Automatic Tablet Counter: The Complete FAQ Guide In 2025

Have you kept yourself updated about the growing advancement in technology? It is obvious, that world is moving towards the age of mechanization where reliance on machines is increasing, and human labor is decreasing. Similar is the case in medical field, where automatic equipment are showing their outstanding performance.

Among many other things, tablet counting is a crucial step in processing pharmaceuticals. Therefore, the introduction of an automatic tablet counter has reduced on large scale, the errors, time spent and labor cost. You can simply use it for the exact counting and filling of tablets without additional maintenance. So, let's start exploring the diverse features of an automatic tablet counter and take benefits!

1.What Is Automatic Tablet Counter?

Automatic tablet counter refers to a machine that is designed to accomplish the task of counting tablets, pills and capsules automatically. It is incorporated with certain essential features of electronic monitoring and detection system that helps in the exact counting of tablets. It works through automatic processing and touch screen control system that restrict the direct user interference, eventually enhancing the counting speed, accuracy and precision.

The applications of automatic tablet counter are quite vast with counting tablets other than pharmaceuticals. This is the reason for its growing popularity in large industries engaged in similar processing, such as pharmaceutical industry, nutraceutical industry, food industry and veterinary industry etc.

2.What Are The Essential Features Of An Automatic Tablet Counter?

Automatic tablet counter is made in such a way that carries great significance for user as well as the security of tablets. Below explanation

High Accuracy

One of the most essential features of an automatic tablet counter is the high level of counting accuracy it ensures during operation. The dynamic scanning sensor perfectly detects tablets and makes sure the elimination of a single defective tablet.

Robust Construction

The machine is constructed from high quality durable stainless steel that is bacterial-free, portable and can be simply integrated with other machines for higher throughput.

Fast Performance

Automatic tablet counter is the best ever solution for counting large number of tablets. With its fast and speedy performance you can better increase your production volume.

Easy to Clean

Cleaning and maintenance is a crucial factor needed for smooth functioning of any machine. Here, this task is achieved without making any efforts due to low requirement of parts changeover.

User Friendly

The automatic nature and PLC control system make the machine more user-friendly, as a result it is easy to understand the working specifications and operate it accordingly.

3.Which Type Of Products Can Be Counted By An Automatic Tablet Counter?

Automatic tablet counter is an effective machine that is capable of processing huge number of products along with pharmaceutical tablets, pills and capsules. It can be used for the counting of every type of beans, coated or uncoated medicated and food tablets. The products mentioned below indicates that automatic tablet counter can be used not only for pharmaceutical or nutraceutical tablets rather it has a good demand in different types of food processing industries.

- Tablets

- Pills

- Capsules

- Chocolate balls

- Milk tablets

- Candies

- Bubble gum

- Gummy Candy

- Beans

4.Write Down The Working Principles Of An Automatic Tablet Counter?

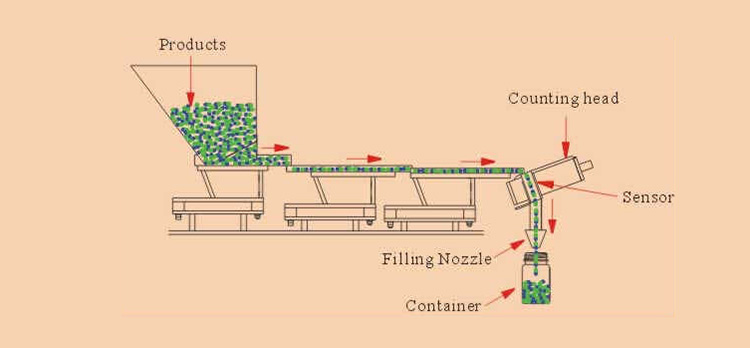

Working principles of an automatic tablet counter are simple as the entire mechanism is based on self operated system. They are as follows:

Adjust Setting

Before starting machine, check the setting of machine and fix it as per your requirements. For instance, you can manage the speed and time for tablets counting in the initial step.

Material Loading

Once the dimensions are fixed, you can load the hopper of machine with tablets, pills, capsules or other products like candies and gummy etc.

Starting Operation

Now the machine is ready to be started by turning on the power button. The vibration feeder creates the movement of tablets lying in hopper, as a result of which the tablets will gradually fall down from hopper over the guide plate.

Detection

The guide plate give sequence to the tablets laid over it and pushes them forward. Here these tablets are detected by the sensors through infrared light. At this stage, the tablets are counted and collected into memory flap.

Bottle Filling

At the end, counted tablets are discharged by the nozzle into bottles or containers which are taken by the conveyor belt.

5.Explain The Various Parts Of An Automatic Tablet Counter?

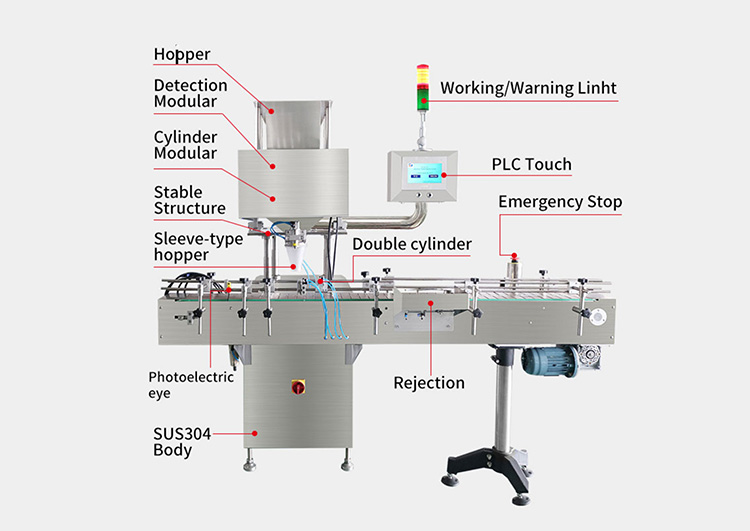

Automatic tablet counter is composed of several components which together contribute in the excellent performance of machine. Below is the description of these parts:

Main Body

The main frame of machine is the largest part that consists of overall body, stainless steel structure, electric cabinet, supporting stand and electric motor etc.

Hopper

Hopper is located on the top of machine which is used for holding bulk tablets which are to be counted by the machine. It is also known as vibrating feeder as it consists of vibrator which creates movement in tablets to fall down from hopper.

Detection Modular

Detection modular is another part of automatic tablet counter that perform the core task of counting tablets. It composed of tablets aligning plate, counting sensors and dropper.

Cylinder Modular

Cylinder modular connects the detection modular and sleeve hopper. It holds the counted tablets in memory flaps until they are delivered to sleeve hopper for final discharge of tablets.

Sleeve Type Hopper

Sleeve hopper is located under cylinder modular that accomplishes the function of taking tablets from cylinder modular and delivering them for filling bottles.

Conveyor Belt

Conveyor belt is a sort of transportation device that helps in moving the bottles from one end to another in order to make them filled with tablets.

Control Panel

The control panel refers to the touch screen display which enables you to control the machine and display you entire information of machine during its processing.

Rejection Station

With the help of photoelectric eye located on the side wall of conveyor belt, each passing bottle loaded with tablets is detected. In case of error the bottle is rejected and separated.

6.Describe The Different Categories Of Automatic Tablet Counter?

Automatic tablet counter can be further divided into two categories; fully automatic tablet counter and semi-automatic tablet counter. They are explained below:

Fully Automatic Tablet Counter

Fully automatic tablet counter is self reliant machine that carries out the entire process of tablet inspection, filling and discharging in a non-stop continuous run. It is highly fast and precise in counting tablets. It requires less maintenance and give high output that ultimately attract the owners of large scale industries.

Components

It consists of feeding hopper, aligning trays, sensor, cylinder modular, secondary sleeve hopper, nozzle, conveyor belt, control panel, electric cabinet, automatic rejection system and emergency stop.

Working Principles

Automatic tablet counter has simple working principles which start with setting the machine as per your requirements. After that, machine is loaded either manually or attached to the product feeding station from where tablets are continuously delivered to hopper through vacuum pump. As the machine get started, tablets fall down from hopper over tray where detection occurs and tablets are delivered to bottles via nozzle.

Semi-Automatic Tablet Counter

Semi-automatic tablet counter is different from fully automatic machine. It has normally lower counting capacity thus require less energy. It is cost-effective as a result most of the medium scale production sectors are preferring using this machine.

Components

The structure of semi-automatic tablet counter is simple composed of few components including hopper, detector, control system, discharge chute and bottle locators.

Working Principles

The machine requires user to load the hopper and place bottles on locator. After that, machine is powered on and the counting of tablets started. Fixed amount of tablets are counted and discharged through sliding chute into bottles. After bottles get loaded with tablets, the operator can manually pick them up.

7.Compare And Contrast Between Automatic Tablet Counter And Semi-Automatic Tablet Counter?

Automatic tablet counter and semi-automatic tablet counter are two distinct machines designed for carrying same task. In this question, we will highlight the key differences which distinguish one from another:

Nature

Automatic tablet counter is an independent machine with automatic features of fast performance that reduce manual intervention.

While as, semi-automatic tablet counter is medium scale machine with limited capacity of counting tablets and pills.

Structure

The structure of automatic tablet counter is somehow complex than that of semi-automatic machine due to heavy-duty task and auxiliary machines.

In contrast, semi-automatic tablet counter is precise; having few parts and is highly portable.

Working Principles

The working procedure of automatic tablet counter is simple with determining parameters and starting machine. The rest process is done by machine itself.

However, the semi-automatic tablet counter is dependent on user for the completion of its working such as material loading and bottle placing etc.

Speed

Automatic tablet counter has exceptional performance in terms of counting tablets. It can count up to 4000 tablets in a minute.

On the other hand, the speed of semi-automatic tablet counter is lower than automatic machine and can only count 1000 tablets per minute.

Cost

The cost of automatic tablet counter is high due to its complex structure and automatic processing.

While as, semi-automatic tablet counter is less expensive and cost-effective.

Application

Most of the large industries including pharmaceutical, food and chemical industries prefer to use automatic tablet counter.

In contrast, semi-automatic tablet counter is suitable for small batch and medium scale production such as test laboratories and small scale confectionary and chemical industry.

8.Is It Possible To Integrate An Automatic Tablet Counter Directly With Other Machines?

Whenever, there question arise about whether automatic tablet counter can be integrated with other machines, the answer will be absolutely yes! It can be definitely connected to other machines for higher production such bottle capping machine, sealing machine and labeling machine etc.

It is among the benefits of an automatic tablet counter that it can carry out excessive workload with the help of other machines. Most of the large scale industries take advantage of this great feature.

9.Highlight The Areas Where Automatic Tablet Counter Can Be Used?

There are number of areas where you would find the need of an automatic tablet counter. Some of these are as follows:

Pharmaceutical Industry

Pharmaceutical industry revolves around the processing of drugs where the use of automatic tablet counter cannot be overlooked. Millions of tablets are produced every day with diverse applications to provide the world with healthy lifestyle. Thus, the security, counting and packaging of tablets is an important step.

Nutraceutical Industry

Medicines made from direct source of vegetables, fruits, nuts and beans are known as nutraceutical. They contain good amount of vitamins, minerals and proteins which are combined in form of tablets and pills. Here, the processing of tablets require number of machines in which automatic tablet counter is notable one.

Veterinary Industry

Similar to other industries, veterinary industry is also engaged in making medicines for animals. Therefore, they too require all the essential equipment needed for tablets processing such as tablets manufacturing unit, automatic tablet counter and packaging machine etc.

Food Industry

It is obvious that counting of large number of food tablets, candies, chocolate balls and jellies is somehow impossible without a machine. This is the reason why most of the large scale food processing industries and confectionary industries often use automatic tablet counter for achieving this task.

Chemical Industry

Chemicals processing needs exact amount of elements for which this machine is essential. Furthermore, different types of chemical tablets such as water purification tablets in form of chlorine tablets and aqua tabs are good examples for which the help of automatic tablet counter is taken..

10.What Is The Production Line For Automatic Tablet Counter?

The production line for automatic tablet counter will show you the machines which together give you extraordinary results with each and every step of counting and packaging done on same place. It consists of:

Bottle Unscrambler

As the name indicates, bottle unscrambler is a type of machine designed to feed the bottles to production line. This machine plays an effective role in reducing time by providing empty bottles to the automatic tablet counter. These empty bottles are first loaded in the hopper of machine which are then conveyed for filling tablets through a conveyor belt.

Bottle Capping Machine

Another machine that cannot be ignored while using automatic tablet counter is the bottle capping machine. It comes into action when bottles are filled with tablets, where they need to be well capped. It simply works by putting lids over bottles and cap them tightly through screws.

Induction Sealing Machine

Sealing is one of the important part of tablets packaging. Therefore, the use of induction sealing machine is more popular than other types of sealing. It is used to apply heat for bonding thermoplastic material to bottleneck. With the help of this machine, aluminum foil present inside the bottle cap stick to the bottle mouth and completely isolate the inside content from air, moisture and light. This process extend the shelf life of product.

Bottle Labeling Machine

Another machine you would need to integrate with your automatic tablet counter is bottle labeling machine. It simply applies adhesive stickers labels to over bottles which display information about the company, product name, description, batch no and expiry date etc.

Cartoning Machine

Last but not the least; a cartoning machine is used for completing tablets counting process. This machine performs the function of manufacturing various types of cartons including cartons like side seamed, folded or close. The purpose of using this machine is to give extra protection to the loaded bottles and provide additional information chart with them.

11.What Are The Common Abnormalities Of An Automatic Tablet Counter? And How Would You Correct Them?

Let's discuss the common abnormalities you might face when using an automatic tablet counter. They include:

| No | Abnormalities | Causes | Solutions | Pictures |

| 1 | Problem in displaying counting figure | There are two possible causes for this problem. The incorrect insertion of aligning trays or the damaged display | Make sure the trays are inserted correctly, control panel is cleaned and in case of damage change the screen |

|

| 2 | The incorrect counting | It occurs when tablet trays are dusty, sensors are defected or the machine starts before pills are loaded on turntable | Clean the trays and other parts of machine which are in direct contact with tablets, replace sensors if defected and load tablets before starting operation |

|

| 3 | The numbering on screen remains the same | It may be due to strong light or insufficient power supply | Mobilize machine to indoor area and check if the sensor socket is plugged incorrectly |

|

| 4 | Tablet dispensing for two bottles at same time | The only reason is loose screws of changing flippers | Tight the screws |  |

| 5 | Too much noise during counting | It happens when vibrating tray directly connect to the discharge channel or vibratory trays are loose centered | Keep the screws of vibration tray for avoiding noise |

|

| 6 | Pills are dispensed without counting | Sensor are may be contaminated with tablet residues | Turn on the machine and clean sensor |  |

12.Which Tips Should Be Followed For Getting The Best Automatic Tablet Counter?

It should be noted, that purchasing a right automatic tablet counter will definitely be a game changer for your production. Therefore, must keep in mind the helpful tips we have provided here:

Additional Features

The best way to check the machine excellence is in getting information about its features such as error detection, alarming system, speed of counting tablets and most important the ionized cleaning system.

Capacity

Now comes the core aspect of your automatic tablet counter which is the capacity of counting tablets. You must have this query in mind to ask about the tablets handling capacity of the machine, as different machines have different capacities.

Quality Assurance

It is most important to know about the quality certification of the machine you are interested in purchasing. For this, you can check the warranty policy of vendor and the international certification such as ISO and GMP etc.

Customer Feedback

You can also check the customer feedback through their reviews. It would help you to know the company's services such as customer support, quick change of parts and the performance of machine.

Technical Assistance

Among other things, technical assistance provided by vendor is crucial as most of the brands are not associated with delivering support after selling. Thus, it is necessary to get a machine that is backed by spare parts inventory and installation support.

Conclusion

Did you get the answers to questions you have in mind regarding automatic tablet counter? If yes! You have probably understood this guide. An automatic tablet counter is a key element in your pharmaceutical processing. So, don't waste time in taking right decision as it will hinder your business growth. If you are interested in purchasing an automatic tablet counter then what are you waiting for? Just click on the given link and contact us for further details.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide