How To Choose The Right Spout Pouch Filling Machine For Your Business?

Are you tired of the traditional and inefficient packaging methods? Or are you wishing to take your packaging to the next level? In any case you need an advanced and sophisticated machine like Spout Pouch Filling Machine to streamline your production. If you are struggling with How To Choose The Right Spout Pouch Filling Machine For Your Business, we are here with this comprehensive guide!

This informative review will enable you to get the knowledge about a Spout Pouch Filling Machine whether it is working principles, applications, types of machines or filling methods used by it. Not only this, but you will also know how to improve the efficiency and boost production. Stay tuned and keep reading to explore every information provided below!

1.What Is A Spout Pouch Filling Machine?

AIPAK Automatic Food Spout Pouch Filling And Capping Machine

Spout pouches are flexible packages considered as innovative and convenient alternative to rigid packaging forms such as plastic, metal, or glass containers. These spout pouches are preformed that comes with plastic spouts and caps offering great strength and visual impact. A machine used to fill liquids and semi-liquids into spout pouches is called a Spout pouch filling machine.

Spout pouch filling machine is an automated equipment tailored with advanced technology to automatically undertake the entire process. It has robust structure that is made up of stainless steel to avoid contamination and corrosion. The machine can handle filling of multiple products and is popularly used in food industry, beverage industry, and cosmetic industry.

2.How Does A Spout Pouch Filling Machine Work?

A Spout pouch filling machine automatically fills and seals these smart and flexible pouches by following various steps. Let's know how the process takes place!

Machine Setting

The working mechanism of a Spout pouch filling machine starts with setting of machine. It involves adjusting the parameters of machine through a control panel for the amount of product to be filled, sealing heat, and labeling data etc. Similarly, the structural adjustment of machine is also undertaken at this step to make the machine ready for operation.

Hopper Loading

The next step involves loading the bulk of material into the hopper of the machine. For this purpose, an additional feeding unit may be integrated with the main machine to carry out smooth processing and avoid interruption caused by inadequate supply of the product.

Pouches Loading

Spout pouch loading into machine: Picture Courtesy: Micmachinery Mike

In addition to hopper loading, preformed pouches are supplied to the machine. These pouches may be loaded manually, however, in automatic machines the empty pouches are loaded into the machine magazine.

Pouch Opening

The next step consists of pouch opening where empty pouch is picked up from the magazine. The pouch is opened via mechanical arms or blowing the air inside, so as to open it up for smooth product filling.

Pouch Filling

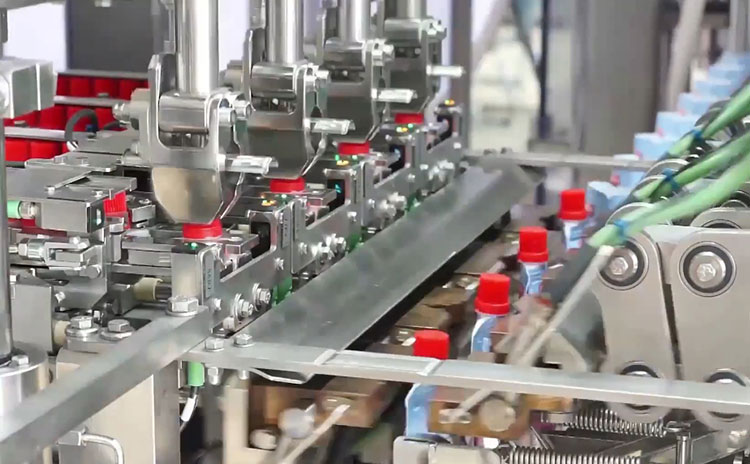

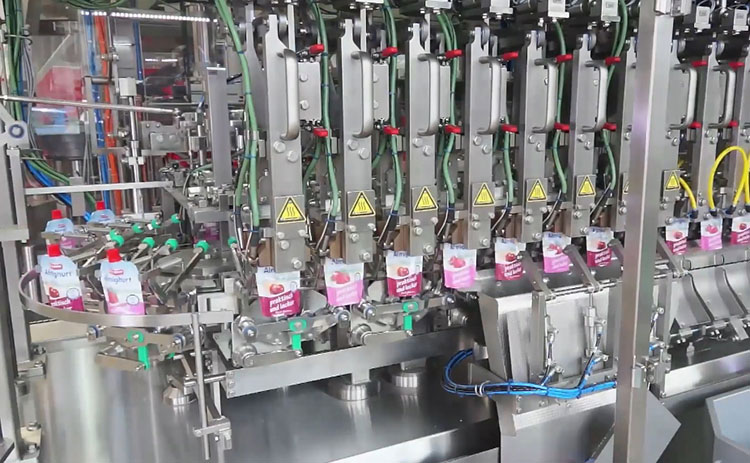

Spout pouch filling process- Picture Courtesy: Micmachinery Mike

Once the pouch is opened, the process of filling takes place. Here, the machine accurately measures the desired amount of product to be filled and precisely dispense into the pouches. In order to prevent leaks and avoid splashes, different types of filling methods are used which include gravity, pump-based, or volumetric filling.

Pouch Sealing or Capping

Spout pouch capping process- Picture Courtesy: Micmachinery Mike

As the pouch is filled with product, it is proceeded for closure. In case of fill and seal machine, the pouch is sealed through heat pressure, while as, in case of fill and cap machine, the machine picks up a caps, tightly place it over the spout and tighten securely.

Pouch Coding

Upon sealing and capping, the pouch is properly printed with batch code and data including date of manufacturing and expiration.

Pouch Discharging

Spout pouch discharging over conveyor belt- Micmachinery Mike

As all the steps of spout pouch filling, sealing, and labeling are properly completed now there is time for pouch discharging. The finished pouch is discharged from the machine via conveyor.

3.Which Industries Use Spout Pouch Filling Machines?

A spout pouch filling machine is an astonishing machine utilized for the filling and packaging of wide range of products including liquids and semi-liquids. In this way, some of the prominent industries which use spout pouch filling machine are highlighted below:

Food Industry

Food spout pouch packaging- Picture Courtesy: Lanker Pack

Food industry is one of the prominent industries where application of a spout pouch filling machine is realized for enhanced safety and efficiency. It is popularly used for the filling of wide range of food products into spout pouches such as baby food, yogurt, sauces, cooking oil, and jam etc.

Pet Food Industry

Pet food spout pouches- Picture Courtesy: jindepacksupply.com

Pet food industry is another industry that uses spout pouch filling machine for pet food packaging. The common examples include broth, salmon, and other liquid food for cats, puppies, and dogs.

Beverage Industry

Various types of fruit juices and smoothe in glasses- Picture Courtesy: Fitterfly

Spout pouch filling machine is highly automatic and intelligent equipment that can precisely carry out the filling of clear liquids such as water, juices, milk, and energy drinks. Keeping in view these features, beverage industries are using this machine to fulfill the requirements of large scale production.

Daily Chemical Industry

Liquid daily chemical spouch pouches- Picture Courtesy: wellfapack.com

Daily chemical industry encompasses the field where manufacturing of household cleaning products takes place. These items such as liquid detergents and dishwashing liquids are to be properly packed for which spout pouch filling machine is utilized.

Beauty Care Industry

Vonco Products

Beauty care industry revolves around the production, packaging, and distribution of products related to beauty care such as body washes, shampoo, hand wash, and sanitizer etc. All of these products are used on daily basis and for their convenient packaging spout pouch filling machine is used.

Lubrication Industry

Grease spout pouches- Picture Courtesy: kdxlubricants.com

Lubrication industry produces various types of oil, greases, and similar liquids which are meant to reduce the friction and wear in machines and automobiles. Therefore, spout pouches are now popularly used for lubricants due to increased feasibility. Thus, the industry is using a spout pouch filling machine to accomplish this task of lubricants filling into spout pouches.

4.What Types Of Products Can Be Filled With A Spout Pouch Filling Machine?

Spout pouch filling machine can fill wide range of products including clear liquids, pastes, and semi-liquids etc. Some of the major types of products are as follows:

Free Flowing Liquids

Milk pouring from jug into a glass- Picture Courtesy: nutritionsource.hsph.harvard.edu

Free flowing liquids are low viscosity liquids which can flow smoothly. The common examples include water, milk, and fruit juices. Such type of liquids are clear and can be easily filled with a spout pouch filling machine.

Viscous Liquids

Viscous honey flowing into the jar- Picture Courtesy: astorapiaries.com

Viscous liquids are fluids which resist flow due to internal friction called viscosity. The common examples include honey, oil, shampoo, sausages, and melted chocolate. These products are easily filled with a spout pouch filling machine.

Semi Solids

Chilli sauce in a bowl- Picture Courtesy: Marion's Kitchen

Semi solids are the products containing qualities of both liquid as well as solid. Products such as smoothie, soups, milkshake, pet pastes comes under the category of semi solids. Thus, a spout pouch filling machine is capable of filling these products into pouches.

5.What Are The Different Types Of Spout Pouch Filling Machines?

Spout pouch filling machines are of different types. These machines can be better described under two categories: on the basis of structure and on the basis of automation. The explanation is given below:

On The Basis of Structure

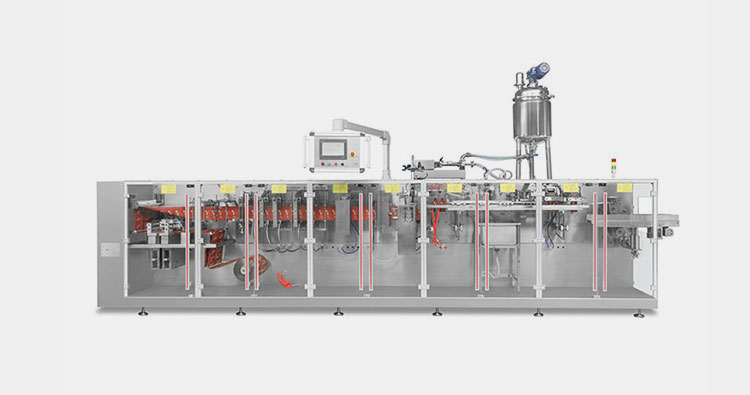

Horizontal Premade Pouch Filling Machine

APK-130S/240DS Premade Pouch Filling Machine

Horizontal premade pouch filling machine is an automatic machine designed to carry out the filling of premade pouches. It has robust structure made up of stainless steel, intelligent control panel, and transparent glass window for enhanced protection against moisture and dust. It carries out the pouch filling process in a gentle way where each step is undertaken horizontally. The machine is suitable for all kinds of liquid and semi-solid products.

Vertical Premade Pouch Filling Machine

APKRL200-Y Rotary Liquid Premade Pouch Filling Machine

Vertical premade pouch filling machine is an innovative machine designed for finishing different bag types with spouts. The machine uses automation for high speed filling as well as sealing. It has vertical body integrated with a piston filler. The rotary station is responsible for holding premade empty pouches, their opening, product filling and tight sealing. It is applicable to all kinds of free flowing and viscous liquids in different industries.

On The Basis of Automation

Fully Automatic Spout Pouch Filling Machine

Automatic Liquid Spout Pouch Filling Capping Machine- Picture Courtesy: MAKWELL

Fully automatic spout pouch filling machine is a multi function equipment utilized for the independent filling and capping of spout pouches. It works automatically by carrying out pouch loading, vacuuming, fixed-position filling, nitrogen flushing, spout cleaning, cap placing, and screwing etc. The machine uses specialized filling system to ensure filling accuracy. Moreover, it can be integrated with other machines for enhanced efficiency and production.

Semi-Automatic Spout Pouch Filling Machine

Semi-Automatic Spout Pouch Filling Machine- Picture Courtesy: wmdequipment.com

Semi automatic spout pouch filling machine is an advanced solution for premade spout pouches. The machine has compact design and is capable of filling liquid and viscous substances including pumpable liquid, creams, pastes, sauces, and others. The product is filled by means of a piston filler with an adjustable dosing range. It requires operator intervention for conduct the process such as loading and unloading of pouch and pushing handle etc.

Manual Spout Pouch Filling Machine

Manual Spout Pouch Filling Machine

Manual spout pouch filling machine is available in form of benchtop volumetric filler. Such type of machine is designed for low volume of production that ensure simple and accurate filling method. The machine has small footprint and does not require electricity for operation. It has stainless steel vessel, a narrow nozzle, handle, and base. It can precisely dispense low viscosity liquids such as juices, sauces, and detergents.

6.What Are The Differences Between Manual, Semi-Automatic, and Fully Automatic Machines?

The primary difference between manual, semi-automatic, and fully automatic spout pouch filling machine lies in the level of automation. Some of the prominent distinctions are explained below:

| No | Aspects | Fully Automatic Machine | Semi-Automatic Machine | Manual Machine |

| 1 | Definition | Fully automatic machine is an advanced equipment that comes with automated system. | Semi-automatic machine has medium level automation with limited human intervention. | Manual machine is a compact machine that is used with the help of human intervention. |

| 2 | Working Process | It has simple automatic process of pouch loading, opening, product filling, and pouch capping or sealing. | The process involves operator loading of pouch in the machine and pushing a handle to fill the pouch. Similarly, pouch is manually discharged. | Its process is entirely manual where the user hold an empty pouch and push the handle to fill it. Once filled, the pouch of removed and sealed with a cap. |

| 3 | Structure | The structure of fully automatic machine is heavy-duty and long that consists of main frame, filling station, control unit, electric cabinet, transparent glass windows, and filling and sealing mechanism. | Its structure is medium size with main components comprising support stand, wheels, product hopper, pouch holder, and push handle. | The manual machine is precise in size with only few components including base, hopper, filling nozzle, and push handle. |

| 4 | Output | It has ultra high production output with filling up to 50 bags per minute. | Semi automatic machine has fast production suitable for medium scale business. | The production output of manual machine depends upon the user. |

| 5 | Cost | Fully automatic has high cost due to the price of machine along with operation and maintenance charges. | Semi-automatic machine is a cost-effective solution. | Manual machine is a low-cost equipment. |

| 6 | Picture |

Fully Automatic Spout Pouch Filling Machine |

Semi Automatic Spout Pouch Filling Machine- Picture Courtesy: WMB Equipment |

Manual Spout Pouch Filling Machine |

7.How Many Filling Heads Are Available For Spout Pouch Filling Machines?

Spout pouch filling machine comes with varying number of filling heads. They are commonly offered with configuration such as 2, 4, 6, 8, or more heads if customized for increasing production. The details are given below:

2 Heads

Semi-Automatic Spout Pouch Filling Machine

Dual heads spout pouch filling machine comes with 2 filling heads that has precise structure. It is often suitable for low level of production where demand for production output is moderate.

4 Heads

Semi-Automatic Filling Machine For Spout Pouch

Spout pouch filling machine may also come with 4 filling heads. It is available in fully automatic and semi-automatic machines. The 4 head filling machine is considered vital for high production output.

6 Heads

6 heads spout pouch filling machine- Picture Courtesy: camelsdairymachine.com

6 heads spout pouch filling machine is designed for high-speed operations. Such machines are suitable for large scale production and they are capable of filling thousands of spout pouches in an hour.

Customized Options

Other than conventional 2, 4, and 6 heads spout pouch filling machines, some machines can be configured even with more heads such as 8 to 12 heads in order to maximize the efficiency.

8.Which Filling Methods Are Used: Gravity, Pump-Based, or Volumetric?

When it comes to highlight the various filling methods used for spout pouch filling, they can be categorized into three types which are explained below:

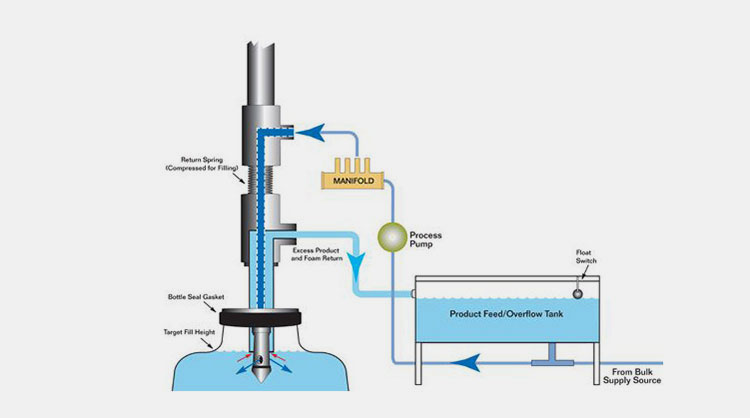

Gravity Filling Method

Gravity filling method- Picture Courtesy: fillers.com

Gravity filling method is one of the three methods utilized for the filling of thin liquids into spout pouches. The common examples include water, fruit juices, and solvents etc. This method is based on the principle of gravity where each spout pouch is filled by pulling the liquid down through timed valves.

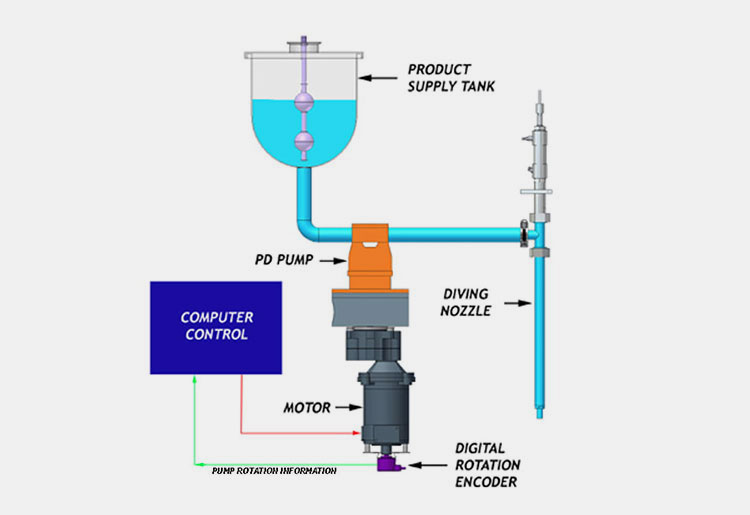

Pump-Based Filling Method

Pump based filling method- Picture Courtesy: forum.sistermonk.com

This filling method involves the pump that moves product from tank into the spout pouches via filling head. It is suitable for filling viscous liquids such as ketchup, shampoo, and pastes etc.

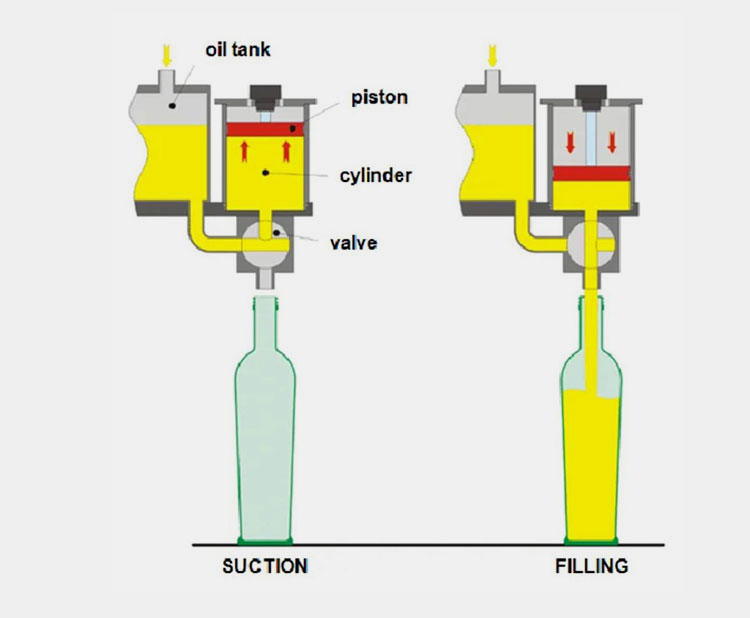

Volumetric Filling Method

Volumetric filling method- Picture Courtesy: vkpackfillers.com

Another method used for spout pouch filling machine is volumetric filling method in which a piston is used to carry the fixed amount of liquid and fill it into the pouch. It is suitable for filling thick and semi-liquids that contain particles such as cream, pickles, and jam.

9.Can The Machine Handle Different Pouch Types Like Gusseted, Stand-up, or Flat Pouches?

Yes, a spout pouch filling machine can handle wide range of pouch types such as gusseted pouch, stand-up pouch, and flat pouch etc. The description of each pouch filled by a spout pouch filling machine is provided as under:

Gusseted Pouch

Gusseted liquid spout pouches- Picture Courtesy: dxcbag.com

Gusseted pouch can be simply described as a flexible pouch having extra flaps on certain sides. Such type of spout pouches are designed to carry large volume of product due to increased space.

Stand-up Pouch

Stand-up pouch- Picture Courtesy: chouqin.com

Stand-up pouch is also called doypack which is a flexible pouch made up of multiple film layers for enhanced protection. It has bottom gusset that allows the pouch to stand upright on shelve.

Flat Pouch

Flat spout pouches- Picture Courtesy: Freepik

The machine can easily handle the filling of flat pouch with a spout. Such type of pouch has limited space for holding product therefore, it is used for single serving.

10.What Are The Key Features To Consider When Buying A Spout Pouch Filling Machine?

When buying a spout pouch filling machine, it is crucial to consider several features and based upon these characteristics one can select a compatible machine. These are as follows:

Production Needs

Spout pouch capping process- Picture Courtesy: pkengg.co.in

The very first factor you must look for is your production demand and scale of operation. In addition, in case of small scale or medium scale business a semi-automatic machine is the best solution. In contrast, for high speed production fully automatic machine is suitable to fulfill the output requirement.

Product Characteristics

Sauces with various viscosities- Picture Courtesy: beefitswhatsfordinner.com

Another essential factor to consider is the characteristics of product that include viscosity and flow properties. These aspects are associated with the choice of filling method for machine such as gravity filling, pump-based filling, and volumetric filling machine etc.

Versatility

Consider another significant feature of a spout pouch filling machine which is versatility. Choose a machine that is flexible and can be adjusted to accommodate different types of pouches as well as the products.

Filling Accuracy

Liquid filled transparent spout pouches mfirstpack.com

Check the filling range and accuracy level of the machine. It is eminent to take account of the filling accuracy range of a spout pouch filling machine in order to avoid under filling and over filling and allow smooth and consistent product quality.

11.What Is The Filling Accuracy Of A Spout Pouch Filling Machine?

Accuracy icon- Picture Courtesy: universitytranscriptions.co.uk

Filling accuracy of a spout pouch filling machine refers to the ability of the machine to dispense exact amount of product such as liquid or semi-solid into containers. It ensures minimized product deviation such as over filling or under filling etc. This level of filling accuracy depends upon several factors including design of the machine and viscosity of the product.

A spout pouch filling machine is intelligent to fill viscosities up to 100,000 cP by maintaining ±0.1% accuracy. This is done by the automatic system installed in the machine that enables it to precisely measure out the product's liquid contents and discharge into the pouches.

12.What Viscosity Of Liquids Can The Machine Handle?

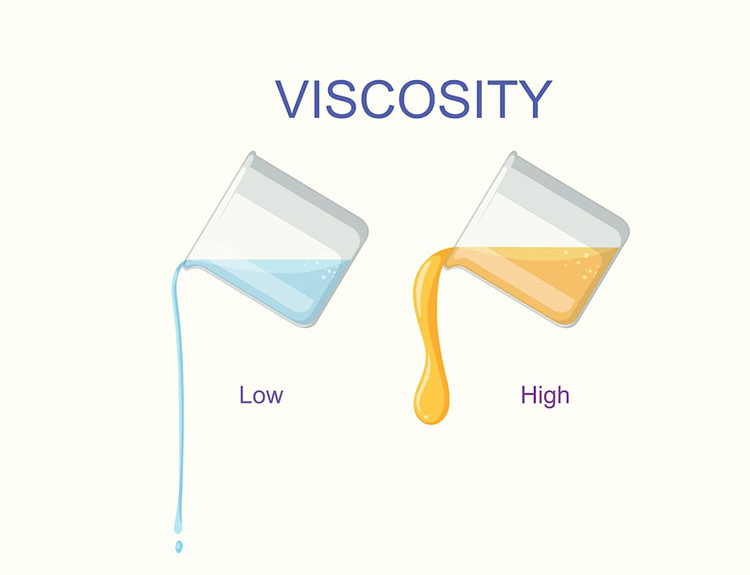

Low and high viscous liquids flowing from beaker- Picture Courtesy: Freepik

Viscosity is a fluid's resistance to flow. The high rate of the liquid flow means the product is less viscous. In contrast, if liquid has poor flow then it is highly viscous. Depending upon the different filling methods used by a spout pouch filling machine such as gravity filling, pump-based filling, and volumetric filling, it can handle range of viscosity of liquids which you will know in the table below:

| No | Material | Viscosity |

| 1 | Water | 1-5 cps |

| 2 | Corn Syrup | 50-100 cps |

| 3 | Maple Syrup | 150-200 cps |

| 4 | Caster Oil | 250-500 cps |

| 5 | Honey | 2-3,000 cps |

| 6 | Molasses | 5-10,000 cps |

| 7 | Chocolate Syrup | 10-25,000 cps |

| 8 | Peanut Butter | 150-200,000 cps |

| 9 | Crisco/Lard | 1-2,000,000 cps |

13.How Can Leakage Be Prevented During Filling?

Liquid filled spout pouches- Picture Courtesy: OK Packaging

Leakage can be prevented by maintaining proper filling speed and seal strength. In addition, correct alignment of filling nozzles with pouches plays an important role in avoiding leaks. Regular cleaning and routine inspection of filling area help keep the process smooth and leak-free.

Conclusion

To conclude, we are hopeful that you have got the answer to How To Choose The Right Spout Pouch Filling Machine For Your Business? It is a critical decision that significantly impact your production efficiency as well as packaging quality. It is way more easier by considering certain factors such as assessing your needs, evaluating the features of machine, and understanding the maintenance requirements. If you are interested in purchasing a spout pouch filling machine, we are here to provide you a long list. Feel free to contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide