Pallet Strapping Machine: The Complete Buying Guide In 2025

Thousands of goods and products are manufactured every day which include medicinal drugs, food products and other consumer items. These goods then have to be shipped all around the world without getting damaged. Moreover, they need to reach their destinations as soon as possible without any delay.

Due to this, they are packed in carton boxes of different shapes and sizes. These cartons then undergo strapping which secure these boxes and make them safe for transportation.

In order to strap these boxes, pallet strapping machine is used to secure these goods for storage and transportation. So why is this machine used out of all the other available in the market? What makes it the best option for strapping pallets? What kind of benefits and features it can offer? In order to answer these questions, let us discuss in detail about the specifications of this machine.

1.What is pallet strapping machine?

Pallet strapping machines are used to stack bundles of cartons boxes together with the help of a strapping tape so that they reach safely from their area of origin to area of destination.

This is a highly efficient and a versatile machine which is extremely valuable for small scale and large scale industries where thousands of goods are put into boxes and shipped to their destination each day.

The use of it prevents the cartons from getting damaged during the transportation process. It can be used for several types of carton boxes which come in different shapes and sizes.

2.What are the advantages of pallet strapping machine?

Installing this machine in your production line would be a wise choice since it has many benefits to offer. Let us discuss why this machine is an excellent option for securing your goods.

Provides protection to products

Undoubtedly, the main use of pallet strapping machine is to protect the goods from falling apart or getting damaged when they are shipped from storage facility to their area of destination. It stacks them together securely, keeping them intact and sturdy.

Improves the overall efficiency of your production

Since using this machine will send your products to their destination quickly, it improves the efficiency of your production by saving time on securing and strapping boxes manually.

Ability to stack various kinds of products

This machine is highly versatile since it has the capability to strap various kinds of carton boxes of different shape and size. Thus, it can be used in lots of industries where it can serve different purpose.

3.What are the applications of pallet strapping machine?

This highly versatile machine can be used in several industries such as pharmaceutical, chemical, cosmetic, food, agriculture etc. let us discuss each of these industries below.

Pharmaceutical industry

This large-scale industry deals with the production of various medicinal drugs which are used to cure people’s diseases. Thousands of medicines are produced each day which need to be transported safely and efficiently as soon as possible.

The use of pallet strapping machine can cater to the high volume production by stacking these drugs in a carton and strapping them, making them ready for shipping.

Chemical industry

This industry is used to make several chemicals such as dyes, solvents, pigments, paints which are then used in other industries to make final product. These chemicals are usually packaged in carton boxes and are then strapped together with the help of pallet strapping machine.

These compact, strapped boxes are then sent to storage facility where they are ready to be sent to their destination.

Food industry

Food industry deals with various food items such as confectionery items including chocolates, candies, gummy. These products need to be stacked together carefully and send to their destination as quickly as possible to prevent them from getting spoiled. Pallet strapping machine can easily fulfill these requirements.

Cosmetic industry

Cosmetic industry manufactures various beauty products such as serum, shampoo, body lotion etc. This multi-billion dollar industry which has high demand throughout the globe needs quick shipping. Securing them by using this machine and sending them to their destination will cater to the supply and demand.

Agriculture industry

This industry is involved in variety of items such as fertilizers, wheat, corn and rice crops, livestock feed and pellets. After their production, they are packaged into various boxes and strapped together with the help of pallet strapping machine and are sent for shipping.

Ceramic industry

Ceramic industry uses clay as raw material and produces glass, ceramic tiles, cement and bricks. These items need maximum protection to prevent them from getting damaged since they are highly fragile to any mechanical stress. Strapping them in good quality boxes by using this machine will secure them.

Construction industry

This industry deals with building, maintaining and repairing structures and creating infrastructure in an area. It consists of several raw materials including marble, limestone, wood, cement, brick, mortar, sand etc. many of these materials are heavy and secure a strong packaging solution for maximum protection.

Thus, pallet strapping machine would be an excellent choice for securing them.

4.What are the different types of pallet strapping machine?

This machine has several types, each with their own features and benefits. Let us discuss in detail what kind of characteristic each type of pallet strapping machine has.

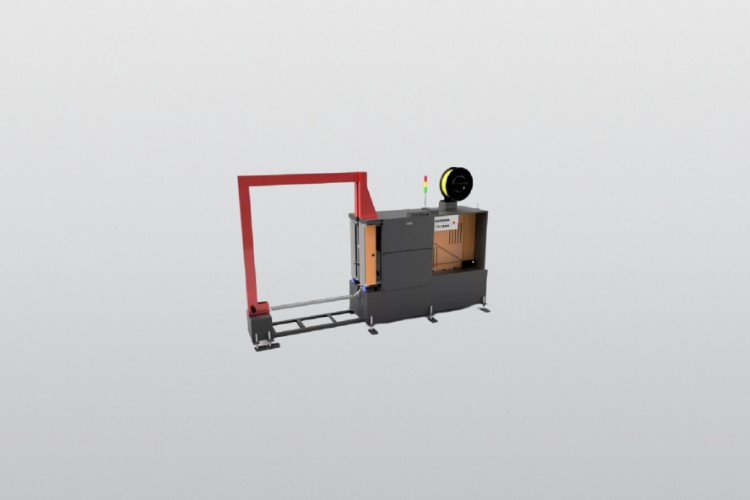

Horizontal pallet strapping machine

This type of pallet strapping machine, as the name suggests is used for strapping boxes horizontally, ensuring a compact and secured package. It consists of an anti-vibration frame which provides great stability to the load during the strapping process.

Moreover, it also features an automatic lateral compactor which compacts the load before strapping.This type is an excellent choice if you want to prevent the load from slipping or shifting during the shipping process and if you are using carton boxes for your packaging.

Vertical pallet strapping machine

This type of pallet strapping machine offers maximum support since it can strap on all four sides of the load. It consists of a 90 degrees rotation system to strap the boxes vertically. Its lateral shift system prevents the load from slipping during the process.

As a result, it decreases the space requirements in the production line and provides great stability to the packaged boxes.Moreover, it also has an automatic edge band applicator which protects the box and provides an aesthetic look by strapping them in an orderly fashion.

Automatic pallet strapping machine

This type of pallet strapping machine, as the name suggests is used to strap boxes automatically without any human interference. It is an excellent choice for large scale industries where there is high volume production and require quick and efficient strapping. This machine has the ability to strap around 65 straps per minute.

Also, it only needs a worker to monitor the process by using control panel. It is relatively more expensive than semi-automatic or manual pallet strapping machine. Thus it is ideal for large factories and companies which have enough capital to invest in it.

Semi-automatic pallet strapping machine

This type is similar to automatic pallet strapping machine. However the main difference is that while in automatic pallet strapping machine, it parcels, cuts and strap on its own, in semi-automatic pallet strapping machine, the worker would have to do this whole process.

This type is ideal for small-scale industries and for those who need a less expensive machine to carry out their strapping process.

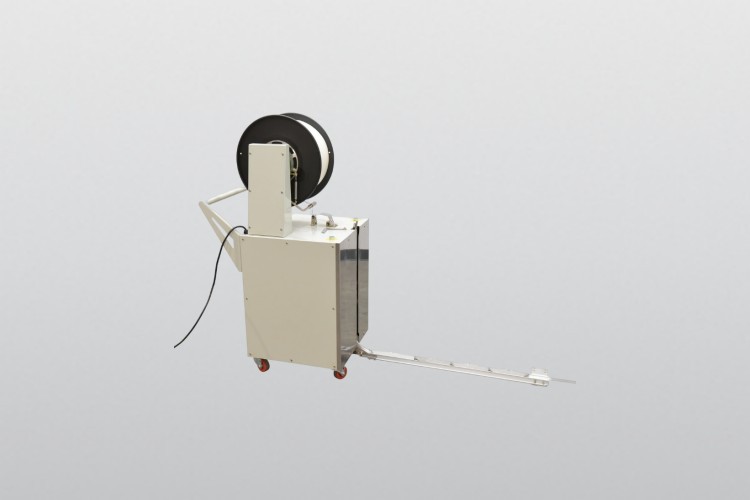

Manual pallet strapping machine

This type of pallet strapping machine, as the name suggests is used to strap boxes manually in which a worker is required to carry out the process. The positive points of this type are that it is lightweight, cheap, portable and requires less space than other types.

Thus it can be taken anywhere without any hassle for the strapping process.Moreover, its cheap price is ideal for small businesses and factories which have small volume production and have low capital to invest in a strapping machine.

5.What is the working principle of pallet strapping machine?

When the box is placed inside the machine, it senses it with the help of sensors. After that, the box is transported via the conveyor belt system to the targeted area. The mechanical spinners or arm orient the strapping tape in line with the box. This process is either done by a worker or the machine does it on its own if it is automated.

After this, the machine begins the main process by strapping the box with a tape which is made from plastic. This strapping tape is tough and thick, providing strong support to the box. Finally the strapped box is leaves the machine and goes to storage area where it is ready to be shipped out.

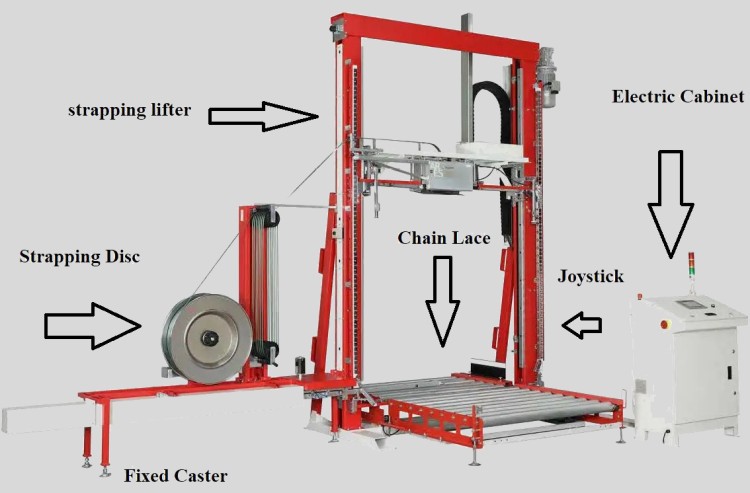

6.What are the components of pallet strapping machine?

Pallet strapping machine has different components. Each serve its own purpose. Let us take a look at the function of these parts.

Model Switch:using this button will start the machine.

Electric Cabinet:using this cabinet you can control the parameters of the machine.

Joystick:this is used to increase or decrease the values of the parameters accordingly.

Strap Lifter:this lifter, as the name suggests lifts the strap tape upwards at an appropriate height so that the whole part of the strapping tape can be wrapped around the load automatically.

Strap Cutter: this part, as the name suggests is used to cut the strap tape when it is wrapped around the good. The amount of strap which needs to be cut is different for different loads.

Chain Lace: with the help of chain lace, the load which needs to be strapped is brought closer to the worker to prevent him from bending over to do carry out the process.

Strapping Disc: this is a circular shaped mold in which the strapping tape is placed which would then be used to secure the desired load.

Fixed Caster: this part is used tosupport the machine ergonomically.

7.How does horizontal pallet strapping machine differ from vertical pallet strapping machines?

Even though both the types of pallet strapping machines serve almost the same purpose, that is, it secures, compacts and unifies the products in one place, however there are slight differences between them.

In vertical pallet strapping machine, the process takes place on all four sides of the machine whereas in horizontal pallet strapping machine, the cartons are strapped horizontally.

To provide stability to the boxes and prevent the load from slipping,vertical pallet strapping machine is provided with lateral shift system whereas horizontal pallet strapping machine is provided with anti-vibration frame.Vertical pallet strapping machine is ideal for those items which need to be secured to the base of the pallet.

These items include boxes, cardboard, bottles etc. whereas horizontal pallet strapping machine is ideal for those items which do not need to be secured on the base of the pallet and only require compaction and unitization of the load together.

8.What are the differences between automatic pallet strapping machine and manual pallet strapping machine?

Automatic pallet strapping machine consists of a wrapper which automatically picks up the load from the pallet through the conveyor belt, sends it for the strapping process and moves the strapped load to the out-feed conveyor.

Whereas in manual strapping machine, the worker has to put the load in an appropriate position and strap it by using the machine.

Automatic pallet strapping machine uses touch screen with HMI interface. This controls all the parameters of the machine and the worker simply has to monitor it. However in manual pallet strapping machine, there is no touch screen or any automated process through which the parameters can be controlled.

Automatic pallet strapping machine is equipped with auto film clamp device, auto film cut, brush device and blow air device. After the load is strapped with film by film brush, the load is wrapped neatly around the film.

Moreover, it has top sheet dispensing device which automatically adjusts the height of the load accordingly. Whereas in manual pallet strapping machine, the height needs to be adjusted by the worker manually.

9.Which typesof strapping tapes can be used in pallet strapping machine?

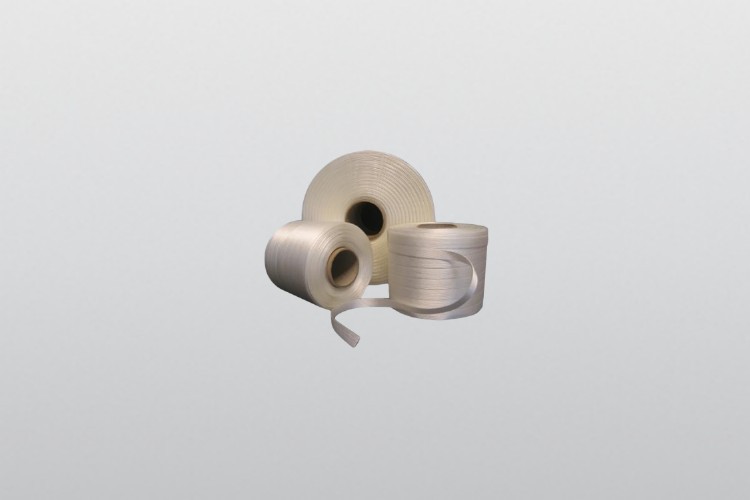

There are various kinds of strapping tape available in the market. These tapes have different characteristics. So you need to choose which one is best suited for your product. Let us discuss what kinds of strapping tapes there are.

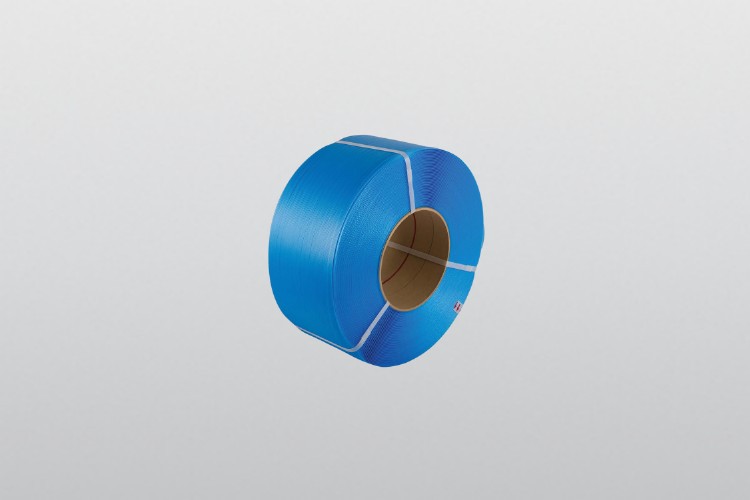

Polypropylene

This tape is ideal for strapping light-weight products. It can strap products which weigh around 350kg. it is quite flexible and therefore is convenient to use. It can also be used to secure fragile goods and is quite resistant to external factors such as dust, moisture and high temperatures.

Its cheap price makes it ideal for small businesses. Unboxing the product is quite easy since polypropylene can easily unwind manually.

Spun polyester

Spun polyester is the most resistant out of all the strapping tapes available in the market. It can strap goods which can weigh as much as 950 kg. This feature makes it ideal for packaging heavy items and is perfect for fragile items.

Its light textile material does not leave any marks on the boxes and makes it easy to use. They are best used by hand with tensioners.

Extruded polyester (PET)

Polyester tape (PET) is excellent for heavy weight items weighing up to 1000kg and for strapping compressible loads such as wood, cardboard and other construction materials.

Due to its high strength and resistance, it offers maximum protection during the transportation process. It is quite resistant against moisture, UV rays and high temperature of 80 degrees Celsius. It can also be used for those products which need to be kept for long period of time.

Steel straps

Steel straps are tough, strong straps which are ideal for heavy items and rigid loads which are not flexible. Since steel straps are not malleable, they are ideal for securing those products which have rough edges such as iron and concrete.

Metal straps can secure goods which weight up to 2000 kg, thus providing a strong protection to these bulky items during the shipping process.

10.What are the problems and troubleshooting of pallet strapping machine?

| Problems | Solutions |

| The machine is making noise when the strapping process is taking place | Check whether the strap and the strap holder are in line with each other.

Also see if the strap is threaded onto the brake lever. |

| The strap bends abnormally. | Lower the tension force to an appropriate level. |

| The strap breaks from time to time. | Adjust the temperature to avoid improper sealing. |

| Smoke starts coming out from the strapping head | Check whether the ventilation system is functioning properly and rectify the problem immediately. |

| The tension force for strapping boxes is inefficient. | Using boxes of different shapes and sizes can cause difference in the tension force. Try to use same boxes. |

| The machine cockles the strap when it is withdrawn from it. | Use compressed air to clean the machine from any dust or dirt. |

Conclusion

After discussing all the points above, we now know in detail about pallet strapping machine. This machine is an excellent choice for anyone who is looking for a flexible and cost-effective equipment to secure his goods. No matter what industry you belong to, if you’re looking for a strapping machine, it is the best choice for you! For more information and details, visit website www.allpackchina.com.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide