Gallon Filling Machine: The Complete FAQ Guide In 2025

Mostly food, beverages, pharmaceutical, and chemical industries use gallon for storing their products in large quantities. These gallons are precisely filled using gallon filling machines that enhance the productivity and efficiency of the system. The products remain fresh for a longer period as it is sealed completely in those gallons made up of either plastic or metal material.

Globally many manufacturers are busy producing these gallon filling machines and it might confuse the buyer to select the best and most reliable one from those. Allpack is here to solve all your queries and also to respond to those points. This complete FAQ guide has been designed to mention all machine-related information. So that the most of it.

1. What Is A Gallon Filling Machine?

Gallons are usually used to fill and store bulk quantities of liquid or viscous products in replacement of containers and jars. For filling these large size gallons, a special type of filling machine is used that is commonly known as gallon filling machine. A gallon filling machine usually fills gallons of different sizes with liquid products like water, milk chemicals and etc.

This material is then easily distributed to other places or small-sized industries. The liquid content can directly be consumed from these gallons or also be converted into small containers and bottles. The machine typically helps in the efficient moving of gallons through its conveying system and further, it is filled by various sizes of filling nozzles.

2. What Are The Applications Of A Gallon Filling Machine?

Some of the industries where gallon filling machines is used are

- Food Industry

The vast usage of gallon filling machine can easily be seen in food industry and liquid water, liquid milk, viscous paste and other products can easily be filled in big gallons using this type of machine. The machine can easily fill large number of gallon with high efficiency level and consistency.

- Beverages Industry

Along with food industry, beverages industry also uses a gallon filling machine for accurate filling of juices and carbonated drinks. Such type of products is then delivered comfortably to medium and small scale industries where they are divided into small packaging materials.

- Pharmaceutical Industry

Large scale pharmaceutical industries use gallon filling machines to fill highly sensitive products like antibiotics, syrups, liquid serums and etc. These products require a high level of sensitivity as they get contaminated when in contact with the environment. The sealing performed by the gallon filling machine keeps the product safe for a longer period.

- Chemical Industry

Chemical products including detergents, paints, colors, coatings, cleaning liquids and others are precisely filled in heavy gallons using a gallon filling machine. The liquid pigments and drops are more consistently alive to use with greater expiry levels when filled using gallon filling machine.

- Lubrication Industry

Different types of oils and lubricants that are used in heavy machines, automobiles and industries are also filled in gallons using gallon filling machines.

3. What Material Of Gallons Bottles That Are Filled Using A Gallon Filling Machine?

Gallon bottle material selection depends upon the volume, material weight handling capability, and hardness that nothing should happen to it when moved to large distances. Some of the common gallon bottles used in gallons filling machines are

- Glass Gallons

Other than plastic gallons, glass gallons are the second most reliable source used for filling of different types of products. Gallon filling machine offers high level of feasibility to glass gallons and fills it without any process damage. The glass gallons can withstand when kept in high temperatures and can also be recycled.

- Metal Gallons

Metal gallons made up of stainless steel and aluminum is widely applied for filling of oils and solvents using a gallon filling machine. The material being highly durable and also resists corrosion even when kept in humid conditions.

- Plastic Gallons

The most abundant material used for making of gallons is plastic. Plastic gallons can be found in any part of the world and can be used in any type of industry. Any of the products can be filled in one depending upon its shelf life and environmental influence. Plastic materials like polyethylene, polyethylene terephthalate and polypropylene are used for the preparation of these gallons. Food, cosmetics and lubricant industry mostly uses gallons of plastic and fill it using gallon filling machines.

4. What Are The Advantages Of A Gallon Filling Machine?

There are many advantages that we can get from a gallon filling machine. Some of them are

- Consistency

The most important benefit that we can get from a gallon filling machine is its consistency. Machines are highly versatile that they can produce each of the gallons with same amount of product. Not even a single percent of tolerance is present there while filling gallons. This ensures that how technology is used to produce products that human being cannot.

- Productivity

Globally gallon filling machines are famously used in industries to increase its productivity and output results. Large number of gallons can be filled in a small fraction of time as compare to manual methods. Industries can easily scale up their productivity using a gallon filling machine.

- Versatility In Filling

Gallon filling machines are capable of filling wide range of products using a single machine. In this way a single machine can be used to fill all chemicals, food products, lubricants and also medical syrups.

- Customization

Gallon filling machines can be customized according to different sizes of gallons and fill all of those by just adjusting the opening stand and weight controller. It’s not a big thing to take long hours and can be done in much minimum time period that also increases the productivity of any industry.

- Reduction In Manpower

Huge gallons and containers cannot be moved easily, it requires highly energetic individuals that can carry those gallons from one place to another. Gallon filling machines have eased human life in this aspect too that all the processes are carried out automatically and also moved from one system to another using conveyors. It can indirectly reduce the labor cost and make the system economical.

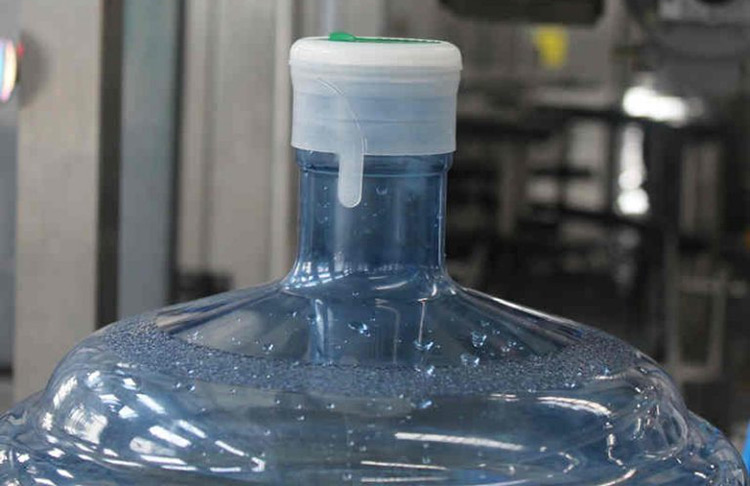

5. How Is Sealing Applied On Filled Gallons Using A Gallon Filling Machine?

The concept of sealing gallons is equally important as its filling. This sealing process is the thing that keeps the product safe from leakage and any type of spillage. The methods for the application of seal on gallons are

- Cap Snapping

This is a method where a particular amount of pressure is inserted on the cap of gallon and helps in its application. It is most importantly protection from contamination and humid conditions for the gallons of material.

- Cap Screwing

Some of the glass, metal and plastic gallons have screw thread on their top. The screw cap is initially applied on the top of gallon and then it gets tightened by the mechanical shaft. All the screw thread guarantees material and product safety for long periods.

- Heat Sealing

Another method of applying capping on gallons is heat sealing. Metal cans are mostly sealed at the top to secure the packaging material. Gallon filling machine has a heat sealer in its filling process that seals the cap or lid by applying proper hermetic sealing.

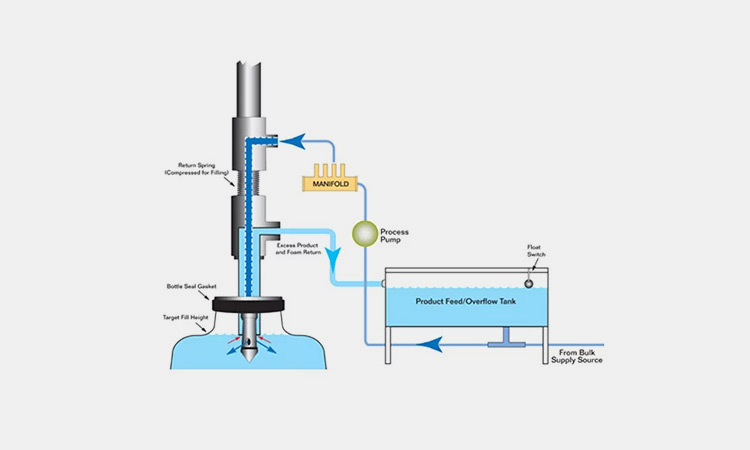

6. What Is The Working Principle Of Gallon Filling Machine?

We usually get confused with the big size of a gallon filling machine but it has a simple working principle like other liquid filling machines. The steps involved in its working are:

- Initially the gallons are cleaned properly to avoid contamination and remove any type of bacterial presence. The gallons are then filled with products that are to be packaged.

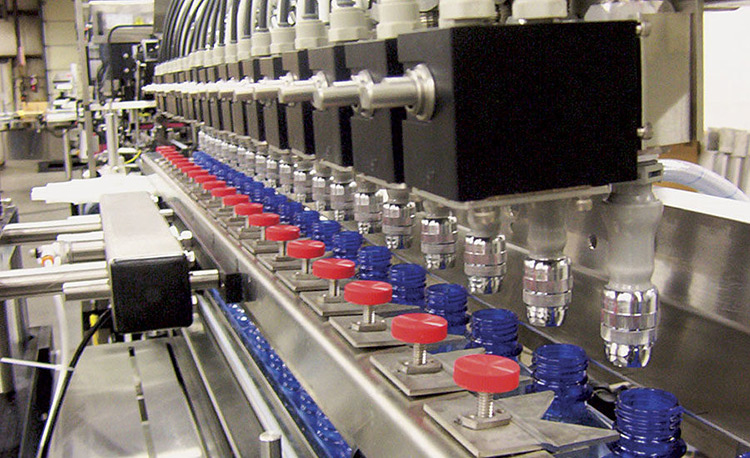

- Further, in the second step the empty gallons are placed manually under the filling nozzle or automatically using conveyor belts.

- The gallons once detected by the sensors present in a gallon filling machine direct the system to get activated and start dispensing the product. As the system gets activated, the valve of filling nozzle are opened and it continuous flow of product into the gallon or container.

- Both volumetric and weighted factor is used in proper filling of gallons in the system and it automatically gets shut once the desire value is achieved.

- Accurate and desirable amount of liquid is filled that does not create any wastes. It is further moved where capping, labeling and coding processes are carried out.

- The finished gallons are then moved on the conveyors and collected at the end of the system.

7. What Are The Main Components In A Gallon Filling Machine?

Like a liquid filling machine, a gallon filling machine also has the same components in it. Only the size of the system enlarges due to heavy weight and the big size of containers or gallons. Some of the basic components of a gallon filling machine are

- Monitoring System

A monitoring system supports the operator to look at complete gallon filling machines operations. It also helps the system in controlling the filling parameters like conveyor speed, filling volume and pressure, pneumatic values, sensor ranges, and system temperature.

- Containers

Huge containers are associated with gallon filling machines that are responsible for feeding the material into different sizes of containers and gallons. Containers are mostly made up of stainless steel that it keeps the product free from contamination and rust. The filling material travels from these containers to the filling nozzle and is then dispensed into specific gallons.

- Actuators

Actuators, commonly known as sensors are the primary source to ensure safe and secure process of a gallon filling machine. These sensors are in built in the machine and used for identification of bottles presence under the filling nozzle. After confirming the presence by the actuators, the system allows the filling head to release products present in the container or feeding area.

- Filling Heads

Filling heads are the one from where the product is released into the gallons. These filling heads are made up of stainless steel that never allows as contamination or rusting. Filling heads are also easy to remove and clean and are available in different opening sizes depending upon the packaging product.

- Pumps

Pumps are there for easy traveling of product from large feeding head to the filling system. These pumps work depending on the materials' viscosity and flow rate.

- Mechanical Drive System

A mechanical drive system is the main mechanism controller that includes all motors, actuators and gears. The mechanical system of a gallon filling machine ensures proper movement of all these mechanical parts present within the system. It also supports in their process when they are operating and is used during production. The liquid released in gallons are also maintained by these mechanical drivers.

- Conveyor

Conveyors are important to appreciate as it makes the process easier in terms of weight and saves a lot of human effort. The product easily travels throughout the system despite of its heavy weight in a simple manner.

- Controlling System

Controlling system is also there in a gallon filling machine that includes the programmable controls and there assistive devices. These components are important for proper machine operations that are responsible for gallon filling process.

8. What Are The Types Of Gallon Filling Machines?

Some of the types of gallon filling machines are

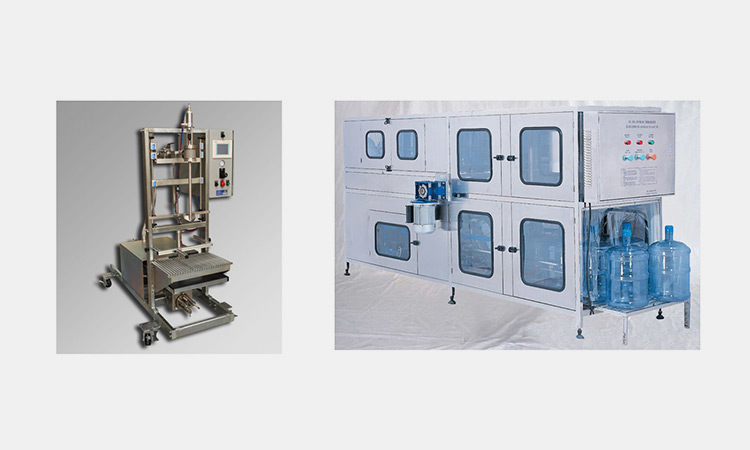

- Fully Automatic Gallon Filling Machine

A fully automatic gallon filling machine completely relies on automation and integers with no human involvement. The machine itself travels the gallon or container via a conveyor and takes it to the final labeling step. Gallon filling machine is used in industries where the production volumes are higher in numbers and give a healthy production environment.

- Semi-Automatic Gallon Filling Machine

Semi-automatic gallon filling machines are based on a human-machine interface and require both objects equally. The operator places the gallon into the system and there the system automatically fills it in an efficient manner. Finally, the operator takes the filled gallon out of the system in the last step. Semi-automatic gallon filling machines are much more reliable for small and medium-scale industries.

- Weight Gallon Filling Machine

A weight gallon filling machine fills maximum amount of product without any tolerance. The machine dispenses the desire amount of product into gallons that is set initially. Once the level is achieved it cut the system and prevents wastage. Heavy-weighted containers are filled using a weight gallon filling machine.

- Gravity Gallon Filling Machine

A gravity gallon filling machine uses gravity as a source for filling gallons of different sizes. The product is moved to the nozzle with the help of gravitational pulls and requires no other source. Gallons are efficiently filled first and then the valve closes once the gallons fills completely.

9. What Are The Differences Between Semi-automatic and Fully Automatic Gallon Filling Machines?

Semi-automatic and fully automatic gallon filling machines are differentiated on the basis of automation, applications and controls. Some of the differences are

- Automation Level

Semi-automatic gallon filling machines are based on both machine and human involvement and work directly with their collaboration. The gallon is just placed and picked by the operator and rest is performed by the machine itself.

On the other hand, complete automation is present in a fully automatic gallon filling machine. The process of filling and sealing is efficiently performed by the machine and the output results are in decent look and shape.

- Applications

A semi-automatic gallon filling machines are used is small and medium scale industries mostly as they produce only 5 to 15 bottles per minute.

While fully automatic gallon filling machines are used in high volume production setups where the production ranges from 30 to 100 gallons in a minute.

- Flexible Controls

Semi-automatic gallon filling machine have flexible controls and the operator can easily see them in the front of the machine. Parameters pressure, valve timer, speed, temperature and volume can easily be adjusted from there.

In a fully automatic gallon filling machine the operator just selects the type and size of gallon and the rest is set by the machine itself.

10. How A Single Gallon Filling Machine Be Compatible With Multiple Shapes And Sizes Of Gallon?

A single gallon filling machine has a feature that it can fills gallons of different sizes and shapes. This makes the system more economical and efficient to handle. The key adjustment done in this regard is

- Height Setting

The basic changing is to set the height if the filling station according to the height of gallon and also with respect to the filling nozzle. This can be achieved automatically by just selecting the type of gallon and its filling product.

- Filling Handle Adjustment

The filling handle adjustment is carried due to the different sizes of gallon openings. Simply nuts and bolts are present there in the opening end of machine and it can be loosen or tighten according to the opening of gallon.

- Replacing Parts

Some of the gallons also require changeover of different parts and it is also carried out is a small fraction of time. Gallon filling machines mostly have easy way to change these parts like filling nozzle. The operator changes the segments according to the product requirement.

11. What Are The Differences Between Liquid Filling Machine And A Gallon Filling Machine?

Some of the differences between liquid filling machine and gallon filling machine are

- Size Of Container

With comparison to gallon filling machine, liquid filling machines are used to fill containers, bottles that are smaller in size. The machine can easily handle these shapes and sizes.

Whereas a gallon filling machine can fill huge gallons, drums, containers that even weight above 100 Kg.

- Automation Level

Both liquid filling and gallon filling machines have semi-automatic and fully automatic level of automation and are used according to the requirement of production.

- Weight Handling

Containers, jars, tubes, pouches, vials and bottles of light weight are handles in a liquid filling machine and can be set with normal conveying system.

Conveyors with high weight bearing feature are used as container, gallons and drum of several hundred liters are moved in a gallon filling machine.

- Productivity

Liquid filling machine are quick and efficient and can produce more than 100 products per minute.

Gallon filling machines on the other hand are able to fill around 5 to 100 gallons per minute depending upon the level of automation.

12. What Should Be Considered Before Purchasing A Gallon Filling Machine?

Some of the important factors that should be considered before buying a gallon filling machine are

- Size Of Gallon

The most important factor before purchasing a gallon filling machine is to check the compatibility of machine with different sizes of gallon bottles or drum. It is necessary to compare it with your packaging material and then select the best type.

- Product Type

The thickness, viscosity, lubrication, thinness are some of the important factors related to product that are necessary to think off. Whether the machine supports such materials or not? Without considering it can be a big disaster.

- Product Security

Product when sealed travels a long way afterwards. It is important to take of this factor that whether the packaging will keep the pureness of product alive for a longer period or not. Contamination and rusty results on machine should also be considered on priority.

- Machine Assistance

Many manufacturers deliver their product without any machine guidance or assistance. It is important to select the best manufacturer that provides complete machine related documents and also gives assistance when required.

Conclusion

Big sized containers and gallons are filled with accuracy and precision using a gallon filling machine. The demand of gallon filling machine is increasing rapidly due to the greater productivity and material security. Therefore, many manufacturers are busy in manufacturing these gallon filling machines. Allpack also provides you variety of gallon filling machines along with its accessories. If there is any question in your mind you can call our representative or visit our website https://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours