Beer Can Seamer: The Complete Buying Guide In 2025

Are you ready to maintain the taste of your beer for longer period by reducing the environmental interference? Just take the step forward for doing it practically!

The packaging industry has now presented the best solution of a beer can seamer in order to better enable you in sealing your favorite drinks. With precise structure and convenient usability this machine is cost-effective and provide you lots of other benefits. To fully understand the functions, working and role of a beer can seamer go through this detailed buying guide!

1.What Is A Beer Can Seamer?

A beer can seamer is a machine used to seal the top of a beer can after it has been filled, and the contents have been carbonated. The machine works by first cleaning the top of the can and then using a series of rollers to crimp the top of the can, creating an airtight seal to keep the beer fresh.

Beer can seamers are used in the production and packing of canned beer, but they also have a wide range of other uses, including the processing of various cans carrying juices, cold drinks, and food items.

2.Why Should You Use A Beer Can Seamer?

There are several reasons why a beer can seamer is an important tool in the manufacturing and packaging of canned beer.

Airtight Seal: The primary function of a beer can seamer is to create an airtight seal on the top of the can. This helps to preserve the freshness of the beer by preventing oxygen from entering the can and potentially spoiling the contents.

Consistency: Beer can seamer machines are designed to produce a consistent and reliable seal on every can. This ensures that every can of beer will maintain its quality and taste, which is important for maintaining a good reputation for the brewery.

Speed and Efficiency: Beer can seamer machines are able to seal cans quickly and efficiently. This is important for high-volume production, as it allows breweries to produce large quantities of canned beer in a relatively short amount of time.

Economical: A beer can seamer is a cost-effective way to package beer. Cans are cheaper to produce than glass bottles, and they are also lighter and more durable, making them cheaper to transport and store.

Versatile: Beer can seamer machines are versatile and can be used to seal a variety of different types and sizes of cans. This allows a brewery to package different beers or even non-alcoholic beverages in cans.

Overall, a beer can seamer is an essential tool for any brewery that produces canned beer. It helps to ensure the quality and freshness of the beer, while also increasing production speed and efficiency, and reducing packaging costs.

3.Highlight The Reasons For Popularity Of A Beer Can Seamer?

A beer can seamer is a machine used to seal the tops of filled aluminum cans with a thin layer of metal. There are a few reasons for the popularity of beer can seamers:

Cost-effective

Canning beer is a more cost-effective packaging option compared to bottling. Cans are cheaper to produce, lighter to transport, and take up less space than bottles.

Convenience

Canned beer is easy to store, transport and drink. They are also more portable, making them a popular choice for outdoor events like picnics and camping trips.

Preservation

Cans protect beer from light and air, which can negatively affect the taste of the beer. This helps to preserve the freshness and flavor of the beer.

Environmentally friendly

Cans are more easily recyclable than bottles and take up less space in landfills, making them more environmentally friendly.

Branding

Beer cans can be easily printed with high-quality graphics, making them an ideal packaging option for brands looking to make a strong visual impact.

Efficiency

Beer can seamers are fast and efficient machines that can seal hundreds or thousands of cans per hour, making them a practical choice for large-scale production.

Customization

A brewery’s unique needs can be taken into account when designing a canning line, which improves the efficiency of the manufacturing process. Due to the adjustable height of the can holder, this machine can seal cans of various sizes and shapes.

4.What Is The Method Of Operating A Beer Can Seamer?

A beer can seamer is a device that attaches the lid to the body of a can of beer. The actions that are normally taken when using a beer can seamer are as follows:

Loading cans

The operator loads empty cans onto the machine, which are then automatically transported to the filling station.

Filling cans

The machine fills the cans with beer, and then automatically transports them to the seaming station.

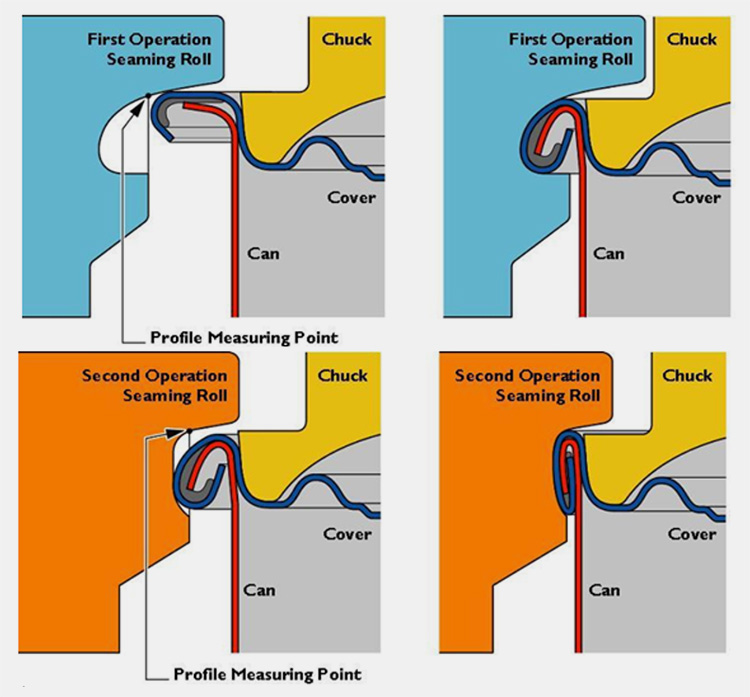

Seaming

At the seaming station, the machine applies a lid to the top of the can and then uses a seaming roller to crimp the lid onto the can body, creating an airtight seal.

Testing

Some canning lines also include a testing station, where the cans are checked for leaks or other defects before being packaged.

Packaging

Finally, the sealed cans are automatically packaged and prepared for shipment.

It’s important to note that there are different types of seaming equipment, each with their own specific methods and operating procedures. The can seamer that you use will depend on the type of can and the size of your production line.

5.What Are The Uses Of A Beer Can Seamer?

A beer can seamer has various uses, which are illustrated for you in the details provided below:

Beer Packaging:

Beer can seamer is an essential instrument that play a beneficial role in wine industry for the hermetic sealing of beer filled cans. This is the reason, why the popularity of this machine is growing day by day.

Beverage Packaging:

Beverage packing is the most common type of canning product after beer packaging. Common beverages that are packaged in cans and ready for sealing by a beer can seamer include soda water, milkshakes, and fresh juices.

Milk Packaging:

The introduction of shelf-stable milk is of greater relevance to owners of dairy farms and milk processing businesses. So, the concept of putting milk in cans has been used for which the need of a beer can seamer is also realized. You may now get fresh carbonated milk in either its original or chocolate-flavored forms.

Food Packaging

In addition to sealing cans of beverages and wine, beer can seamers are also used to seal cans of food, including cooked food, seafood, dry food, and other goods.

6.Why Beer Cans Are Preferred Over Beer Bottles?

There are certain justifications for choosing beer cans over beer bottles. Here are some of them:

Lightweight and portable: Cans are lighter and more compact than bottles, making them easier to transport and store. This makes them a convenient option for outdoor activities such as camping, hiking, and tailgating.

Better for the environment: Cans are more easily recycled than bottles and have a smaller carbon footprint. They also take up less space in landfills.

Keeps beer fresh: Cans protect the beer from light and air, which can spoil the beer and give it an off-flavor.

Convenient for cold storage: Cans cool faster than bottles and are stackable, which makes them easy to store in a refrigerator or cooler.

Cost-effective: Cans are cheaper to produce and transport than bottles, which can result in lower prices for consumers.

Perfect for Carbonated drinks: Cans are better for carbonated beverages because they can withstand the pressure of carbonation and do not allow any light to come in contact with the liquid and spoil the taste.

7.Describe The Major Components Of A Beer Can Seamer?

A beer can seamer typically consists of the following major components:

Feeder

The feeder is responsible for delivering the cans to the seamer in a consistent and orderly manner.

Seaming head

The seaming head is the main component of the seamer and is responsible for forming the can lid to the can body.

Seaming Rollers

Seaming rollers are located in the seaming head which seals the lids over cans while rotating in fast speed.

Drive unit

The drive unit provides the power to operate the seaming head.

Guide Rail

It is also known as the conveyor belt whose primary function is to move the cans from filling station to sealing and discharging respectively.

Control system

The control system is responsible for controlling the operation of the seamer, including the speed and timing of the seaming process.

Lubrication system

A lubrication system is used to lubricate the seaming head and other moving parts to ensure smooth operation and prolong the life of the machine.

Chute

The chute is used to guide the sealed cans out of the seamer.

Other possible components include a can cleaner, a can inspector, and a can rinser, to ensure that the cans are clean and free of debris before they are sealed.

8.What Type Of Labeling Methods Are Adopted For The Recognition Of Bear Cans?

Numerous techniques, some of which are detailed here, are employed to identify the brand and type of canning by labelling:

Optical Character Recognition (OCR)

This method involves using machine learning algorithms to extract text from an image of a bear can label and then match it against a database of known bear can label.

Barcode scanning

Bear can labels may include a barcode that can be scanned using a barcode scanner and then matched against a database of known bear can label.

Image recognition

This method involves training a machine learning model to recognize the specific design or logo on a bear can label. The model can then be used to identify the bear can by matching the image against a database of known bear can label.

QR code scanning

Bear can labels may include a QR code that can be scanned by a smartphone, then match it against a database of known bear can label.

9.How Would You Categorize Beer Can Seamer?

Beer can seamers come in a variety of styles with varying costs, capacities, and efficiencies. They are as follows:

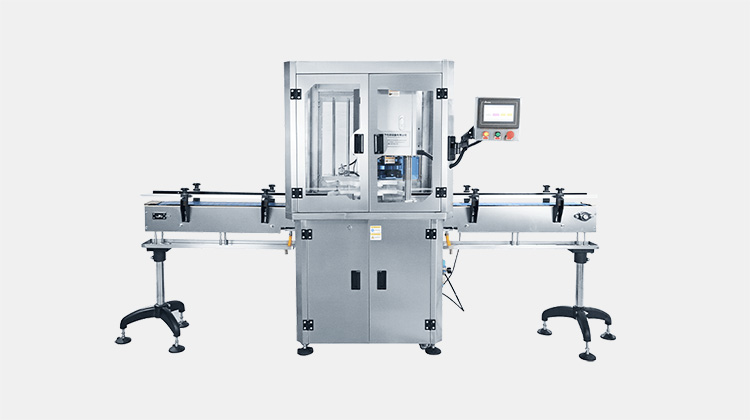

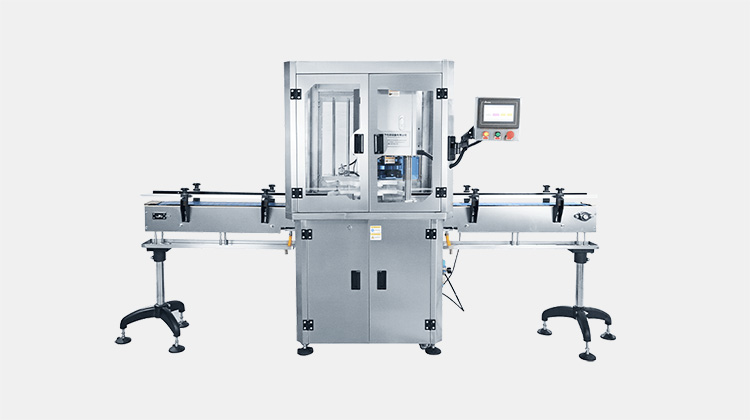

Fully Automatic Beer Can Seamer

A fully automatic beer can seamer is equipped with cutting-edge technology that carries out the complete process of bottle capping and sealing automatically. It creates hermetic sealing while producing an incredibly high output in terms of efficiency.

Structure

The machine’s structure is intricate and made up of numerous parts, including a driving unit, control system, lid-delivering station, seaming head, joining rollers, and stainless steel body.

Process

Once the operator has set the parameters, the machine goes through an automatic process. Delivered filled cans are covered with lids at the lid delivering station before being transferred to the seaming head. When they arrive, seaming rollers move swiftly around the bottle and firmly join the lid to the can body to create a tight seal. Beer cans that have been sealed are then released and prepared for additional packing.

Application

Fully automatic beer can seamers are perfect for businesses that produce large volume of beer cans.

Semi-Automatic Beer Can Seamer

Another type of beer can seamer is semi-automatic, which has a small design and reliable operation to produce outstanding results. It also has a good processing yield and is economical.

Structure

The main frame, control board, seaming head, can holding tray, can uplifting tray, and seaming rollers make up the machine.

Working Process

When the can is placed over the holding tray that has beer in it, it operates in a straightforward manner. By manually lifting the can toward the seaming head through the handle, seaming rollers begin to move around the bottle mouth and firmly seal the lid to the bottle mouth.

Application

It can be used in small scale production areas where beer packaging is processed.

Manual Beer Can Seamer

This manual beer can seamer is a small, hand-operated device with a compact design. This is the ideal solution at a fair price if you process any kind of home-based beer or beverage business.

Structure

It is made up of a wheel, a handle for operating it, a sealing head, rollers, and a stand for holding cans.

Working Process

The holding tray is manually covered with a can that has been filled with beer and has a lid on it. When the can reach to seaming head, operator raise the handle. Now, the sealing of the can happens gradually as the wheel is moved.

Application

It is vitally used in home brewery, clubs and restaurants etc.

10.What Is The Ratio of Sustainability For Beer Cans?

The ratio of sustainability for beer cans can vary depending on the specific practices and materials used by the brewery or can manufacturer. Some factors that can impact the sustainability of beer cans include the use of recycled materials, energy-efficient manufacturing processes, and recycling and disposal practices.

Additionally, some breweries may also take steps to reduce their overall environmental footprint, such as using sustainable sourcing for ingredients or implementing conservation and water-saving measures. The sustainability of beer cans is a complex issue that can depend on a variety of factors, and it’s not possible to provide a specific ratio without more context.

11.What Role The Different Machines Play In The Packaging Of Beer Cans Along With Beer Can Seamer?

In the packaging of beer cans, there are several machines that play different roles. The main machine used in the process is the beer can seamer, which is used to seal the tops of the cans with a metal lid, known as a “can end.” Other machines that may be used in the packaging process include:

Can Filling Machine

Can filling machine is used to fill the cans with accurate amount of beer. It is composed of several parts including conveyor belt, can rolling device, filling station, material tank and control system. During filling, the machine also carbonates these cans and flush them with nitrogen for preserving the taste of beer for longer period.

Can washer

Before the cans are filled with beer, this machine thoroughly cleans and sanitises them. It is incorporated into the primary beer can seamer line. To clean empty cans, they are placed all together in the can washer and moved through a succession of washing stages.

Labeling Machine

Your cans are labelled with this machine. You may observe many types of print labelling, paper labelling, and shrink sleeve labelling, demonstrating the variety of labelling machines.

Can Packaging Machine

Machines that pack cans into packaging like six-packs, twelve-packs, cases, etc. are known as can packaging machines. Cans are packaged using shrink wrapping and carton sealing equipment.

Palletizer

This machine stacks the packaged cans into pallets for the purpose of storage and easy transportation. Stretch wrapping machine is the common type of palletizer used for bulk cans to be packed.

Overall, the process starts with cleaning and sanitizing the cans and then filling them with beer, then the cans are sealed and labeled, and then packaged and stacked in a pallet for storage and transportation.

12.Factors To Look For The Selection Of Beer Can Seamer?

When selecting a beer can seamer, there are several factors to consider, including:

Production capacity

Consider the amount of cans you will need to seal per day and choose a machine that can handle that capacity.

Can size compatibility

Ensure that the machine can accommodate the size of cans you will be using.

Seaming quality

Look for a machine that can provide a consistent and high-quality seal on the cans to prevent leaks and ensure product freshness.

Durability and maintenance

Pick a device that will last a long time and needs little upkeep. Check the assembly and disassembly process as well because it has to be clean and lubricated.

Safety features

Safety features such as emergency stops or automatic shut offs can prevent accidents and injuries. So, never overlook to check these features.

Automation

Some beer cans seamers come with automation features that can improve efficiency and reduce the need for manual labor.

Brand reputation

Look for a reputable brand in the market that has a good track record in providing quality and reliable machines.

Price

Look for a machine that provides good value for money and fits within your budget.

Conclusion

In conclusion, a beer can seamer enables a quicker and more effective packing procedure. Every business in the relevant production sector therefore strives to use this technology. However, the majority of manufacturers are perplexed as a result of the difficulties in locating the best brand. Allpack is constantly prepared to offer its customers the best beer can seaming solutions to address these problems. If you are interested in purchasing a beer can seamer, simply move forward and contact us via the provided link. http://www.allpackchina.com/

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide