Induction Sealing Machine: The Complete FAQ Guide In 2025

When it comes to sealing of containers and cans, induction sealing machine comes at the top of rest sealing techniques. It provides perfect sealing to keep the product fresh and live for longer duration.

But for a new buyer of induction sealing machine, it is always a difficult decision to select the best. As it involves a lot of time and money investment. For this we Allpack are providing you this guide which will resolve are your queries related to an induction sealing machine. Go through the complete buying guide and take the most from it.

1. What Is An Induction Sealing Machine?

An induction sealing machine seals metal foils on the top of cans, bottles, containers and jars with the help of electromagnetic induction hermetic seal. The process is applied in pharmaceutical, chemical, beverages, food and other industries to maintain products freshness and avoid any leakages.

Variety of sealed cans made up of plastic, metal or glass can easily be sealed using an induction sealing machine. Different types of induction sealing machine are used in industries depending upon their productivity and needs.

2. What Types Of Containers Can Be Sealed By the Induction Sealing Machines?

Different types of containers can be sealed using an induction sealing machine depending upon the specification and design of those containers. Some of containers that are sealed by an induction sealing machine are

- Plastic Cans

Plastic material cans are also available that undergo induced electromagnetic field. Paper cans are commonly used for packaging of chemicals and lubricating products because no chemical reaction takes place when both of them combine. Chemicals when packaged in steel or aluminum cans lose their properties.

- Glass Jars

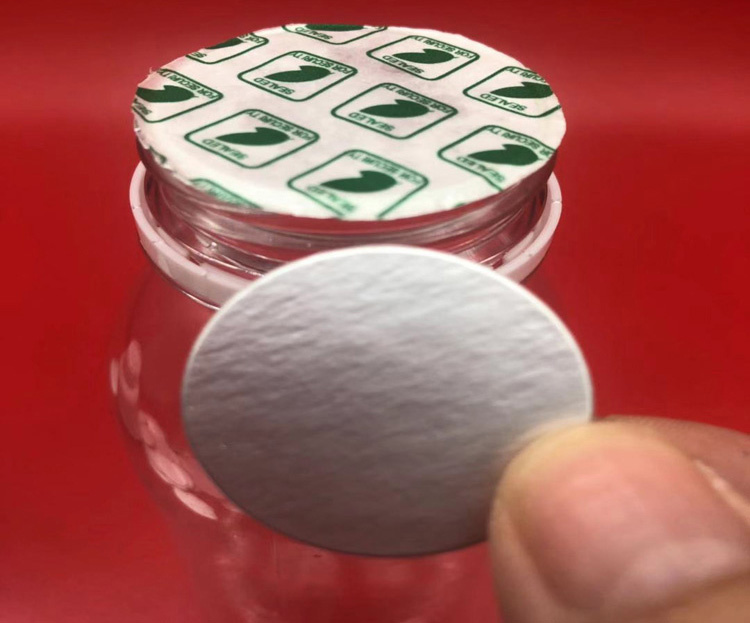

An induction sealing machine is used to seal glass jars by using induction sealing technology. When the jars are transported through the sealing head , an aluminum foil lid enters the sealing head and heats the metal foil liner. The melted polymer coating causes strong bond to the rim of the glass jar and forms a hermetic seal.

Glass jars that are used in food, beverages, cosmetic, pharmaceutical and chemical industries are sealed using induction sealing machines to ensure product freshness and integrity.

3. What Sealing Types By Induction Sealing Machine Are There?

Induction sealing machines are used in many industries for application of following types of seals

- Aluminum Seal

The most common type of seal that is applied using an induction sealing machine is an aluminum seal. This type of seal is performed in almost every industry due to its durability and economical feature.

- Double Type Seal

Double type seal including both inner and outer seals are applied onto the products using an induction sealing machine. This makes the container much secure and helps in preventing any material wastage during its transportation.

- Three layered Seal

An induction sealing machine is also applicable in performing three layered sealing. More security of material is assured as compared to double layer sealing and the material remains fresh for longer period.

4. What Are The Applications Of An Induction Sealing Machine?

Induction sealing machines provide efficient and precise sealing to lots of products that are manufactured in different industries. Some of the applications of an induction sealing machine are

- Pharmaceutical Industry

Pharmaceutical industry is the one where the application of induction sealing machine is found the most. Medicines, supplements, tablets and vitamins that are packed in bottle are further sealed using these induction sealing machines. Sealing provides medicine safety to a greater instant as it directly relates with the medical conditions of human life. This seal protects them and maintains their purity.

- Food and Beverages Industry

Food and beverages industry applies induction sealing machine for sealing of jars, bottles and cans that are filled with eatable products. The food remains highly preserved when the air tight sealing is provided to them. An induction sealing machine also ensures that the product remains fresh, pure and of same quality for a longer period.

- Cosmetic Industry

Like other industries, induction sealing machines also have variety of applications in cosmetic industry. Bottles and small metal jars carrying personal care materials and sealed using an induction sealing machine. As cosmetic materials are also related with human skin, this is why their effectiveness and quality matters a lot. An induction sealing machine provides both of these features until the products shelf life ends.

- Chemical Industry

Chemical products are highly sensitive when it comes on their transportation and handling. Induction sealing machines are used in chemical industry for this purpose as it prohibits any type of leakage no matter the product is to travel in any part of the world. Liquid, solid, fluid, oils, and other chemical products are packed in bottles, cans and jars using induction sealing machines.

5. What Are The Features and Advantages Of An Induction Sealing Machine?

Induction sealing machines are one of the most popular sealing machines that are used now worldwide in different packaging processes. The increases in demand of induction sealing machine is due to following unique features.

- Multiple Frequency Sealing

The most unique feature of an induction sealing machine is that the machine offers variety of sealing frequencies to each of the product. As products made up of different types of materials undergo sealing process, an induction sealing machine sealing machine can set its electromagnetic sealing frequency according to that particular material.

- Adjustable Sealing Head

Sealing head of an induction sealing machine can be set according to the size of product. For variance in sized of products, there is a height controller to perform proper sealing.

- Sealing Power

The amount of sealing power that is emitted by an induction sealing machine also depends on the nature of material and product. This makes the machine more precise and reduces entrance of any wave into the material that is to be packed.

- Adjustable Sealing Time and Pressure

An induction sealing machine offers adjustable sealing time and pressure for each of the material that achieves desired sealing conditions and avoids any type of waste caused by improper sealing.

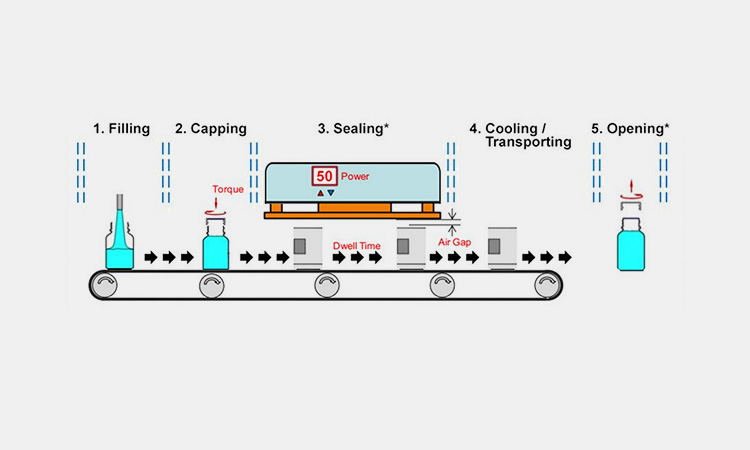

- Efficient Cooling System

Another feature of an induction sealing machine is that it has an efficient cooling system at its exit room. This cooling system maintains the heating temperature within the system and avoids any type of dangerous condition. Also swift sealing is performed due to this cooling system.

- Customizable Sealing

Sealing of materials like glass, paper and plastics can be performed in different types of sizes using an induction sealing machine. The machine can be customized according to the size, material and product that make it much beneficial.

- Material Safety

Tempered evident sealing of products can be achieved by an induction sealing machine. This type of sealing maintains machine quality and provides consistent packaging solutions. The material that requires sensitive controlling and monitoring of induction machine can be easily sealed and the material inside it can be easily used anytime.

Also foil material is saved a lot from any wastage while using an induction sealing machine.

- Environment friendly

Induction sealing machines are designed in a way that all the rules and regulations according to international standards are fulfilled. The machine produces no harm to the environment and is eco-friendly. Man, machine, material and nature all remain safe during the operation of an induction sealing machine.

6. What Are The Working Principles Of An Induction Sealing Machine?

An induction sealing machine follows following working principle in its operation

- Initially containers, jars or bottles in which the material has to be filled are kept on the conveyor or inserted manually in the system

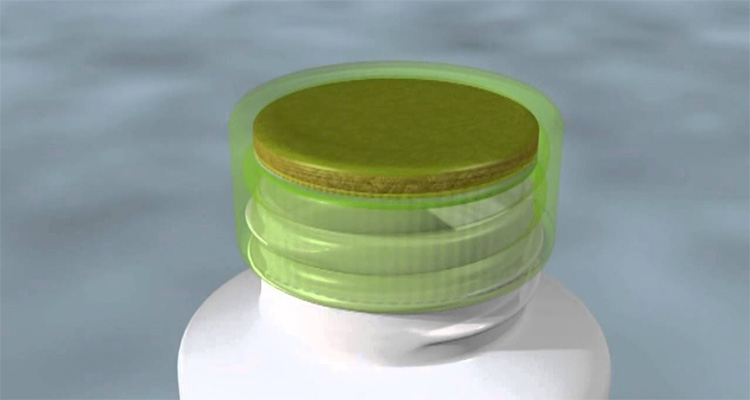

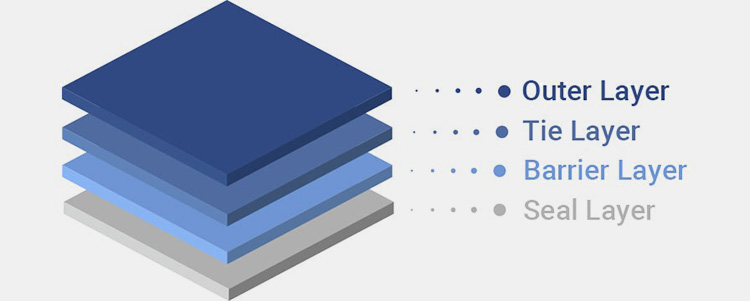

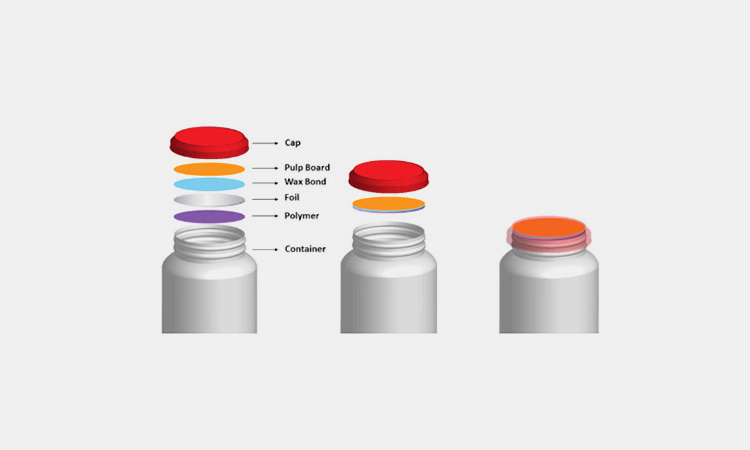

- The product is filled with the desire material when passed through the induction sealing machine and a sealing foil or lid made up of mostly aluminum is applied on it. This lid has mainly a sensitive coating in it that melts when the product observes electromagnetic field.

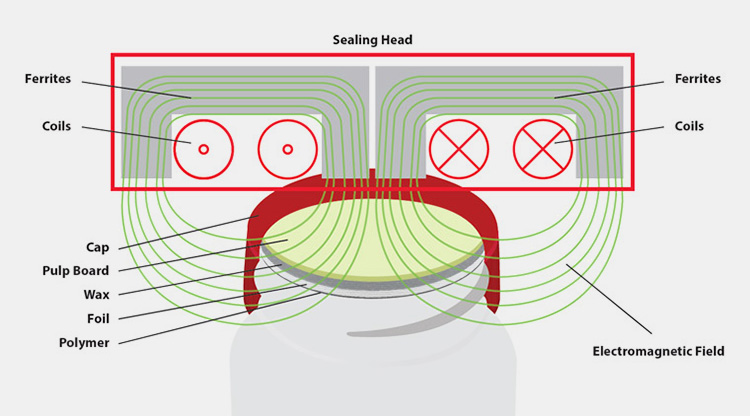

- After application of lid the container enter the sealing system and here an electromagnetic field is generated by the coils. This field induces current on to the product which results in melting of the heat sensitive material present on aluminum lid.

- As the sealing is applied, the product becomes air tight and the sealing process gets completed. The sealed product is then carried out of the system and final cover is applied on it.

High sensitive and effective sealing is provided by an induction sealing machine which resists the entrance of any microbes in it.

7. What Are The Main Components Of An Induction Sealing Machine?

Both the automatic and manual induction sealing machine has most of the common parts in them. The difference is that a manual induction sealing machine has a compact design, rest the mechanism remains same. Some of the essential components that are present in both types of induction sealing machine are

- Vents

In manual induction sealing machine, vents are present on the outer part of machine that is responsible for taking out of heat radiation present inside the system. This is also used to cool down the system.

- Sealing Head

The most important part in both types of induction sealing machines is their sealing heads. This is the place where the electromagnetic coils are present and the inductive current is produced onto the product. In short the sealing mechanism is applied in this part of an induction sealing machine.

- Foil Roller

Foil rollers are present in automatic induction sealing machines. The roller contains the foil material which is used as a lid or sealing head. It is mostly present at the back of an induction sealing machine and from there is rolls in alignment to the conveyor.

- Power Supply

An induction sealing machine requires standard power for its operation. This power is maintained using a power supply unit and this is responsible to activate the electromagnetic field in coils.

- Conveyors

Automatic induction sealing machine have conveyor belts attached in their entry and exit channels. They are used to move the containers through the ceiling system in an efficient and easy manner.

- Electromagnetic Coil

Mostly aluminum and copper coils are present in the sealing head of an induction sealing machine. These coils are heated using electric power and as a result electromagnetic field is produced in the system. This field is responsible of sealing the products.

- Cooling System

A cooling system mostly fans are there in an induction sealing machine that are used to prevent overheating and keeping the system under control temperature.

8. What Types Of Induction Sealing Machine Are There?

Out of several types of inductions sealing machines, some of them are

- Manual Induction Sealing Machine

Manual or Hand-held induction sealing machines that are used to seal containers involves complete manual processes. The machines are easy to move and can be used as portable induction sealing solution. Induction wads are placed on the top of cap and a non contact sealing by induction mechanism is performed.

Small scale businesses can ideally use this manual induction sealing machines in their production setups where 5 to 10 caps are induced per minute.

- Semi-Automatic Induction Sealing Machine

A semi-automatic induction sealing machine involves both manual and automatic operations. Small and medium scale industries mostly use semi-automatic induction sealing machine to fulfill their requirements.

Small conveying systems designed according to the sealing product are present in a semi-automatic induction. The products travel on this conveying pattern and when it reaches the sealing system, the operator places lid on it. After placing the lid the operations gets start and are highly efficient and sealing is performed with precision and accuracy.

- Automatic Induction Sealing Machine

Automatic induction sealing machines are designed to perform high production rate sealing in medium and large scale industries. All the processes are carried out automatically with more powerful sealing of products. From product inlet to their exit from the system, each one of the tasks is performed by the machine itself.

The products travel on the conveyors and when it reaches the sealing system, an automatic pattern of lid follows from the lid feeder on it. After placing the lid the operations gets start and are highly efficient and sealing is performed with precision and accuracy.

- Overhead Induction Sealing Machine

Overhead type induction sealing machines are associated with production setups and are present above the production line. They seal the products as it passes underneath it. Speedy and high production volume industries mostly use overhead induction sealing machine.

- Bench top Induction Sealing Machine

Bench top induction sealing machines are also like manual induction sealing machines but only differ in their placement. The machines are designed in a way that they are placed on tables and are used to perform stationary sealing of products.

- In-Line Induction Sealing Machine

Packaging lines that hold sealing methods in their processes usually have in-line induction sealing machines in between. The machines fit into the production setups and perform sealing whenever the product passes through it. Large scale industries mostly get benefited from in-line packaging machines.

- Continuous Induction Sealing Machine

Continuous induction sealing machine is designed in a way that continuously, high speeds sealing takes place and are suitable for large-scale industries. Conveyor system is there that moves the container through the sealing process and allows multiple containers to be sealed at the same time.

An effective seal is observed as a result of continuous induction sealing and reduces waste to a greater extent. These machines are mostly used in food, beverages, pharmaceuticals and chemical industries.

9. Can Induction Sealing Machine Be Used To Seal Metal Material?

Induction sealing machines cannot be used to seal metallic materials. The induction sealing process works by heating the metal foil through induced electromagnetic field that is adhered on to the top of a container. It created a tight bond with the container.

This process is not effective for sealing of metals materials and lids because of their high tensile strength. The metallic bond cannot be easily melted and further with induced electromagnetic field they can result in flammable gases and poor sealing.

10. Can the Induction Sealing Machine Applied In Sealing Flammable Liquids?

Induction sealing machines cannot be used for flammable liquids but depends on particular solution and requires precautions taken necessary to ensure safely operation. Flammable liquids can directly spark when the process of induced electromagnetic takes places and the current present in the system may support the liquid to catch flame. These flammable liquids are a direct source to fire and can catch fire easily during heating and sealing process. It is always important to consult with the manufacturer and ask for proper standardize product safety data.

Proper ventilation and explosion proof apparatus should be used to minimize risk and training regarded packaging material is necessary to be given to the safety coordinators.

11. What Are The Differences Between Induction Sealings And Other Types Of Sealing?

An induction sealing machine performs non contacting sealing with the help of electromagnetic field in the sealing head. The generation of electromagnetic field is carried out within the coils. The heat due to induced electromagnetic field melts aluminum material and seals it right onto the top of product.

- Induction Sealing VS Heating Sealings

Heat sealing is a contacted sealing method where the lid is simply heated and that heat causes melting of thermoplastic material. The heated plastic seals the top of container and protects the material from all type of atmospheric influence.

- Induction Sealing VS Conduction Sealing

Conduction sealing on the other hand, uses direct contact with a heated sealing head to heat the sealing material. This heat is transferred from the sealing head to the material and causes it to melt and forms a seal. This method is typically used for containers made of metal or other conductive materials.

- Induction Sealing VS Shrink Wrap

Shrink wrap is a method of packaging products by encasing them in a clear plastic film that shrinks when heated. The shrink wrap material is applied to the products and then heated using an external heat source such as a shrink wrap machine. As the material shrinks it forms a tight and secure fit around the product. This tight fit provides protection against dust, moisture, and other environmental factors.

- Induction Sealing VS Blister Sealings

Blister sealing refers to seal blister and paper cards by heat sealings with pressure and molds. Blister sealings are mainly applied for all kinds of exquisite toys, stationery, batteries, food and daily necessities. Blister sealings can be performed by kinds of machines including high-frequency machine, heat sealing machine, ultrasonic machine,blister molding and packaging machine.

12. What Are the Auxiliary Component For Induction Sealing Machine?

Some of the auxiliary components that support the operation of an induction sealing machine are

- Compressors

Air compressors are mostly associated with manual type induction sealing machines to cool down the temperature of heated seal and sealing head. It is also somewhere used in controlling of pneumatic conveying system.

- Cap Sorters

Production setups where bottles are sealed uses cap on their tops. These caps are sorted using an efficient cap sorter that aligns the same type of caps to implement after induction sealer is performed.

- Leak Detectors

Sensors that detect the leakage after sealing are also associated with induction sealing machine. These sensors indicate whether proper sealing is performed or not.

- Foil Detectors

Some detectors are also associated with foil roller that detects the presence of foil and its movement. The detecting sensors automatically stop the system as the foil roller gets empty.

- Pneumatic Cylinders

For proper supply of air pressure and air tight sealing during sealing process is ensured through these pneumatic cylinders.

13. Does Induction Sealing Machine Have Radiation? Will It Be Harmful To Human Body?

Electromagnetic fields are generated in an induction sealing machine during its process. Like other microwave ovens, induction sealing machines emit harmful radiations but these radiations are of low-frequency and low-intensity. This is why these radiations are not considered to be harmful to human health.

However, it is important to follow proper safety procedures when operating an induction sealing machine to avoid direct exposure to the electromagnetic field. Additionally, it is important to follow all manufacturer instructions and guidelines to ensure safe and proper use of the machine.

14. What Common Factors Should Be Considered Before Purchasing An Induction Sealing Machine?

Several important factors that should be taken under consideration during the purchasing of an induction sealing machine are

- Container Types

The most important thing to be noticed before purchasing an induction sealing machine is to check what type of containers, bags, bottles or can be adjusted within the heating system of the machine. Versatile machines in which the height is adjusted according to the shape and size are always best to select.

- Strength of Seal

The sealing parameters of the machines should also be checked properly and be clear with the manufacturer regarding accurate outcomes. The sealing strength becomes the most common but important factor that is to be noticed otherwise wrong decision can cause a lot of economical loss.

Conclusion

Induction sealing machines are highly versatile and efficient when it comes in sealing procedures. Unlike other techniques, induction sealing machine provides tempered and unbreakable sealing options. Allpack are providing you this complete FAQ buying guide that will assists you in every moment of life. Feel free to contact our customer service office or visit our website http://www.allpackchina.com/ .

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide