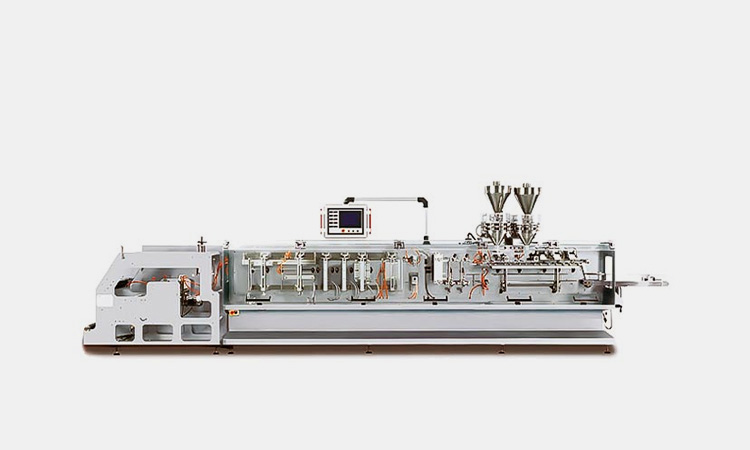

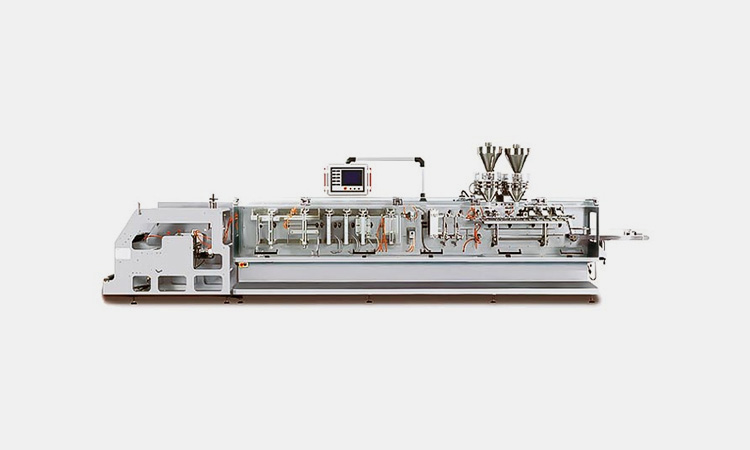

5. PFM Packaging

Company Background & Information

PFM Packaging is highly expert in manufacturing packaging machines that can be flexibly used in both food and nonfood industries. The company started its business in 1964 and since its first day, they're continuously improved their technology to fulfill global demand. PFM packaging follows ISO 9001:2015 quality system in their process to produce high-definition machines with customer satisfaction and ease.

Key Products

- PFM D320 DUPLEX

PFM D-EPT SERIES SIMPLEX

PFM D400 DUPLEX

Recommend Reason

- Their nearly 30 packaging research centers are busy in developing flexible machines that can easily accommodate in any production line.

- They offer remote training and assistance facility to their customers.

- Machines can easily save up to 30 to 40% of the film roll and avoids any type of wastage.

- Innovative packaging with ecological, economic and printable patterns can be gained using HFFS machines of PFM Packaging.

- The main feature of their machines is that their spares are easily available that reduces machine breakdowns.

6. BW Flexible Systems

Company Background & Information

BW flexible systems are globally accepted manufacturer of packaging systems for both food and non food industries. They have a wide network of customers and have their locations in more than 40 countries of world. They are expert in producing flow wrap machines, feeding and bag filling machines, form fill and seal machines, paper and mailer insertion and etc. Their products are globally used in food, pharmaceutical and packaging industries due to high efficiency and reliability.

Key Products

ROSE FORGROVE INTEGRA (BOTTOM REEL)

SCHIB CO90

SCHIB® CO50 HORIZONTAL FLOW WRAPPER

Recommend Reason

- Their 60 years or experience make sure their products are reliable and flexible during any type of production setup.

- BW flexible systems offer designing, delivery of design and single piece perfection that values its customers.

- BW flexible systems produces high quality packaging machines that can easily be used for any type of packaging style including doy style, flat bottom and etc.

- They have a wide coverage area that they can directly react to complain of their customers.

- HFFS machines can be easily used in home, food, pharmaceutical, personal care and industrial purposes.

7. LENIS

Company Background & Information

LENIS machines are global producers of sealing, wrapping, packaging, capping, cartooning, and bottling machines along with their filling process systems. They have been in this business for over 50 years now and are experts in high productive setups. They are focused on developing their machines and networks day by day empowering their employees to create more innovative ideas.

Key Products

MUSTANG-180 HFFS Doypack, Spout Pack, Flatpack Pouch Packaging Machines

MUSTANG-280D HFFS Doypack, Spout Pack, Flatpack Pouch Packaging Machines

APPALOOSA-180 HFFS Doypack, Spout Pack, Flatpack Pouch Packaging Machines

Recommend Reason

- Machines can easily be installed and commissioned when and where required.

- HFFS machines of LENIS are compatible with all sorts of packaging and filling machines.

- Pre made pouches and bags can easily be formed. These are further filled and sealed.

- Rotary or circulators mechanism is used for any type of machine that LENIS produces.

- They provide free of cost consultation to their customers and take their feedbacks as a challenge to achieve higher goals.

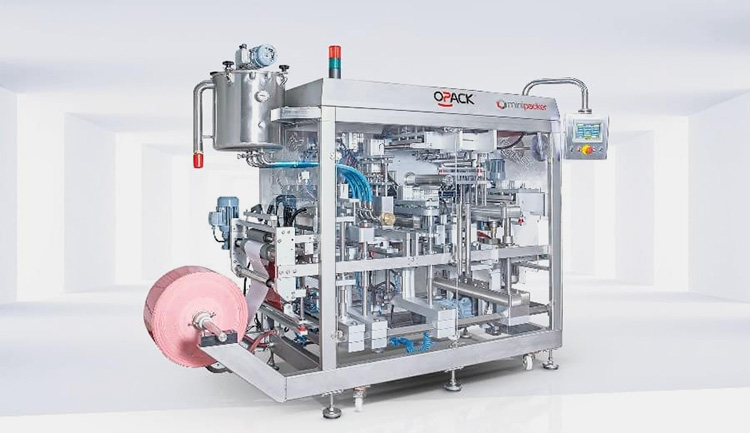

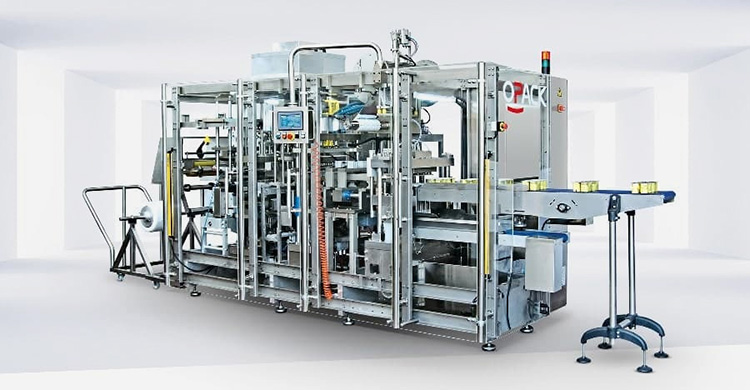

8. OPACK Machine

Company Background & Information

OPACK machine was founded in 2000 and is one of the leading manufacturers of packaging machines. They have a wide range of network that is spread in over 80 countries on different continents. They have been producing HFFS, VFFS, sealing machines, single and multi-head weighers, and other automatic packaging systems for food, pharmaceutical, beverage, chemical, and cosmetics industries. Today OPACK machines have around 2000 employees and strive together to design more advanced packaging machines.

Key Products

QT SERISI

QT SERISI-1

QT SERISI-2

Recommend Reason

- Machines of OPACK are highly versatile and give precise results that make it reliable to the customer.

- Their HFFS machines have the ability to maintain similar packaging results with efficiency and effectiveness.

- They produce a variety of HFFS machines that can be used in both medium and large scale industries.

- OPACK has a wide network of packaging and thermoforming machines.

- OPACK machines are globally recommended due to their greater export network in both Asia and Europe.

9. Bossar Packaging

Company Background & Information

One of the most reliable and authentic in terms of producing packaging solutions is “Bossar Packaging”. With over 190 years of experience, Bossor started its business back in 1831 and since then they have been the pioneers in manufacturing pouch, packages, cartons, and containers forming and sealing machines. Their machines are quick, efficient, reliable, authentic, convenient, and easy to operate. Their main goal is to work in a better way for better customer satisfaction and they are on the right path.

Key Products

BMS

BCF

FSK

Recommend Reason

- Bossar packaging produces highly automated HFFS machines that can easily be adjusted in any packaging line.

- Bossar produces the most sustainable packaging solutions with plenty of features.

- Can easily be bought and are economical for new users.

- Machines are easy to handle that no prior expertise are required.

- HFFS machines produce high quality, reliable packaging that does not gets affected even after its transportation to global customers.

10. Imanpack

Company Background & Information

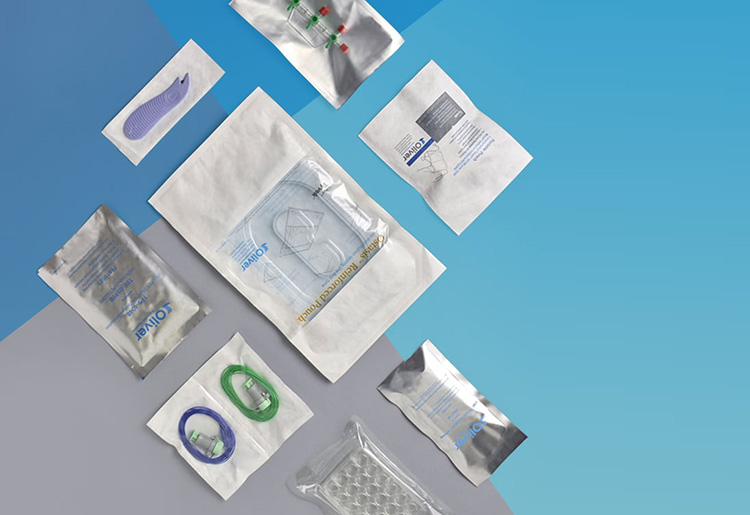

With over 45 years of experience, Imanpack was founded in 1975 and are specialized in producing and designing high-quality customized packaging lines. Their machines are widely used in the food, pharmaceutical and cosmetics industries due to their precise and high-definition cutting solutions. Imanpack has continuously evolved through customer feedback and return innovations. They have a total of 60 subsidiaries globally and produce case packers, cartooning machines, VFFS, and HFFS machines.

Key Products

MICROPACK PRO BAGMATIC

MICRO PRO LTS

MOONLIGHT LTS PBA-PBB

Recommend Reason

- The most unique advantage that Imanpack offers is that the machines can easily package multiple styles of bag including quad seal, pillow bags and gusseted sealing.

- The film tracking system can assure the alignment of in feed film for proper packaging.

- The packaging bags are precisely sealed in a uniform manner using HFFS machine of Imanpack machines.

- Machines have built in pneumatic systems that help in long size sealing options up to 250mm.

- Imanpack offers pleasant wrapping using polyethylene and polypropylene films that can wrap up to 100 bags per minute.

Conclusion

All of your queries regarding this top 10 global horizontal film form and sealing machine manufacturers are now been answered and you have got all the necessary information. If the article still leaves some questions or you are stuck in selecting the best machine for your setup, Allpack is providing you a variety of HFFS machine options. Our customer service representatives are here to assist you 24/7 or visit our website www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours