Horizontal Wrapping Machine: The Complete Buying Guide In 2025

When it comes to effective packaging processing, there is no doubt that the horizontal wrapping machine is an innovative and efficient way of quickly packing products in protective films. This machine can be tailored for use in different industries such as food, beverage, pharmaceuticals, chemicals or any other type of product requiring a reliable and accurate wrapping solution.

Not only does this equipment offer great speed with accuracy but also requires minimal setup time making it ideal for manufacturers who are looking to save time on their production lines. What’s more is that these machines are built to last due to robust construction materials giving them high operational life. Read on and find out exactly what features make these machines so desirable!

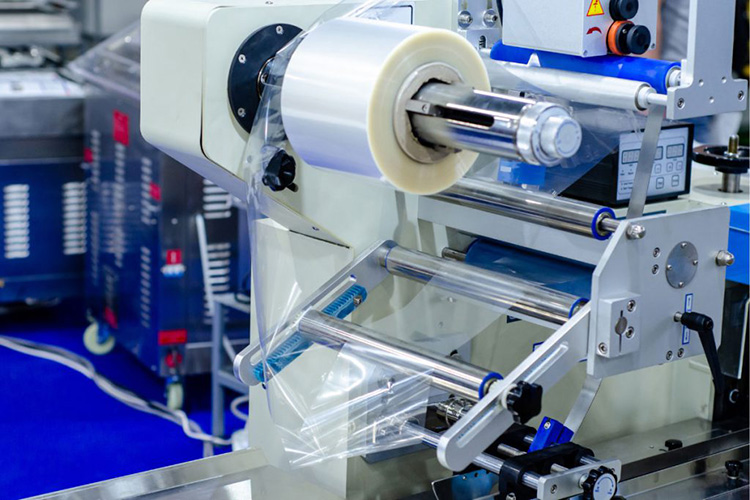

1.What Is A Horizontal Wrapping Machine?

A horizontal wrapping machine is an automated packaging machine designed to wrap products in a protective film of polyethylene. The product passes through the machine while the film wraps around it at high speeds, creating a tight and secure package. This process helps protect products from damage and contamination during storage or transport.

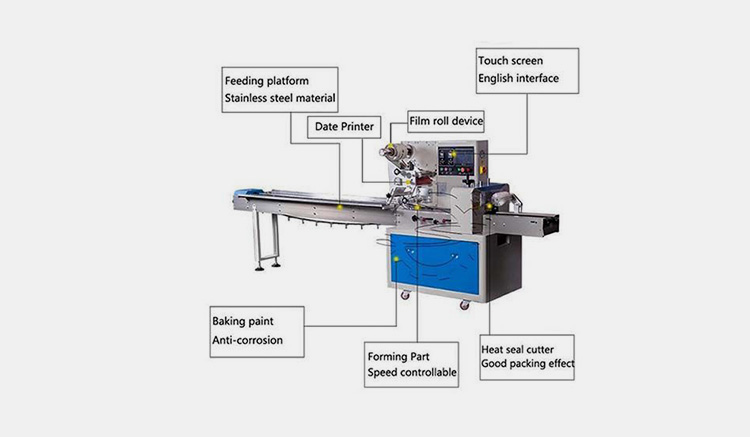

2.What Are The Components Of A Horizontal Wrapping Machine?

Feeding Platform

The feeding platform is used to place the product for wrapping. It should be stable and have a smooth, non-slip surface so that the product doesn't move during the wrapping process.

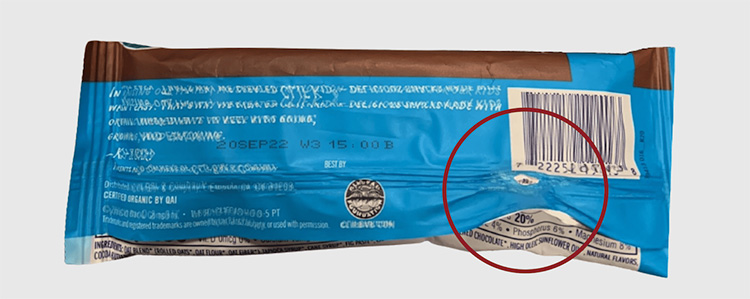

Date Printer

The date printer is used to print the production date and other information onto the product being wrapped.

Film Roll Device

The film roll device is used to hold the wrapping film in place during operation. It can be manually or pneumatically operated to change rolls when needed.

Touch Screen

The touch screen is used to control the functionality of the machine. It enables operators to adjust parameters such as wrapping speed and film tension, as well as monitoring production data.

Baking Paint

The baking paint is used to seal the film onto the product. It enables a tight and secure bond that will not come apart during transportation or storage.

Forming Part

The forming part is used to form the film into the desired shape and size. It can be adjusted according to different products, allowing for customized wrapping solutions.

Heat Seal Cutter

The heat seal cutter is used to cut the film after it has been sealed. It ensures that there are no loose ends or sharp edges, making the product safe for consumption.

3.What Are The Benefits Of Using A Horizontal Wrapping Machine?

Enhances Quality

Horizontal wrapping machines ensure a consistent, high-quality output for every package produced. This results in improved customer satisfaction as well as increased brand recognition from consistently produced packages that stand out from the competition.

Protects Products from Damage

The horizontal wrapping machine is designed to protect products from damage due to handling and transportation. By using materials such as shrink wrap, plastic film, or paperboard, the machine ensures that the wrapped product remains intact throughout its journey.

Extends Shelf Life

The horizontal wrapping machine provides a tight seal around the product, thereby extending its shelf life. This helps to keep products fresher longer, reducing waste and saving money.

Customizable

When it comes to customization, horizontal wrapping machine offers a wide range of options, allowing for precise adjustment of product size, shape, and weight based on customer requirements.

Versatility

Also, horizontal wrapping machines can be used to package a variety of products, from produce, beverages and pharmaceuticals to cosmetics. This versatility allows for the efficient packaging of different types of products in one system.

Enhanced presentation

The horizontal wrapping process produces neat and uniform looking packages that are attractive on retail shelves.

4.In Which Industries Can A Horizontal Wrapping Machine Be Used?

A horizontal wrapping machine can be used in a variety of industries include:

Cosmetic Industry

A horizontal wrapping machine is ideal for the cosmetic industry because it can wrap products like lipstick, mascara, soaps and eyeliner into small packages. This helps to minimize product damage while also making the items more aesthetically pleasing on store shelves.

Food Packaging

The horizontal wrapping machine is suitable for food packaging applications as it can wrap products like cookies, cakes, and chocolates. This helps to ensure that these food items stay fresh for longer periods of time while also making them look more appealing to potential customers.

Pharmaceutical Industry

Pharmaceutical companies also rely heavily on horizontal wrapping machines to package their products. The machine's ability to form a tight seal helps keep medication and medical supplies uncontaminated during transit or storage.

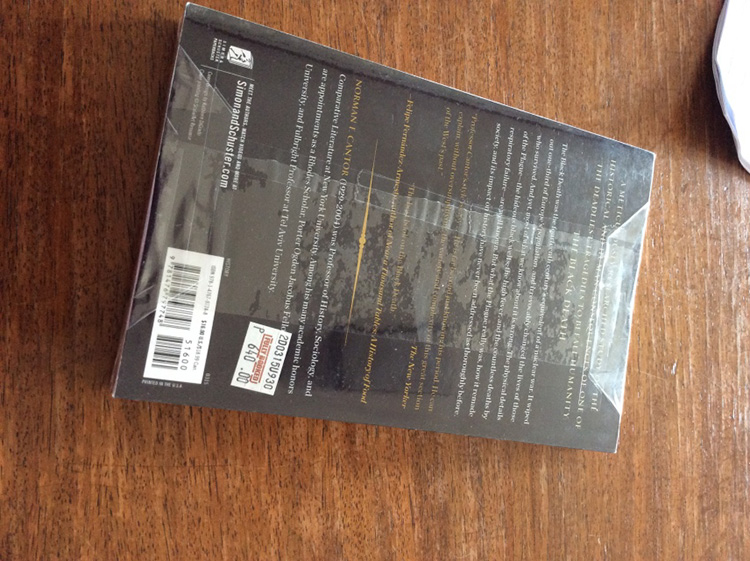

Retail Industry

The horizontal wrapping machine is used in the retail industry to wrap products like books and toys into waterproof packaging materials. This ensures that these items arrive at their destination in perfect condition.

Agriculture Industry

Horizontal wrapping machines are an essential tool for agriculture businesses. These machines can be used to package fruits, vegetables, and other agricultural products in airtight wrappings that help prevent spoilage.

Manufacturing Industry

Horizontal wrapping machines can be used in manufacturing industries to bundle products together for easy transport or storage. The bundling process helps to reduce labor costs and improve product traceability.

Electronic Industry

In the electronics industry, a horizontal wrapping machine can be used to package components and boards in protective covers that help prevent damage and keep parts secure for transportation and storage.

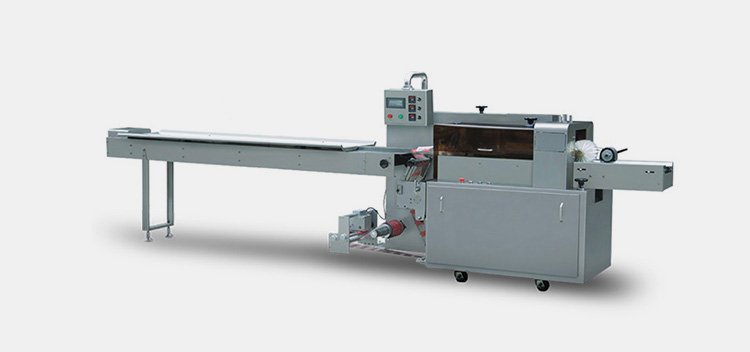

5.How Does A Horizontal Wrapping Machine Work?

A horizontal wrapping machine works by taking flat material from a roll and wrapping it around the item or bundle that's being packaged. The horizontal wrapping machine has two main components - an infeed system, which takes in the material; and a wrapper, which applies the material to the product.

The infeed system typically consists of a feed motor, an uncoiler, and an inlet guide. The wrapper usually has a rotary cutting head, tensioning devices, and nip rollers to ensure that the material is applied correctly.

The process begins with the material being fed into the infeed system. The feed motor is used to provide tension and motion to the material, while the uncoiler unwinds it from the roll and guides it into the inlet guide. The material then passes through a nip roller which ensures that it is held securely against the product as it moves along.

Next, the wrapper turns the material on its side and begins to wrap it around the item. As it wraps, tensioning devices keep the material taut around the product being wrapped. The rotary cutting head is used to cut off sections of the wrapping material at precise intervals. Finally, nip rollers are used to press down the edges of each section, ensuring that the product is securely wrapped.

6.What Is The Difference Between A Horizontal Wrapping Machine And A Shrink Wrapping Machine?

A horizontal wrapping machine and a shrink wrapping machine are both types of packaging machines used to wrap products. However, they have distinct differences that set them apart from each other like the type of wrapper material they use and the size and weight of the products which they can package

A horizontal wrapping machine uses a flat surface combined with flexible film to wrap products in either plastic or paper material. The wrapper passes through the rollers which press the two surfaces together, forming a tight seal. It is suitable for packaging large and heavy products such as furniture or car parts.

On the other hand, a shrink wrapping machine uses shrink film to encase products before they are heat sealed into their wrapping material. This method helps to keep the product secure and prevents air leakage or contamination. It is most commonly used to wrap food products such as candy bars or bottles, and can also be used for items like clothes or gift baskets.

7.What Are The Different Types Of Horizontal Wrapping Machines That Are Available On The Market?

a) Automatic Horizontal Wrapping Machine

Automatic horizontal wrapping machine is a fully automated version that can wrap multiple products at once in one cycle. It utilizes robotic arms to feed the product into the wrapper and then seal it with heat or adhesive tape depending on the requirements. The automatic horizontal wrapping machines are ideal for higher volume operations, providing faster output and improved efficiency.

b) Pre-Stretch Horizontal Wrapping Machine

This type of machine utilizes a pre-stretch film to reduce the amount of material used, resulting in cost savings. It is designed to wrap multiple products at once and is suitable for larger items such as furniture or appliances.

c) Overwrap Horizontal Wrapping Machine

Overwrap horizontal wrapping machine is designed to wrap products with pre-printed film or paper labels, which adds an extra layer of presentation and protection to the product. The overwrap horizontal wrapping machines are ideal for applications where presentation is a priority, such as retail packaging.

8.What Is The Difference Between A Horizontal Wrapping Machine And A Vertical Wrapping Machine?

a) Horizontal wrapping machines are designed to wrap packages that are laid out horizontally, while vertical wrapping machines are designed to wrap packages that are laid out vertically.

b) Horizontal wrapping machines can be used for a wide range of items, including boxes and pallets, while vertical wrapping machines are primarily intended for cylindrical objects such as pipes and cables.

c) Horizontal wrapping machines are more versatile and can handle a wide range of products, while vertical wrapping machines offer the advantage of increased speed when it comes to cylindrical objects.

d) Horizontal wrapping machines also tend to be easier to set up, as they require less adjustment and customization than vertical wrapping machines.

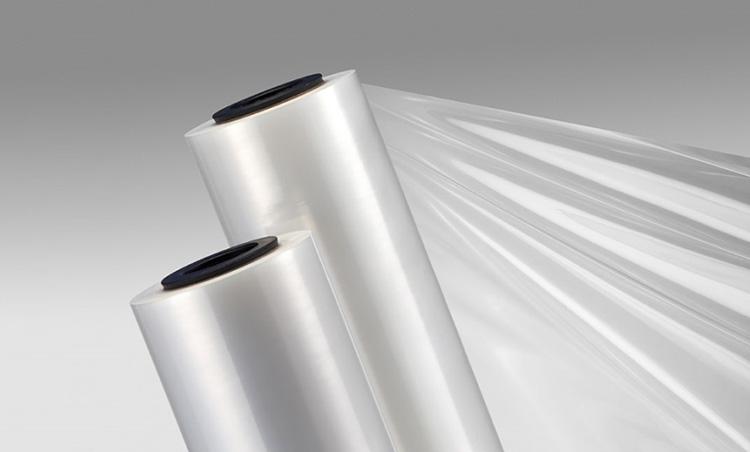

9.What Type Of Films Can Be Used With A Horizontal Wrapping Machine?

Polyester (PET) Film

PET films offer a barrier protection against moisture, dust, and other contaminants as well as excellent mechanical properties such as tear resistance and temperature tolerance. They are also available in a variety of thicknesses and transparencies.

Polyethylene (PE) Film

Polyethylene film is commonly used in horizontal wrapping machines because it can easily form flexible wraps. PE films come in a variety of forms ranging from high-density polyethylene (HDPE) to low-density polyethylene (LDPE).

10.What Types Of Products Can Be Wrapped With A Horizontal Wrapping Machine?

Horizontal wrapping machines are versatile tools that can be used to wrap a wide variety of products. These include:

- Food items such as bread, cakes, cookies, and pizza

- Snack foods

- Candy

- Medical supplies

- Soap

- Detergents

- Electronics

- Pharmaceuticals

- Envelopes and Documents

- Fruits

11.Are There Any Industry Standards Or Regulations That Should Be Followed When Using A Horizontal Wrapping Machine?

Yes, there are some industry standards and regulations that should be followed when using a horizontal wrapping machine. They include:

Ensure that you have the proper training on how to operate the machine safely and correctly. This includes understanding how to set up and adjust the machine properly, as well as understanding safety protocols such as wearing protective clothing and safety glasses.

Make sure that your horizontal wrapping machine is equipped with guards or other protective devices to keep you away from moving parts, as well as checking for any worn or damaged components of the machine.

Periodically inspect the wrapping material used with the machine for tears or breaks in its construction which can cause product damage or operator injury.

Make sure that any machine operation is in accordance with the manufacturer's instructions and all applicable standards and regulations.

12.Can A Horizontal Wrapping Machine Be Used To Wrap Irregularly Shaped Products?

Yes, it is possible to wrap irregularly shaped products with a horizontal wrapping machine. This type of machine offers flexibility when it comes to size and shape as it can be adjusted according to the product's dimensions. It also has the capability to reliably wrap any surface thanks to its adjustable components such as pressure rollers and film tension variables.

Depending on the shape, size and complexity of the product, a horizontal wrapping machine can be used to wrap products effectively. Additionally, this type of machine provides superior load stability for irregularly shaped items when compared to traditional packing methods.

13.What Are The Common Problems Associated With A Horizontal Wrapping Machine And Their Possible Solutions?

Jamming of The Film Roll

This is a common problem that can occur when the horizontal wrapping machine is not properly maintained. The solution is to ensure the film roll is loaded into the machine correctly, and that it is regularly checked for any signs of wear or damage. Additionally, ensuring that the film roll has sufficient slack can help reduce the chance of jamming.

Poorly Formed Product Wraps

This is another common issue that can arise from improper machine maintenance or incorrect loading of the film roll. To solve this problem, it is important to ensure the wrapping parameters are set correctly and that all components of the machine are in good working order. Moreover, using a higher quality film roll can help ensure better product wraps.

Poorly Cut Film Rolls

This problem is usually caused by a dull or misaligned blade in the horizontal wrapping machine. To fix this problem, it is necessary to replace the blade or realign it if possible. If that doesn't help, then replacing the entire machine may be required.

Machine Breakdowns

This is usually caused by overuse or inadequate maintenance of the horizontal wrapping machine. To prevent this from happening, it is important to regularly inspect and service the machine according to manufacturer’s recommendations. Also, you should make sure that only trained personnel are operating the machine and that all safety protocols are followed.

14.How Can You Choose The Right Horizontal Wrapping Machine For Your Needs?

Selecting the right horizontal wrapping machine for your need can be a daunting task. However, here are some of the considerations to guide you in selecting the best horizontal wrapping machine.

Determine the size and type of products that need to be wrapped

The first step in selecting a horizontal wrapping machine is determining the size and shape of the product that needs to be wrapped. This will help narrow down your options when selecting a machine, as different models are designed for specific sizes and shapes of products.

Consider the speed and performance requirements

Different horizontal wrapping machines offer different levels of speed and performance, so it’s important to think about how quickly your products need to be wrapped. This can help you when selecting your horizontal wrapping machine.

Think about the types of materials that need to be used

Generally, different types of wrapping materials can be used with different horizontal wrapping machines, so you’ll need to consider which type of material is best for your product and budget.

Consider the cost

Cost is another consideration when it comes to selecting horizontal wrapping machines because these devices come in a wide range of prices, depending on their size and performance capabilities. Therefore, you’ll need to think about how much you’re willing to spend on your horizontal wrapping machine, and then look for models that fit within your budget.

Look for a reliable manufacturer

Finally, it’s important to find a reliable manufacturer of horizontal wrapping machines so that you can be sure you’re getting a quality product. Do some research and read customer reviews to find out which manufacturers offer the best machines for your needs.

CONCLUSION

When it comes to using a quality horizontal wrapping machine, the choice is clear, Allpack provides the best combination of pricing and performance. Plus, our machines are easy to use and intuitive for anyone who has handled packaging machinery before. And if you ever have any questions or concerns about your product's packaging requirements, our skilled technicians are always ready to answer calls and provide advice. So if you're looking for a reliable solution for wrapping packages that come in all shapes and sizes, then contact Allpack today. We'll make sure your experience with our horizontal wrapping machine surpasses your expectations!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide