Universal Crusher: The Complete Buying Guide In 2024

Are you familiar with the universal crusher? The functions which it performs? Or the reason for its growing popularity in every sector associated with drug manufacturing, food processing or chemical industry? If you have ever heard about it, you will definitely know the importance of a universal crusher in modern Industries. However, if it is unknown to you, there we have some interesting facts about a universal crusher that can benefit you in a lot of ways.

Universal crusher is innovative equipment employed to deal with the heavy-duty task of reducing wide number of material size by compression. Its automatic functioning, vast application and safe processing lowers damage, human labor and give you outstanding results. These and many other aspects of a universal crusher are highlighted below. Just take time and go through this article for bringing revolutionary change in your existing production line!

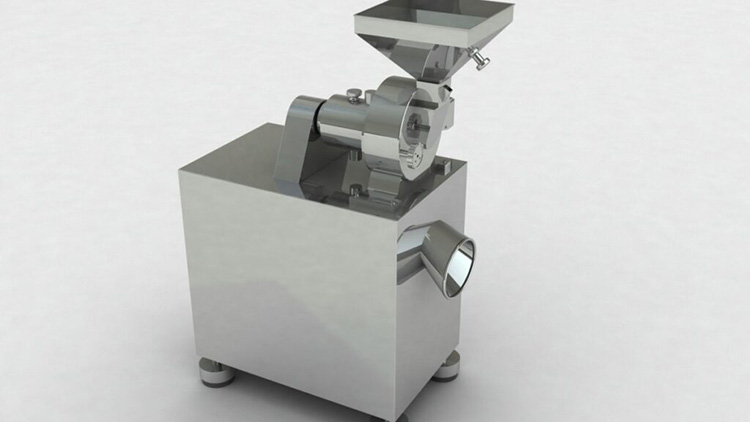

1.What Is A Universal Crusher?

Universal crusher is a type of grinding machine that effectively crush hard to soft materials into the lowest possible form. These materials include herbs, spices, vegetables and fruits seeds and chemicals etc. It has simple mechanism of crushing that starts with material loading in hopper. These materials the pass through number of sharp knives located in the crushing chamber and get discharged as fine particulates mostly in form of powder.

This machine is among important accessories being utilized in pharmaceutical industry, food industry and chemical industry as it is the requirement for making drugs, chemical formulations and food items. There are various kinds of universal crusher you would find in market which better suits the varying needs of modern businesses by providing additional safety.

2.Enlist The Products Which Can Be Processed By A Universal Crusher?

Universal crusher is capable of processing huge number of products from diverse sectors. Some of the prominent materials are mentioned below:

Spices

Spices is the most common thing processed by universal crusher. In the past, people used to grind condiments by using mortar and pestle, as it gives however, the introduction of universal crusher has eliminated the tiresome

Dry Fruits

Dry fruits such as peanuts, almond, pistachio and walnuts are most of the time sold in crushed form, for which a universal crusher can be used.

Herbs

Herbs are botanical plants which are used for medicines, adding flavors and colors to meal. They are also well crushed by this machine before using.

Wheat

Wheat is one of the substantial crop which can be crushed by universal crusher. It contains high number of proteins and vitamins and supply your body with starch and energy. Most of the countries around the world consume wheat as an obligatory part of meal.

Rice

Rice is a cereal crop rich in carbohydrates which can be used for making recipes and sweets. It is widely used for making products like semolina, pasta and vermicelli rice is first crushed with the help of universal crusher.

Pulses

There are large varieties of pulses such as black lentils, chickpeas, kidney beans and split peas among others. All these contain good amount of zinc, calcium, iron and magnesium which are helpful in the fulfillment of nutritional requirements. Most of the time, they are used in powdered form for making recipes for which they are crushed by a universal crusher.

Tea

Tea is derived from the leaves of plants named camellia sinensis which is taken as a hot drink by infusing the crushed leaves into hot water. A universal crusher is best capable to crush all variations of tea including black tea, green tea and red tea etc.

3.What Are The Benefits Of Using A Universal Crusher?

By using a universal crusher you can get substantial benefits that will boost your business growth. These benefits are explained below:

Easy Usability

Using a universal crusher is as simple as operating any other grinding machine. There is no rocket science behind its use, you can operate it conveniently without having any experience. This also benefits you economically by eliminating the need for labors.

Portable

This machine is highly portable with advanced structure and precise composition. You can easily move it from one place to another.

Uniform Crushing

It must be noted here, that many sectors such as medical industry needs uniform particles of ingredients for producing medicines. A universal crusher is thus perfectly equipped with gadgets which enable it to better crumble the loaded material and give them final shape of uniform particles.

Safe Performance

The ancient method of crushing food products was laborious and dangerous, as most of the time airborne spices and herbs get into eyes. However, the universal crusher is completely safe for both the user and the material for the reason of reducing harm and ensuring product safety.

Effective Results

Universal crusher is best known for its effective results which can be seen in the solutions prepared by it. The number of sharp cutters located in crushing chamber reduce the size of items to the lowest possible form. Hence, they can be better used for making pharmaceutical formulations and other purposes.

Wide Application

Another benefit of a universal crusher is its flexibility and versatility which makes it capable to process number of hard to soft materials. For instance, chemicals, crops, herbs are all different products which can be perfectly crushed by this machine.

4.How Would You Operate A Universal Crusher?

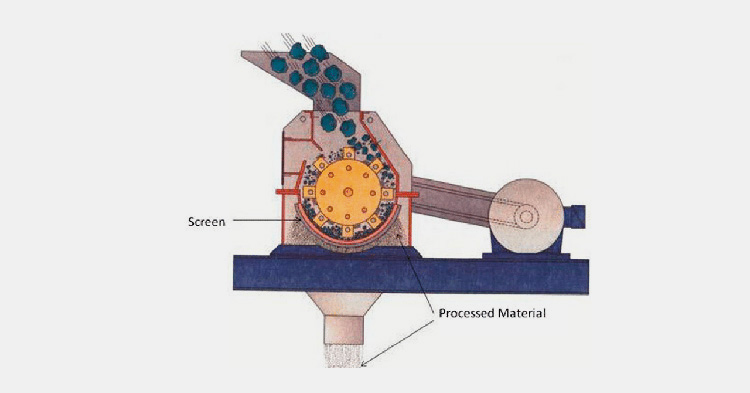

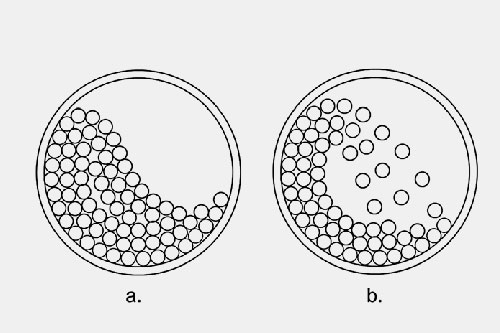

Picture Courtesy: Research Gate

Universal crusher works by constantly rotating the fixed and movable knives plate. Its process is quite convenient which consists of the following stages:

Feeding

The very initial step of operating universal crusher is to feed the hopper of machine with material either manually or with the help of gravity filling machine.

Crushing

After feeding comes the crucial phase of crushing, where the crushing chamber come into action when loaded material is delivered from hopper. These substances are well crushed by the speedy movement of opposite blades and knives. The constant friction of knives teeth reduce the size of material and turn it into powder.

Screening

After the completion of each cycle, processed material is screened by separating the fine particles in bottom and rough substances remains in the chamber for further crushing.

Discharging

In the final stage, fine particulates are released into a container by the product outlet port.

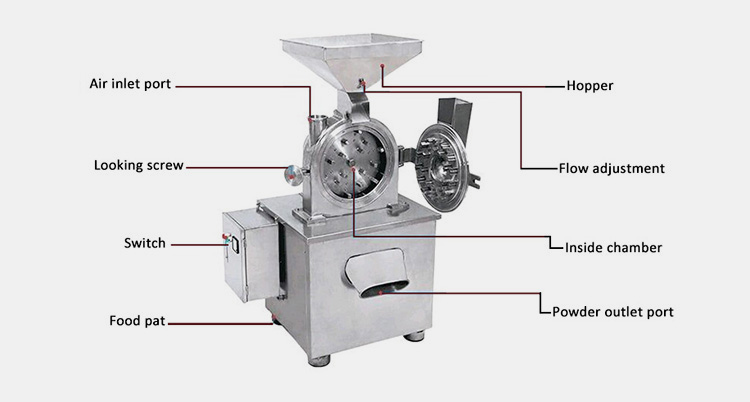

5.Describe The Structure And Functions Of A Universal Crusher?

A universal crusher is composed of several parts each performing different tasks. They are described below in detail:

Hopper

Hopper is a hollow container placed at the top of universal crusher where bulk products are loaded before their processing. The larger the hopper the more would be machine's capacity to crush material in one run.

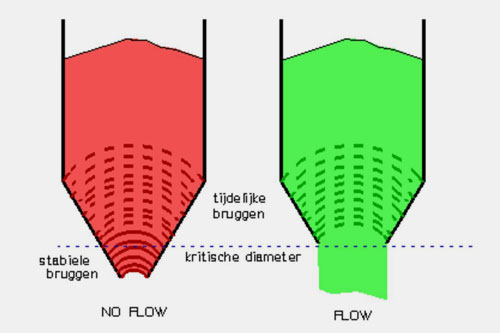

Flow Adjustment Device

Flow adjustment device is located at the end of hopper connecting it to the crushing chamber. By using this device, flow of material which enter into crushing chamber can be adjusted.

Air Inlet Port

As the name indicates, air inlet port is an open area above the crushing chamber. Its purpose is to provide air for the continuous smashing of material.

Water Cooling Inlet

Sometimes the machine get heated during crushing and this can affect the quality of material being processed. Therefore, a water cooling inlet is attached outside the crushing chamber to keep the temperature normal.

Locking Screw

There is a part over crushing chamber that joins the sieving cavity to openable knife plate, this part is known as locking screw. It helps in tightly locking the crushing chamber, so, material being processed would be completely isolated from external environment.

Crushing Chamber

It is the core element of a universal crusher that performs the actual task of crushing. It consists of sieving cavity and knife plate with sharp edges. During the process, sieving cavity adopt the state of constant rotation and let the product fully crushed through knives.

Powder Outlet Port

This part of machine is also known as discharge port which is used to deliver the final finished material from crushing chamber in form of powder.

Electric Cabinet

Electric cabinet is the motherboard of universal crusher which composed of the electric motor, machine switching system unit and integrated functions. It controls the entire mechanism of crushing.

Foot Pads

There are four foot-pads attached to the external body of machine which makes it vibration resistant during operation.

6.Which Are The Factors That Influence The Size Of Particles In A Universal Crusher?

There are some basic factors which can directly influence the size of particles produced by a universal crusher. These are as follows:

Size of Loaded Material

Oversized loaded material such as large salt stones can cause problems during crushing. Instead, the size of the material processed by various machines is fixed. Make sure the material you put in the hopper is the right size for the machine.

Crushing Blades

Crushing blades are another element that can affect particle size. The particles would be absolutely crushed in the best way possible if blades are sharp and in close contact with opposite side knives plate. However, crushing hammers with excessive gaps and flat edges would eventually result in the production of coarse particles.

Nature of Material

It means that material you are processing is fully dry or semi liquid. If the material have presence of any sort of liquid, it will be crushed inadequately and would get stick together.

Time Duration

Time duration for each cycle is a necessary factor for reducing the size of particles. However, it depends upon the nature of object. For instance, soft products would require less crushing duration compare to those with hard structure.

7.What Are The Different Types Of Universal Crusher?

A universal crushing machine can be divided into two types depending upon the type of material which they are capable to process. They are as follows:

Universal Crusher for Dry Products

This type of universal crusher is a standard machine which is used for grinding dry substances into powder. It can be used in different industries from pharmaceutical and chemical industry to foodstuff industry. It is highly portable, precise and covers less space.

Components

The structure of machine is compact having few but major parts such as hopper, crushing chamber, electric cabinet, product outlet port and mainframe.

Working Principles

Working principles of the machine are too simple. The process starts by feeding hopper with material which is then delivered to crushing chamber to carry out grinding. Once the material get processed, it simply falls down from discharge chute into a container.

Universal Crusher For Oily Products

Another type of universal crusher is used for processing material having oily nature such as almond, peanut and walnut. It can perfectly produce the desired size of particles by simply altering the distance of crushing rollers.

Components

It has vertical shape body with series of crushing rollers. The main components of machine include feeding station, crushing chamber, electric unit, discharge port and foot pads.

Working Principles

It can be operated by putting bulk products into feeder. Material will then pass through number of crushing rollers to make the best particles of desired level. After the process get completed, finished particles will be discharged be the chute into collection tray.

8.Highlight The Major Areas Where A Universal Crusher Can Be Used?

Universal crusher is applicable to crush enormous things from different industries. Some of these areas where its use is obligatory are taken into account:

Food Industry

In ancient times, people used different types of tools such as mortal and pestle for grinding spices, seeds, beans and rice. This method was quite difficult that required too much physical force and time which often leads to harm during process. Therefore, the introduction of universal crusher has created much ease for food industries to take its help and process huge number of products without any danger.

Pharmaceutical Industry

Medicines and drugs are made from the combination of different ingredients which are derived from natural sources such as plants, herbs, fruits and vegetables. These materials are passed through number of stages for deriving the desired ingredients among which the crushing is a crucial step that is carried out by a universal crusher.

Herbal Industry

The term herb encompasses variety of plants, leaves, flowers and seeds carrying great benefits for human health. The importance of herbal industry is expanding day by day, as most of the people prefer using herbal products over high dose pharmaceutical drugs for many reasons. This is escalating the production need of herbal industry, eventually making the use of a universal crusher inevitable.

Chemical Industry

Similar to other things, chemicals which may be in form of organic, inorganic or minerals are used for various purposes such as making glass, cosmetics and dyes etc. These chemicals need to be transformed from its raw form to purified form. During this phase, universal crusher play a key role in providing crushed ingredients which can be used for further processing.

Pigment Industry

Dyes and colorants come from stones, cost tars and petrochemicals which needs to be well crushed. Hence, the use of a universal crusher is also realized in pigment industries.

9.How To Clean And Maintain A Universal Crusher?

There is always a room for maintaining your machine and keeping it clean for smooth running. Similar is the case with a universal crusher, and you should perform this task responsibly to make your machine stay longer. Keep following the instructions given below:

Cleaning Of Universal Crusher

Cleaning makes your machine more efficient and provide hygienic environment for your material to be processed. Therefore, make sure your machine is clean after ending the operation. For proper cleaning, disconnect main power supply, disassemble the major parts such as hopper, outlet valve and crushing chamber. Clean these components through a cloth or air chiller. Keep away water from electric components.

Maintenance Of Universal Crusher

For daily maintenance, keep the moving parts of machine well lubricated and replace oil after every 5 months. Seal the machine properly after daily task get completed. Inspect the screws before starting operation and tight them well.

10.What Are The Malfunctions Of A Universal Crusher And How Can They Be Cured?

Make a comprehensive inspection of your machine before starting and during operation. Here, we have mentioned some solutions to the possible problems which may occur during operation of a universal crusher. Make sure to understand them:

| No | Malfunctions | Causes | Solutions | Pictures |

| 1 | The outlet valve of hopper get blocked | It occurs when the hopper is overload or space is narrow for passing material | Reduce the material amount in hopper and increase material passing space through flow adjustment device |  |

| 2 | Too much vibration | The possible causes are inaccurate placing of mallets or loose screws | Remove crushing knives and put them back in accurate way. Join the nuts and screws tightly |  |

| 3 | There is problem in grinding process | The incorrect placement of opposite knives create grinding issues | Make sure the gap between grinding mallets is not too large nor too small |  |

| 4 | Material get stick during crushing | The possible cause is presence of water which can lead material clotting | Use material which is fully dry and keep the air inlet port open for free flow of air into machine |  |

11.What Are The Standard Quality Certifications Required For Assessing The Quality Of A Universal Crusher?

In a world where thousands of industries are producing machines of different types, it becomes difficult to find trustable supplier for purchasing right machinery. Therefore, in this question, we have provided you the international quality certifications which will determine whether the machine is complying quality standards or not:

International Organization for Standardization (ISO)

ISO is an international organization for approving standard quality goods. Headquartered in Switzerland, ISO is composed of 160 representatives each from one member state. These members countries are authorized to certify the companies who manufacture industrial products in compliance with ISO standards.

Good Manufacturing Practices (GMP)

GMP is a system for manufacturing firms to ensure that they are engaged in producing goods of high quality. Industries complying GMP's regulations can be trusted for purchasing any type of machine.

CE Certification

CE marking indicates that products are recognized by European Union. Companies who get EC certification can sell their products throughout in European market without any hindrance.

12.Which Factors Should Be Considered When Buying A Universal Crusher?

There are some factors which should be kept in mind for getting a superior quality universal crusher. These factors include:

Feed Quantity

One of the foremost thing is to ask your vendor about feed quantity the universal crusher is capable of processing. It is important to know this fact, as most of the machines have small hopper and loading it too much can cause blocking of material delivery to crushing chamber.

Material Properties

Another point to look for is the material properties of machine. It includes the breaking behavior of universal crusher which it adopts for smashing. For instance, the types of blades and knives can affect the shape and size of material.

Fineness Requirement

You can also consider the fineness requirement of output material. A superior universal crusher can give you extra fine finishing of material. On the other hand, ordinary machines will give you final output in form of rough particulates.

Feed Size

Using a universal crusher does not mean that you can put objects of every size, instead there is maximum size limitation for feed products. Thus, it is better to ask the supplier about the size of feed the machine can crush.

Conclusion

To sum up, a universal crusher is the inevitable part of every industry associated with producing drugs, food products, chemical formulations and cosmetics. It can benefit manufacturing process by giving higher throughput while reducing waste and time. Hence, it is the key for successful businesses. If you have understood the above details you would be also wishing to make it a part of your production line. In this way, we recommend you to prefer Aipak Pharma, which is a renowned supplier of all types of pharmaceutical applications with ergonomic structure, effective performance and full time customer support.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide