Can Capping Machine: The Complete FAQ Guide In 2025

“Are you tired of manually sealing cans? Look no further than a can capping machine!”

If you want to increase efficiency and productivity in your canning process, a can capping machine is the solution. Take the next step in automating your canning operation with a top-of-the-line can capping machine. From small-scale production to large-scale industrial use, a can capping machine can meet all of your sealing needs.

Let’s dive in and explore what you should look for when buying a Can Capping Machine

1.What is a Can Capping Machine?

A can capping machine is a machine that is used to seal the tops of cans by crimping a metal lid onto the rim of the can. The process is called “capping” and is typically used in the food and beverage industry to seal canned goods and preserve their freshness.

Can capping machines come in various types and designs, but they all operate on the same basic principle: a metal lid is placed on top of the can and is then crimped onto the rim of the can using a mechanical press.

Some can capping machines are manual, while others are automatic and can cap many cans at once. They can be semi-automatic also. These machines are used to seal cans in various sizes, and can be adjusted to accommodate different can diameters.

2.Why the Can Capping Machine is so popular today?

The can capping machine is popular today because it is a highly efficient and cost-effective way to seal cans and bottles. The machine uses a variety of sealing methods, including screw caps, snap-on caps, and press-on caps, to ensure a tight seal that keeps the contents fresh and prevents leaks.

The machine can be used for a wide range of products, including food and beverages, chemicals, and pharmaceuticals. Additionally, the can capping machine is easy to operate and maintain, making it a popular choice for manufacturers and processors of all sizes.

Additionally, the machine can work at high speed, this allows companies to increase their production and efficiency, which can lead to cost savings and increased profits.

Overall, the can capping machine is a versatile, efficient, and cost-effective solution for sealing cans and bottles, making it a popular choice for many companies today.

3.What are the key features of Can Capping Machines?

A can capping machine is a device used to seal the tops of cans, typically those used for food or beverage packaging. The features of a can capping machine can vary depending on the specific model and manufacturer. Some common features include:

Automatic: These machines areautomated and can cap cans at high speeds with minimal human intervention. They typically use sensors and other electronic controls to automatically detect and apply the cap to the can.

Speed Control: Many can capping machines have speed control feature, where the operator can control the speed of capping.

Adjustable height: Some can capping machines have adjustable height feature, where the operator can adjust the height of the machine according to the height of the cans.

Cap tightness control: Some can capping machines have adjustable cap tightness control feature, where the operator can set the tightness of the cap.

Safety features: Some can capping machines come with safety features like emergency stop, safety guards and interlocks to prevent injury.

Customizable: Some can capping machines can be customized to suit different types of cans and caps.

4.What are the applications of Can Capping Machines?

Can capping machines are used to apply and seal caps or closures onto cans or containers. Some common applications include:

Beverage packaging: Can capping machines are commonly used in the beverage industry to apply and seal caps onto cans of soda, beer, and other carbonated drinks.

Food packaging: Can capping machines can also be used to seal cans of food products, such as canned fruits and vegetables, soups, and sauces.

Chemical packaging: Can capping machines can be used in the chemical industry to seal cans or containers of liquid or powdered chemicals, such as pesticides or fertilizers.

Pharmaceutical packaging: Can capping machines can be used in the pharmaceutical industry to seal cans or containers of medication, such as pills or capsules.

Personal care packaging: Can capping machines can be used in the personal care industry to seal cans or containers of products such as hair spray, deodorant and other aerosol products.

5.What are the major components of Can Capping Machine?

A can capping machine typically consists of several major components, including:

Cap/Lid Feeder:

The cap/lid feeder is responsible for feeding and orienting the caps/lids into the correct position for capping.

The cap/lid feeder typically consists of a hopper that holds a supply of caps/lids, a vibratory feeder that orients the caps/lids into the correct position, and a chute that directs the caps/lids into the capping machine. The feeder ensures that the caps/lids are correctly positioned and spaced for the capping process.

Press-On Head:

The press-on head is responsible for applying the necessary force to secure the cap/lid onto the bottle. The press-on head is a mechanism that presses the cap/lid onto the bottle. It may have an adjustable pressure setting, allowing for different types of caps/lids to be used. The head can be a single or multiple units, depending on the production rate required.

Rotary Clincher:

The rotary clincher is a rotating mechanism that helps secure the cap/lid onto the bottle by applying pressure around the circumference of the cap/lid.

The rotary clincher is a mechanism that rotates around the circumference of the cap/lid to secure it onto the bottle. The clincher ensures a tight seal by applying pressure to the cap/lid. The speed of the clincher can be adjusted to accommodate different types of caps/lids and production rates.

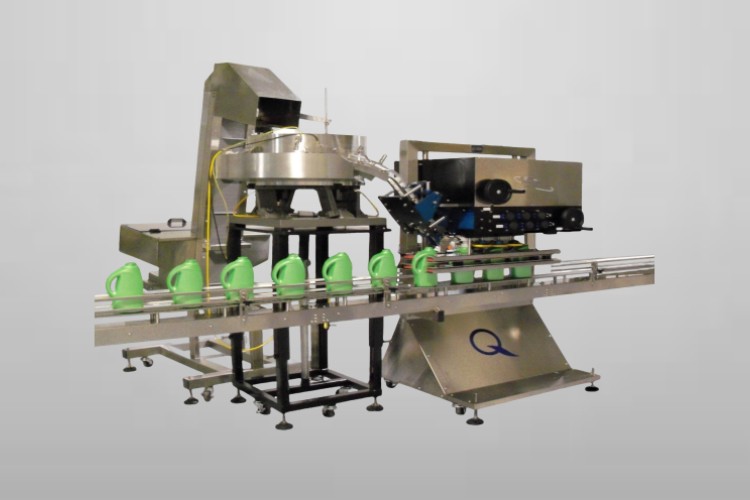

Conveyor Belt:

The conveyor belt is a moving surface that supports and transports the bottles through the capping machine. The conveyor belt may be adjustable, allowing for the bottles to be positioned correctly for the capping process.

The speed of the conveyor belt can also be adjusted to match the production rate of the machine. The conveyor belt may also have a system for stopping the bottles in the correct position for the capping process.This machine is used in various industries like food, beverage, chemical, cosmetic, and many more.

6.What are the working principle of Can Capping Machine?

A can capping machine is used to seal cans or jars by applying a metal or plastic cap to the top of the container. The working principle of a can capping machine typically involves a series of mechanical and pneumatic components that work together to apply the cap to the container.

- The first step in the process is to load the cans or jars onto a conveyor belt or into a hopper. The containers then move through the machine, where they are inspected for any defects or damage. If any defects are found, the containers are rejected and removed from the line.

- Next, the caps are fed into the machine and placed onto the containers. The caps are typically held in place by a chuck or gripper, which is controlled by a pneumatic cylinder. The chuck or gripper then rotates to tighten the cap onto the container.

- Once the cap is securely in place, the container is moved to the next stage of the production line. Some capping machine also have sensors to check if the cap is properly sealed and if not will be rejected.

The specific details of how a can capping machine operates can vary depending on the design and manufacturer of the machine. However, the basic principle of using mechanical and pneumatic components to apply a cap to a container is the same for most can capping machines.

7.What are different kinds of Can Capping Machine?

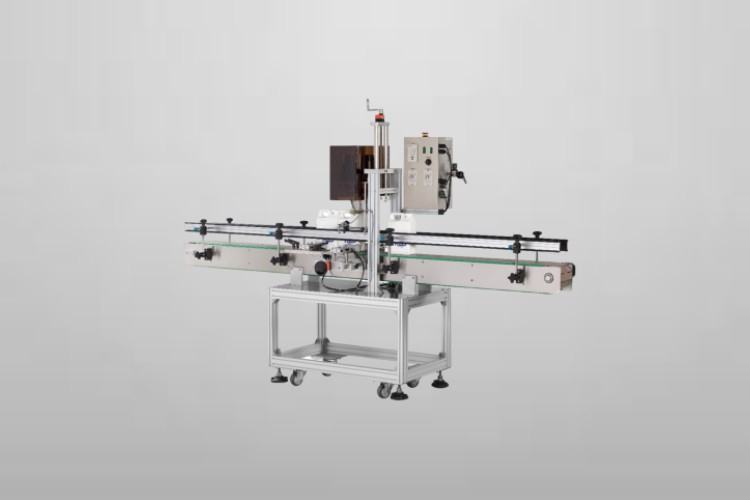

- Spindle Capping Machines:

Spindle Capping Machines are machines used to seal containers with screw-on-caps. The machine operates continuously, repeating the process for each container until the desired number of containers have been capped. The speed of the machine and the tightness of the cap can be adjusted to suit the specific needs of each application.

- Chuck Can Capping Machine:

Chuck Can Capping Machines are widely used for capping various types of containers with screw caps, snap-on caps, and other closure types. Chuck Can Capping Machines are designed to automate the capping process, providing consistent and efficient cap application.

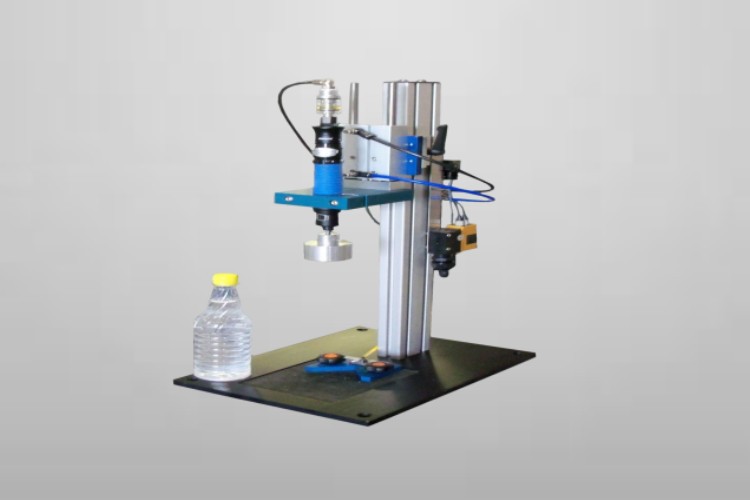

- Hand-held Can Capping Machine

A hand-held Can capping machine is a device used to secure caps onto bottles or other containers. The hand-held can capping machine is a simple, manual device used to secure caps onto bottles or other containers.

It consists of a handle, cap-holding mechanism, and capping head, which applies the necessary force to seal the cap on the bottle.

- Twist-Off Cap Screwing Machine

A twist-off cap screwing machine works by using a screwing unit to apply torque to the cap and screw it onto the container, and a conveyor belt to transport the containers to the screwing station.

- Benchtop Can Capping Machine

A benchtop can capping machine s a device used to apply caps to bottles or containers. It is designed compact and will not occupy too much space, which is very convenient to use.

- Rotary Can Capping Machine

A rotary can capping machine is different from other can capping machine because it can cap bottles continuously by rotating,the speed of this machine is very fast,it is suitable for large scale production.

●Screw Can Capping Machine

A screw can capping machine is a machine that is used to apply screw-on caps to containers, such as bottles or jars. The machine is high speed and it is mostly suitable for capping PET caps.

- Induction Sealing Can Capping Machine

An induction sealing can capping machine is different from others because the working principle of it is based on electromagnetic induction. When an alternating current is passed through the induction coil, it generates an electromagnetic field,then applying the caps to containers.

8.What are differences between Hand Can Capping and Automated Can Capping?

Hand vs Automated Can Capping

Hand can capping and automated can capping are methods used for sealing cans to preserve their contents.

Hand can capping:

- Involves manually placing the cap on the can and manually tightening it into place.

- Typically used for small-scale operations or for sample cans.

- Slower and less efficient compared to automated can capping.

- Prone to human error and inconsistencies in cap tightness.

Automated can capping:

- Involves using a machine to place the cap on the can and tighten it.

- Typically used for large-scale operations where high speed and efficiency are necessary.

- Faster and more consistent compared to hand can capping.

- Generally more accurate and reduces the chance of human error.

In conclusion, while hand can capping is a suitable method for small-scale operations, automated can capping is better for large-scale operations where speed and efficiency are important.

9.What are the distinguishing features of Can Capping Machine VS Can Seamer Machine?

Can Capping VS Can Seamer

Can capping machine and can seamer are both commonly used in the canning and packaging industry, but they serve different purposes.

Can Capping Machine:

Its primary function is to screw the cap onto the top of the can to secure the contents inside.

It typically uses a twisting or screwing mechanism to secure the cap in place, and can be automated or manual.

It is used for products that require a secure, tight seal to prevent leaks or contamination.

Can capping machines are designed for specific cap sizes and types, so it’s important to choose the correct machine for your specific application.

Can Seamer:

Its primary function is to crimp or seam the lid to the can body.

It uses a rolling action to create a tight, secure seal between the lid and the can body.

It is used for products that require a tamper-evident seal, such as food and beverages.

Can seamer is also designed for specific can sizes and types, so it’s important to choose the correct machine for your application.

In summary, the main difference between a can capping machine and a can seamer is their purpose: the former is used to screw a cap onto the top of the can, while the latter is used to crimp the lid to the can body.

10.What type of caps are use in sealing with Can Capping Machine?

Can capping machines are typically used to seal cans or containers with metal or plastic caps. The type of cap used in can capping machines can vary depending on the application and the type of product being packaged.

The most common types of caps used in can capping machines include:

Metal caps:

These are typically made of aluminum or steel and are used to seal cans of products such as food, beverages, and chemicals. Metal caps are known for their durability and resistance to corrosion. They are also easy to recycle.

Plastic caps:

These are typically made of polypropylene or polyethylene and are used to seal cans of products such as food, beverages, and cosmetics. Plastic caps are known for their light weight and flexibility.

Crown caps:

These are typically made of steel and are used to seal cans of carbonated beverages. Crown caps are known for their tight seal, which prevents carbon dioxide from escaping and keeps the beverage fresh.

Screw caps:

These are typically made of plastic or metal and are used to seal cans of products such as food, beverages, and chemicals. Screw caps are known for their easy opening and closing, making them ideal for products that are frequently opened and closed.

Snap-on caps:

These are typically made of plastic and are used to seal cans of products such as food and beverages. Snap-on caps are known for their easy opening and closing and are ideal for products that are frequently opened and closed.

Can capping machines are designed to work with specific types of caps, so it is important to choose the right type of cap for the application and the type of product being packaged.

The can capping machine can be adjusted to adapt different size and type of caps. The machine will also have a cap feeder that will feed the caps to the machine at a steady rate.

The machine will then place the cap on the container and secure it in place. Depending on the machine, the caps may be secured using a variety of methods, including mechanical crimping, induction sealing, and heat sealing.

11.What is the level of maintenance required for Can Capping Machine?

The level of maintenance required for a can capping machine can vary depending on the specific machine and the environment in which it is used. However, in general, regular maintenance is required to ensure that the machine is operating correctly and efficiently, and to extend its lifespan.

Here are some general tasks that should be performed regularly to maintain a can capping machine:

- Cleaning: Can capping machines should be cleaned regularly to remove any debris or build-up that could cause issues with the machine’s operation.

This includes wiping down surfaces and cleaning the cap chute and other parts of the machine that come into contact with cans or caps. - Lubrication: Can capping machines have moving parts that require lubrication to function properly. Lubrication should be applied to the machine’s gears, bearings, and other moving parts on a regular basis to ensure smooth operation.

- Inspections: Can capping machines should be inspected regularly to check for any wear and tear, damage, or other issues that could affect its operation.

This includes checking the machine’s seals, gaskets, and other components for leaks or damage. - Adjustments: Can capping machines may require adjustments over time to ensure that they are functioning correctly.

This can include adjusting the machine’s conveyor belt, cap chute, or other parts to ensure that cans and caps are being positioned and sealed correctly. - Maintenance schedule: It’s important to schedule the maintenance check and follow the schedule to keep the machine running in good condition and to ensure that the machine is operating safely and efficiently.

It is also important to note that, depending on the specific machine, there may be additional maintenance tasks that are required. It is always best to consult the machine’s manual or contact the manufacturer for specific maintenance instructions.

12.Is the Can Capping Machine customizable to meet specific production needs?

Yes, Can Capping Machines can be customized to meet specific production needs. The customization options may vary depending on the manufacturer and model of the machine, but some common options include:

Cap size and type: Can capping machines can be designed to handle different sizes and types of caps, such as screw caps, snap-on caps, or press-on caps.

Production speed: Different machines have different maximum production speeds, and some can be adjusted to run at different speeds to match the output needs of the production line.

Cap orientation: Some machines are designed to orient caps in a specific way before they are applied to the cans, such as with the logo facing a certain direction.

Cap torque: Some machines can be adjusted to apply a specific amount of torque to the caps when they are tightened, which can be important for maintaining consistent product quality.

Additional features: Some machines come with additional features such as automatic cap sorting and counting, or automatic rejection of cans that have not been properly capped.

Overall, the level of customization will depend on the manufacturer and the specific machine. It is important for the company to communicate their production needs clearly to the manufacturer to make sure that the right machine is purchased.

Conclusion

In conclusion, a can capping machine is a valuable investment for any business that bottles and cans liquids. With the wide range of options available, it is important to consider your specific needs and budget before making a purchase.If you still have problems about this machine,welcome to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide