Your Ideal Continuous Sealing Machine Manufactruer

- Step-less Speed Regulation

- Various Materials Continuously Sealing

- Electronic Constant Temperature Control

Continuous Sealing Machines

Are you a fully-equipped pharmaceutical, food processing plant, or stationary factory? Are you looking for equipment sealing your products in individual containers or raising the working efficiency of your clients, so that to extend the shelf time of your products? One of the pieces of equipment that you may consider adding to your cart is the continuous sealing machine. The continuous sealing machine can seal plastic films made from various materials continuously. A sealing machine is a machine for sealing a container filled with a package. In order to seal the product, maintain the product quality, and avoid product loss, the packaging container needs to be sealed. Allpack continuous sealing machine is consistent in transferring, sealing, and lettering. There are a lot of materials that can be sealed by the Allpack continuous sealing machine. It adopts the technologies of electronic constant temperature control and transmission machinery of step-less speed regulation. Continuous band sealers are very versatile as they can seal thermoplastic bags of any size, length, and thickness.

The Buyer's Guide

Continuous Sealing Machine: The Complete Buying Guide in 2025

When we discuss buying a continuous sealing machine there are many different aspects that are involved. It includes the type of machine, the model, and what type of material is being persevered.

Spending money on is sealing machine is indeed a big investment for your venture. While thinking about the acquisition of new packing machinery, you will need to set aside the effort to get to know about the product details.

Assuming you need to realize what sorts of apparatus are accessible, the materials they run, their appropriate and safe working methods, and how to keep them running at top execution, this article will furnish you with all the data you are searching for.

Let’s get started.

1.What Is A Continuous Sealing Machine?

Before getting into the details, first, learn about this machine and its purpose thoroughly.

Continuous sealing machines are the most efficient and versatile sealers on the market today. It is ideal for heat sealing of laminated or non-laminated pre-made pouches. You will get continuous carrying, sealing, and printing in one operation with a continuous band sealer. If you want to speed up your production line and automation is not an option, then a continuous sealing machine is what you need. The materials used in the construction of such machines include powder-coated metal alloys besides stainless steel. These band sealers are perfect for sealing individual bags automatically. It offers you many benefits since it rapidly seals many different bags, including all types of plastic bags.

The sole purpose of a continuous band sealer machine is to securely seal individual packages and bags with liquids, sprays, powders or grains, and other similar contents. It also uses various packaging materials like aerosol containers, boxes, bags, pouches, cartons, and bottles. Therefore, you can handle everything from pet food and grains to construction rocks with band sealers.

Not only can the machine handle different grades of plastic materials, but it also comes with different types of models. It includes Nitrogen filling attachment, printing attachment, vacuum options, and heavy-duty continuous band sealers. You can set it to run vertically or horizontally according to your application. All these models adhere to industry standards, appropriate design, and safe handling. It’s better to consider a complete analysis of the sealer’s features and applications before selecting.

Undoubtedly, it is great to seal any thermoplastic material, including polyethylene, polypropylene, and foil laminations (you know the packages for holding coffee). But you will be amazed to learn that the machine has a variable temperature controller and speed control to accommodate a wide range of applications. Temperature is adjustable to suit various grades of materials.

2.How Does Owning A Continuous Sealing Machine Benefits You?

You should own a continuous sealing machine with conveyors if fast, sturdy, and hand-fed secure sealing are what you desire. It can improve the overall performance effectively and make your seal appear professional. It is easy to use and comes with synchronous speed adjustment.

Here are some of the reasons why you must own this best service provider machine.

Highly Versatile

Continuous band sealers are very versatile as they can seal thermoplastic bags of any size, length, and thickness. The most amazing feature is that it has adjustable or variable conveyor belt speed to accommodate materials with different thicknesses. You can raise or lower the conveyor belt in some models and even tilt it to a suitable angle. It can better penetrate heat to seal even the thicker materials.

Fast Sealing

A continuous sealing machine provides fast and stable operation since the operator does not have to wait for the seal cycle to end. It can be used uninterruptedly in the assembly line with a maximum speed of 24m/min. Thus, owning a band sealer increases your workforce by one person by decreasing packaging time in half.

Excellent Product Features

The machine adopts high powerful fine copper motor with strong conductivity and power. The closed gearbox helps in noise reduction and shock absorption. Good insulation makes the operation safer. And, most notably the machine is equipped with a PID temperature controller and speed control. It has two-way systems for vertical and horizontal configuration. Moreover, it has an adjustable two-way pulley system for pouch stability and clear embossing.

Applicable To All Industries

You should have one since it is suitable for all kinds of heat-sealed packaging bags. It can seal aluminum foil bags, Kraft paper, plastic bags, tea bags, shrink film, etc. Its versatility is useful in food, pharmaceutical, chemical, agricultural, lubricating oil, and electronic industries. A vertical band sealer is also suitable for solid and liquid products.

Equipped With Printing Device

Sealing and printing can be achieved in one operation with minimal manual movement. It is an optional feature in the latest models. It can have different sealing pattern effects along with printing date, time, and logo simultaneously with the sealing. Solid ink printing offers clear printing and instant drying. You can print out all the information about the product you want by using alphanumeric letters.

Isn’t it amazing that you get a secure, air-tight, and professional seal in one go?

Strict Quality Control

These machines come with strict inspection quality control tests of conveyor speed, the rotational speed of fans, the noise, and pure copper heating/cooling block testing. It has overload protection and a rubber cover to make the operation buttons more durable.

Simple Maintenance

Just like it requires minimal space, it needs minimum maintenance as well.

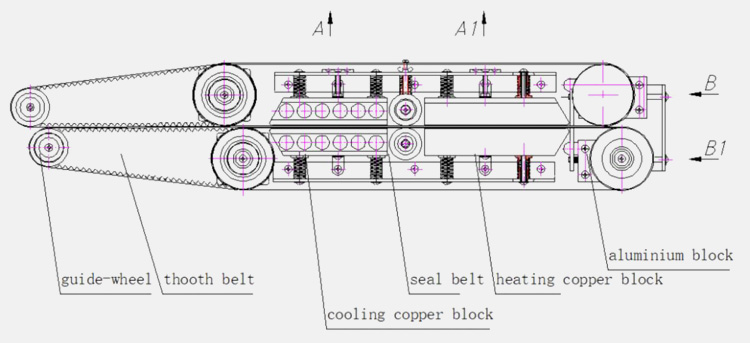

3.What Are The Parts Of The Continuous Sealing Machine?

Working of the Continuous Sealing Machine

A stainless industrial grade continuous band sealer comprises speed adjusting mechanisms, a sealing temperature control system, and a transmission system. Some models have two modes: vertical and horizontal set up to accomplish a wide range of applications and industries. Here is the principal working of all continuous heat sealing machines.

Basic Principle

A continuous pouch sealing machine is user-friendly and very easy to operate. Adjust the temperature and place the thermoplastic materials (PP, PE, laminates) bags on the conveyor to seal. The conveyor carries it forward and seals the bag instantly. There is no need for pushing or pulling.

Moreover, the continuous band sealers are the type of direct heat sealers (constant heat sealers). The operating principle is similar to that of impulse sealers by heating both jaws simultaneously. It results in better heat penetration to seal thicker materials. In the continuous method, the film passes through the heating up and cooling down areas.

The sealing cycle is executed stationary between sealing bars to perform the heating up and cooling down process. Since both heating and cooling jaws are sliding contact with the band’s interior, they must be made up of a suitable material. It needs to be PTFE-coated.

Working Of Continuous Band Sealer

The working of this machine requires minimal operating training, and it warms up fast. A band sealer in a continuous sealing cycle passes the material between the heating jaws, mainly irons containing a heating cartridge to seal it. The hot pressing sealing method provides heat to allow the continuous scrolling of the material at the sealing orientation to make it viscous. It then pressurizes to seal it. The material passes between cooling irons block as soon as the heating iron passes it. Here, it allows heat to dissipate and materials to stiffen. Then, the material goes between two knurled wheels for the knurling process. It gives a final appearance to the sealed package. Finally, the conveyor forwards the material on date coder, trimmer, on a packaging line, or let the material ends up in a carton.

Turn On the Power And Heat Switch

Switch on the circuit breaker. Turn on the heat, fan, and power switches and allow the pre-heat by starting it at low temperature for few moments. Running at a low temperature if the machine is not in use for a longer time will help to dry out any moisture left behind. It will cause a rapid rise in the temperature of the heating blocks. Belts and conveyors will also start moving simultaneously. Desired temperature and conveyor speed can be preset via temperature controller and speed adjusting tool. The settings will vary according to the bag material and thickness.

In the case of uncertainty, start the machine at a low temperature of 150 degrees (C) and gradually increase it. Notice at which temperature it seals your material and does not increase it above 200 degrees.

Place the Material On The Conveyor

When the adjusted temperature has been reached, put the bags on the positioning plate. Being an operator, you or your worker only need to feed the bags/pouches into the guide and conveyor system. It is advised not to push or pull the material when placing it on the guide. It can cause irregular sealing.

Sealing

These filled containers then move along an adjustable motor-operated conveyor belt. The conveyor then takes the plastic material between the heating blocks to seal together. It holds the bag until the sealing process is finished. Material is then passed through the cooling blocks to congeal.

Embossing or Printing Operation

The material passes through the embossing or printing wheel for a meshed seal line in the last process. Some models come with the options of embossing or solid dry ink coding. The embosser coder in the fr770 band sealer continuously prints characters on your pouch/bag. It uses pressure and not ink, but in printing, it uses dry ink. The embossing wheel is for one-line embossing with 15 characters. You need to install the typeset carefully. Moreover, the two-line embossing is an optional feature and can be purchased separately.

Many sealers are available with hot roll or hot stamping printer coders. They are equipped with an imprinter or an ink coding system. It helps to record dates, words, and codes on each seal. The machine works with a solid-ink coder to print the labels while sealing. It prints two lines in font size two (18PT) or three lines in font size five (10.5PT) for R arrange type. Both R arrange, and T arrange of types are used by printing wheels.

Turn Off the Heater Switch

Before you shut down the machine, wait until the temperature drops down. Turn off the heater switch and follow the proper procedure to prolong the life of sealing belts and, ultimately machine. You can press emergency stop to shut down the sealer. However, don’t forget to turn the knob 120 degrees clockwise and release the emergency stop before restarting the machine.

Isn’t it amazing that the machine instructs the top of each bag by PTFE bands throughout the process? The turbine drives the sealing belts, drive belts, and conveyors at the same time.

4.Compare And Contrast Vertical Sealing Machine And Horizontal Sealing Machine?

Vertical Sealing Machine

Continuous sealing machines provide you with fast and stable operations. It comes in a dual positioning system; horizontal band sealers and vertical band sealers. You can interchange between vertical and horizontal modes according to your needs. Sometimes, the original packaging is in horizontal mode, and you might need to assemble the parts for vertical mode.

Comparison between Vertical & Horizontal Sealing Machine

Horizontal Sealing Machine

In comparison, all the features and characteristics that are similar in both styles will be discussed.

- Both are durable stainless steel that requires minimal operator training.

- The pre-heat time is fast in both styles, and they can seal any thermoplastic materials (PP, PE, and laminates).

- Both possess a solid-state temperature controller to regulate seal bars for a consistent seal.

- Both have motorized rubber conveyors with speed control and embossing pressure wheels with adjustable pressure. Moreover, a pair of heating and cooling jaws and an emergency stop button are present in both sealing machines.

- Both use the same sealing method that is constant direct heat.

- The spare kit in both includes PTFE sealing belt, drive belt, and typesets.

The contrast between Vertical & Horizontal Sealing Machines

Horizontal band sealers lay bags flat on the conveyor and are therefore known as a continuous flat conveyors. It works best when the user can lay their pouch flat. It has an integrated conveyor that can tilt as much as 30 degrees for easier handling.

On the other hand, vertical band sealers allow bags in a standing position on the conveyor. It typically seals small solid products like vegetable seeds, coffee, grains and powder, and liquids. If the customer uses a stand up pouch, then it is the most suitable choice. It is designed for the stand-up, square bottom, or gusseted bags sealed in a vertical position.

Some additional parts are required for vertical sealing machines. You need to connect the long shaft to the umbrella gear base. Most importantly, adjust the height of the band sealer suitable for the user’s bag to be sealed in a vertical configuration only.

5.Compare And Contrast Continuous Sealing Machine And Induction Sealing Machine?

Induction Sealing Machine

A sealing machine comes in various types like hot bar sealers, continuous heat sealers, impulse heat sealers, induction sealers, and vacuum sealers. The induction sealing method is a non-contact type of sealing, particularly for inner seals in bottle caps. Whereas the continuous sealing machine uses moving belts overheating elements of nichrome.

Let’s compare both these sealing machines.

In similarities, the continuous heat sealing and induction sealing machine functions a non-stop operation guaranteeing large-scale output. The speed conveyors in both machines are adjustable, and the voltage is 220V. Both find their application in several chemical, pharmaceutical, agricultural, food, and cosmetic industries.

The contrast between Continuous Heat And Induction Sealing Machine

Induction sealing machines apply the induction heating method to seal glass and plastic (non-metallic) containers. It has various applications but is preferably helpful for cap sealing which involves a non-contact mechanism, applying heat to the inner aluminum foil of the cap. It involves the mechanism of eddy current since induction units generate a strong electromagnetic field. In contrast, the heat sealing method involves uninterrupted procedure of sealing two thermoplastic materials fused by both thermal and heat pressure.

A versatile continuous heat sealing machine applies to a wide range of materials whereas, an induction sealing machine works on specific thermoplastic materials.

You don’t require a lid or cap to seal your products in heat sealers, but induction sealing differs since it requires a liner or cap.

A natural heat source is used to melt and dissolve the seal, and you have to wait for some time for the system to reach the desired temperature. But, you can begin sealing instantly in induction sealing.

More care and maintenance are required in continuous heat sealing since your products are in physical contact with the machine.

In short, the main difference is that the continuous induction sealing machine does not utilize direct heat transfer and purely works on a non-contact procedure.

6.What Is The Minimum And Maximum Bag Height When The Tabletop Continuous Sealing Machine Is In The Vertical Position?

In the vertical configuration, the minimum bag height is about 7.8″, and the maximum bag height is 12.0″. The sealing head is adjustable in the latest models for a wide range of pouches from 31″ to 44″ from the floor. It precisely locates the sealing position.

Moreover, the sealing width for the bag ranges from 5-15mm and its thickness from 0.02-0.80 mm.

7.What Factor You Must Consider When Buying A Continuous Sealing Machine?

Choosing the best continuous sealing machine is a challenging decision for users. However, if you consider some of the following factors, you can have the best sturdy seals for your materials. When your product is so unique, the sealing should also look professional. Therefore, make your experience worthwhile by considering some features.

Horizontal Or Vertical Mode

You need to find which model you are required with when buying a band sealer. Vertical band sealers are useful in sealing small solid products like grains, tea, powders, and liquid products. It works best if the user’s packaging products use a stand up pouch. In horizontal mode, products lay flat on the conveyor, and it works best if the users want to lay flat their solid products for sealing.

Dry Coding Vs. Embossing

Latest band sealers come with the feature of embossing or printing as well. The characters are embossed directly on the up in embossing, and it is best for foil bags. In comparison, a roller with heat stimulated ink transfers to print in dry ink coding.

Moreover, some band sealers prefer a seal running either right to left or left to right direction options.

Appropriate Heat Sealing Method

Since you have learned about the working principle of the hot-press sealing method, you must consider the applicable heat sealing methods. There are many types of sealing, such as ordinary heat sealing method, ultrasonic sealing, pulse sealing, high-frequency sealing, and induction heat sealing. Other heat and pressure sealing methods include flat heat continuous band sealer, belt heat sealing, disc heat sealing, and slide clip sealing.

Appropriate Heat Sealing Material

Most of the damage to the bag can occur in the heat sealing part. Heat-sealed bags find their applications in daily chemical product packaging, food, and drugs fields. So, the heat seal of these packaging bags is most likely to leak during filling. Selecting the correct sealing material and other parameters can lessen the damage and waste of the production line rate. Make sure you have the bag material before buying a sealer since it will determine what sealer will work.

You must consider the properties of the film since they are also different along with the different sealing methods. For instance, ultrasonic and high-frequency sealing is most applicable for films that are easily crippled by heat. Direct heat sealers recommend these materials; gusset bags, coated Kraft paper bags, compound bags, fresh-paper bags, electrostatic bags, aluminum foil bags, PE bags, Accordion pocket, coated PP, waxed paper, cellophane, and Yin-Yang bag.

Size of The Sealer

The size and width of the sealer are one of the key characteristics to determine which suits best for your application. The size of the sealer depends on the thickness of the material to be sealed. It is recommended to add one inch to the thickness of the material to be sealed. It will help you determine the sealer length for easier driving. Moreover, the cutter on the band sealer trims at slightly less than the thickness of the sealer arm.

The width of the sealer is determined by the heating elements such as round or flat. The round wire cuts and seals with no excess material above the seal line. For the width of the flat wire, sealers come with a thickness of 2-3 mm, 5 mm, or 10 mm.

Quality Control Testing

Manufactured band sealers must pass CE certificate and be certified under ISO 9001:2008. To ensure a high-quality machine, here are some quality tests for all band sealers. It is better to give it a read before purchasing.

- Ensure all wiring on the unit are tight and connected correctly.

- Check the parts like wheels, belts, knobs, etc., to ensure they are working properly.

- Turn on the sealer and check the seal, fan, and printer along with all the knobs. They must start and stop in the right position. The air should be exiting out of the fans.

- The noise should not be more than 80 decibels. (Make necessary adjustments in the case of unusual sound).

- The conveyor belt must be working smoothly and evenly.

- Test the proper working of the sensor and coding set.

- Operate the machine for half an hour after it reaches the seal temperature. Try sealing a bag for a sample to ensure a high-quality seal.

- In addition, make sure ink heating blocks and wheels are working at optimal heat temperature in the case of band sealers with printing features.

8.How Far Out Can The Conveyor Be Positioned In A Continuous Sealing Machine?

The bags are placed on the conveyor system, which can be adjusted for a wide range of applications. You can adapt conveyor height from the conveyor to the center of the seal belt within the distance of 114 to 254mm (4.5 inches to 10.5 inches). The size of the conveyor in the Fr-770 continuous sealing machine is 38 into 7 inches.

In Air flushing continuous band sealer, the distance from the center of sealing to the conveying table is about 10-40 mm.

9.What Is The Maximum Load The Conveyor Of A Continuous Sealing Machine Can Withstand?

Different Packs Packed

A continuous sealing machine can withstand the maximum conveyor load of about 6.6 pounds or 3 kg. The single conveyor load is about 2.2 pounds or 1kg.

out of them by following the instructions that are provided with each model. Thanks for reading!

10.What Is The Most Command Part To Replace Of A Continuous Sealing Machine?

All the important parts and spare parts have been listed in the above section. However, sealing belts or Teflon belts and conveyor belts are the most essential parts requiring instant replacement. Replace the Teflon belt if it gets dirty since it can affect the sealing effect. You will find more about how to troubleshoot and replace problematic parts in this guide. Keep on reading!

11.How Many Bags Can The Continuous Sealing Machine Seals In A Minute?

Sealed Rice Bags

Direct heat sealers have so many different sealer types in which a continuous band sealer works at the fastest speed. Portable sealers can seal up to 10 packages per minute (ppm), foot sealers can hold packages up to 20 ppm, and Tabletop sealers can seal up to 15 ppm. However, the automatic band sealers are the most efficient with unlimited seal length, and they can hold up to 30 packages per minute on the conveyor. Depending on the bag seal characteristics, some models exhibit 0-12m/min.

The speed of continuous band sealers is faster than intermittent types of sealing which ceases the process at intervals. So, they are perfect for production lines that require higher production rates in less time and costs. Moreover, they are ideal for projects which require minimal space.

12.How Is The Temperature Controlled On A Continuous Sealing Machine?

Temperature Control System

The continuous sealing machine is equipped with a thermostat or an electronic temperature controller. It helps you to set the temperature depending on the material to be sealed. For your information, the temperature range of a continuous sealing machine is 0°C-300°C.

Here is a quick guide on how to adjust or control the temperature in your machine.

Before starting, know that temperature is not displayed in Fahrenheit; instead, it will always be Celsius. And, the red light (PV value) indicates the actual temperature, and the green light (SV value) depicts the desired temperature setting. If you are unsure of the temperature at which material will be sealed, try to set it and notice the suitable temperature.

- Press the SET button to adjust the temperature.

- Click the

- Wait till the PV value is exact the SV value to match your desired temperature. You might need to wait for at least 5-10 minutes.

13.What Amount Of Maximum Electric Voltage Can A Continuous Sealing Machine Afford?

The amount of maximum electric voltage for a continuous band sealer is 220V/50Hz with EU plug for EU members or 110V/60Hz with US plug for USA/Canada/Mexico

14.How to Maintain a Continuous Sealing Machine?

Machine after Proper cleaning

After reading about all the specifications and benefits of owning a continuous sealing machine, you must also learn its maintenance. But no need to worry since, in this part of the guide, you will be given the tips to prevent problems and ensure the longevity of your machine.

Many problems can be avoided if you learn to install and maintain your band sealing machine properly. Keep the machine in a dry and ventilated place where the normal temperature is maintained. Worn or cracked parts should be replaced. The pressure of the roller must be appropriate to allow the bags to travel on the conveyor belt and never exceed the maximum strain. Turn on the cooling switch before shutting down if the machine works for too long.

Following maintenance procedures should be followed for improved performance.

Observation and Cleaning

- Look over your machine in a timely manner. And cover the machine to keep it clean when not in function.

- Inspect the sealer temperature periodically and fix it if required.

- Clean the surface of the machine table, groove, the bottle plate, the mold slide, and the positioning rod.

- Check the roller pressure regularly to ensure it is appropriately set.

- Make sure no dirt or contamination is adhering to the band sealer.

- To wipe out the sealer’s tooth knife, plug the drain holes of the lower mold with a cotton ball. Then add boiling water into the groove of the lower mold and push it into place. Lower the upper mold and let the tooth knife dipped for a few seconds. Repeat it several times until it is clean.

- Clean out your band sealer with silicon spray and a cloth. Avoid applying silicone directly to the sealer. The most important thing is not to wash your machine with water at all.

Note: the power supply must be plugged off and restore to room temperature before cleaning.

Changing Of Sealing and Drive Belts

Daily maintenance, including replacing parts of your sealing machine, is essential to keep your machine in its optimal condition. Both sealing and drive belts are consumable items that need changing from period to period. Band sealer might begin to indicate “spotty” sealing, or you might notice any burnt or worn-out areas. If the belts become hard or brittle, worn out, or burnt, replacing them is necessary. Change the drive belts when they break or crack.

But how to change the belts? For this, you need to make sure that the machine is switched off. Take off the safety cover and two drive belts. Sealing belts can be easily removed by pushing on adjustment blocks. Then, put new sealing or drive belts in the position of the previous one. Verify the machine and make adjustments accordingly. Put back the safety cover, and you are done.

For more clarity, you should watch online video tutorials for changing parts of sealing machines.

Turbo Case Care

- You need to wipe out the dust and clean the motor regularly.

- Prevent its contamination with alcohol, gasoline, and benzene chemicals.

- Remove the back lid and find the turbo case. Refill or add new oil in the case of depleted gear oil.

- Moreover, the motor brush also needs replacement at regular intervals since it is created to be used for 2500 hours constantly.

Besides maintaining the turbo case, you need to regularly grease the lower mold sliding plate, guide rail, guide post, eccentric wheel, pressure bar bearing, and other transmission parts.

15.What Way Do We Troubleshoot The Continuous Sealing Machines?

It would be best to identify potential problems and take instant action as soon as you discover them. It will help you improve the performance and extend the lifespan of your continuous bag sealing machine. Troubleshooting the problems and analyzing their causes will help you find the particular solutions.

Here are given some common sealers-related problems in detail, along with the ways to solve them when they occur.

Sealing Belt Is Deviating

When you find the sealing belt is off the track, the main reason is that the driving wheel is not parallel to the passive wheel. By adjusting the two screws on the adjusting block until the seal is in the right orientation, you can avoid sealing deviation.

Avoid Sealing Belt From Breaking

When the sealing belt is tearing apart, there must be the following causes to consider.

- There is too much tension, or the sealing belt is too tight.

- Adjust the vertical screw on the passive wheel to lessen the over-tightness on the sealing belt.

- The sealing belt is deviating.

- There is a crease on the sealing belt.

- Ensure no creases when installing the belt or replace the belt.

- Debris, adherent film, or other contaminant is present on the surface of the sealing belt.

Remove dirt by cleaning the surface with cloth regularly.

You can prevent premature wear on sealing bands by decreasing the temperature of the sealing system or using a thicker PTFE coating material. Always switch to a wear-resistant material.

Printing Not Clear

It might occur due to a worn-out embossing roller, and you can replace it. Another reason is that the compression spring on the roller base needs to be pressed tightly. Adjust this pressure spring of the embossing roller.

Burning Seal Belts

When the seal is crumpled, and film adheres to the belt, the sealing belt is likely to burn. It is due to extremely high temperature or incorrect position of guide belt. In such cases, you are required to reduce the temperature or adjust the guide belt. Your bags will also stick if the plastic gets melted on the sealing belt. Fix the gap between the heating block. Also, replace or clean the sealing belt if needed.

Bags/Pouches Not Sealing Properly

Improper Sealed Bags

There are many common reasons why band sealers are unable to seal the product.

- Temperature is too high or too low, resulting in poor sealing. Adjust the appropriate temperature or reset the temperature controller.

- The speed regulation is abnormal, and belts run too fast. Fix the speed or replace the speed board.

- A large gap between heat blocks can cause improper sealing.

- Motor brushes are too short for the machine to run so, replace them.

- Sometimes, to think band material can also cause sealing issues. If that’s the case, then try using a thinner PTFE coating.

Temperature Is Not Controlled

When the temperature doesn’t rise or can’t be regulated, it may be due to a damaged heat switch or coupling. Try replacing the heat switch as well as the heater. Thermocouples and temperature controllers can also solve the issue.

Power And Heater Switches Do Not Light Up

The reason could be no AC voltage, damaged lamp, and open fuse. Please, check the power source and replace the fuse or lamp if needed.

In addition, if the lamp lightens up but the motor does not function, then the motor speed controller needs replacement.

Reason for Band Coating Cracks

Cracks in the band can be for numerous causes. Reduce the belt speed or decrease the sealer temperature to prevent the risk of cracking. Try using a thicker PTFE coating.

Resistance When the Sealing Belt Is Conveyed

It is probably due to the small gap between the heating or cooling blocks resulting in too much friction. It does not allow materials to pass through the sealing blocks. You can adjust these blocks and make an appropriate gap. Typically, the gap between the two-block is about the width of one layer of packaging. It ensures quick sealing and clear embossing.

Seal and Cut Using Band Sealer

You will find two types of “seals and cut” in sealing equipment. The first one is to cut excess material to have a seamless seal essentially for shrink wrapping. And, the second one includes the use of a trimmer on a sealer. Various band sealers come with sliding cutters to cut off excess bag material that is too long or to make poly tubing. Moreover, the blade can trim material about ¼″ to 1/2″ from the seal line.

Conveyor Belt Off Tracking

When the passive roller shaft and active roller shaft are not parallel, it causes the deviation of a conveyor belt. You can fix the adjustment knobs of the passive shaft to ensure that both are parallel and properly tightened.

One such case is that the conveyor belt and sealing tape does not move at the same speed. It is due to not having enough tension on the conveyor belt, or it is too loose. Here, you can properly tight the front and middle shaft belts to connect to the rollers. You can also tight the conveyor belt.

Bag/Pouch Gets Turned At The End Of The Running To The Embossing Roller

It happens when the middle-pressure roller or embossing roller is compressed too tightly. Adjust the pressure of the middle wheel or embossing wheel in such a way the two sealing strips are about the width of one layer of the package

Conclusion

Finding an ideal machine with outstanding strength and visual appeal? Hualian band sealer will provide you a higher production rate with a professional look and reliable performance.

A continuous sealing machine is a new generation industrial sealing machine that integrates sealing, printing, and continuous conveying. It is simple to operate and also a cost-effective automatic sealing machine. The use of fr900 machine is much extensive in chemical, pharmaceutical, medical, food & beverages, cosmetics, and electronics industries. You can find different versions of these sealing machines with different specifications. However, they must be proven to stand the test of time, pressure, and temperature. They must pass standard tests for verification and validation protocols.

Please go through the safety instructions since your safety is your responsibility.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours