VFFS Packaging Machine: The Complete Buying Guide In 2025

Are you looking for a packaging solution that helps maximize efficiency and reduce costs? VFFS packaging machines could be the answer. This type of machine is designed to quickly produce packets, bags or pouches from flat rolls of heat-sealable material with speedy precision.

From small bakeries to large industrial production plants, VFFS Packaging Machines are widely used in many industries due to their versatility, affordability and reliability. Keep reading this blog post if you’re interested in learning more about a VFFS packaging machine and what it can do for your business.

1.What Is A VFFS Packaging Machine?

A VFFS packaging machine is a type of automated packaging equipment that forms and seals pre-made packages from flexible packing material such as plastic film. This device can be adjusted for different packaging materials, sizes and shapes, allowing it to adapt to a variety of products.

2.What Are The Components Of A VFFS Packaging Machine?

A VFFS packaging machine is composed of several components that work together. The main components include:

Feeder

This component is responsible for holding and delivering the product into the VFFS machine in a continuous flow. This should be adjusted according to the type and size of product being packaged.

Forming tube

This element uses a rotating system to form the flexible packaging material into an open bag and then seals it.

Filler

An auger filler is responsible for filling pre-made bags with products. It features a rotating auger that moves the product into the bag, and is usually adjustable in order to accommodate different sizes and weights of product.

Sealing jaw

Responsible for sealing the VFFS bag once it is filled with product.

Cutoff

This component cuts the VFFS package into individual pieces after they have been sealed.

Printer

VFFS packaging machines often feature an integrated printer, which is responsible for labeling the filled bags with expiration dates, barcodes and other information.

Control panel

The control panel is the user interface of the VFFS packaging machine and allows operators to adjust settings and monitor the VFFS process.

Conveyor

VFFS packaging machines generally include an exit conveyor which is responsible for delivering the finished bags from the VFFS packaging machine.

3.What Are The Advantages Of A VFFS Packaging Machine?

Increased Efficiency

The high speed and accuracy of VFFS packaging machines makes them extremely efficient for large-scale production. These devices can produce thousands of packages per hour with minimal waste.

Cost-Effectiveness

Also, VFFS packaging machines require less labor than manual methods, resulting in cost savings. Additionally, because of their high production rates, they can minimize the amount of packaging material needed for a given order.

Versatility

When it comes to versatility, VFFS packaging machines can be customized for various product sizes and shapes. This makes them ideal for a wide range of packaging applications, including food, pharmaceuticals, and cosmetics. They are also capable of working with a wide range of materials, from paper and plastic to foil and film.

Improved Packaging Quality

In terms of quality, VFFS machines can produce high-quality packages with precise seals, ensuring that the product inside is kept safe and secure during shipping and handling. These tools are also capable of producing aesthetically pleasing packages, making them an attractive option for consumers.

4.What Are The Applications Of A VFFS Packaging Machine?

Food Packaging

VFFS packaging machines are commonly used in commercial food packaging and can be adapted to various product sizes and shapes. These machines are designed to quickly package a wide range of items such as nuts, candies, cereals, snack mixes, cookies, pastries and other items.

Pharmaceutical Industry

In the pharmaceutical industry, VFFS packaging machines are commonly used to package products, such as tablets, capsules and powders. These machines can accurately measure doses and dispense them into individual packages.

Cosmetics Industry

Cosmetic packages such as lotions and creams can also be packaged using VFFS packaging machines. These devices can accurately dispense the product into individual packages while maintaining sterility.

Household Items

VFFS packaging machines are used to package household items such as detergents, cleaning solutions and other products.

5.What Are The Working Principles Of A VFFS Packaging Machine?

1.Film Transport and Unwind

Rollstock, or a single sheet of film material rolled around a core, is what vertical packaging machines employ. The term “film web” refers to the length of packaging material that runs continuously. These materials can include polyethylene, laminates made of cellophane, foil, and paper. At the back of the machine, a spindle assembly receives the roll of film.

The film is typically removed from the roll when the VFFS packaging machine is in use by film transport belts that are positioned to the side of the forming tube, which is at the front of the machine. The most popular kind of transportation is this one.

2.Film Tension

The film is unwound off the roll and passes over a dancer arm, a weighted pivot arm at the back of the VFFS packaging machine, during unwinding. There are several rollers built into the arm. The arm glides up and down as the film travels to maintain tension. This makes sure that film does not wander from side to side as it is moving

3.Optional Printing

The film then passes through the printing equipment, if one is present, after the dancer. Printers come in thermal and ink-jet varieties. The printer prints the desired dates or codes on the film or can print logos, artwork, or registration markings.

4.Film Tracking and Positioning

![]()

The registration photo-eye is passed after the film has gone below the printer. The registration photo eye controls the pull-down belts in touch with the film at the forming tube by detecting the registration mark on printed film. This photo eye keeps the film in the right position so that it will be cut in the right place.

The film then passes by film tracking sensors, which track the film’s location as it passes through the packing machine. The sensors will generate a signal to activate an actuator if they notice that the edge of the film has moved from its typical location. As a result, the entire film carriage will move to either side as necessary to bring the edge of the film back to the right position.

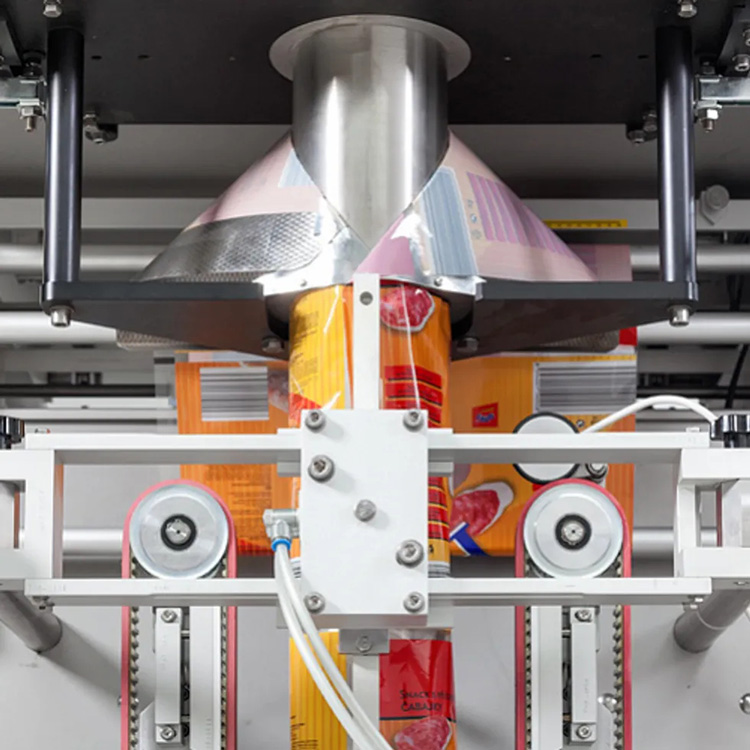

5.Bag Forming

The film then enters a forming tube assembly from this point. It is folded around the forming tube when it crests the shoulder (collar), resulting in a length of film with its two outer edges overlapping one another. The bag-forming process starts.

You can set up the forming tube to create a lap seal or a fin seal. Although a fin seal marries the insides of the two outer edges of the film to form a seal that sticks out like a fin, a lap seal overlaps the two outer edges of the film to make a flat seal. In general, a lap seal is thought to be more aesthetically beautiful and requires less material.

Near the forming tube’s shoulder (collar), a rotary encoder is mounted. It is driven by the moving film that makes contact with the encoder wheel. At each length of movement, a pulse is produced and sent to the PLC (programmable logic controller).

In intermittent motion machines alone, the bag length setting is set as a number on the HMI (human machine interface) screen, and once it is reached, film transport ceases. Machines that operate continuously do not stop.)

Two gear motors that drive friction pull-down belts on either side of the forming tube draw the film down. Friction belts can be changed out for pull down belts that use hoover suction to grab the packaging film.

6.Filling and Sealing

With intermittent motion packaging machines, the film will now quickly stop so the created bag may get its vertical seal. The hot, vertical seal bar advances and comes into contact with the film’s vertical overlap, which fuses the film’s layers together.

The film does not need to stop in order to receive its vertical seam when using continuous motion VFFS packing equipment since the vertical sealing mechanism is continuously in touch with the film.

The top seal of one bag and the bottom seal of the following bag are then created by joining a set of heated horizontal sealing jaws.

Ultrasonic, which is frequently employed in sectors with messy or heat-sensitive materials, provides a possibility for a “cold sealing” system. In order to create molecular friction during ultrasonic sealing, vibrations are used. This friction only creates heat in the space between the film layers.

The product that is being packaged is dropped down the center of the hollow forming tube and filled into the bag while the sealing jaws are closed. It is the responsibility of a filling device, such as a multi-head scale or auger filler, to accurately measure and release the precise amounts of goods to be dropped into each bag.

These fillers must be acquired in addition to the machine itself because they are not a regular component of a VFFS packaging machine. The majority of companies combine a filler with their packaging machine.

7.Bag Discharge

A sharp knife inside the heat seal jaws advances and slices the bag once the product has been delivered into it. The packaged bag falls when the jaw opens. On a vertical packing machine, this marks the conclusion of one cycle. VFFS equipment can accomplish between 30 and 300 of these cycles every minute, depending on the machine and bag type.

The completed bag can be unloaded into a container or placed on a conveyor for delivery to downline machinery such as checkweighers, x-ray machines, case packaging, or carton packing machinery.

6.What Type Of Pouches Can Be Used With A VFFS Packaging Machine?

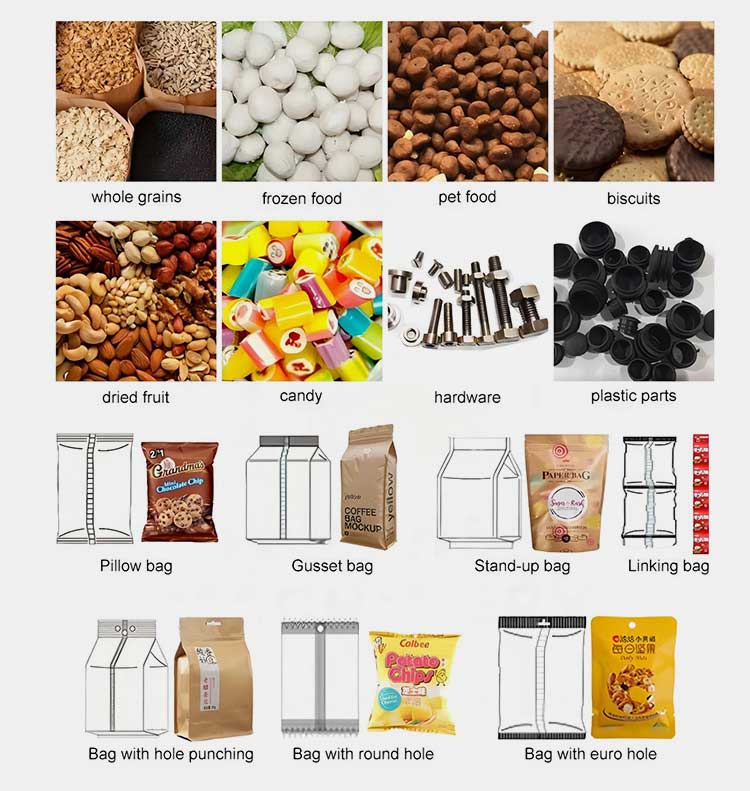

A VFFS packaging machine can be used with various types of flexible pouches, including:

Stand-Up Pouches

Snacks, condiments, and other products that need a stand-up base to display the product information are frequently packaged in this type of pouch. Also, because they shield the contents from moisture, they are perfect for products with higher fat content.

Flat Pouches

These pouches, which are often referred to as pillow pouches, offer a square or rectangular shape for product packing. They are frequently used to pre-package foods including pasta, cereal, and nuts.

Gusseted Pouches

This type of pouch is used for products that require extra space. Normally, the bottom and sides are expandable thus making them ideal for packaging bulky items such as pet food or detergents.

Spouted Pouches

Spouted pouches are designed with a spout to allow liquid products such as cooking oil or juice to be dispensed more easily.

Roll Stock Pouches

Roll stock pouches are pre-made bags, usually made of flexible plastic or laminate material, that can be run through VFFS packaging machines. They are ideally used in the packaging of products including frozen foods, fruits, and vegetables.

7.What Type Of Products Can Be Packaged Using A VFFS Packaging Machine?

A VFFS Packaging Machine can be used to package a wide range of products, including:

Powders and Granules: These can include anything from pet food to fertilizer.

Liquids and Pastes: Products such as sauces, dressings, soups and jams can also be packaged using this machine.

Solid items: VFFS packaging machines can be used to package solid items such as chocolates and candies, nuts and dried fruits.

Non-Food Items: This type of packaging machine also has the ability to package non-food products such as pharmaceuticals, medical devices and cosmetics.

8.What Are The Different Types Of VFFS Packaging Machines?

There are a variety of VFFS packaging machines. They include:

Continuous Motion VFFS Packaging Machines

These VFFS packaging equipment use continuous motion to form, fill and seal the bag. They are the most popular machines due to their speed and efficiency.

Intermittent Motion VFFS Packaging Machine

An intermittent VFFS machine is used for packing slower-moving products in smaller quantities. It stops after each cycle and requires manual product handling.

Multi-Lane VFFS Packaging Machines

These VFFS machines are designed to produce multiple packages at once. They feature multiple sealing systems, which can be used to produce several bags of the same type or mix and match different bag styles.

9.What Is The Difference Between A VFFS Packaging Machine And A Horizontal Form Fill Seal Packaging Machine?

a) VFFS Packaging Machine

b) Horizontal Form Fill Seal Packaging Machine

The main difference between a VFFS packaging machine and a horizontal form fill seal packaging machine is the alignment of the product being packaged. A VFFS packaging machine packages products in a vertical orientation while the horizontal form fill seal packaging machine packages products in a horizontal orientation.

Another difference between these two machines is that the former uses a continuous film and the latter uses a preformed pouch. A continuous film, which runs through the VFFS packaging machine is used to package products in an automatic process while a preformed pouch is filled manually and then sealed.

Also, a VFFS packaging machine has higher speeds and produces more consistent seals. In addition, this device takes up less floor space compared to a horizontal form fill seal packaging machine since it works in a vertical orientation.

On the other hand, a horizontal form fill seal packaging machine offers better control over product presentation as well as greater flexibility when it comes to product size. It is also suitable for use in low-volume production runs where the cost of purchasing a VFFS packaging machine is not viable.

10.What Are The Different Packaging Options For A VFFS Packaging Machine?

VFFS Bags

VFFS packaging machines are used to produce pre-made bags on a roll that are formed, filled and sealed all in one process. These bags come in either flat or gusseted styles, with options for custom printing, zip-lock closures and even Euro-slot punching.

VFFS Pouches

VFFS packaging machines are also used to produce flexible pouches, which typically require a more specialized and complex machine. These pouches are typically made with webbed film that is converted into stand-up pouches, flat bottom bags or 3-side seal bags.

VFFS Wrappers

VFFS packaging machines are used to produce wrappers, which are typically used in the confectionery or pharmaceutical industry. These wrappers can be produced with a variety of materials including aluminum foil, polyethylene film and paper/film laminate.

11.Can You Use A VFFS Packaging Machine For Multiple Products?

The answer is yes, VFFS packaging machines are designed to be versatile and can easily accommodate multiple products. Also, VFFS machines have a wide range of features that make them perfect for packaging a variety of products.

Moreover, VFFS packaging equipment can create packages in a variety of configurations, including bag-in-box, pillow packs, and gusseted bags.

12.Are There Any Regulations That Need To Be Followed When Working With A VFFS Packaging Machine?

Safety regulations that should be followed when working with VFFS Packaging Machine include:

- Ensuring that all operators are wearing protective clothing and equipment, such as safety glasses and gloves.

- Inspecting the machine before use to ensure it is working properly and all parts are functioning correctly.

- Regularly cleaning the machine to prevent contamination of the product being packed.

- Checking that all safety guards are in place, and any access doors or panels remain closed while the machine is in operation.

- Making sure that all operators understand how to use the VFFS Packaging Machine properly and safely.

- Following all manufacturer’s instructions for the VFFS Packaging Machine, including proper maintenance and calibration procedures.

13.What Are Some Of The Common Problems With VFFS Packaging Machines And Their Possible Solutions?

Jamming

VFFS packaging machines are susceptible to jamming, which can occur if the product being packaged does not fit correctly in the bag or pouch.

To reduce the risk of jamming, you should ensure that your products are compatible with the machine and that it is functioning properly before use.

Poor Seal Quality

VFFS packaging machines use heat to create a hermetic seal around the product. Poorly maintained or damaged heat seals can cause problems with the performance of the machine, leading to poor quality seals.

To prevent this, regular maintenance of the heating element and seal is necessary, as well as ensuring that any damaged parts are identified and replaced.

Leakage

Poor seals can result in leakage and damage to products during transport.

Possible solutions to leaking include using automated quality control systems to check the quality of the sealing process; implementing a double-sealing system; and regularly inspecting machine parts for any signs of wear or tear.

Contamination Risk

Due to the many moving parts, VFFS packaging machines can be prone to contamination due to the foreign objects such as dust.

Possible solutions include regularly cleaning and inspecting machine parts; using high-quality materials that are designed for use in packaging machines; and installing a device to filter out fine particles.

CONCLUSION

VFFS packaging machine is becoming a popular choice in many industries today due to its outstanding advantages. These tools are more cost-effective, easier to use, and require less operating space than other machines. It is also possible to achieve much higher speeds when working with these machines. Also, working with a reputable supplier like Allpack means that you can benefit from the exceptional quality of their machines alongside the personalized customer service they offer throughout the entire purchase process. If you are looking for a quality VFFS packaging machine don’t hesitate to contact Allpack for more information.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide