Why Choose Our Lubricant Oil Filling Machine?

High Accuracy Filling

Servo or piston-driven pumps guarantee ±0.2% volume precision, even for viscous oils and large drums.

Durable and Corrosion-Resistant

All liquid-contact parts are made of SUS304/316L stainless steel, resistant to abrasion orchemical corrosion, ensuring long-term reliability.

Automatic & Flexible

Adjustable filling range from 0.5L to 20L. Compatible with bottles, jerry cans, and drums. Optional automatic capping and labeling integration

Leak-Proof & Clean

With anti-drip nozzles that can prevent oil spillage, and maintain a clean production line and reduce waste, largely save your cost.

User-Friendly Operation

Intuitive PLC touch screen interface for easy parameter setting, batch counting, and error detection.

Varous ALLPACK Lubricant Oil Filling Machine Production Line For Your Choice

Allpack 1-5L Fully Automatic Lubricant Oil Filling Machine Production Line for Bottles & Cans

Allpack 1-5L lubricant oil filling machine production line is engineered for bottling all kinds of engine oils, gear oils and hydraulic lubricants. With PLC programmable control, automatic bottle feeding, precise piston or flow-meter filling and automatic capping, the whole production line can deliver consistent fill volumes, drastically lower product giveaway and reduce labour costs. It is ideal for manufacturers scaling up production, and can handle bottle sizes from 0.5 L up to 5 L with quick format change-over.

High Filling Precision

Wide Filling Range

Handles High-Viscosity Oils Smoothly

Allpack 5-30L Automatic Lubricant Oil Filling Machine for High-Viscosity Lubricant Oils

Allpack 5-30L lubricant oil filling machine is designed specifically for thicker lubricants such as gear oil and high-viscosity engine oil, the whole production line uses piston pump technology and a user-friendly touch-screen interface to deliver accurate dispensing into containers. Operators only need to simply place the container and press start, the production line will fill, stop at the preset weight/volume, and alerts for container removal. It is perfect for medium-scale lubricant plants seeking flexible production with minimal investment.

PLC Touchscreen Control System

Automatic Bottle Feeding & Capping

Anti-Drip Nozzle Design

Allpack 200L Lubricant Oil Filling Machine Drum & Pail Filling System for Bulk Lubricant Oil Packaging

Allpack 200L is designed for large-volume lubricant production, this bulk filling system handles drums, pails and IBC containers efficiently and accurately. Equipped with weigh-scale feedback, anti-foam filling nozzles and variable speed modes, it ensures safe and precise filling of 20 L to 200 L containers. With rugged stainless steel construction, it withstands heavy-duty production environments and supports frequent product change-over, making it ideal for lubricant fill-and-ship operations.

Explosion-Proof and Safe Design

Weighing & Flowmeter Options

High Production Efficiency

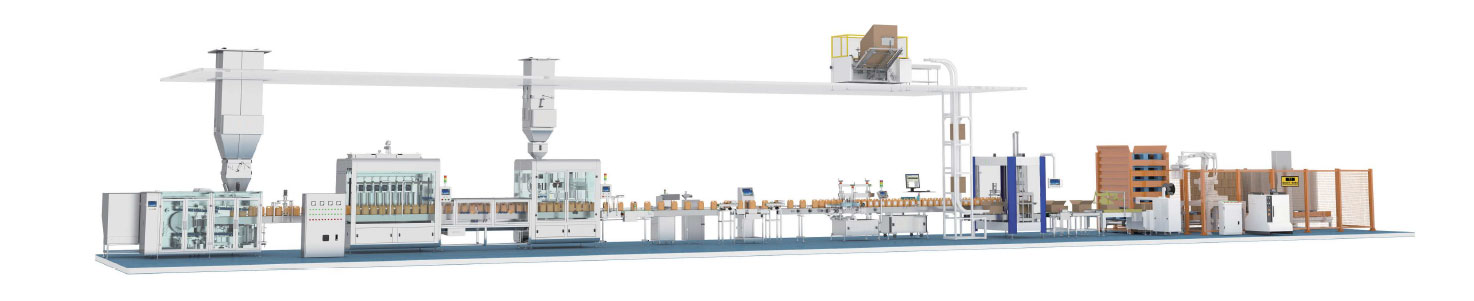

Allpack Ton Drum Turnkey Lubricant Oil Filling Machine Production Line

Allpack ton drum lubricant oil filling machine production line integrates automated bottle unscrambling, feeding, filling, capping and optional label/printing station into one seamless process. It is best built for lubricant manufacturers who demand high throughput (e.g., 600 + bottles/hour) and flawless consistency, the line supports multiple container formats, auto-adjusting for volume, label size and cap type. With explosion-proof design options and rapid format change kits, it suits for engine oil, brake-fluid and industrial lubricant product lines.

Adjustable Filling Speed

Smart Error Detection System

Energy-Efficient Operation

Trusted by Middle Eastern Manufacturers

Used by industrial plants in UAE, Saudi Arabia, Qatar, Oman, Egypt, Turkey, and Iran, our filling machines ensure consistent quality, stable operation, and reduced downtime for high-volume lubricant production.

ALLPACK Lubricant Oil Filling Machines FAQ

Q1: Can this machine handle large drums or only small bottles?

It supports bottles, jerry cans, and drums up to 1000L, depending on nozzle configuration.

Q2: Is the machine suitable for very viscous oils?

Yes. The servo piston system ensures precise filling for high-viscosity lubricants without foaming or overflow.

Q3: Can the machine integrate with capping or labeling lines?

Yes, we offer full automation lines with filling, capping, labeling, and conveyors.

Q4: Is this machine safe for flammable oils?

Yes, we provide explosion-proof designs for flammable lubricants and oils.

Q5: Do you provide installation and support in the Middle East?

Absolutely. Our team offers on-site installation, operator training, and remote technical support across the Middle East.

Optimize Your Lubricant Oil Production Today

Contact us for a customized solution for your factory in UAE, Saudi Arabia, or Egypt.