Continuous Band Sealer: The Complete Buying Guide In 2025

Sealing multiple kinds of pouches & packets with the help of continuous heat can be done while using a tool which is very effective.

And that tool is continuous band sealer, which is used in sealing pouches in a continuous fashion with the help of heat and pressure by using a conveyor belt and jaws.

Do not think too much because all of your confusion will be gone after reading this complete guide about continuous band sealer and its different industrial aspects. So, without wasting any time let’s read.

1.What is continuous band sealer?

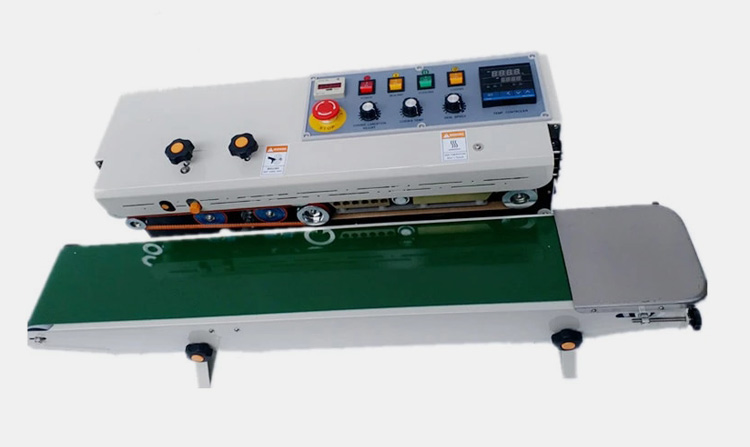

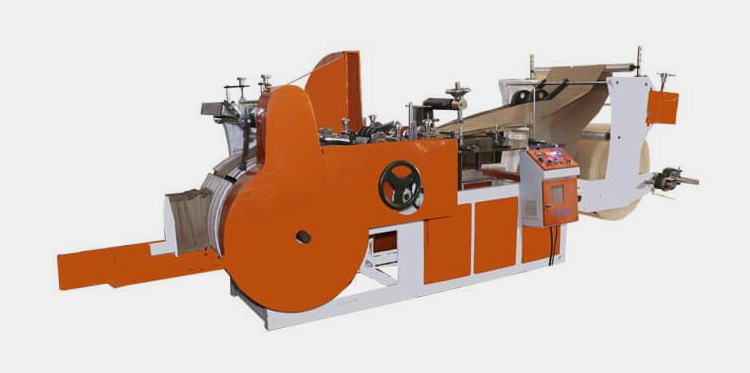

Continuous Band Sealer

Continuous band sealer is a very efficient and effective device that is extensively used for sealing different types of bags and pouches with the application of continuous pressure and heat.

This type of sealer employs the use of its jaws and conveyor belt for continuously sealing different kinds of products in different types of packaging materials such as Led Aluminum, Polyethylene, PP materials, Nylon and laminated BOPP.

The continuous band sealer combines the function of knurling or printing and bag sealing.

2.Why it is called continuous band sealer?

The continuous band sealer is named so because of its mode of action. It performs its function of sealing continuously without any pauses, breaks or delays.

Application of continuous seal by employing continuous heat and pressure makes the continuous band sealer a very efficient and time saving device and that is why it is called continuous band sealer.

3.How continuous band sealer work?

Continuous Band Sealer

The working of continuous band sealer is very simple and easy to understand. The body of the continuous band sealer is made up of stainless steel frame.

The machine has controlling systems for adjusting the speed and heat of sealing and it also has a transmission system. An immediate rise in temperature is caused by turning ON the heat of the continuous band sealer.

The operator adjusts the speed of sealing according to the type of material he is going to seal. After all the conditions are set for sealing, the package to be sealed is placed on the conveyor belt.

The conveyor belt then moves with the speed adjusted by the operator and takes the package to be sealed towards the heating blocks for sealing it.

There are two heating blocks and the package to be sealed is placed between them and these heating blocks then seal the package by the application of the heat as specified by the operator.

After the package has been sealed well enough, it is then taken to the cooling block. In the cooling block, the package is allowed to cool down and congeal.

When the package has been cooled, the sealing operation is almost complete but there is one last step remaining. The package is sent to the embossing wheel where a mesheedd seal line is applied.

It must be noted that all the moving parts of the continuous band sealer like conveyer belts, sealing belts and drive belts are operated by the motor.

4.What are the different working parts of continuous band sealer?

Continuous band sealer has many working parts which work in harmony to ensure the proper functioning of the continuous band sealer. Some of these parts are described below.

Power Button

The power button is used to turn the continuous band sealer ON and OFF. This is the most basic yet very important part of the continuous band sealer

Temperature Controller

The temperature controller of the continuous band sealer is a very important part as it allows the operator to adjust the temperature of the heating rods according to the packaging material.

Adjustment of the temperature in the continuous band sealer is very important as different materials require different amount of heat to get sealed properly.

Speed Controller

This part of the continuous band sealer is used to adjust the speed of the operation. A perfectly adjusted speed is very important for efficient working of the continuous band sealer.

Conveyor Belt

Conveyor belt is another important part of the continuous band sealer. It performs the important function of moving the packages to be sealed from one point to the other.

The conveyor belt takes the packages from the starting point to the sealing jaws and then to the cooling site form where the sealed packages are collected.

Based on the requirements of the operator and the size of the machine, the conveyor belts are available in a variety of size, curvature, direction and pace.

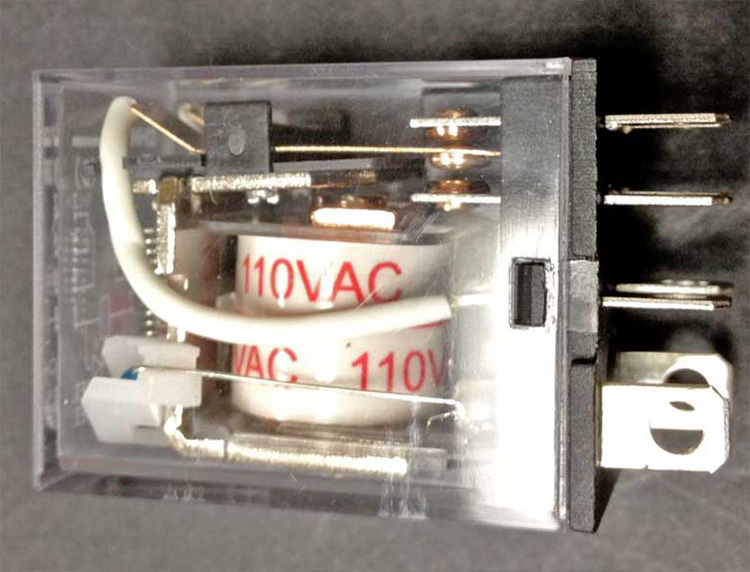

Relay

The relay is an automatic switch that employees the use of electromagnetism for converting the small electrical stimuli into larger currents.

It is used to control the flow of electricity in the continuous band sealer.

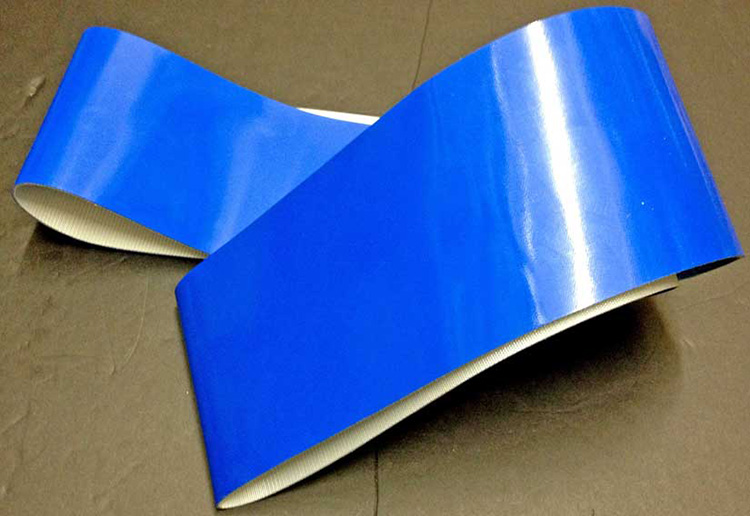

Sealing Band

Sealing band of the continuous band sealer is the most important part that performs the most important function of sealing.

It has heating blocks that apply heat to the package and seal it. The amount of heat applied is adjusted by the controller according to the requirements.

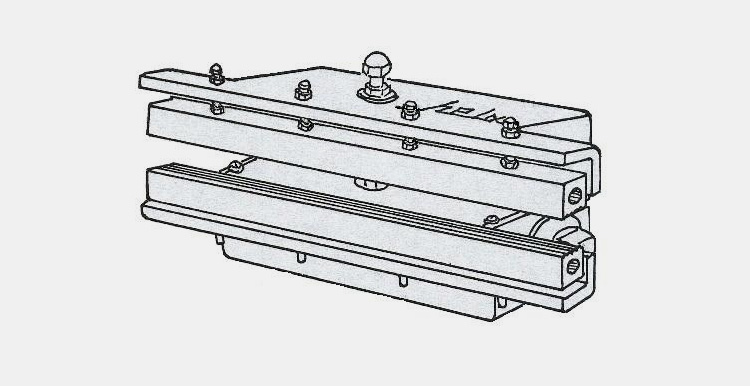

Jaws

Jaws of Continuous band sealer

The jaws are part of the continuous band sealer that are used to apply pressure on the package for sealing purpose.

Application of the right amount of pressure on the package is very important for the application of an efficient seal on the package.

The Cooling Block

The cooling block of the continuous band sealer is the part where the sealed packages are allowed to cool down.

When the packages come out of the heating block, they are very hot due to the application of heat in the heating block. These packages are sent to this cooling block where they get cooled down and congealed.

5.What are the advantages of having a continuous band sealer?

Continuous band sealer has proved to be a very beneficial invention for many industries. It has many advantages.

Some of these advantages are discussed below.

Efficient Operation

The continuous band sealer is a very efficient sealing device. Efficiency here means that the sealing of the packages by the continuous band sealer is reliable and there are almost zero chances of any spillage or leakage from the packages sealed by the application of the continuous band sealer.

User Friendly

The continuous band sealer is a very user friendly device as it is really easy to operate. The operator just needs to set up the speed and temperature for the operation and the continuous band sealer does the rest of the work according to the instructions specified by the operator.

Therefore, no professional training is required for operating the continuous band sealer.

Economical Machine

The continuous band sealer is very budget friendly and economical machine. Given the wide range of advantages, the price of the continuous band sealer is very reasonable.

The machine also does mot use a lot of electricity so you do not need to worry about the bills and expenses.

Versatile

Among various advantages, one of the most prominent benefits of this machine is its quality of being highly versatile. It can process products of every nature whether solid, semi-solid, and liquid or powder etc. Furthermore, it can effectively seal bags of any shape or length.

6.What are the different types of continuous band sealer?

The continuous band sealer has different types based on the automation of the operation of machine. These types are described below.

On The Basis Of Automation

These categories display the kinds of continuous band sealer, in a way, that how much degree of automation they possess:

Fully Automatic Continuous Band Sealer

The fully automatic continuous band sealer is the most advanced, and the most efficient variant of the continuous band sealer. As the name indicates, the working of the automatic continuous band sealer is fully automated and it requires minimum human help for its operation. The efficiency of machine is highest however; it will take your good amount of money due to its expensive price.

Components

Fully automatic continuous band sealer has its own parts and also auxiliary devices. Together they include: sealing head crank, movable conveyor, cooling block, embossing wheel, circuit breaker, heavy duty stainless steel stand, wheels, emergency stop and control board which is itself collection of many controlling systems like temperature speed, conveyor speed and coding etc.

Working Principles

The operator is just required to adjust the speed and heat of the automatic continuous band sealer and place the packages on the conveyor belt. The packages are taken by the automatic continuous band sealer towards the heating blocks for sealing and then towards the cooling block for cooling down the packages. All the work of sealing, embossing and cooling is done by the automatic continuous band sealer itself and the operator then collects the sealed package out of the machine.

Application

The automatic continuous band sealer is suitable for larger industries where large number of packages is required to be sealed in short time such as condiment industry, dairy industry, baking industry and snack food processing industries.

Semi-Automatic Continuous Band Sealer

The semi-automatic continuous band sealer is less automated and need more human intervention than the automatic continuous band sealer.

Unlike the automatic variant, the semi-automatic continuous band sealer requires the operator supervision and help to perform the sealing function. Although, it is economical solution for packaging of your vary goods.

Components

It is composed of main frame, conveying system, heating system, sealing bars, control panel, emergency stop, and casters and sealing head etc.

Working Principles

Semi automatic continuous band sealer ask an operator to provide it with filled bags, so the process can be further taken on basis of already fixed configurations. The opening of bag is appropriately positioned in the bag entry place. Now comes the function of machine where it carries bag via conveyor belt and passed through sealing strips. Here, heat is released which gets the dual layers of bag stick together, after which phase of cooling and embossing is achieved through driving. A line of dry ink is then printed over bag and sealing is completed with conveyor discharging bag.

Application

This machine has good demand in medium scale production firms like bakery, grocery market or chemical industry etc.

Manual Continuous Band Sealer

As clearly indicated by the name, the manual continuous band sealer is a manually operated device that requires an operator for its operation. It is manually operated thus has low speed in processing. Although, it is less expensive and cheap in price.

Components

This machine has few parts such as stainless steel body, power cable, upper and lower sealing bars, switch button, power indicating light and screw button for temperature adjustment.

Working Principles

With easy usability, you just have to put the bags between sealing bars and press the upper side of machine in order to connect it with lower side tightly. It would only take few moments to hermetically seal the packs.

Application

You can use this precise and portable machine in your houses, stores and laboratories etc.

These are the three variants of the continuous band sealer and all of them are used in different sizes of industries where they are best suited.

On The Basis Of Structure

Horizontal and vertical continuous band sealers are the two major kinds on structural basis. Their structure can be analyzed as:

Vertical Continuous Band Sealer

Vertical continuous band sealer is popular sealing machine integrated with full heavy-duty stainless steel stand that is employed to seal vertical bags with high volume. It works automatically and has good output ratio.

Components

Structure of machine is made up of vertical stand, driving wheel, embossing block, sealing head, movable wheels, bag loading plate, machine adjusting handle, temperature control, conveyor speed control, printing device, emergency alarm button and sealing clips.

Working Principles

Its operation is somehow different from other kinds of sealers as bags are placed in upward direction, so their mouth can touch the sealing strips and get attached to the opposite layers of film, eventually embossing and coding is done. After finishing each pack, the sealer grabs another object via conveyor belt and start revising same method.

Application

Bags containing rice, flour, cereals and high density items are often processed by this type of sealer. In addition, semi-solid products like pickles, ginger and garlic paste etc.

Horizontal Continuous Band Sealer

It is the most prevalent equipment integrated with certain features. With good speed up, horizontal continuous band sealer ideal for solid and powdery substances but not suitable for liquid materials. You can also attach this machine with additional stand depending on the height your production line suit. Furthermore, it is available in automatic and semi-automatic form.

Components

Major elements of machine are horizontal frame, cooling block, embossing wheel, guiding rail, heat controller, power system, digital display, emergency stop and sealing strips etc.

Working Principles

Like other sealer, you are first required to set up measurements and let the filled bags be passed through heating phase through guide rail. After getting heat, sealing is cool down and printed right after embossing. When task is accomplished, line of ink is drawn by printer. Now, the use can pick out the bag.

Application

This device is recognized by diverse sectors of production like pharmaceutical, food, baking, and milk powder manufacturing industries.

7.Differentiate between Horizontal continuous band sealer and Vertical continuous band sealer?

Some prominent distinctions between horizontal and vertical continuous band sealer can be understood by factors configured below:

| No | Features | Horizontal Continuous Band Sealer | Vertical Continuous Band Sealer |

| 1 | Structure | It is horizontal shaped, which process light weighted bags | It is vertical shaped, that process light weighted bags |

| 2 | Process | Bags are laid in horizontal position and passed through sealing, cooling, embossing and printing phase | Bags are placed in standing position and sealed through heated sealing bars, cooling, embossing and dry coding |

| 3 | Components | It consists of standard parts, but there is no distance between sealing head and conveyor belt | With usual parts it has additional stand located between sealing head and conveyor belt which differs it from horizontal sealer |

| 4 | Capacity | Its capacity is good but for low volume products only | It is fast for both low and high density items |

| 5 | Application | Peanuts, coffee beans, snacks etc. | Milk powder, rice, flour, sugar etc. |

| 6 | Example |  |

|

8.In which industries continuous band sealer is used?

As already discussed, the continuous band sealer is a very versatile device and is used in many different industries for packaging and sealing a variety of products.

Some of the industries in which the continuous band sealer is used for packaging and sealing are described below.

Food Industry

The continuous band sealer is most extensively used in the food industry. It is used for packaging various food products such as dairy products, teas, chips, sea foods, meat, fruits, vegetables and various other plant and animal products.

Confectionary items can also be efficiently packed and sealed by the application of the continuous band sealer.

The reason behind this extensive use of continuous band sealer in the food industry lies in the fact that the food requires a proper sealing for the maintenance of its quality and freshness.

The food needs to be saved from the air and moisture because these can lead to contamination and ultimately the spoiling of food products. This goal can be successfully achieved by the continuous band sealer.

The efficient sealing of the continuous band sealer does not allow any air or moisture to enter the package and therefore the freshness and the quality of the food product is maintained.

Pharmaceutical Industry

The pharmaceutical industry also employees the use of the continuous band sealer for sealing the packaging of the drugs that are prone to damage due to atmospheric moisture and air.

Presence of moisture provides an ideal atmosphere for the growth of microbes and the air contains many contaminants that may deteriorate the quality of the pharmaceutical product.

Therefore, the efficient sealing of the continuous band sealer is used in the pharmaceutical industry for preserving the quality and efficacy of the products.

The Cosmetic Industry

Cosmetic products also require proper sealing for the safety of the cosmetic products from the environmental hazards. Therefore, the continuous band sealer is used in the cosmetic industry also to seal the cosmetic products efficiently.

The Chemical Industry

There are many chemicals that get damage due to moisture and require sealing to avoid any damage due to moisture. The continuous band sealer does this important work and thus finds application in the chemical industry also.

The Automobile Industry

Vacuum Sealed Automobile Parts

The steel parts of the automobile industry are prone to damage due to rusting. Rusting is caused by the atmospheric moisture and so, there is a need for sealing the steel spare parts to avoid rusting.

The continuous band sealer is used in the automobile industry for sealing the parts that are prone to rusting.

9.Is it safe to use continuous band sealer for sealing food products?

The safety of any machine in the food industry is very important because it is directly related to the health of the consumer. The continuous band sealer is absolutely safe for use in the food industry for sealing the food products.

The efficient and fast operation of the continuous band sealer makes it a very strong candidate against other sealing devices for use in the food industry.

10.Describe the auxiliary devices for a continuous band sealer?

Are you administering the business of vast production? If yes! Then, this aspect of article is exactly for you, because it will enable you that how you can better manage the entire mechanism affiliated with bag production. Below accessories are essential for completing your production line. They are:

Bag Forming Machine

When talking about the supportive equipment for a continuous band sealer, we cannot ignore highlighting the importance of a bag forming machine. Depending on the stuff, either plastic or paper roller is placed in its location and through predetermined process these rollers are turned into desired shape of bags which can be used for grocery products, dairy products, snacks and many other things.

Bag Filling Machine

This machine is used to fill the bags with numerous items like cereal, beans, biscuits and peanuts etc. Before operation, material is loaded into the hopper and amount for filling each bag is fixed through control board. Thus, when mechanism begins, bags are carried out by conveyor belt and filled with load one after another. After their filling, they are sealed by continuous band sealer.

Vacuum Conveying Machine

Vacuum conveying is another crucial device majorly utilized for cleaning granules and pellets etc. Most of the products get dusted after passing through production phase, like candies, seeds, capsules and tablets etc. For their appropriate sanitation, vacuum conveyor is always preferred. There are different categories of vacuum conveyors, which are too eligible for processing liquids.

Nitrogen Gas Cylinder

Have you ever thought why the packs of chips are filled with air? And what is the nature of gas filled inside? It is due to their fragile nature, due to which nitrogen gas is infused into packets so their sterility and crisp could be well retained until it reach to consumer. For this purpose, nitrogen gas cylinder is the key component for a continuous band sealer.

11.Highlight the possible problems and their countermeasures for a continuous band sealer?

Whenever you counter any sort of hardship while using a continuous band sealer, you must have knowledge about the cause which is creating the problem. To accustom to with such information, we have brought you productive chart with possible issues their causes and remedies as well. Just keep reading:

| No | Problems | Causes | Remedies |

| 1 | Sealer is not running | Poor supply connection or inaccurate speed of sealer | Re-plug the machine and assure that speed of machine is well maintained |

| 2 | Seal gets crushed and film stick to the sealing bars | There are many reasons like intense temperature, incorrect conveyor placement or the melting of bag plastic | Try to control the temperature at modest level also modify guide belt. Do clean sealing bars or replace if damaged |

| 3 | The shape of dealing is irregular | Due to dirt or residual particles on sealing belt, sealing is often uneven | Thoroughly examine and clean the dust from sealing belt before starting operation |

| 4 | Sealer creates problem in temperature adjustment | Either the temperature controller switch, heat switch or heater itself is damaged | Check and replace the switches for entire heating system of sealer |

| 5 | Sealing belt and conveyor belt move non-parallel | Lack of force on conveyor belt | Make sure the front and middle shafts of conveyor belt are tightly screwed |

| 6 | Position of dry coder cannot be well regulated | It is due to loose coding wheel or the broken printing potentiometer | Fix the screw on coding wheel and replace the damage potentiometer |

12.What factors are essential to look for when purchasing a continuous band sealer?

There is no need to be hasty or hurried in purchasing a continuous band sealer rather in such circumstances you have to be vigilant and updated enough about the equipment you are intending to make part of your firm. For your assistance, following factors are essential:

Production Volume

Have you measured your daily production capacity? If not! Just do it, because it is the best time to shape the path for your business success. If you are producing moderate volume then semi-automatic is good but for high volume fully automatic is ideal. Likewise, for solid objects horizontal sealer while as for weighted and semi liquid products vertical sealer is best option. So, choose the machine which would take your production to next level.

Support Equipment

It is another question to think about, because your choice of sealer will ultimately determine the type of support equipment. Suppose, you are going to buy a fully automatic continuous band sealer, then you should have available equipment needed for operation. Moreover, for fragile materials like crunchy chips gas flushing machine is must as they get crushed if sealed without infusing gas.

Customer Support

Never ignore the factor of looking a reputable brand, because the vendor would always want to satisfy customers by providing full remote support. This can prevent you from big loss as you would have available platform to ask for help in case of confronting any issue.

Warranty Policy

Purchasing a machine is not something that can be taken light rather you are spending your precious amount of money. For making sure, that it is spent in accurate place you should never overlook the warranty policy of vendor.

Conclusion

Allpack continuous band sealer is an efficient, highly productive, easy to use and an economical device that has a wide range of applications in a variety of industries. Addition of the Allpack continuous band sealer in your industry can prove to be very beneficial in terms of boosting profit and reducing expenses. Please feel free to CONTACT US because It can prove to be a really healthy investment for your business.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours