Stick Packing Machine: The Complete Buying Guide In 2025

Stick pack is considered a popular single-serve packaging style because of its distinct shape, unlike sachet packaging. The rising demand for such carry-on packaging has driven the expansion of the stick packing machine market.

It is used for feeding all and sundry products like granules, powders, semi-solid, viscous liquids, and many more inside easy-to-open stick packs. Its convenience, simple operation, efficiency, and affordably have led to its frequent use in various industries, especially in the food and beverage industry.

Are you involved in the packaging business and want to add or upgrade a stick packing machine? Then without further ado read this blog to understand the essential parameters and working of such handy equipment.

1.Define Stick Packing Machine.

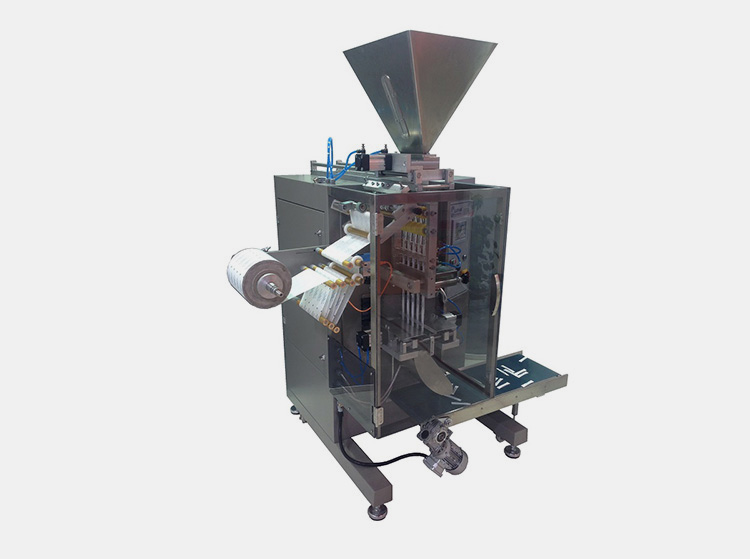

Aipak Stick Packing Machine

Stick pack is a prominent packaging format besides sachet and contains individual servings of products and is well-favored by go-the-go consumers. A special device known as a stick packing machine forms, fills, and seals stick packs that are longer in length but a minimal width.

A stick packing machine is a flexible and handy unit, capable of fabricating a tubular long stick pack. It packs a one-time serving of different products like granular, semi-viscous, viscous, free-flowing, powdery, gels into a stick pack.

This machine is designed with one up to 20 lanes and can output a maximum of 1600 stick packs per minute. Due to its increased efficiency, it has a dominant place in different industries from food to pharmaceutical and many more.

2.What are the Primary Benefits of Stick Packing Machine?

Due to the popularity of single-serve stick packs, more and more stick packing machines are utilized in industries. Stick packing machine is a remarkable equipment, generating profits for ventures, due to its high speed and efficiency. Some of the primary benefits of stick packing machines are:

High Efficiency and Speed

High Efficiency and Speed- Picture Courtesy: Aipak Pharma

The use of stick packing machines in lean packaging operations is rising because of their high efficiency and speed. With multi-lanes, it can output thousands of stick packs per minute. Moreover, with automated controls and high-tech systems, this machine has a high throughput, in turn increasing the number of products in the market.

Ease of Use

Ease of Use

This machine is designed with HMI, PLC systems, and high-efficiency sensors that allow the operator to monitor the progress of stick packing operation by remote connectivity. Moreover, HMI is a state-of-the-art system that aids operators in the convenient programming of protocols using pre-saved recipes.

Lower Packaging Waste

Lower Packaging Waste- Picture Courtesy: ePac Flexible Packaging

The utility of a stick packing machine is acquiring popularity, because of minimal use of packaging materials, which not only saves money but, also results in lower packaging waste. This in turn lowers the carbon footprint of the stick packing machine and enhances its sustainability.

Hygienic Design and Clean Packaging

Hygienic Design and Clean Packaging

The stick packing machine is manufactured by stringent practices of GMP, FDA, and GAMP5. Therefore, it has a hygienic design that is integral in maintaining sterility and cleanliness of the filling. By using a stick packing machine with laminar flow, gas flushing, and UV lights in the packaging operations, cross-contamination of the products is averted.

Versatility and Flexibility

Versatility and Flexibility of Stick Packing Machine- Picture Courtesy: Aipak

One of the huge benefits of a stick pack machine is its versatility. This flexibility is vital in processing present-day stick-pack styles and is good for future stick-pack formats as well. With fast format change between various batches, the stick packing machine has minimal downtimes and can process a wide-range of products, raw materials, and packaging films.

3.What are the Industrial Uses of A Stick Packing Machine?

The utility of stick packing machines in different industrial sectors is because of their ultimate fill accuracy and precision. Due to a list of various economic advantages, it is used in far and wide industries, for instance;

Food Industry

Use of Stick Packing Machine in Food Industry- Picture Courtesy: Behance

A stick packing machine is high in demand in the food industry for its simple fabrication of stylish stick packs that are popular among hard-at-work consumers. This machine packs diverse food types, like pastes, sauces, condiments, oils, salt, pepper, sugar, coffee, dressings, and so much more in the stick pack.

Beverage Industry

Use of Stick Packing Machine in Beverage Industry- Picture Courtesy: London Loves Beauty EU

It is yet another industry that increasingly utilizes the stick packing machine because of its accessibility and consistent performance. It is often used for packing sports drinks, juices, shakes instant coffee powders, etc in elegant and vibrant stick packs.

Pharmaceutical Industry

Use of Stick Packing Machine in Pharmaceutical Industry- Picture Courtesy: Labels & Labeling

Due to its clean packaging, the stick packing machine is employed in the pharmaceutical industry for housing medicinal powders, granules, liquids, pastes, and gels inside the stick pack. This machine packs gastric powders, electrolytes, and dermal creams in stick packs.

Nutraceutical Industry

Use of Stick Packing Machine in Nutraceutical Industry- Picture Courtesy: Korpack

Due to rising awareness of health, the demand for sports supplements, dietary fibers, energy drinks, etc., has increased. Therefore, a stick pack machine is used in the nutraceutical industry for filling probiotics, prebiotics, vitamin powders, protein shakes, and mineral supplements inside the stick packs.

Cannabis Industry

Use of Stick Packing Machine in Cannabis Industry- Picture Courtesy: Weedmap

In addition to the pharmaceutical and nutraceutical industry, a stick packing machine is also utilized in the cannabis industry for packing flavored cannabis powders into the stick packs. In the cannabis industry, the stick packing machine is mainly used for its consistent fill and quick packaging.

Cosmetic Industry

Use of Stick Packing Machine in Cosmetic Industry- Picture Courtesy: Dieline

A stick pack machine is also used in the cosmetic industry for the packaging of lotions, creams, foundations, hair gels, moisturizers, shampoos and conditioners in individual stick packs for travel cases. The stick pack is also a promotional format and is also distributed as a sample among customers.

4.What are the Essential Parts of a Stick Packing Machine?

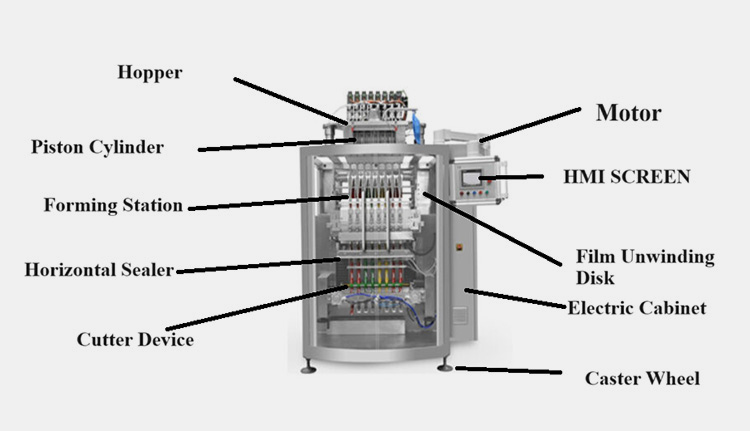

Stick packing machine is designed with numerous parts that have their specific role in the stick-pack packaging. A list of these essential components is given below:

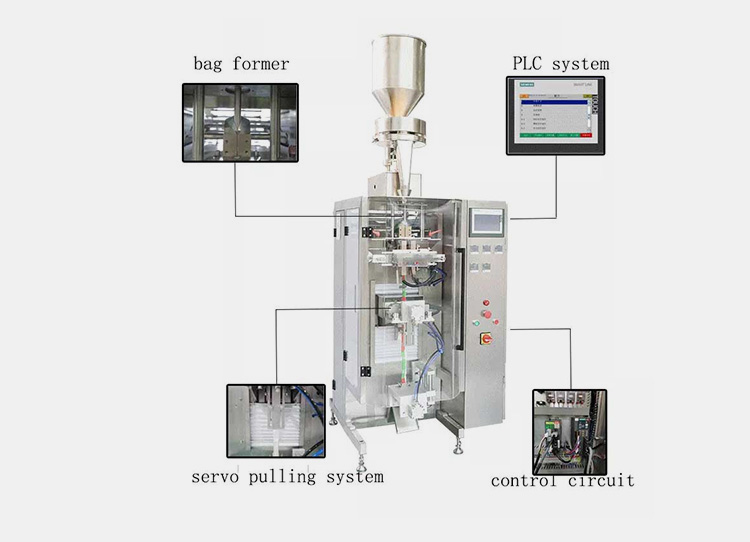

Parts of Aipak Stick Packing Machine

| Hopper | It is a bulk storage device that is seen at the top of the stick packing machine. This is a square or round hopper that meets out the right quantity of products to the filling devices. |

| Motor | It is considered the powerhouse of the stick packing machine. It is indispensable in the movement of all mobile parts because it provides them with mechanical energy for their work. |

| Piston Cylinder | The piston-cylinder encloses a piston device that goes forward and back to apply pressures on liquid products for their fluidity. |

| Forming Station | It is the part, where the strips are fashioned into stick packs by vertical sealers and forming tubes. |

| HMI Screen | It is an interactive interface that provides operator expediency in inputting packaging parameters. Self-diagnosis and troubleshooting are its other benefits. |

| Horizontal Sealer | This part via heat, pressure, or ultrasonic waves fuses the top and the bottom edges of the stick pack. |

| Cutter Device | The stick packing machine has sharp cutting knives at the lower portion that trim the edges of the stick packs for their disjoining. |

| Film Unwinding Disk | The packaging film stacked on the rolling stock untwists and voyages over the roller by the action of the unwinding disk. |

| Electrical Cabinet | The relays, breakers, switches, and wires are present in the electric cabinet for safety purposes. It is like the motherboard of the stick packing machine. |

| Caster Wheel | The caster wheels move and provide stability to the stick packing machine. They bear the weight of the machine and maintain its balance. |

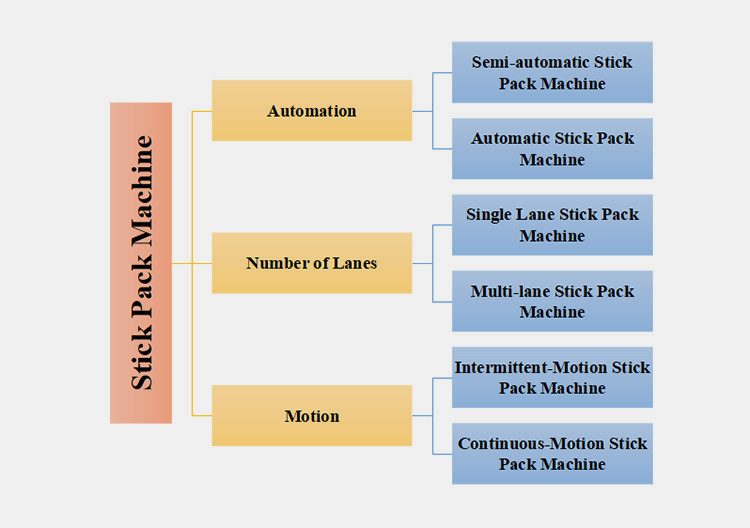

5.How Do Classify Stick Packing Machines?

The stick packing machine is categorized into several classes based on the level of automation, number of lanes, and motion types. The complete detail of its classification is penned below:

According to Automation

Semi-automatic Stick Packing Machine

Semi-automatic Stick Packing Machine

It is a simple compact machine, easily added in small and medium-sized businesses. This machine has straightforward working controlled by the machine PLC component. The filling, forming, and sealing of stick packs is autonomous. However, this machine is labour-intensive, as the operators load and remove raw materials and stick packs by hand from the machine.

It is comprised of one to two lanes, hence; its productivity is low.

Automatic Stick Packing Machine

Aipak Automatic Stick Packing Machine

It is a large-sized machine consisting of 4 to 20 lanes; thus, it is a fast and efficient unit. The machine packaging operation is fully automatic with the loading of raw materials, forming of stick packs, and their filling, sealing, and unloading of stick packs are performed by the machine automatically with no operator involvement.

It is an integral component of massive-scale operations due to its increased productivity.

According to the Number of Lanes

Single Lane Stick Packing Machine

Single Lane Stick Packing Machine

Its name is derived from a single lane in its design construction. Its processing volume is low because it forms and fills a single stick pack during one cycle. Mostly, this unit is a part of small and medium-scale enterprises.

Its biggest advantage is its compact construction with a smaller footprint; therefore, it is quite easy to clean, maintain, disassemble, and reassemble single lane Stick Packing Machine.

Multi-lane Stick Packing Machine

Aipak Multi-lane Stick Packing Machine

This type of stick packing machine boosts several lanes going as high as twenty. Due to the existence of multiple lanes, this machine can process multiple stick packs in one cycle. Because of its swift packaging, this machine is an important part of industries for packaging on-the-go products.

Every lane form, fill, and seal stick pack is in complete harmony. However, because of the presence of several lanes, space is its major drawback, as it needs more room for working.

According to the Motion Type

Intermittent-Motion Stick Packing Machine

Intermittent-Motion Stick Packing Machine- Picture Courtesy: Schmucker (S.R.L.)

As the name suggests, the mode of operation in these kinds of stick packing machines is intermittent, meaning the machine pauses when it is creating, loading, and sealing a stick pack, consequently, it has low processing capacity than a continuous-motion Stick Packing Machine.

It is also known as start and stop equipment. intermittent-motion stick packing machine is designed for production, where precise filling of delicate items is required.

Continuous-Motion Stick Packing Machine

Continuous-Motion Stick Packing Machine

This machine’s processing capacity is on the high end because it processes stick packs without pausing and stopping,g so it is a part of mass-scale operations. Continuous-motion stick packing machine works continuously without stopping between cycles.

It is a flexible and versatile unit, best for handling bulk items and heavy loads. It is more suited for filling robust products at a higher pace.

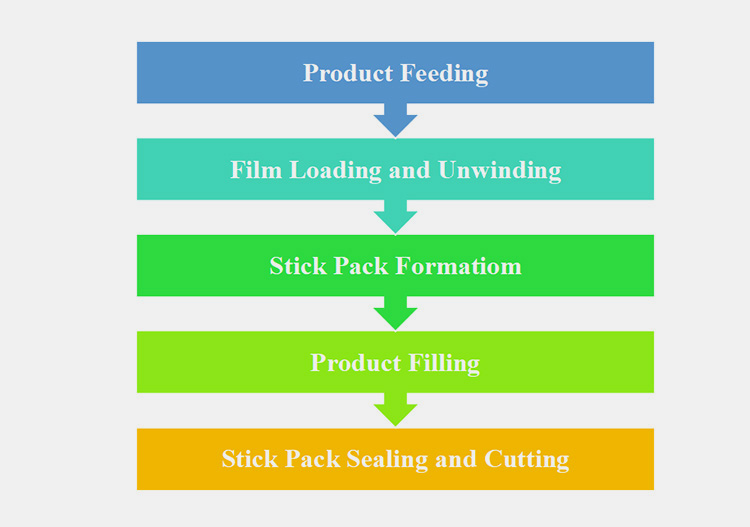

6.What is the Working Principle of the Stick Packing Machine?

The stick packing machine is comprised of various mechanical parts that act seamlessly to ensure perfect coordination in machine forming, filling, and sealing operations. Here is a list of different working steps:

Product Feeding

Product Feeding

The operators load the bulk quantities of product whether solid or liquid into the large square or circular type hopper normally present at the top of the machine. product feeding is important for seamless operation. Sometimes, infeed tanks are employed for dispensing products inside the hooper.

Film Loading and Unwinding

Film Loading and Unwinding- Picture Courtesy: Uslupak

Operators or robotic arms place a huge film roll over the rolling stock. The film unfurls by the movement of the film unwinding disk and is moved to sharp blades that cut the film into small individual strips. The number of strips formed in this section is dependent upon the number of lanes featured in the stick packing machine.

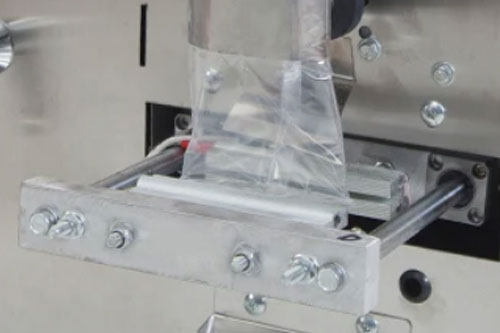

Stick Pack Formation

Stick Pack Formation

The film strips are then moved to the respective forming tube, where the forming collars of conical-shaped forming stations double and wrap the strips to form stick packs By ultrasonic waves or by high-temperature, vertical sealers fuse side seams of the tubular pouch and horizontal sealers seal the bottom seam. Due to the action of these sealers stick packs are formed.

Product Filling

Product Filling- Picture Courtesy: Marchesini Group

After stick pack formation, the filling devices in the stick packing machine activate and fill the products into the stick pack. By the rotation of the auger and volumetric cup, movement of the piston, and vibration of vibratory plates, the product flows from the hopper in the filling station and is then gradually dispensed inside the stick packs

Stick Pack Sealing and Cutting

Stick Pack Sealing and Cutting

Upon product dispensing, the final steps in the working of the stick packing machine are- cutting and sealing. These horizontal heated bars seal the top sides of stick packs while the sharp blades present in the center of horizontal bars separate two adjoining stick packs from each other.

7.What are the Filling Devices in Stick Packing Machine?

Filling Devices in Stick Packing Machine

Depending upon the nature of the products, there are different types of filling devices present in the stick packing machine. These filling devices are penned below:

Auger Filler

Auger Filler- Picture Courtesy: Helix Packaging

This is comprised of auger shaft, spinning plate, screws, funnel, and dispensing nozzle. It is a closed device that lowers product contamination. It is commonly used for dusty powders and granules. Auger shaft powered by motors rotates to mete out products from the nozzles. Auger fillers are accurate filling devices.

Piston Filler

Piston Filler- Picture Courtesy: Hunter Filling Systems

It consists of a hopper, piston, cylinder, and filling nozzles. The to-and-fro motion of a piston in the cylinder is essential in forcing the liquids and gels from the hopper to the cylinder and then to the stick pack. It is the most precise filling system, ideally used for viscous creams and pastes.

Volumetric Cup Filler

Volumetric Cup Filler- Picture Courtesy: Packaging and Labeling

It is mostly used for filling granular, powdery, and pellet products like grains, salt, coffee grounds and many more in the stick pack. It consists of rotating plates that have several cups and a calibrated syringe. At first, the syringe measures the volume for filling the cup and then it is dispensed inside the cup, from where it is loaded into the stick pack.

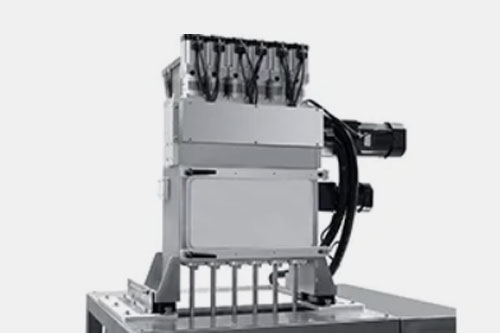

Multi-head Filler

Multi-head Filler

This filler in the stick packing machine loads snacks, confectionaries, and other small foodstuff in the stick pack. It is composed of multiple heads that work in synchronicity to fill stick packs. Multi-head fillers have high processivity and are highly accurate.

Pump Filler

Pump Filler

It is a filling device present in a stick packing machine, commonly employed for loading free-flowing and non-viscous liquids into the stick pack. With the rotation of the pump, like gear or lobe, an accurate quantity of liquid is dispensed in the filling nozzle. These filler nozzles then introduce liquids like juices into the stick

8.What are Different Patterns of Seals Created by a Stick Packing Machine?

Stick packs come with diverse patterned seals, as the stick packing machine is adjusted to accommodate different seal patterns, for instance:

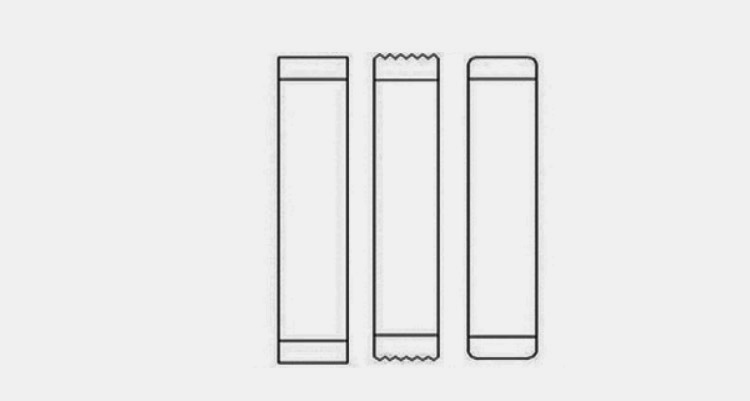

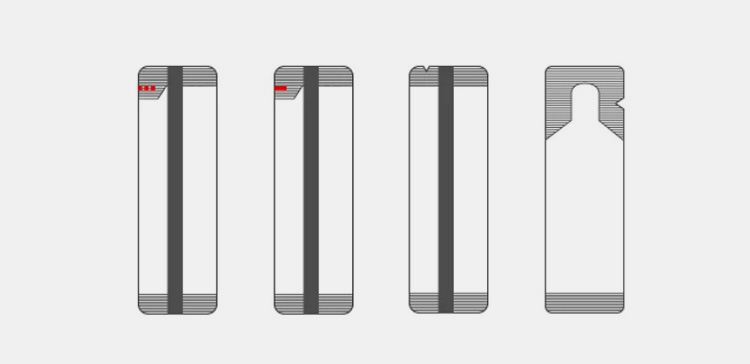

Seal Cut Options

Seal Cut Options

Different types of cutting blades like zig-zag teeth cutters are used to cut sides in straight lines, zig-zag patterns, and round corners on the stick pack seals.

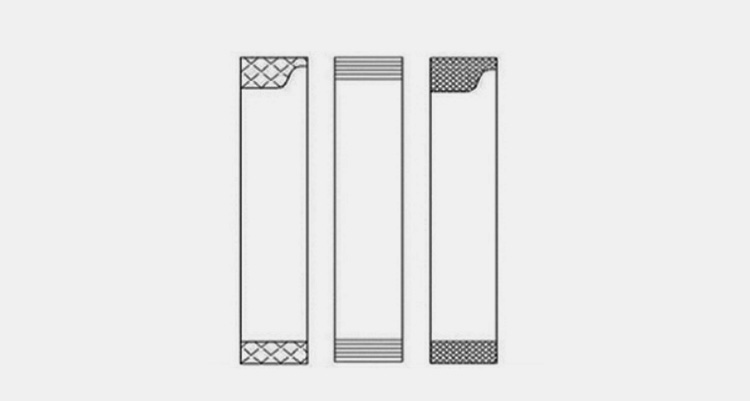

Seal Type Options

Seal Type Options

The sealing jaws are customized to create beautiful seals, for instance, diamonds, strips, narrow straight lines, and small diamond types on the seals. Attractive seal types differentiate stick-pack products from competitors.

Seal Shape Options

Seal Shape Options

To create diverse seal shapes on stick packs, sealing jaws are customized. These seal shapes are straight, central-neck, side-neck, and round seal.

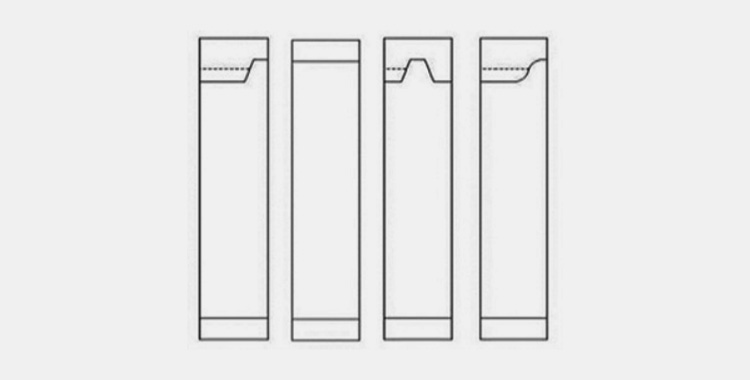

Easy-Open Seal Options

Easy-Open Seal Options

For the convenience of users, the stick packing machine is tailored to make easy open seals in the stick packs. These easy options are tear-notch, dot break, V cut, and micro-perforations.

9.What Stick Pack Styles are Handled by Stick Packing Machine?

The packing machine can easily process different stick-pack styles to boost product appeal and impulse buying. These styles are detailed below:

Regular Stick Pack

Regular Stick Pack

It is a typical stick pack with a tubular shape and features a narrow structure. It has a higher length and smaller width. regular stick packs are the common stick pack format.

Pillow Stick Pack

Pillow Stick Pack- Picture Courtesy: TurboSquid

This stick pack has a central seal just like a pillow pouch and has more room for branding. It has three seals-top, bottom, and middle.

Twin Stick Pack

Twin Stick Pack- Picture Courtesy: Aranow

The stick packing machine can also form double twin stick packs using two hoppers. They are connected stick packs having a common top seal. These are used for filling complementary products.

Shaped Stick Pack

Shaped Stick Pack- Picture Courtesy: Aranow

Sometimes, a specialized stick packing machine is used to create customized stick packs that have captivating shapes, such as tubes, oval, round, bottles, etc.

10.Are there Any Safety Certifications for Stick Packing Machine

There are various kinds of safety certifications for the stick packing machine to protect operators, production plants, and the environment. These certifications are discussed below:

| ISO

ISO Certification |

It stands for International Organization for Standardization. This safety certification of the stick packing machine guarantees that this equipment conforms to all safety protocols. It ensures that safety guidelines are implemented in designing and manufacturing machinery to avert health risks. |

| OSHA

OSHA Certification- Picture Courtesy: OSEA |

It stands for Occupational Safety and Health Administration. It is a safety guideline for stick packing machines used mostly in the United States. If this machine is OSHA certified it means that during its operation, it will pose minimal risk to the operator's health and working environment. |

| CE

CE Certification |

It is a safety marking, necessary in the European Union for machines, like stick packing machines made and sold in these countries. To obtain CE certification, manufacturers first, must conduct a risk assessment to show that machinery is not harmful to the operator and environment. |

| UL

UL Certification- Picture Courtesy: Hardcore Electric |

It stands for Underwriters Laboratories. It states machinery including the stick packing machine had undergone stringent safety tests to ensure the safety of the workforce and workplace and it meets all safety standards. |

11.Tips and Tricks-How to Troubleshoot Basic Problems of Stick Packing Machine?

Unexpected and unanticipated problems in the stick packing machine could be troubling and bothersome for the operators and owners alike, causing loss of revenue and productivity. To resolve these issues, we are giving some tips and tricks:

| Reason | Remedy | Picture |

| Abnormal Sounds and Vibrations are Heard from Equipment | ||

| Machine components are loose and are not aligned properly

Improper lubrication in machine parts. Instability of the rotating components, for instance, filling devices |

Realign the machine components

Lubricate and oil all the mobile parts as well as nuts and screws Tighten and level the rotating parts. |

Abnormal Sounds and Vibrations are Heard from Equipment |

| Foreign Objects and Debris in Product | ||

| Poor cleaning schedule

Improper cleaning of the machine after the packaging shift leads to cross-contamination of products from an earlier batch Poor or defective seal, causing entry of foreign objects |

Practice a regular clean schedule

Implement CIP and WIP to thoroughly clean and wash the machine Check and inspect sealers for fault |

Foreign Objects and Debris in Product |

| on-uniformity in Shapes and Sizes of Stick Packs | ||

| Wrong forming input

Inadequate film tension Wrong sealing temperature programming Faulty sealing bars Inadequate sealing pressure |

Check and reprogram the length of stick packs

Inspect and adjust film tension Adjust the sealing temperature Repair or replace the faulty sealing bars Reprogram the sealing pressure and make sure it is uniformly distributed during the sealing process |

Non-uniformity in Shapes and Sizes of Stick Packs |

| Non-uniformity in Material Feeding | ||

| The machine hopper and other filling devices are not properly cleaned.

Out-of-order product weight or volume measuring devices Wrong fill parameter input |

Regularly clean the machine hopper and other filing devices

Recalibrate the measuring devices Adjust the fill parameters |

Non-uniformity in Material Feeding |

| Non-uniform or Rough-Cut Stick Packs | ||

| Blunt cutting blades

Defective or worn-out cutters Misalignment of cutting knives in the middle of sealing jaws High film tension |

Sharpen blunt cutter

Replace or repair defective cutting blades Properly realign cutting blades Reduce film tension |

Non-uniform or Rough-Cut Stick Packs |

12.What are the Future Prospects of the Stick Packing Machine?

Stick Packing With High Future Market

A stick packing machine has brought unparalleled convenience and flexibility to you that helps people in accurate packaging in their fast and busy schedules. This is a portable solution you can install in your facility that assists pre-measured amounts of ingredients frequently enabling easiness in your business and lowers the risk of errors by filling doses to make your medication routine properly maintained.

The stick packing machine is a relatively new invention, as the first it was presented in Japan in 1975. Although it is new machinery than other packaging machines, its market experienced high exponential growth. It is forecasted that it will have a CAGR rate of 6.60% during the years 2021-2028. It is estimated that it will grow to US$ 4,602.00 million in 2027 from US$ 2,884.71 million in 2020.

Conclusion

A feasible and convenient packaging format- a stick pack is processed by the versatile and adaptable manufacturing unit called a stick packing machine. With its flexibility, high efficiency, automation, consistent performance, and branding, it generates gigantic profits for the packaging industry. Are you interested in procuring a stick packing machine? If you do not know where to search, then look no further, as you have landed on the right website. We, Allpack manufacture exceptional quality machines at affordable prices.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours