How Will You Benefit From ALLPACK Chemical Filling Machine?

Anti-Corrosion Design

All liquid-contact parts are made of SS316L or PTFE materials for long-lasting protection.

Flexible Filling Options

Available in 2–12 nozzle configurations, suitable for bottles, drums, jerry cans, and more.

PLC + Touchscreen Control

Intuitive operation with real-time volume monitoring and adjustment.

Explosion-Proof Options

Safe for flammable or solvent-based liquids.

CIP (Clean-in-Place) System

Fast cleaning to prevent cross-contamination.

High Accuracy

±0.2% filling precision even for high-viscosity.

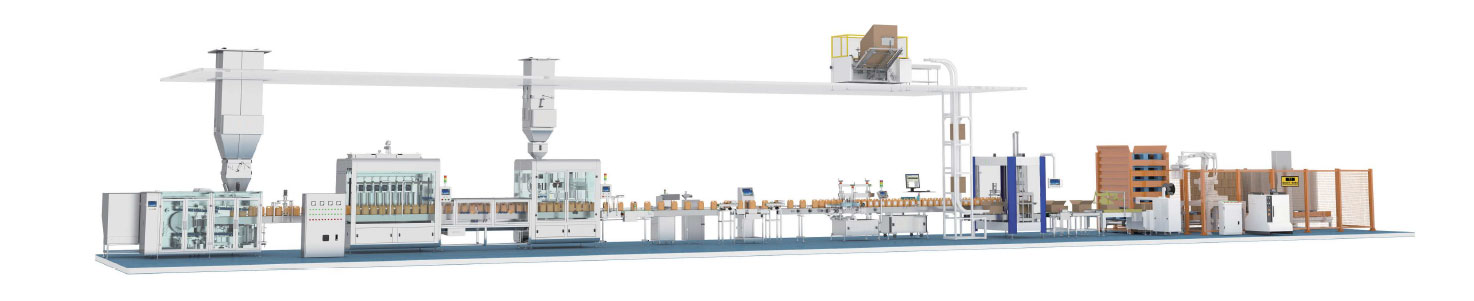

Various Chemical Filling Machine Production Line For Your Choice

Automatic 1‑5L Chemical Filling Machine Production Line for Bottles and Small Containers

Allpack 1-5L chemical filling machine is designed for corrosive and sensitive liquids, it has durable PP construction and an intuitive PLC touch screen interface, and it can accurately fills 1‑5L bottles with minimal waste, improving production efficiency and ensuring operator safety. The whole chemical filling machine production line is ideal for small to medium-scale chemical manufacturing and laboratory-scale production.

Corrosion-Resistant Materials

High Filling Accuracy

Wide Capacity Range

5‑30L Drum Chemical Filling Machine Production Line with High Accuracy and Fast Operation

Allpack 5-30L chemical filling machine is engineered for 5‑30L plastic or metal drums, this filling machine features a precise weighing system and chain-driven mechanism for stable, consistent filling. Dual-speed modes allow efficient handling of different liquid viscosities, reducing errors and chemical waste. The whole chemical filling machine production line is perfect for industrial chemicals, detergents, and cleaning liquid filling and sealing.

PLC + Touch Screen Control

Dual-Speed Filling System

Anti-Foaming Design

200L Large Drum Chemical Filling Machine Production Line for Industrial Chemical Manufacturing

Allpack 200L chemical filling machine is designed for 200L drums packaging, it can provide automatic drum positioning, real-time weight feedback, and precise filling control. This whole production line can support high-volume production of disinfectants, detergents, and other industrial liquids. With enhanced safety features and corrosion-resistant materials, it ensures both operational efficiency and product quality consistency.

Explosion-Proof Structure

Easy Integration

Real-Time Weight Feedback

Ton‑Container Chemical Filling Machine Production Line for Large-Scale Manufacturing

Allpack ton drum chemical filling machine is capable of automatically filling ton-sized containers, it can handle both foam and non-foam chemical liquids efficiently. Equipped with real-time monitoring, automatic alarms, and robust anti-corrosion construction, the whole production line can ensure safe, high-speed, and precise filling. It is ideal for large chemical plants requiring consistent output and operational reliability.

Automatic Leak Detection

Safety Interlock System

Adjustable Nozzle Height

Why Middle Eastern Manufacturers Choose Us?

Proven stability in hot and humid environments

Local service coverage in UAE, Saudi Arabia, Egypt, and Turkey

Support for customized filling lines and integration with labeling/packaging systems

Decades of experience in chemical and pharmaceutical liquid filling solutions

Frequently Asked Questions About Chemical Filling Machines

1.What types of liquids can your chemical filling machine handle?

Our machines are designed for a wide range of chemical liquids — including acids, alkalis, detergents, solvents, lubricants, disinfectants, and other corrosive fluids.

Each system can be customized based on viscosity, foaming characteristics, and chemical compatibility.

2.What materials are used to resist corrosion?

All contact parts are made from SS316L stainless steel, PTFE, or anti-corrosion plastics to ensure long-term resistance to acids and solvents.

Optional explosion-proof components are available for flammable liquids.

3.Can the machine fill both small bottles and large drums?

Yes. We offer modular nozzle designs from 2 to 12 heads, supporting a wide range of container sizes — from 100 ml bottles to 1000 L drums or jerry cans.

4.How accurate is the filling process?

Our high-precision flowmeter and servo control system ensure ±0.2% filling accuracy, even for high-viscosity or foaming liquids.

5.Is the machine suitable for hot or humid environments like the Middle East?

Absolutely. The machines are built with sealed electrical systems, heat-resistant structures, and IP65-grade enclosures, ensuring stable operation under harsh environmental conditions.

6.Do you provide local installation and service in the Middle East?

Yes. We support clients in UAE, Saudi Arabia, Egypt, Oman, Turkey, and other GCC regions through on-site installation, operator training, and technical support.

7.How easy is cleaning and maintenance?

Our filling lines come with CIP (Clean-in-Place) systems and quick-release pipelines, allowing for fast cleaning and product changeover with minimal downtime.

8.Can the machine be integrated into a full production line?

Yes. It can be connected with capping, labeling, and packaging machines for a complete chemical liquid production line — fully automated and GMP-compliant.

9.What safety features are included?

Safety systems include emergency stop buttons, level sensors, automatic leak detection, and explosion-proof design options to ensure safe operation with hazardous liquids.

10.How can I get a quote or test my product?

Simply send us your liquid sample or viscosity data. Our engineers will recommend the most suitable model and provide a customized quotation within 24 hours.

Make Every Fill Count

Whether you’re upgrading an existing line or building a new chemical plant, choose a system that brings accuracy, durability, and compliance together.

Request a Quote Today

Discover how our chemical filling machine can optimize your production efficiency across the Middle East.