A Comprehensive Look At Medical Blister Packaging

It seems like you are looking forward for a Comprehensive Look At Medical Blister Packaging. Well, in that case we welcome you to this informative review. In today's era, the healthcare industry is more focused on securing the produced drugs in best possible ways. One such method is blister packaging which is popular for its affordability, convenient usage, and enhanced protection.

This review contain information about the various aspects of medical blister packaging such as its advantages, various types of blister packaging, materials used for their manufacturing, and much more. It will also explore the advanced equipment and technology employed for making the production of blister packaging more feasible. So, let's begin reading it!

1.What Is Medical Blister Packaging?

Medical blister packs- Picture Courtesy: inspirontourism.com

Medical blister packaging refers to the packaging of drugs such as tablets, capsules, and ampoules into the flexible blister packs. These blister packs are designed with food grade materials which is fully safe for all kinds of drugs. It aims at providing unit dose packaging to individual medication, promote convenient handling, and help in protecting drugs in solid dosage form against environmental factors.

Medical blister packaging consists of key components that include:

Forming Film:As the term illustrates, forming film is the part of blister pack that is shaped into blisters. These formed blisters are then used for putting drugs.

Lidding Foil:Lidding foil refers to the part of blister pack which is used to cover the blister packs. It is straight and flat.

Adhesive:Adhesive is a form of glue used between forming film and lidding foil for tight sealing. Although, adhesive may not be seen apparently on blister packs, but it is present between the forming film and lidding foil.

Blister packaging is widely used in healthcare industry for various reasons. Some of the notable factors include:

Improved Dose Tracking

The unit dose of blister packs has improved dose tracking. It helps caregivers and patients to adhere to medication regimens. Similarly, the risk of overdose and underdose is reduced. In addition, pills for normalizing periods and birth control often comes in two different colors due to different levels of hormones. In this way, blister packaging is useful for providing better tracking.

Reduced Cross Contamination

Blister packs are better for their quality of reduced cross contamination. The individual blister packs allow enough room for each tablet or capsule, thereby restricting cross contamination. For instance, in most cases, pills stick to each other which cause them to break. To avoid such instances, blister packs are considered suitable choice in healthcare field.

2.What Are The Types Of Medical Blister Packaging?

Although, medical blister packs have the same structure, however, they are of different types. Depending upon the material used for manufacturing and designs adopted for medical blister packs, they can be divided into four types which are explained below:

Alu-PVC (Aluminum-Plastic) Blister Packs

PVC- Aluminum Blister Packs- Picture Courtesy: iStock

The very first and most common type of medical blister packaginig include PVC/ Aluminum blister packs. These blister packs consists of Polyvinyl Chloride (PVC) cavity and an aluminum foil lid. Such type of blister packs are quite flexible which can be easily mold using heat. They are also cost-effective and offer convenience to visually inspect the drugs due to transparency of cavities.

Alu-Alu (Cold Form Blister/ Aluminum-Aluminum) Blister Packs

Alu-Alu blister packs- Picture Courtesy: insajo.edu.co

Another type of medical blister packaging include Alu-Alu blister packs which are famous for their superior barrier properties especially against oxygen, moisture and light. They are formed using cold forming technique where adhesive instead of applying heat is used for sealing. Despite being costly, they are used for high-demand medicines due to better temperature and humidity resistance.

Paper-Alu-PVC Blister Packs

Paper-Alu-PVC blister packs- Picture Courtesy: romaco.com

Another type of blister packaging include Paper-Alu-PVC which is a multi layer blister pack. Such type of blister pack is sustainable as made up of thin layers. It offers convenience by pushing out the product smoothly out of the pack. It is suitable for drugs meant for short time.

ALU-PVC/ PVDC Blister

Alu-PVC/ PVDC blister pack

Aluminium-PVC/ PVDC blister is a food grade pharmaceutical packaging that combines multiple layers for enhanced protection. It has semi-rigid base made from Polyvinyl Chloride which is transparent. Coating of Polyvinylidene Chloride is added to the base for improving barrier properties. Similarly, the lidding of blister is of aluminum which is durable enough to protect drugs and easy to tear.

Alu-PVC/ Aclar (PCTFE) Blister

Aclar PCTFE blister packs- Picture Courtesy: kaatimex.bg

Alu-PVC/ Aclar blister is another significant medical blister packaging with highest barrier properties against oxygen, moisture,and light. Aclar is non-flammable and biochemically inert as a result of which its combination with other plastics for thermoforming is ideal for sensitive drugs preservation.

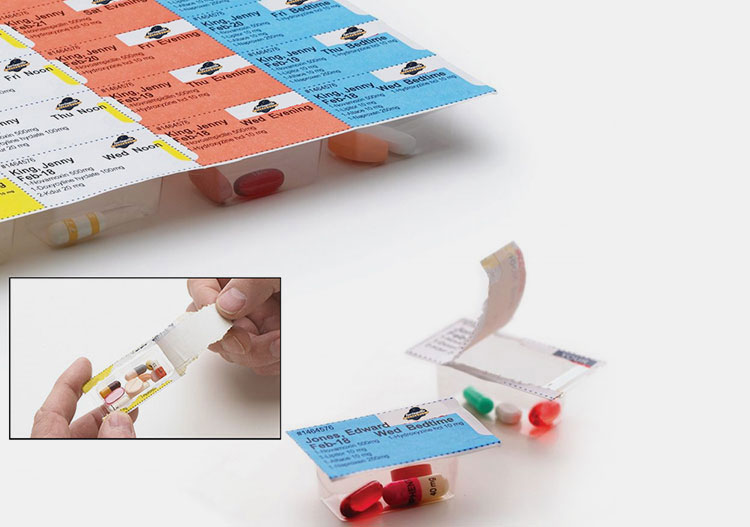

Child-Resistant and Senior-Friendly Designs

Child resistant blister packaging: Picture Courtesy: Web Packaging

Child-resistant and senior-friendly designs are true innovation for the reason that they offer easy access for adults but not for childern. The common example include push smart design where a person is required to exert pressure on specific marked area for releasing pill. Similarly, drawing tray design has been introduced to get the drugs out of blister packs. Such blister packs are both safe as well as convenient to open for seniors.

Customized Blister Packs for Special Drugs

Customized blister packs for drugs- Picture Courtesy: macdonaldspharmacy.com

There is another type of medical blister packaging which is customized for special drugs. Bingo cards or bubble packs is the one such examples which are designed to hold various drugs for patients with changing medication. Each blister offers one dose of medication and each bingo card comes in a 30 or 60 count card depending upon dosage frequency. In this way, patients can get blister packs with long term care facilities.

3.Write Down The Substantial Advantages Of Medical Blister Packaging?

Medical blister packaging is well-known for their substantial benefits comprising product protection, improved patient compliance and cost-effectiveness in large scale production. Each benefit is well explained in the upcoming paragraphs:

Product Protection and Extended Shelf Life

Various solid dosage form drugs in blister pack- Picture Courtesy: skpharmacy.com

Medical blister packs have tamper-evidence design that safeguards drugs from environmental factors such as moisture, air, and contamination. In such way, the drugs long for last in their original quality.

Improved Patient Compliance and Safety

A person taking capsule out of a blister pack- Picture Courtesy: Shutterstock

Another significant benefit of medical blister packaging is the improved patient compliance and safety. For instance, the light weighted blister packs are appealing to consumers especially for traveling purposes. Each blister corresponds to a single dose that makes it easy for patients to track their medication dose.

Cost-Effectiveness in Large-Scale Production

Large scale production of medical blister packaging- Picture Courtesy: ppsnordic.com

Blister packs are highly cost-effective especially in large-scale production due to the reduced level of material usage. The material used is affordable than other forms of packaging. Moreover, the light-weight design make it more feasible for their transportation.

4.What Are The Materials and Technology Behind Blister Packaging?

Certain materials as well as technologies are used for the creation of blister packs for medications. The details are given below:

Common Materials Used

Material for medical blister packaging

PVC:Polyvinyl Chloride is the most commonly used material for medical blister packaging. It offers transparency to visually inspect drugs and is also affordable. It can be easily molded into different shapes of blisters, however, compared to other materials, PVC has poor barrier properties.

PVDC:Polyvinylidene Chloride is another form of plastic materials which is used for blister packaging. It is often added to the PVC to increase oxygen and moisture barrier properties.

Aclar:Aclar is a clear, high-barrier poly-chloro-tri-fluoro-ethylene (PCTFE) thermoformable material. Its laminate films are crystal clear, biochemically inert, and free of plasticizers and stabilizers. It is well known for protecting drugs stability to provide highest moisture barrier properties.

Aluminum:Aluminum is light, silver colored, and naturally abundant metal which is turned into thin foil and is popularly used for high quality drugs. Aluminum blister packs have excellent corrosion resistance and protection against ultraviolet radiation.

Heat-Sealing vs. Cold-Forming Techniques

The primary techniques used for blister packaging include heat sealing and cold-forming which are explained below:

| No | Points | Heat Sealing | Cold Forming |

| 1 | Definition | Heat sealing is also known as thermoforming which involves application of heat for molding plastic material into blisters. | Cold forming is a technique that uses high-pressure stamping to shape aluminum foil laminates into blister packs. |

| 2 | Process | It has fast production where plastic material is heated and then turned into blisters using vacuum or pressure. | Cold forming is a slow process that involves application of high pressure for multiple layers of aluminum, PVC, and nylon for creating molds. |

| 3 | Cost | Lower material and production cost. | Higher material and production cost. |

| 4 | Barrier Properties | Poor barrier properties against oxygen, moisture, and light. | Excellent protection against moisture, light, and oxygen. |

| 5 | Suitable for | Suitable for unsusceptible medicines meant for short term use. | Suitable for sensitive drugs meant for long term use. |

| 6 | Picture |

Pills blister pack sealing- Picture Courtesy: Accupack |

Cold form blister packaging sample- Picture Courtesy: Packaging World |

Sustainability and Eco-Friendly Materials

Eco-friendly blister packs- Picture Courtesy: plasticfree.com

It is crucial to maintain environmental sustainability by reducing packaging waste and using resources which are not harmful to the ecosystem. In this way, eco-friendly materials are used for making blister packs. These materials are biodegradable and easily recyclable. Some of the common examples are as follows:

Paper Based Solution:It refers to paperboard which is a sustainable alternative to traditional materials. It may be combined with special barrier coatings for drugs protection.

Fiber Based Solution:Fiber based materials are biodegradable and compostable. For making blister packs, it is obtained from renewable plant-based sources.

Mono Material Plastic:Mono material plastics are made from single type of plastic. It eliminates the use of multi layers of different types of plastics; thus, recycling become easy.

5.Describe The Blister Packaging Equipment And Also Explain The Process?

Blister packaging equipment are numerous in numbers. These machines include the automatic blister packaging machines, quality control systems, and track and trace and serialization system which works on specific principles. They are described below:

High-Speed Blister Packing Machines

Thermoforming Blister Packaging Machine

DPP-150E Automatic Rotary Blister Packaging Machine

Thermoforming blister packaging machine is another significant equipment designed for Alu-PVC blister packaging. It has robust structure made up of corrosion resistant stainless steel. Some of the important parts include film roll, touch screen interface, inspection unit, blister forming unit, filling unit, and sealing station etc. It works automatically by unwinding film from roll, turning it into blister packs, filling individual blister, and creating a strong seal. The working mechanism of the machine is based on heat sealing.

Cold Form Blister Packaging Machine

DPP-180H High Speed Tablet/Pill/Capsule Alu Alu Blister Packaging Machine

Cold Form blister packaging machine is an astonishing machine designed with automatic features for undertaking blister packaging of Alu-Alu blister packs. The machine is made up of stainless steel body and other components including electric cabinet, alarm indicator, control system, blister molding unit, blister filling station, and blister lidding and sealing mechanism. It works on cold forming mechanism and is suitable for sensitive drugs.

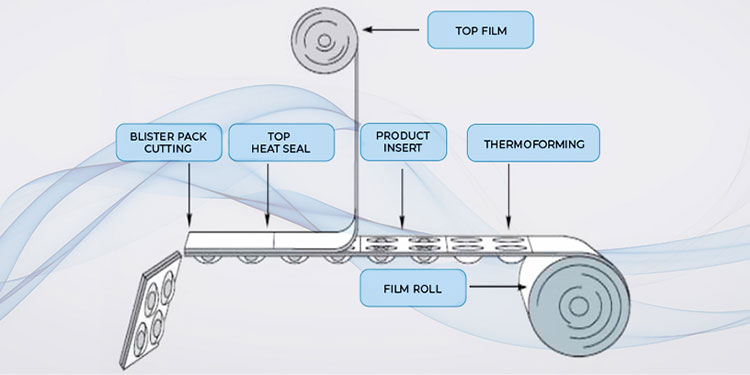

Process

The manufacturing process of blister packaging involves various steps to make sure the precise packaging. It consists of the following major steps:

Blister packaging process- Picture Courtesy: insajo.edu.co

Forming The Base Web: In the first step, selected material which can be plastic or aluminum is formed into blister packs. It is the base web inside which drugs are filled such as tablets and capsules etc.

Filling The Blisters: At this point, each capsule and tablet is properly counted and then filled into blisters.

Sealing With Lidding Material: Once blisters are filled with product, the lidding material is introduced between the base web and lid foil. It ensures tamper evident sealing so, the product may be protected against moisture and air etc.

Cutting and Finishing: With the help of sharp cutter, the blister packs are then separated into individual blister packs and are properly finished.

Quality Testing: Now, the finished blister packs are thoroughly tested for quality control. The major testing include seal integrity testing, tensile testing, oxygen permeability testing, and water vapor testing.

Printing and Cartoning: The final step involve printing of codes and serial number over the blister packs. These finished blister packs are then packed into cartons.

6.What Are The Regulatory And Compliance Standards For Medical Blister Packaging?

Regulatory and compliance standards refer to the rules and regulations used for checking the quality control of goods and products. Some of the important regulations for pharmaceutical blister packaging are as follows:

FDA and EU Requirements for Pharmaceutical Packaging

CE and FDA icons- Picture Courtesy: defibshop.co.uk

FDA is USA based agency that stands for Food and Drugs Administration. While as, EU stands for European Conformate. Both are quality regulating bodies aim at promoting the safety of drugs and related machines.

GMP and ISO Standards in Blister Packaging

ISO and GMP icons- Picture Courtesy: cinoll.com

Good Manufacturing Practices and International Organization for Standardization are the other quality standards which provide guidelines for using appropriate packaging materials. The packaging materials used for blister packaging must adhere to the set principles for enhanced safety and protection of drugs.

7.What Are The Challenges and Future Trends For Medical Blister Packaging?

While blister packaging is considered important, it faces several challenges and is expected to be influenced by some major changes in the future such as:

Sustainability and Green Packaging Solutions

Globe icon- Picture Courtesy: construct.dtu.dk

One of the notable challenges faced by blister packaging is the increasing concern about sustainability. The use of multi layer plastic films are difficult to recycle which in turn is detrimental to the environment. Therefore, the use of green packaging solutions such as paper based and fiber based materials are expected to grow.

Smart Blister Packs with Digital Features

Smart Blister Packs- Picture Courtesy: Packaging Europe

Traditional blister packs had a problem of missing medication doses which is now replaced with digital features. The innovative smart blister packs are now created with chips and uses embedded sensors, conductive materials, and printed electronics to monitor dose removal effectively.

Innovations in Child-Resistant Designs

Child resistant medical blister wallets- Picture Courtesy: Packaging South Asia

Another notable challenge that comes along the way of blister packaging is the access to child. To counter this problem, now innovations are brought in child-resistant designs. Such blister packs are customized into blister wallet with technology for digital adherence.

8.How To Choose The Right Medical Blister Packaging Solution?

Choosing the right blister packaging solution is both crucial and at the same time require you to go with considering certain factors which are enumerated as under:

Product Sensitivity

It is crucial to look for the drug sensitivity and choose the right blister packaging solution. For instance, if the drugs are moisture and light sensitive, then choosing Alu-Alu (cold-formed) blister is good for enhanced protection. In contrast, if the tablets and capsules are standard then Alu-PVC or PVC-PVDC is usually sufficient.

Barrier Protection Needs

Different medical blister packs- Picture Courtesy: Catty Corporation

Each type of blister encase unique barrier properties which makes them suitable for drugs. These include:

High Barrier:Alu-Alu and PVDC coated films for blisters have higher barrier properties.

Moderate Barrier:PVC and PET films are having medium level specific barrier properties.

Eco-conscious Packaging:Such packaging include combination of paper-plastic and recyclable film structures.

Patient Convenience and Compliance

Calendar medication packs- Picture Courtesy: Holland Pharmacy

The selection of blister packaging solutions may also be affected by the patients category. In addition, if the patients are elderly or pediatric then simple blisters with perforations are desirable. On the other hand, if the drugs are meant for multi-dose therapies then Calendar packs (date-marked blisters) are helpful in tracking medication schedules.

Regulatory Compliance

Icon illustrating checking supplier reputation: Picture Courtesy: Safecoze

It is necessary to ensure that packaging materials used for blisters comply with international standards such as FDA and EMA for safety and quality purposes. Similarly, complying to the regional pharmacopeia standards for enhanced drug stability is also very important. In addition, child-resistant and tamper-evident features may be needed for certain drug categories.

Production Efficiency and Cost

Blister packaging process- Picture Courtesy: ppsnordic.com

Another significant factor to look for is the production efficiency and cost. In case the production volume is high then ALU-PVC blisters are cost-effective and speedy in manufacturing. However, if the products are of premium quality then choosing ALU-ALU blisters may cost you higher but they are worthwhile for better shelf-life.

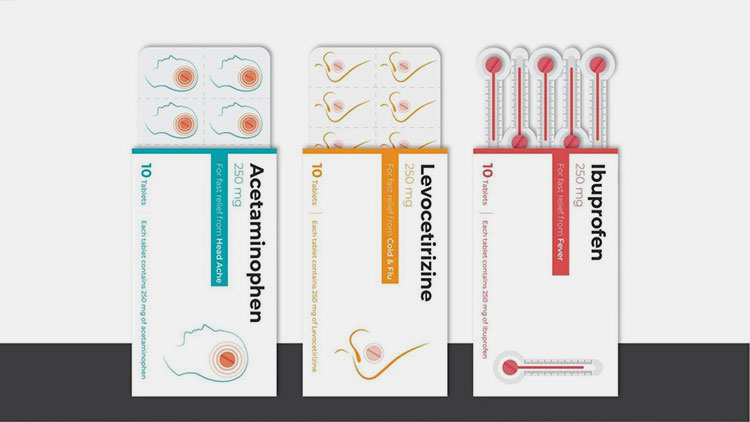

Branding and Market Presentation

Intuitive medicine packaging- Picture Courtesy: worldbranddesign.com

While the barrier properties and compliance of blisters matters the most, branding and market presentation is also very instrumental. In this way, transparent PVC blisters showcase tablets and capsules which gain patient trust. While as, paper or printed backing provides adequate space for branding, dosage instructions, and regulatory information.

Conclusion

To conclude, we are glad to have communicated about A Comprehensive Look At Medical Blister Packaging. The importance of blister packaging is on rise and with that it becomes necessary to have adequate information about the materials used for its manufacturing and the technology behind. It offers significant advantages for drugs preservation and protection. Medical blister packaging can be achieved by using specific equipment and through special process. For selecting the right solution, you must consider factors such as drug sensitivity, cost, and speed etc. If you are interested in buying the equipment, feel free to contact us!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours