Carton Packing Machine: The Complete Buying Guide In 2025

Carton packing machines are globally used for packaging of all types of bottles and cans produced in food and beverages, pharmaceutical and chemical industry. These machines provide convenient packaging for travelling and shipment. The products that are packed using carton packing machine remain safe and hygienic during their transportation from one place to another.

Today there is a competition in manufacturing the best type of carton packing machine and Allpack also provides its customer with the best solution for their production setup. This complete buying guide will help you select the best carton packing machine and resolve all your queries. So let’s go!

1. What Is A Carton Packing Machine?

Carton packing machines are one of the advanced and perfect ways used for sealing multiple sizes of cartons, case and boxes. These machines are used to pack cartons that are made up of paper, word, board or cardboard. Carton packing machine performs a mechanized way to sealing cartons that are filled with bottles, cans, containers and other products.

The packing is performed in such an efficient manner that these cartons can easily be carried from one place to another without any risk of damage or breaking. The operation of a carton packing machine is very simple and convenient for any new user. The cartons are placed in the machine and automatically the sealing is applied on it. It also improves the process and increases productivity of an industry.

2. What Are The Applications Of A Carton Packing Machine?

Carton packing machines are widely applied in following industries

- Pharmaceutical Industry

Most of the application of a carton packing machine is in the pharmaceutical industry. Here cartons that are filled with capsules, supplements, medicines, syrups and other pharmaceutical products are packed in an efficient manner using a carton packing machine. It prohibits any type of contamination and chemical decomposition.

- Food and Beverages Industry

Almost each of the products that are produced in a food and beverage industry is packed in a carton. These cartons may carry bottles, jars, snacks, chips, eatables and other products that are efficient packed using a carton packing machine. The freshness of these products remains alive for a much longer duration and supports in travelling from one place to another.

- Chemical Industry

Carton packing machines are also used in chemical and cosmetic industries for packaging of products like paints, shampoos, lotions, beauty creams and other products. All of these products are packaged in a way that their purity remains same for a longer time.

- E-commerce Industry

One of the leading industries globally i.e. the E-commerce industry also uses carton packing machines for packaging of products that are to be supplied globally. Due to increasing demand of online products, it is necessary to increase the productivity and carton packing machine is one of the sources to it. These different sizes of cartons are then shipped to every part of world.

3. What Are The Characteristics Of A Carton Packing Machine?

Some of the characteristics of a carton packing machine are

- Flexible Construction

The construction of a carton packing machine is carried out to be flexible in nature and can be moved to any degree of rotation. The height of machine can be adjusted to different levels according to the size and shape of carton. This results in an economical decision that a single machine packages multiple types of cartons in a precise way.

- Servo Mechanism

A carton packing machine has an internally assembled servo motor mechanism that supports in high degree packaging of cartons. A feedback mechanism guides the system where the packaging is to be performed and results in perfect, unbreakable packaging.

- Durability

Carton packing machines are highly durable that the can be used for variety of size and shapes. These machines can also be carried out from place to another according to production requirements and packaging lines.

- Packaging Types

A carton packing machine supports multiple types of packaging forms like boxing, sealing, packing, unpacking, removal of waste, auto transmissions and etc. All of these facilitate the user with multiple features in a single machine.

- Friendly Operation

The system of a carton packing machine is designed in a way that it eases the human machine interface and also automized the operation at a high degree level.

- Wear Protection

One of the unique characteristic of a carton packing machine is that has a great wear protection strength between the frame and machine plate. This provides a rigid and strength full operation during packing of carton. The frame and machine move in such a way that a desired torque is produced and also blocks any type of damage.

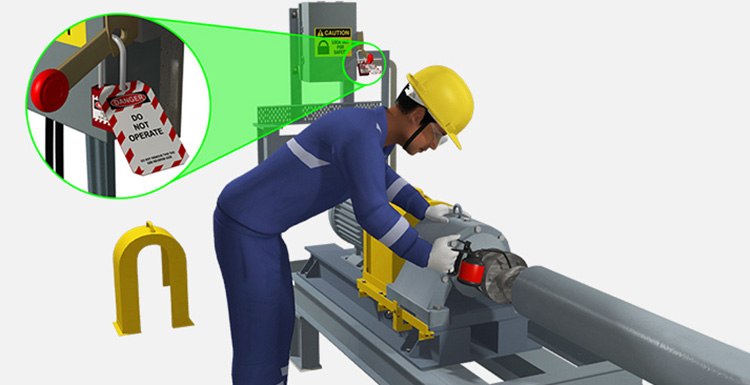

- Safety Measures

Safety measures are always important in a carton packing machine because if a single carton is packed improperly or the alignment gets effected, whole of the production will follow the same pattern. This is why automatic tracking and detection systems are incorporated in machine to ensure proper packing.

4. What Is The Working Principle Of Carton Packing Machine?

Following are the steps taken for packaging a carton using a carton packing machine

- Initially the carton is packed with the desired filling material and placed in the inlet side of a carton packing machine.

- The carton is entered into the system either manually or automatically depending upon the configuration of a carton packing machine.

- Once the box is placed, the system is turned on and all the external and internal parameters including sealing time, temperature, speed are verified. Also the height of guide is adjusted according to the carton size.

- The rollers and guide support the carton to reach its destination. Once the carton is adjusted into the packing system, the actuators get activated and signal the process to get started.

- The package forming devices closes the flaps of carton properly and then applied the packaging tape or glue onto the top of carton first.

- The bottom side of a carton is pressed by the circulating sealing chain and is also wrapped properly.

- Finally, both the top and bottom sides along with edges are packed according to the desired situation.

5. How Do Container Inlet And Container Divider Differ In Working States?

Both of the components container inlet and container divider are parts of a carton packing machine and perform their tasks separately. Some of the differences in their working states are

- Purpose

The main purpose of a carton inlet is to feed the boxes and cartons into the system that are further carried to the packaging lines.

Carton divider on the other hand is used for directing the cartons or boxes towards packaging process. These are also used for dividing them into their separated groups according to their physical appearance.

- Physical Movement

Carton inlets are usually in the form of conveyors or rollers that are used for the movement of boxes or cartons throughout the packing system. They work according to how they are designed.

Carton dividers are like mechanical arms that move based on servo motors and actuators. Dividers also guide the cartons for travelling in a right path.

6. What Are The Main Components In Carton Packing Machines?

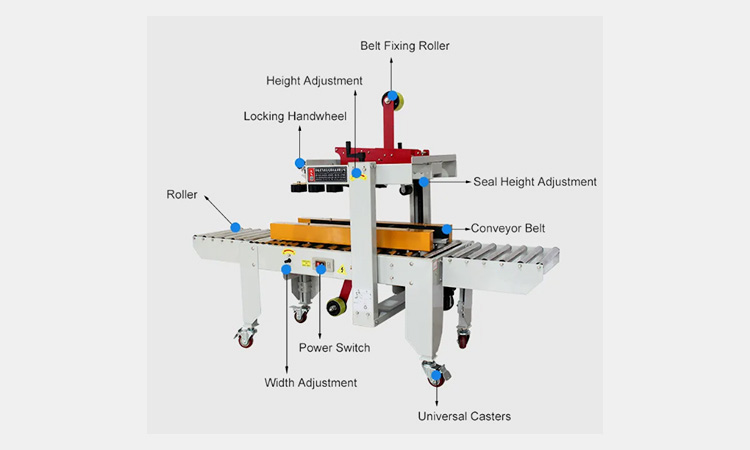

Some of the main components of a carton packing machine are

- Belt Fixing Roller

A belt fixing roller is used for holding the tape or belt that has to be applied onto the carton. It also guides the movement of packaging material so that perfect packing be carried out without any wear and tear.

- Height Adjustment

One of the most important part of a carton packing machine is its height adjustment part. It allows to adjust the height according to the size of carton that is to be packed. If the height is not adjusted properly, it can damage the sides of carton and perform improper sealing.

- Locking Handwheel

The mehanism of a locking handwheel is to lock the height of motion plate to a desired level to prohibit continuous setting. By locking this the packaging remains same throughout the process and it is saves a lot of time.

- Seal Height Adjustment

Similarly like a height adjustment stand, a seal height adjustment is present to adjust the height at which the sealing will be performed. Spillage of products and poor sealing can be prevented by proper adjustment of sealing height.

- Conveyor Belt

Conveyor belts are present at the inlet ant offloading side of a carton packing machine that support in proper movement of cartons. Caoveyors are sometime belts made up of rubber or rollers.

- Roller

In semi-automatic carton packing machine, rollers are used instead of inlet conveyors. They require external push for entering the cartons into the packing system.

- Power Switch

For turning the carton packing machine on or off, power switches are present in the control panel of the machine.

- Width Adjustment

Like a height adjustment part, width of a carton packing machine can also be adjusted using width adjustment. It allows the system to package variety of box sizes.

- Universal Casters

Universal casters are present in the bottom side of a carton packing machine and are used for the movement of carton within the system and also in unloading the cartons. Casters are made up of rubbers, plastics and other composite material with greater strength so that heavy loads can be handled.

7. What Are The Types Of Carton Packing Machines?

Depending upon the configuration, there are two types of carton packing machine

- Semi-automatic Carton Packing Machine

In a semi-automatic carton packing machine the operation is performed by the combination of operator and machine. The operator first places the carton into the inlet side and then pushes it into the system. The machine automatically packs the flaps and sides of carton and then sends it to the unloading side. For flipping of carton, the operator is there to perform this task. Finally the carton is taken out of the system by the operator and the process is completed.

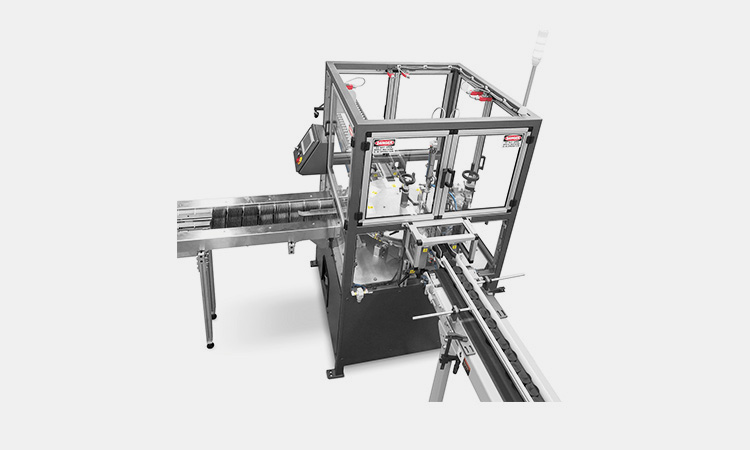

- Fully Automatic Carton Packing Machine

Whereas in a fully automatic carton packing machine, complete packing steps are performed by the machine itself. It supports all sizes of cartons as no load is to be carried by the operator. The conveying system and guides allow smooth travelling of cartons and this support fine and perfect type of packaging.

Other than both of these, there are also some types of carton packing machines depending upon their orientation

- Vertical Carton Packaging Machine

A vertical carton packing machine is designed in a way that is supports carton with that are to be packaged by vertical orientation. Cartons are loaded from the top side of machine and then the process of packaging takes place. Food and pharmaceutical industry mostly prefer this type of packaging machines.

- Horizontal Carton Packaging Machine

As the name describes, the orientation of machine is designed in horizontal way and the products are load from one side of the machine and received on the other. Cosmetic, electronics and chemical industry mostly prefer using a horizontal carton packing machine.

8. How The Top Cover Is Folded In A Carton Packing Machine?

The folding of top cover of a carton certainly depends upon the specifications and design of a carton packing machine. Some of the patterns however are common is each type of carton packing machine that how the top cover is folded. These steps are

- Initially the carton is placed into the loading side of a carton packing machine with its top cover left open.

- The flap folding station in some of the machine comes built-in and others do customization where the top flaps are folded in a way that no damage or tear occurs.

- Similarly the side flaps present on top of a carton are folded and in this way the top covers which remained open now gets bend perfectly.

- These folded flaps are then conveyed further to the sealing station for applying sealing and completing the packaging cycle before the flaps gets open again.

9. What Are The Differences Between Semi-automatic and Fully Automatic Carton Packing Machine?

Both types of machines mainly depend on the level of automation and some common parameters that they are incorporated with. Some of the factors on which semi-automatic and fully automatic carton packing machines are differed are

- Productivity

Fully automatic carton packing machine has no human intervention that makes the process much fast and reliable. The speed of packing is much high that a machine can pack 40 to 70 cartons in a minute.

Whereas a semi-automatic carton packing machine is slow in speed and depends on the efficiency of the operator. The manual adjustments causes delay in processes and only 15 to 30 cartons can be packed in a minute using a semi-automatic carton packing machine.

- Automation

Automatic tasks are performed in a fully automatic carton packing machine from feeding to unloading. Conveying systems are there for providing specific paths to the carton.

On the other hand a semi-automatic carton packing machine has a manual feeding feature and also the operator is responsible for taking out the packed carton out of the system.

- Flexibility

A fully automatic carton packing machines are less flexible as compare to semi-automatic carton packing machine they do not adjustments within the machine. This causes a lot of economical and production losses as separate machines are required for separate boxes.

Semi-automatic carton packing machines are having flexible guiding systems which can easily be adjusted according to the height, width and length of a carton.

- Safety

Both of the machines are incorporated with inbuilt safety systems but a fully automatic carton packing machine is equipped with more advanced sensors and safety options that provide complete security to the man, machine and method.

The operator has to be more conscious when he is operating a semi-automatic carton packing machine as it has less safety features.

10. What Different Types Of Tapes Are Applied For Sealing By Carton Packing Machine?

There are numerous types of tapes that are used for packaging of carton in a carton packing machine. Some depends on environmental factors and other on their adhesive nature. Commonly types of tapes used for sealing of carton in a carton packing machine are

- Masking Tape

Masking tapes are the common type of light duty tapes that are easily available and used frequently for packaging of cartons. These are mostly paper based tapes and are easy to tear whenever required.

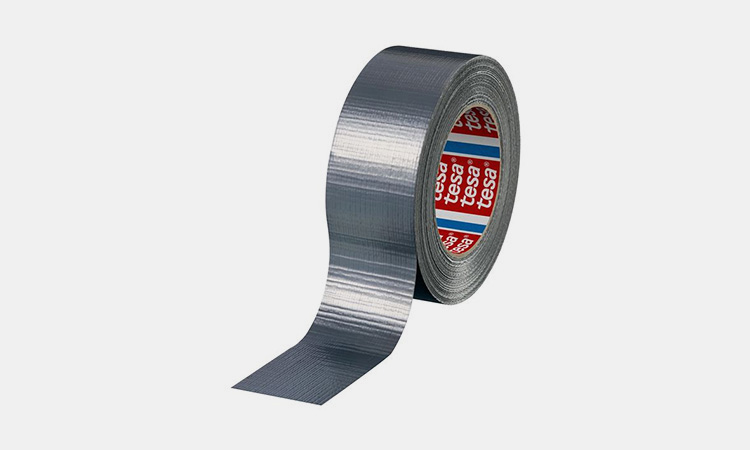

- Duct Tape

A duct tape in made up of polyethylene material and also contains an additional layer of fabric which is used to provide extra power to its adhesive nature. The tapes are globally recommended due to their durability and strength full adhesion properties and also recommended for industrial purposes.

- Pressure Sensitive Tape

A pressure sensitive tape is the most common used type of tape for packing cartons in a carton packing machine. A pressure sensitive tape is made up of polyvinyl chloride, paper and polypropylene material and has qualities of each one of them.

This resistance against pressure and temperature makes this tape recommended for almost every type of industrial packaging. The adhesive nature allows the tape remain unbreakable even if the carton experience high pressure or temperature conditions.

- Gorilla Heavy Duty Packaging Tape

One of the heavy duty tape that is applied on cartons for handling high stress conditions during transportation and movement. An ideal tape has a width between 1.5” to 2” and provides thick liner on the top and bottom sides of a carton.

- Water Activated Tape

Water activated tape commonly called as gummed tape is a type of tape that gets activated when treated with water and provides strong bonding on the surface of carton. Kraft paper is used for making this type of tape and is ideal for packaging of cartons and boxes.

11. What Are The Differences Between Carton Packing Machine And Carton Sealing Machine?

Carton packing machine and carton sealing machine are two interchangeable machines that are used for provides strong packing to cartons. This packaging allows easy travelling of cartons keeping the products secure for a longer period. Some of the differences between both of these machines are

- Functionality

A carton packing machine is used to shape and pack cartons that are made up of box, paper and sometimes wood. All the top and bottom flaps are folded and then packaging process is carried out.

In a carton sealing machine the flaps of cartons are sealed with tapes, glue or other adhesive strengths.

- Operation

The cartons are pushed into the system from loading side and after folding of flaps, the carton enters the packaging system. Here the holders hold the carton the tape erector smoothly applies tape of both top and bottom sides of a carton.

A carton sealer on the other hand operates similarly like a packing machine but only differs in application of sealing material. The holder shaft lowers its mechanism once the carton arrives. Neat and tidy sealing material is applied on it with shaft moving uniformly.

- Machine Speed

Carton packing machines are a bit slower than carton sealer machines and takes around 6 to 8 seconds in application of packaging material.

A carton sealer machine is much more efficient and fast as compared to carton packing machine. The sealing tasks are performed in just 3 to 5 seconds using by this type of machine.

- Customization Feature

Carton packing machines have an ability to be customized according to the size of carton and can easily be used for variety of applications.

Carton sealing machine on the other hand requires additional features for different types of cartons and cost extra charges for these customizations.

- Machine Types

Both of the machines are present in semi-automatic and fully automatic types whereas a carton packing machine also has type according to the orientation of box like vertical and horizontal carton packing machine.

- Complexity

Carton packing machines are more complex in nature because they are easily adjustable according to different sizes and shapes of cartons.

The design of a carton sealing machine is simple along with all its functions and has no complex nature.

Conclusion

Carton packing machines are widely used for efficient and precise packing of cartons globally. Due to their greater demand, now variety of manufacturers has evolved producing this type of packing machine. Allpack is also providing best solutions for carton packing to their customers and also supporting them till complete installation. Our customer service representatives are there 24/7 for your assistance. Feel free to contact us or visit our website Allpack.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours