Industrial Automatic Liquid Soap Filling Machine Shampoo Body Lotion Hair Conditionhand Sanitizer Laundry Detergent Bathroom Shower Gel Automatic liquid filling line

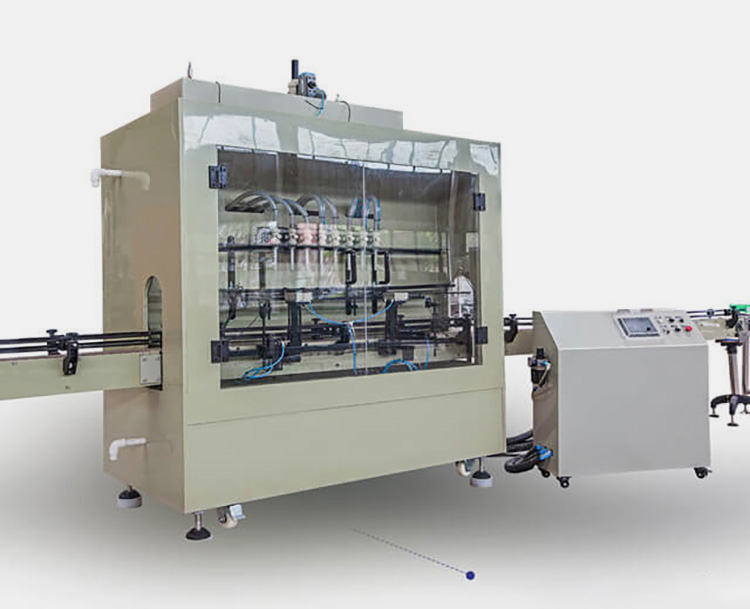

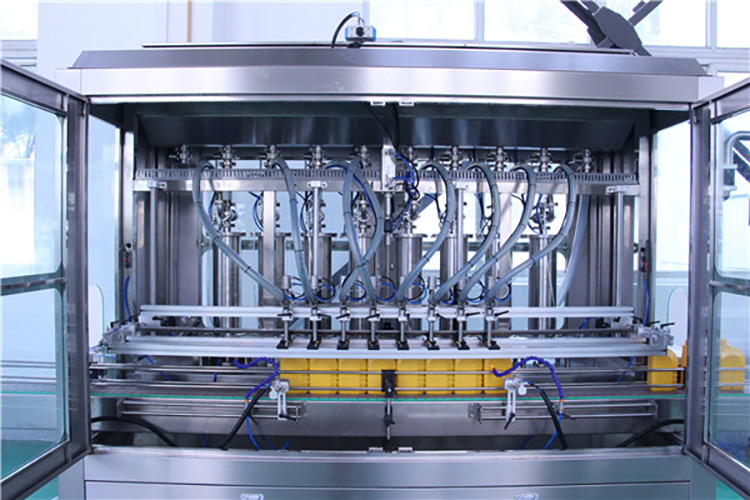

Allpack liquid soap filling machine is suitable for various viscous and non viscous and corrosive liquid. Daily chemical filling machine series include: laundry detergent filling machine, hand sanitizer filling machine, shampoo filling machine, disinfectant filling machine, alcohol filling machine, etc.It adopts linear filling, anti-corrosion materials, independent control of electrical cabinets, unique design, superior performance, other in conformity with the concept of international filling machinery and equipment.

Allpack Liquid Soap Filling Machine Products:

Allpack Liquid Soap Filling Machine Features:

1.304/316 Stainless steel high precision filling nozzle

2.Filling volume adjustable in fine rank, same liquid level after filling

3.All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4.304/316 stainless steel filling pump

5.Efficient spray nozzle rinse thoroughly and save water for flushing

Allpack Liquid Soap Filling Machine Technical Specification:

|

Voltage (V/Hz)

|

220V 380V

|

|||

|

Filling heads

|

6 heads(Customizable)

|

|||

|

Filling range

|

5-1000L(Customizable)

|

|||

|

Filling speed

|

About 16-24 bpm(Mainly depend on filling material)

|

|||

|

Measurement accuracy

|

±1%

|

|||

|

Drip trap

|

Available

|

|||

|

Metering system

|

Piston pump

|

|||

|

Application bottle

|

Circular, round, flat, square, etc

|

|||

|

Dimention(L*W*H)

|

2m*1m*2.2m

|

|||

|

Net weight

|

650kg

|

|||

The Buyer's Guide

Liquid Soap Filling Machine: The Complete Buying Guide in 2024

Did You What Things to Consider When Investing in a Liquid Soap Filling Machine? We know the major ins and outs; the current article is all about it!

From Start to End, you will find the entire discussion fruitful for the final decision.

The liquid soap filling machine is undoubtedly a perfect choice for your company.

Let’s read the article to explore relevant points about the equipment.

1.What is a Liquid Soap Filling Machine?

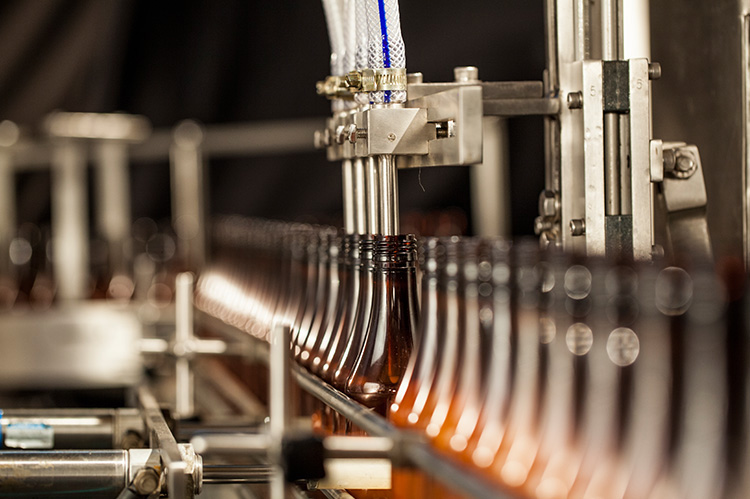

This is a specialized machine that is used to dispense a specified amount of liquid soap into containers.

It is an automatic machine capable enough to handle bottles, containers, and buckets accommodating different volumes of liquid goods in bulk without any limitation for shapes and sizes.

A liquid soap filling machine is available as a semi-automatic and automatic machine with excellent specifications for different types of liquids such as viscous and non-viscous, depending upon the requirement of the manufacturer.

The machine has a significant role, especially in the personal care and toiletries industry, also other industries associated with liquid filling products.

An easy to operate, user-friendly, and bespoke machine that is highly efficient for the production process. Moreover, it ensures highly accurate filling results that improve manufacturer’s business.

2.What Industries Rely on Liquid Soap Filling Machine?

Nevertheless, you can’t ignore the importance of liquid soap filling machines in various industries. The major industries that rely on the liquid soap filling machine are described below:

Personal Hygiene Industry

This is the most relevant industry that utilizes liquid soap filling machines for filling liquid hand washes, cleaners, lotions, conditioners, shampoos, etc., in various jars, cans, buckets, and bottles.

Pharmaceutical Industry

Equally, a liquid soap filling machine is as important as other manufacturing equipment. This is because sterility and precision are two major parameters that ensure reliability and consistency in dosage formulation. Whether automatic or semi-automatic liquid soap filling machines; both offer 100% hygiene and accuracy for large bulk volume product filling in every bottle without sacrificing the quality.

Food and Beverage Industry

The food and Beverage Industry is another major buyer of liquid soap filling machines, but this machine goes by the name of beverage filling or simply liquid filling machine in this sector. As the food and beverage industry deals with viscous liquid (syrup), carbonated drinks, and foaming solvents it requires highly sophisticated equipment to meet customers’ demands and expectations.

Chemical Industry

Chemical Industry manufactures a lot of chemicals that are corrosive, toxic, and harmful if handled without care. This is the reason why the chemical industry employs liquid soap filling machine for the filling of detergents, liquid soaps, organic and inorganic solvents, etc.

Agriculture Industry

To a large extent, liquid soap filling machine finds their utilization in the agriculture industry to fill pesticides. Although the liquid soap filling machine use is limited to filling pesticides at present, however, recent advances in agriculture sciences may lead to further exploration of its working.

3.How a Liquid Soap Filling Machine Works?

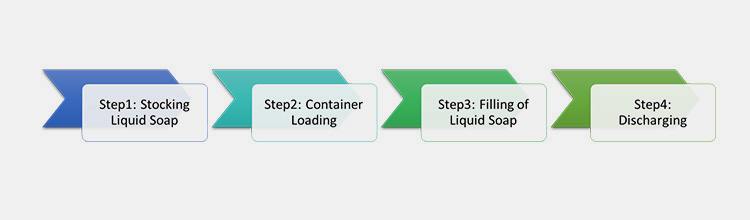

Step 1: Stocking Liquid Soap

In the first step of the liquid soap filling process, the liquid soap is stocked or stored in a designated reservoir or tank. This reservoir is usually connected to the filling machine to ensure a continuous supply of liquid soap during the filling operation.

Step 2: Loading of Container

Once the liquid soap is stocked, the containers, such as bottles or jars, are loaded onto the filling machine. This can be done manually by an operator or through an automated system that feeds the containers into the machine one by one.

Step 3: Filling

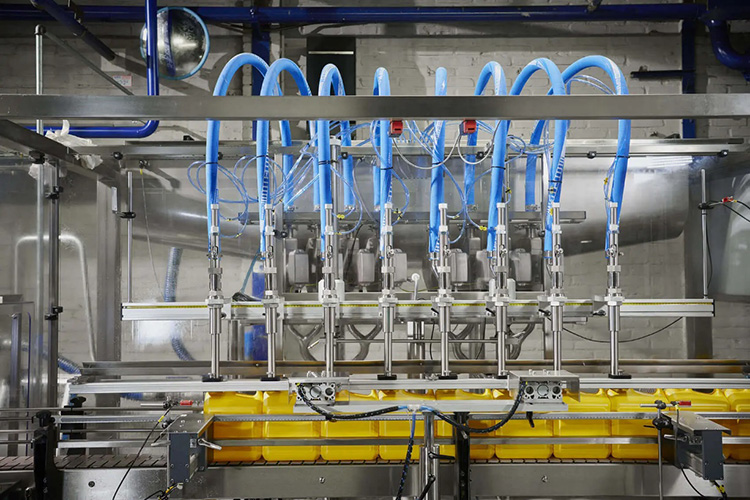

Once the containers are in position, the filling process begins. The liquid soap filling machine is equipped with filling nozzles that are designed to dispense the liquid soap accurately into each container.

The machine can be set to fill a specific volume of liquid soap into each container, ensuring consistency and precision.

The filling process is usually controlled by a PLC (Programmable Logic Controller) system, which regulates the flow of liquid soap and monitors the filling parameters. The nozzles are positioned above the containers, and as the filling operation starts, the liquid soap flows from the reservoir through the filling nozzles and into the containers.

Step 4: Discharging

Once the containers are filled with the desired amount of liquid soap, they move to the discharge area of the machine. This can be a conveyor belt or a designated space where the filled containers are collected or transferred to the next stage of the production line.

4.What is the Basic Classification of Liquid Soap Filling Machine?

The basic classification of liquid soap filling machine is categorized into four broad parts. The description of each of them is defined below:

A) Based on Automation

Semi-Automatic Liquid Soap Filling Machine

This type of machine needs some manual intervention during the work process. For example, placing and discharging containers once they’re filled. The type of machine is basically composed of a filling nozzle, a PLC cabinet, and a filling pump. The limit of filling volume and other processes is executed automatically. The machine is ideal for average to large production businesses that give you a reliable outcome with minimum downtime.

Automatic Liquid Soap Filling Machine

An automatic liquid soap filling machine that offers the entire functionality of filling automatically. This machine is typically constructed to fulfill high production requirements with absolutely excellent filling speed and accuracy. In the terms of configuration, machine designs, and working process, an automatic liquid soap filling machine is way too beneficial that can be customized to consumer requirements. This machine is highly programmable that is regulated by a PLC touch screen control panel that ensures each container is filled correctly with liquid soap.

b) Based on Container Type

Bucket Liquid Soap Filling Machine

When it comes to filling large volumes of liquid soap into bucket-type containers, the bucket liquid soap filling machine takes the spotlight. With its array of pumps and filling nozzles, it ensures precise and efficient filling.

This versatile machine can handle circular as well as square-shaped buckets, making it a reliable choice for various container designs. Load up the liquid soap using flowmeters, pistons, or scales, and let the bucket liquid soap filling machine do the rest.

Jerrycan Liquid Soap Filling Machine

For accurate dispensing of liquid soap in jerrycans, the jerrycan liquid soap filling machine is the go-to solution. This machine employs a weight-based measurement system to ensure the right amount of liquid soap is dispensed. With its bottom-fill nozzles, it minimizes foaming and spillage, maintaining product integrity. Available in both linear and rotary configurations, the jerrycan liquid soap filling machine accommodates different viscosities and can handle jerrycans ranging from 5 to 30 liters.

Drum Liquid Soap Filling Machine

When bulk volumes of liquid soap need to be filled into drums, the drum liquid soap filling machine rises to the occasion. Equipped with multiple filling nozzles (typically 4 to 8), this machine enables efficient filling for large-scale transportation and shipment. Controlled by advanced PLC systems, it precisely dispenses liquid soap quantities ranging from 10 to 300 liters.

With the aid of roller conveyors, weighing mechanisms, and vibration, the drum liquid soap filling machine ensures accurate and reliable filling.

IBC Liquid Soap Filling Machine

Intermediary Bulk Containers (IBCs) play a crucial role in mass shipments of liquid soap, and the IBC liquid soap filling machine is purpose-built to handle this task. Depending on the specific requirements, it can be equipped with a volume filler, gravity filler, or flowmeter filler. Capable of filling large loads of liquid soap, ranging from 60 to 1000 liters, this machine ensures efficient and safe filling. Enhanced with various sensors, it streamlines the process and ensures optimal filling performance.

c) Based On The Filling Process

Linear Soap Filling Machine

This machine fills liquid soap products into each container in a straight or linear fashion. This is a suitable machine for fast work efficiency and minimal labor.

The basic composition includes a filling nozzle, a linear conveyor and a PLC control system for a convenient filling procedure.

Rotary Liquid Soap Filling Machine

This machine is composed of a rotary carousel where empty containers are set for filling tasks. Upon circulation, each container comes in contact with filling nozzles. Once it senses the presence of a bottle/container, the filling of liquid soap takes place automatically. This machine is ideal for smaller workspaces with high production capacity.

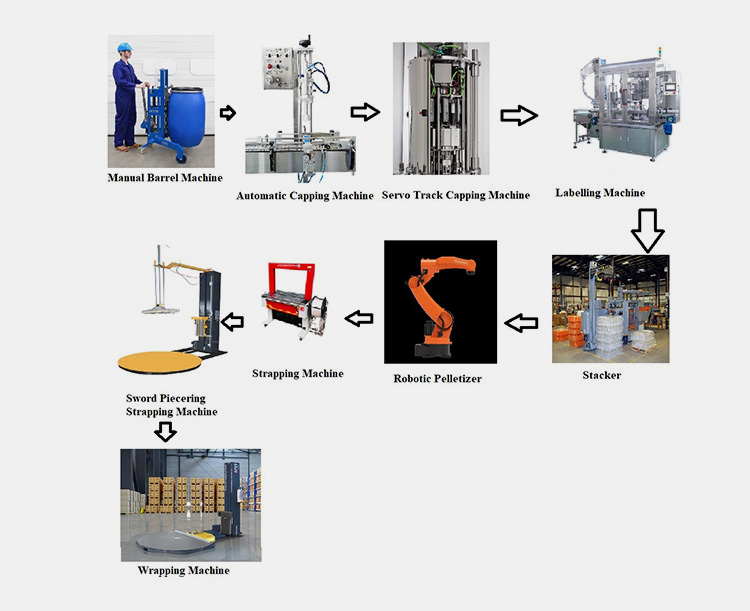

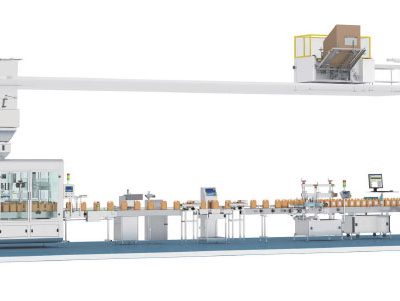

5.What Machines are Needed to Liquid Soap Filling Machine to a Complete Process?

A liquid soap filling machine is able to be integrated with several other machines to complete a production line which will give high output efficiency. These machines are as follows:

| No | Machines | Description |

| 1 | Manual Barreling Machine | A manual barreling machine is used for cleansing and varnishing containers such as drums and buckets before the filling process. |

| 2 | Automatic Capping Machine | An automatic capping machine has been assigned the task of capping lids over jerrycans, buckets, and drums. It works by taking the lids from a feeder and sequentially putting them over containers that are carried by a conveyor belt. |

| 3 | Servo Track Capping Machine | Servo track capping machine is an innovative piece of equipment utilized for closing caps over containers. It has integrated torque with the help of which spouted caps are held together with the containers mouth and closed tightly without any interruption. |

| 4 | Automatic Labeling Machine | An automatic labeling machine is an obligatory part of liquid soap filling production line. It comes into action to effectively paste the sticker labels over containers that contains identification and additional information. |

| 5 | Stacker | Stacker is a loading device, which undertakes the task of stacking filled containers together over palletizer. |

| 6 | Robotic Palletizer | Robotic palletizer is the result of advanced technology that ended human labor. It perfectly moves the stacked containers for palletizing, so they can be transported collectively. |

| 7 | Horizontal Strapping Machine | The horizontal strapping machine straps the palletized containers together to ensure safe mobilization. |

| 8 | Sword Pierce Strapping Machine | It has the same function of strapping containers together, however, it has additional tool names sword, which takes the band and pass it through the surface of the palletizer to avoid scattering of containers during transit. |

| 9 | Wrapping Machine | One of the crucial machines is indeed the wrapping machine, which performs the final step of wrapping bulk containers with flexible plastic to make sure they are integrated and packed as a single unit. |

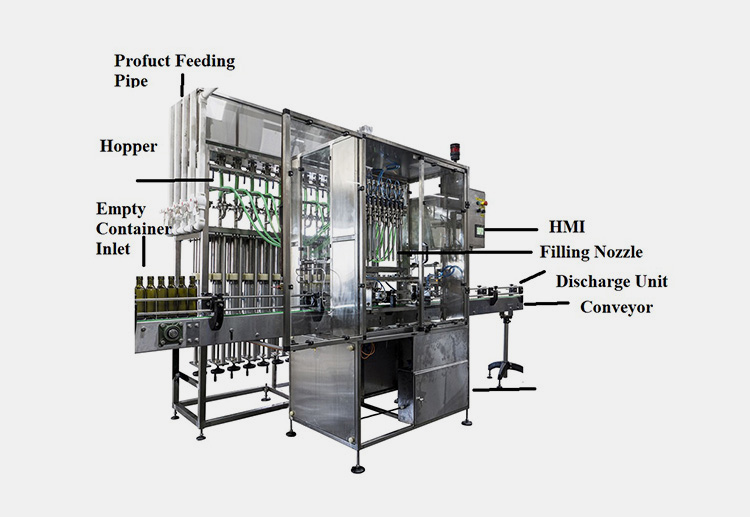

6.What Are Parts of Liquid Soap Filling Machine?

A liquid soap filling machine is composed of key components that collectively contribute to its audacious and effective functioning. These are described below:

Hopper

Hopper is the feeding tank of the machine where the desired volume of liquid soap is poured before starting operation. It is located at the top of the machine, in some cases, an integrated feeding station may be used for large volumes of liquid soap.

Product Feeding Pipe

The product feeding pipe is attached to the hopper through which liquid soap is transferred from the hopper to the filling nozzles.

Empty Container Inlet

Empty container inlet refers to the area from where empty containers are brought under the feeding station via conveyor.

Human Machine Interface (HMI)

HMI is user-friendly touch screen display that allows easy usability of machine. It holds a number of options to set basic parameters for executing the machine and control the operation.

Filling Nozzles

Filling nozzles are narrow tubes made of stainless steel. These filling nozzles are responsible to dispense the accurate amount of liquid soap filling directly into containers without overflowing.

Discharge Unit

The place in liquid soap filling machine where filled containers are transferred is known as the discharge unit.

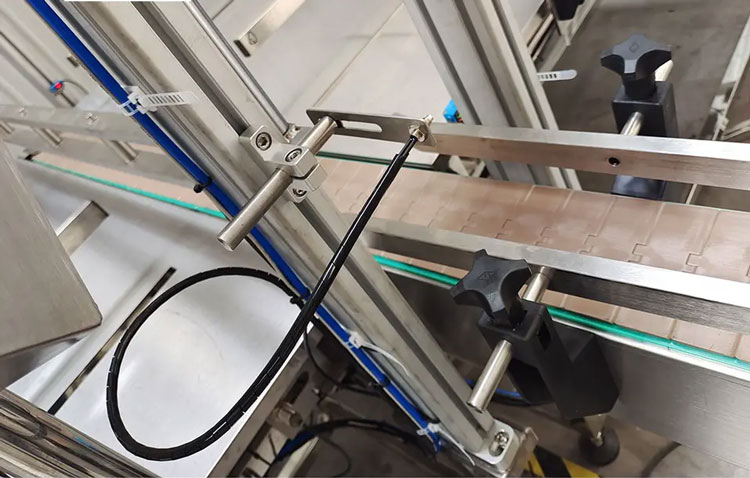

Conveyor

The conveyor is the core part of the liquid soap filling machine, as it facilitates the free and uninterrupted mobilization of containers during the entire mechanism of machine's filling.

7.What Types of Products a Liquid Soap Filling Machine Can Fill?

Knowing the best filling requirements is necessary for every manufacturer. For instance, the net weight, filling volume product’s viscosity. This directly helps you in reaching the best machine for your project.

But there’re some products that require special attention that a liquid soap machine can manage to dispense. The following list of products are:

Liquid with Particulates/Granules

Certain products with particulates may cause problems in filling pathways if subjected to unintended filling machines. For example, jellies with bigger fruity chunks, jams with flavored particulates, etc can block the filling nozzles, and particulates can dispense into the wrong containers or uneven product dispensing.

A piston liquid soap filling machine is a great solution as it is featured a large cylinder to dispense products from bulk containers and offers a great solution for products with large particulates.

Molten Products

These products are those that become solidified in room temperature but liquify in heat.

So, when the filling product is in the molten state it becomes subjected to a filling machine and allowed to be filled into respective bottles and cool to become viscous state after completion.

For such products, such as balms, deodorant, and candles a liquid soap filling machine is preferred.

Corrosion Resistant Products

The liquid soap filling machine has a highly anti-corrosion resistant stainless-steel body.

However, harsh chemicals that may have chance to interact with the machine’s body can cause corrosion and equipment downtime.

Chemicals like bleaches, acids, and relevant chemicals can be filled by a liquid soap filling machine to avoid such circumstances.

8.Why Regular Liquid Soap Filling Machine Cleaning is Crucial?

Indeed, a regular and well-established liquid soap filling machine cleaning schedule is essential to keep the working protocol maintained.

This is required to avoid unwanted breakdowns, cross-contamination and sustaining utility bills.

Any unwanted blockade in the filling line, such as nozzles, pipes, or electric circuits can affect overall production efficiency. Therefore, it is necessary to train the staff when dealing with liquid soap filling machine.

It includes, daily (post working), weekly (machine’ inspection, monitoring electric and main junctions), monthly (external and internal inspection and replacing worn out parts), and yearly (greasing and cleaning of deep tools and replacing damaged parts) clean up and maintenance for optimal operation.

9.What are the Basic Problems and Solutions of Liquid Soap Filling Machine?

| PROBLEMS | SOLUTIONS |

| Unleveled Filling

|

To overcome this, use of overflow filling machine suits to remove out excessive foam that fills the bottles and ensuring that the filling time is increased also gives levelled filling.

Spacers surrounding the nozzles should also be evaluated for checking if they reach desired depth in the bottles for filling process or not. |

| Leakage of Liquid During Filling Process

|

Fastening the pipe clamp.

Make sure that gasket and the O-ring are properly installed and have no wear and tear issue. Use of Piston Filling Machine assures dripless, accurate and precise filling of liquids. |

| Liquid’s temperature and it’s viscosity

|

The viscosity of the liquid depends upon the constant temperature maintenance during the whole filling process. Piston fillers and gravity fillers are suitable for dealing with thin and thick types of liquid products.

Use of anti-dripping nozzles prevent the blockage of fillers. |

| Pump Motor Not working

|

All wiring circuits should be checked whether they’re working properly or not.

Operator must ensure that the type of liquid filled conforms to the type of filling machine being used, otherwise the liquid would be stuck and unable to deliver from the filler. |

| Tipping and spilling of containers

|

Due to unusual sequencing system of bottles, tight gripping around the bottle can push the content out of it before capping and sealing.

Conveyor belt should be checked for any damage to the transfer plate which may push the bottles and cause them to tip over. |

10.What is the Primary Consideration when Selecting a Liquid Soap Filling Machine?

No matter what professional you belongs or related to business industry your liquid soap filling machine can make your production requirement up to the mark if chosen wisely.

The foremost decision relies on trustworthy and right supplier like Allpack. There are the following points to consider when you’re selecting any liquid soap filling machine for your facility.

Your Product

The most important thing you must know is product’s filling requirement. Because material like gels, creams, or anything with highly thicker consistency would need different filling pistons. Therefore, knowing product, machine’s capability, under defined budget would help in smooth running of production facility.

Automation

Up to what level automation you require? If you have to handle smaller number of formulations, then better to go for simpler machines like semi-automatic.

However, some filling products needs high operation or high production expectations, using fully automatic machines may be the best for that. Here, manufacturer may offer conveyors, and other associated units for flexible outcome.

Production Volume

This is also a connecting parameter as above, if your filling volume is higher then surely your machine must have the capability to meet your demands. If you have low production, then smaller equipment can easily meet your expectations. Buying a small machine for larger production is not a wise decision and will lose your time overall.

Conclusion

In conclusion, a liquid soap filling machine is mechanical equipment required for filling containers with a specified concentration of the product. This machine has unlimited benefits on various industrial scales as it can deal with containers of various shapes, sizes, and volumes (from bottles to drums). If you’re interested in purchasing the machine or have any queries, please let us know! Our Team will be delighted to contact you and solve your problems.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products