Automatic Can Sealer Machine: The Complete Buying Guide In 2025

Out of many sealing techniques, automatic can sealer machine is one of the unique sealing machines that preserve material for longer periods. It is commonly used in the beverage, food and other large scale industries.

But before selecting a right type of automatic can sealer machine it is always necessary to have complete knowledge regarding it. Allpack in this regard is providing you complete guide of automatic can sealer machine to resolve your queries. So go through this and take the most out of it.

1. What Is An Automatic Can Sealer Machine?

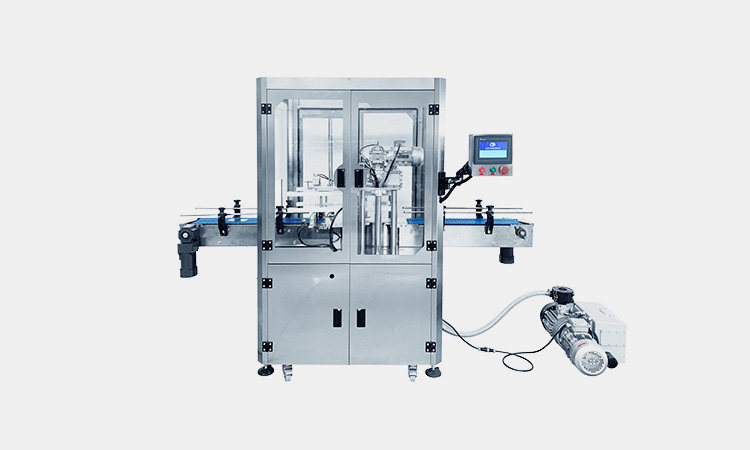

An automatic can sealer machine uses a can as a packaging material and seals it in a way that the products remains preserved and fresh for a longer period of time. An automatic can sealer machine undergoes complete automated process where minimum labor involvement is present.

Pressure, heat or vacuum type sealing methods are used to close the lid on the top of a can. Automatic can sealer machine is efficiently used in food processing, chemical and pharmaceutical industries.

2. What Products Are Sealed And Can Not Be Sealed In An Automatic Can Sealer Machine?

Products Sealed Using An Automatic Can Sealer Machine

- Food Products

Foods and beverages like soda, soups, jams, fruits, pet foods and vegetables are also commonly packaged using an automatic can sealer machine. Same quantity of products is filled in each of the can and the sealing done on final packaged can attract the customer toward its attire.

- Chemical and Pharmaceutical Products

Chemical, personal care, paint, medical and adhesive products also require automatic can sealer machines to get a long lasting effect and security. Products like baby milk powder, paint colors, creams and etc. are available in cans that are sealed using an automatic can sealer machine.

Products Can Not Be Sealed Using An Automatic Can Sealer Machine

Some available materials cannot be sealed using an automatic can sealer machine. Out of them some of the products are

- Temperature Sensitive Products

Some of the food and medical products like frozen meat, fish, injections and others that are highly temperature sensitive cannot be sealed by an automatic can sealer machine due their special handling. The products can lose their actual health if they are not properly handled.

- Environment Requiring Products

Some of the products like coffee bean and coated sugar that require atmospheric influence are impossible to be packaged in cans. These types of products require open air because if they are sealed tightly, they can lose all their natural flavors and ethnicity.

3. What Types Of Cans Are Sealed And Can Not Sealed ByAn Automatic Can Sealer Machine?

Various types of cans can be sealed using an automatic can sealer machines depending upon their size, material type and thickness. Some of the cans that can be sealed using an automatic can sealer machine

- Aluminum Cans

Cans that are made up of aluminum are most likely to be sealed using an automatic can sealer. These types of cans are used in packaging of beverages and food items due to its lightweight and material strength.

- Composite Cans

Cans that are made up of composite materials like plastic, paper, aluminum and wood are also sealed using an automatic can sealer machine. Most of the food drinks and materials are packaged in these types of cans.

- Glass Cans

Cans for jams, pickles and ketchup are usually available in glass material. These cans and jars are efficiently sealed using an automatic can sealer machine in food processing industries.

- Tinplate Cans

Some of the cans made up of tin-coat steel can also be easily sealed using an automatic can sealer machine in a highly automated manner. Chemical and beverage industry apply automatic can sealer machine in their processing units.

- Aerosol Cans

Products like hair sprays, room sprays, insect killers and deodorants use aerosol material in their packaging. The cans made of aerosol material can be best sealed using an automatic can sealer machine.

- Pressure Tank

Mostly fruits and vegetables are pressurized in tanks to preserve the purity and freshness of products. This ensures no entrance of microbes and provides greater life to them.

- PET Cans

Polyethylene Terephthalate plastic is also used to make cans that are sealed using an automatic can sealer machine. These types of cans are mostly used to seal food and beverages products.

So there are plenty type of cans for your choice.

Cans Can Not Be Sealed By Automatic Can Sealer Machine

Automatic can sealer machines follow high sealing pressure and that is why the cans with low bonding strength or irregular shape cannot withstand the pressure and heat an automatic can sealer machine applies.

Mostly cans made up of paper or plastic are those that have low material strength and cannot bear the pressure of an automatic can sealer machine. Other than that the cans that have pre-existing defect like burr, dent or damaged rim are also not suitable for sealing using an automatic can sealer machine.

4. What Are The Applications Of An Automatic Can Sealer Machine?

Automatic can sealer machines have wide range of applications due to their highly versatile actions and sealer application. Some of the industries where these automatic can sealer machines used are

- Food and Beverages Industry

As the products are directly related to human life, contaminated food can affect the human body in a negative manner. Automatic can sealer machines are used in food and beverages industries to preserve fruits, vegetables, drinks and other products from contamination due to the airtight sealing. They shelf life of food also increases by this airtight sealing.

- Pharmaceutical Industry

Products manufactured in pharmaceutical industry do also require high level of consideration while packaging. Microorganism or bacteria if entered in the pharmaceutical product can cause harmful effects. Automatic can sealer machines are used in pharmaceutical industry to perform airtight packaging of vitamins, medicines and other supplements in an efficient and protective manner.

- Chemical and Cosmetic Industry

Another industry that has wide range of automatic can sealer machine is chemical and cosmetic industry. Paints, colors, chemicals and cosmetic related items that are packaged in cans are sealed using this type of sealing machine. It blocks the entrance of bacteria and other microbes and allows the chemical products to be useable for a long period of time.

5. What Are The Advantages Of An Automatic Can Sealer Machine?

After knowing about the automatic can sealer machine application, some of the advantages that you can gain using an automatic can sealer machines are

- Compatibility

Different types of can made up of different materials can be easily compatible in a single automatic can sealer machine. The manufacturer doesn’t require any separate machine to perform its tasks.

- Consistent

Automatic can sealer machines are highly reliable as they perform consistent sealing on each of the can that is to be packaged. There is a minute level of chance for any difference between two cans sealed under automatic can sealer machine.

- High Volume Productivity

An automatic can sealer machine has an ability to handle large volume production setups with safety and precision.

- Customer Attraction

An important advantage that an automatic can sealer machine gives is that the customers are directly attracted towards its packaging and sealing. This can increase the sales demand of any manufacturer.

6. What Is The Working Principle Of An Automatic Can Sealer Machine?

Working Principle of the Automatic Can Sealer Machine

An automatic can sealer machine uses hot air for heating of lid and then fusing of it. The principle is as

- Initially the cans are placed on the conveyors of machine and are directed towards the heat sealing system.

- Once the can reaches the sealing unit, the machine senses its presence and directs the lid feeder to release the lid. Here the lids are heated using hot air present in the heating system.

- This heated lid easily fuses on the top of can and afterwards the sealing of edges is performed.

- The sealed cans are then taken out of the system through these conveyors.

7. What Are The Main Components Of An Automatic Can Sealer Machine?

The automatic can sealer machine is not complicated and the main components are

- Sealing Head

The sealing head of an automatic can sealer machine plays the most important part in its operation. It applies heat and pressure simultaneously both at the same time on the lid of can and seals it. Sealing head of an automatic can sealer machine performs highly precise and accurate lid sealing to prevent any type of contamination.

- Lid Feeder

The lids that are to be installed at the top of a can are placed in this lid feeder. The lid feeder of an automatic can sealer machine supplies lids to the sealing head of an automatic can sealer machine and is directly controlled by highly sensitive sensors.

- Vacuum Pump

The air present inside the can is released by this vacuum pump present in an automatic can sealer machine.

- Temperature Controllers

Sensors and actuators are present in automatic can sealer machine that act as temperature controllers. As the sealing temperature gets out of its applied limits, the actuators get activated and directly maintain the temperature to perform effective sealing.

- Conveyors

Conveyors are used to move the cans within the system. In an automatic can sealer machine complete movement of can is controlled by these conveying systems.

- Automatic Sorting System

An automatic can sealer machine uses automatic sorting unit in which the packaging cans are sorted and aligned properly to perform ideal operation.

- Automatic Feeding System

This is the part of an automatic can sealer that feeds the can to the sealing head. Feeding system segregates the cans according to the sealing pattern that is to be performed.

8. What Types Of Automatic Can Sealer Machine Are There?

There are various types of automatic can sealer machine for your choice, some of the automatic can sealer machines depending upon the type of sealing are

- Rotary Can Sealer Machine

A rotary can sealer machine applies metal lids and caps onto the cans. The rotational central axis moves the can while sealing head applies pressure onto the lid. By this sealing is performed on lid. Airtight seal preserves the contents for a longer time. Food, beverage, and chemical industries mostly use a rotary can sealer machine.

- Vacuum Nitrogen Can Sealer Machine

Vacuum nitrogen can sealer machine are the types of vacuum can sealer machines that are used in the food and beverage and chemical industries to fill cans and then remove air through vacuum pressure and filling nitrogen into the cans. Precise amount of nitrogen gas protects from oxidation and product spoilage.

It provides airtight sealing to maintain the freshness of products and helps in extending its shelf life. Other than food metal, electronics, hardware and plastic items are also sealed using vacuum can sealer machine.

- Induction Can Sealer Machine

Induction can sealer machine works by applying an electromagnetic field to the lid of the can, which induces an electric current and generates heat, causing the lid to melt slightly and fuses to the rim of the can. Metal, food and beverage usually use induction sealer for reliable sealing.

9. What Are The Differences Between An Automatic Can Sealer And Capping Machine?

Both automatic can sealer machine and capping machines are used to apply the top covering to their packaging materials. But the operation and application of both the machine has greater difference. The differences among both of the machines are

- Working Principle

The operation of an automatic can sealer machine is designed in a way that the cans are sealed in a continuously running process. One after another cans are sealed with high precision and accuracy in automatic manner. Once the can is entered in the sealing system, a lid if fed on its top and the principle of sealing takes place. An automatic can sealer provides airtight sealing and prevents contamination.

On the other hand, a capping machine depends mostly on the efficiency of its operator. The machines are available in both manual and automatic operations but are mostly designed to produce batch processes. The operator is responsible to place the cap on the top and then it is tightens with the help of screw block. After capping process the worker takes out the product of the system.

- Characteristics

It can be count as a demerit of an automatic can sealer machine that it is designed to perform sealing on specific type of cans only. Products like drum, bottle or jar cannot be sealed using an automatic can sealer machine.

Unlike an automatic can sealer machine, a capping machine is compatible with any type of can, jar or bottle and also does not depends on the size and shape of product. Capping can be performed on these packaging materials and that is an important characteristic of the machine.

- Application

An automatic can sealer machines are used for applying lid on the top of cans and then heated to perform airtight sealing. These types of machines are applied food, pharmaceutical and chemical industry.

The design of capping machine is to tight the screws of caps on the top of bottle can or jar and gives a simple opening to it. Any type of product that is manufactured using cap on its top can be applied under a capping machine.

10. What Are The Auxiliary Components That Are Associated With An Automatic Can Sealer Machine?

There are always few auxiliary components that take part to complete the sealing process of an automatic can sealer machine. These parts hold a secondary role and can be adjusted according to their usage. Some of the auxiliary components that are associated with an induction sealing machine are

- Air Compressor

Some of the automatic can sealer machines use air compressors for providing required air pressure to the system. These air compressors manage the flow of air and if at any stance the pressure gets effected, it can directly cause poor sealing.

- Vacuum System

For removal of atmosphere particles and air present within the can, vacuum systems are present in most of the automatic can sealer machines.

- Conveying System

Intake and exit conveyors are associated with an automatic can sealer machine that ensures proper flow of can from start to end.

- Laser Inkjet

Cans that are sealed using an automatic can sealer machine hold information regarding its ingredients, manufacturing and other important things on its outer surface. Laser Inkjets are used to print this information on plastic or paper wrapping of cans.

- Cooling System

To prevent poor and unhealthy sealing, a cooling system is present in an automatic can sealer machine that cools down the heating temperature immediately and supports in application of efficient sealing.

- Barcode Writer

Material manufacturing and expiry dates are using these barcode writers. These writers are also used to give unique identification to each one of the can produced as a result of batch process.

- Sensors

To detect the presence of can under the filling nozzle and in the sealing system is sensed by highly active sensors. They also detect the flow of cans on the conveyor and signal the programmable system regarding it. Sensors help to avoid wastage of material also.

11. Why Nitrogen Need To Be Filled With Automatic Can Sealer Machine?

Nitrogen need to be filled with automatic can sealer machine due to various reasons. Some of them are

- Product Protection

The food industry has always been focused on providing consumers with fresh and high-quality products. However, food items are susceptible to spoilage due to bacteria and fungus that grows in the presence of oxygen.

In order to extend the shelf life of food items and preserve their freshness, nitrogen gas is used in the packaging process. Nitrogen gas creates an environment that is inhospitable to bacteria and fungi, thereby preventing spoilage.

- Minimizing Risk Of Contamination

These machines offer a number of benefits, including consistent and efficient operation, which is essential for large-scale packaging operations. The use of automatic can sealer machines also minimizes the risk of contamination, as the machines are designed to prevent the introduction of foreign matter into the packaged food.

- Food Preservation

In addition to preserving the freshness of food items, nitrogen gas also provides protection against oxidation, which can result in the loss of flavor, aroma, and nutritional value. This is especially important for items such as coffee and chips, which are highly susceptible to oxidation.

- Maintaining Oxygen Level

When the automatic can sealer machine is used to fill the packages with nitrogen, it first vacuums the air out of the package. The nitrogen gas is then introduced into the package, replacing the air. This creates an environment with a low oxygen level, which is hostile to bacteria and fungi.

- Product Integrity

The use of nitrogen in the packaging process also helps to maintain the integrity of the food product. For example, chips that are packaged with nitrogen are less likely to become crushed or broken, as the nitrogen gas provides a cushion to protect the chips from damage.

Conclusion

Automatic can sealer machines are highly efficient and productive machines that are used to seal cans are made up of different materials. There are always queries related to selection of right type of automatic can sealer machine and for this we Allpack are here to assist and guide you. For further details kindly contact our customer care agents or visit our website http://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide