Your Superior Vacuum Packaging Machines

- Excellent Vacuum Effect

- Steady Working Performance

- Suitable For House&Industrial Use

Vacuum Packaging Machines

Allpack vacuum packaging machine is widely used for packing various types of food, hardware, pharmaceuticals, chemicals, aquatic products, electronic components and various forms of products (solid, liquid, powder, paste). This machine can prevent the product from oxidation or spoilage which are caused by microorganism and bacteria so that it can achieve the extension of product shelf -life. It can pack small products quickly and easily, it’s easy to operate, clean and maintain.The main structure of Allpack vacuum packaging machine is made of 304 stainless steel, therefore, the machine is corrosion resistant, moisture-proof and durable.Allpack vacuum packaging machine has hygiene chamber and high suction vacuum pump, which can ensure fast and sanitay vacuum, and provide a perfect packaging effect.

Vacuum Packaging Machines

The Buyer's Guide

Vacuum Packaging Machine: The Complete Buying Guide In 2025

Are you familiar with vacuum packaging machine? Do you know how vacuum packaging machine benefits your business? You are at the right place! Vacuum packaging machine is an extensive method where air particles are removed ensuring safest and quality packaging.

In modern era, the use of a vacuum packaging machine is approximately indispensable for commercial and domestic utilization. Similarly, if you are purchasing this equipment for your business or household you have to contemplate on finding perfect one. This blog can add more into your information.

1.What Is A Vacuum Packaging Machine?

A vacuum packaging machine is one of the professional equipment with an exceptional quality performance that is used to pack variety of products. It evacuates the air from bag containing food and seals it properly. Its major purpose is to extend the shelf life of goods while preserving their taste, color and attractive appearance.

It can not only pack foodstuff rather many other materials that are likely to be damaged by external moisture are easily packed by a vacuum packaging machine such as medicine, chemicals, souvenirs etc.

2.What Are The Working Principles of A Vacuum Packaging Machine?

A vacuum packaging machine can be operated by two methods; automatically or manually. Although their basic working procedure is almost same and can be understand by following steps:

Turn on the power switch in order to begin the vacuum packaging process. Load the anti-static aluminum foil container with food, place it over machine chamber and lay down its mouth flat direct under the sealing frame.

Vacuum pump will squeeze the air out present inside vacuum bag. Once the vacuum percentage reach to 100% the machine will stop vacuuming and would use thermal strips to close the bag with hermetic sealing.

The upper cover of machine will open automatically or can be opened manually right after finishing operation. With attractive outlook the bag is finally ready for placing in the shelf.

3.Which Kind Of Foodstuff Can Be Packed By A Vacuum Packaging Machine?

A vacuum packaging machine can be used for the packaging of numerous foods including:

Vegetables

Vegetables are the essential source of energy and its use is almost obligatory in our daily life. Thus, to preserve their freshness, vitamins and minerals for a longer period a vacuum packaging machine is best suitable.

Meat

All types of meat whether fresh meat, aged meat or sausages can be packed by this machine. By emitting harmful external particles from bag it assures the safe and healthy life of meat.

Dry Food

Dried food like dates, cereals, peanuts, raisins etc are usually kept for a long time due to which it requires proper packing and sealing to avoid moisture. For the accomplishment of such task a vacuum packaging machine is highly appreciated.

Sea Food

Most of sea food the consumer look for is packed in a film bag by vacuum packaging machine due to the machine’s firm sealing and the reason that product can be stored for much time.

Fruits

Like many other eatables, fruits too can be beautifully wrapped by this innovative machine. Its antioxidant substance removes the fear of waste of product and preserve its original quality.

Ready to Eat Meal

The rising popularity for ready to eat meal is increasing the importance of a vacuum packaging machine due to fast and safe service. In this way a vacuum packaging machine enables the packing of food in plastic tray or plates.

4.Which Type Of Food Should Not Be Vacuum Packed And Why?

Though vacuum packaging is terrific convenience and most economical, there are some food with anaerobic bacteria which do not require air to grow thus, should be avoid from vacuum packaging. They are as follows:

Raw Mushrooms

Raw mushrooms are ripe like fruits as a result they rot faster when vacuum sealed. If you want to store it then cooked mushrooms are fine for vacuum packaging.

Whole Apples

The idea of packing whole fruit is not favourable, but apples especially should be sliced first if not they can be soon spoiled. For their colour preservation slices can be coat with lemon juice and sealed quickly before they get brown.

Raw Onion and Garlic

Are you aware of those fumes that onions emit during its cutting? These gases continue to emit even after vacuum packaging and create leakage in pack. The two alliums; garlic and onions in fact spoil faster after vacuum sealing. Due to their highly perishable nature they do not last longer nor should be vacuum packed.

Soft Cheese

It is fully safe to vacuum pack hard cheese, but soft cheese like ricotta, blue or unpasteurised cheese are likely to create mould and spoil fast in vacuum sealing than in regular air.

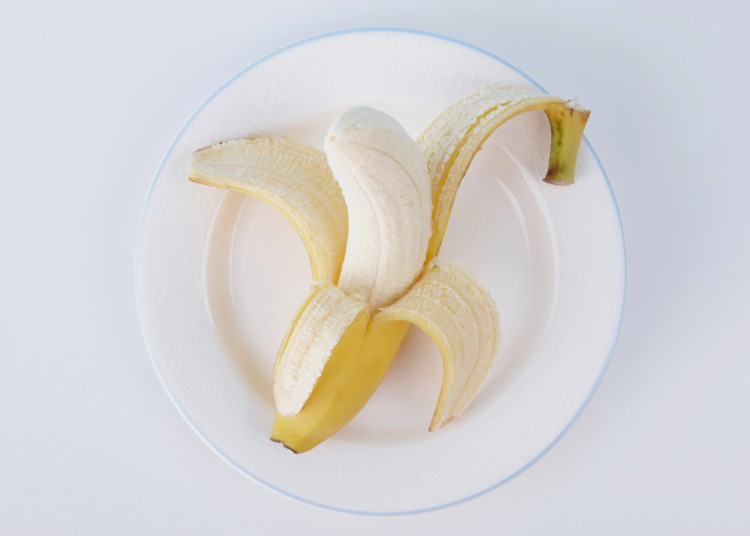

Fresh Banana

Bananas ripen faster in an anaerobic environment which indicates that absence of oxygen cannot help in increasing shelf life. But to prevent its rapid decay first it should be freeze and then vacuum packed.

Cruciferous Vegetables

Like raw onions fresh vegetables in Cruciferae and Brassicaceae family release gases due to which they cannot be directly packed. For their safe sealing make sure its blanching first, dry them well and cool thoroughly after which they can be placed in a vacuum packaging machine.

5.Why Does the Vacuum Packaging Machine Leak Air During Packaging?

Sometimes, the air leakage happens during vacuum packaging. There is lots of reason for it. For instance, too short time of vacuuming, the improper maintenance or aging of vacuum pump and the inaccurate sealing of vacuum studio lead to air leakage during the operation. To avoid such situation, you must have to care for the regular cleaning of your machine because each machinerequires proper maintenance despite being one of the perfect solutions. Moreover, extend the vacuuming time and replace the vacuum pump with one having high power.

6.Explain The Major Advantages Of A Vacuum Packaging Machine?

A vacuum packaging machine is great source of safe packaging and praised with immeasurable benefits of quality preservation, reducing the risk of dehydration, freezer burns and many others discussed below:

Extend Shelf Life

One of the most crucial benefits of a vacuum packaging machine is that it extends the lifespan of foods and liquids. It permits your food to last longer and stay fresher for weeks or even months without getting spoiled.

Packaging Efficiency

Another essential attribute of this innovative packaging equipment is its fast and quick processing. With proper packing and sealing materials it enables you to pack hundreds or thousands of products per hour.

Sanitation

Sometimes food becomes mouldy when kept for longer period. The mould spreads around the refrigerator through spores and spoils other products as well. A vacuum packaging machine prevents the cross-contamination and get rid the problem of mould by packing each product in a separate bag.

Quality Preservation

It not only increases the shelf life of products but also retain their original quality. It locks the water and eradicates oxygen from bags in order to prevent bacteria from growing. Thus it preserves the flavor, color and freshness of food.

Multiple Packaging Options

A vacuum packaging machine comes with diverse packaging options. For instance a user can use film; roller or bag for sealing products which are might be in form of reclosable zippers, foil-lined or easy tear notches.

Improved Product Presentation

Most of the vacuum bags are transparent and represent the alluring picture of food in crystal clear bags to be displayed on shelves. With affordable price it also allows you to print any logo or sticker on bags for the purpose of identification.

7.What Type Of Material Does A Vacuum Packaging Machine Use For Packing Products?

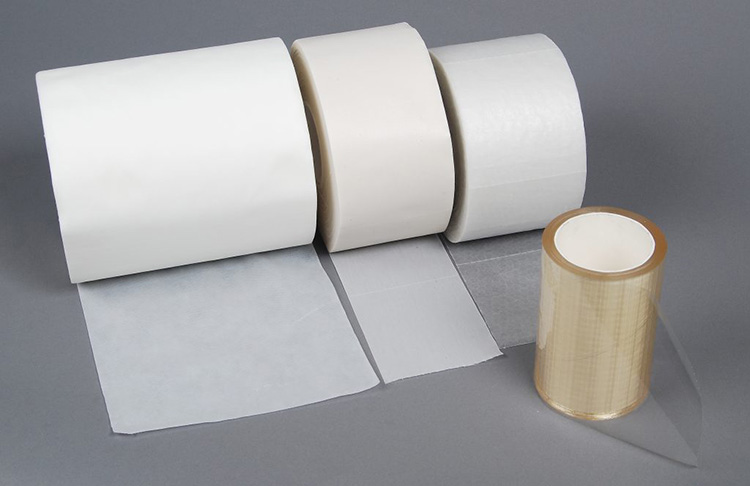

A vacuum packaging machine uses plastic film to pack variety of materials including both food and non-food. However, certain other tools are also used for packaging. These are:

Pouches

Pouches are made of plastic film and most commonly used for vacuum packaging purpose. Every hard to soft product can be easily sealed in these pouches. They are of two types; smooth pouches and perforated pouches. Perforated pouches are expensive but work as micro channel and assist the pump to out the air. They can be used in external chamber machines. While as, smooth pouches are inexpensive and used for in chamber machines.

Canisters

Canisters are type of containers which may be in form of plastic, glass or steel. They are ideal for easily crushed items. Variety of brittle and liquid products like soup and skews etc can be vacuum sealed in these canisters. Their reusable characteristics make them more economical.

Trays

They are also made up of plastic and usually used to pack the prepared food so it can be easily microwaved before serving. Trays are used in every type of machine because they are covered in plastic film but mostly thermoforming vacuum packaging machine use tray.

Bone Guard

Food with sharp edges often punctures the plastic bags because of air suction by machine. In order to avoid this issue, material like bone in meat are simply covered with bone guard sheet and vacuum packed.

8.Describe The Core Components Of A Vacuum Packaging Machine?

A vacuum packaging machine consists of key components that combine together and assist the stable functioning of packaging. Some of the major parts are:

Main Frame

It is the main structure of machine made up of durable stainless steel. With organic glass covers (upper & lower cover) and compact structure it yields smooth stable performance while requiring effortless controlling.

Control Board

Another essential component of this machine is the control panel compromised of various keys for controlling temperature, fixing conveyor belts, sealing nozzle, and emergency stop etc. It provides soft touch interface for setting operational parameters.

Vacuum Room

It is the surface of machine where loaded container is placed for processing. It is like a room for your bags in which they are passed through complete procedure and portrayed as final output.

Vacuum Pump

It would not be wrong to say that vacuum pump is the boss of vacuum packaging machine whose main task is to reduce oxygen level present inside the food container through suction power. It effectively removes all the internal gases from bags ensuring long life for your products.

Universal caster

The universal movable casters are fitted beneath the vacuum packaging machine. These high quality wear-resistant wheels enable machine to rotate around 360 degree and are of great importance for easy handling and movement.

Sealing Frame

The actual and most significant task in a vacuum packaging machine is done by this key component. It is located above the machine surface which allows heated seal bar to join together the sides of plastic film.

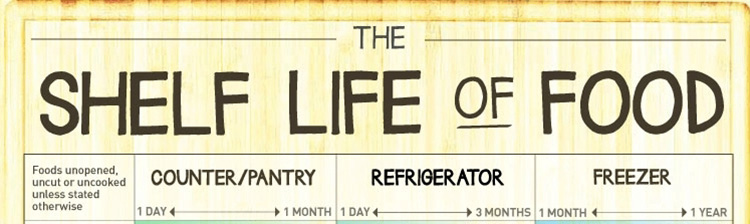

9.What Is The Shelf Life Of Goods Packed By A Vacuum Packaging Machine?

The shelf life of food you are going to pack is the crucial aspect to know. Below, the list of products along with their time for storing has been provided for your guidance:

| Food | Un-Packed | Packed |

| Lamb Meat | Freezer: 4-6 months

Refrigerator: 2-4 days |

Freezer: 24-36 months

Refrigerator: 30-40 days |

| Ground Meat | Freezer: 4 months | Freezer: 12 months |

| Fish | Refrigerator: 1-3 days

Freezer: 3-6 months |

Refrigerator: 4-5 days

Freezer: 24 months |

| Crab | Freezer: 2 months | Freezer: 8-12 months |

| Fruits and Vegetables | Refrigerator: 15-20 days | Refrigerator: 40-60 days |

| Cookies and Bread | Freezer: 2-3 months

Room Temperature: 2-3 days |

Freezer: 12-36 months

Room Temperature: 7-10 days |

| Hard Cheese | Freezer: 2 months | Freezer: 8-12 months |

| Cooked Pasta | Refrigerator: 2-3 days | Refrigerator: 8-12 days |

| Dry Cereals and Beans | Room Temperature: 6-12 months | Room Temperature: 12-24 months |

| Poultry | Freezer: 4-6 months | Freezer: 24-36 months |

| Lobster and Shrimps | Freezer: 6-12 months | Freezer: 12-24 months |

| Pork | Freezer: 4-6 months

Refrigerator: 3-7 days |

Freezer: 24-36 months

Refrigerator: 14-21 days |

10.Explain The Different Types Of A Vacuum Packaging Machine?

There are various types of vacuum packaging machines which can be divided on the basis of two categories. Let’s crack on with their types, working and applications:

Types On The Basis Of Automation

There are three types of vacuum packaging machines available in market on the basis of automation. These can be well understood by knowing the underlying details:

Automatic Vacuum Packaging Machine

An automatic vacuum packaging machine is manufactured with self operating system to seal the products in order to maintain their freshness and extend shelf life. It does not require any intervention by an operator thus has gained much popularity.

Working Principles

The machine starts working when switch is turned on. Machine puts the product in plastic bags and sucked the air out of it. When air is completely removed, opening of film is sealed by sealing strips and the bag is ready for final outlet.

Components

The machine consists of various parts including hopper, vacuum tube, nozzle pipe, vacuum chamber, control panel, sealing silicon strip, air pressure gauge, support table and universal wheel.

Application

It is applicable to large manufacturing firms and can process numerous products including meat, herbs, medicines and other non-food items. For instance, food, pharmaceutical, electronics, hardware and chemical industries are utilizing this automatic equipment on greater extent.

Semi-Automatic Vacuum Packaging Machine

Semi automatic vacuum packaging machines enable users to take part in running the process of machine. They are required to load and unload the products in machine.

Working Principles

After setting of parameters the material is loaded in films and placed in the chamber of machine. The oxygen present inside of bag is removed and sealing is realized as a result of heat.

Components

It consists of control panel, sealing cover, swing arm, travel switch, caster and stainless steel body.

Application

Many companies like food, medical or herbal industries use this machine to support their medium production rate.

Manual Vacuum Packaging Machine

This type of vacuum packaging machine is cheap in price as it does not need complex and expensive parts for achieving the sealing. It can be found both in chamber and portable form with system solely depends upon the user.

Working Principles

Its operating procedure is quite easy with few steps. The filled film bags are placed in the machine mouth where the air particles are excluded from container and the sealing strip seals it firmly.

Components

Its components are sealing ring, sealing strip, plexiglass plate, control panel, safety clasp, silicone article and stainless steel frame.

Application

It is less expensive due to which small industries prefer to use for their low level of production. It can be used in houses, food stores or laboratories etc.

Types On The Basis Of Function

Among the various types of vacuum packaging machine three are most prominent and major one. Let’s crack on with their types and working:

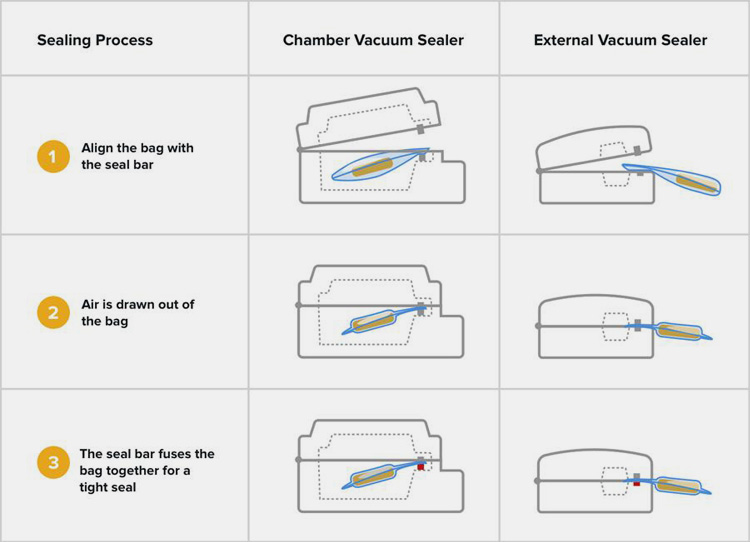

Chamber Vacuum Sealer

Chamber vacuum sealer is most reliable packaging machine ideal for commercial use but can be also used at home. It maintains high hygienic standards by completing the entire cycle inside the machine chamber. It removes air from bag without use of suction and seals it firmly as a result its applicability is more in packaging of liquids and wet food. It lacks the quality of producing larger bags although this issue can be resolved by big chamber that can be further customized.

Working Principles

It maintains high hygienic standards by completing the entire cycle inside the machine chamber. After getting filled with loaded bag it removes the air from bag without use of suction and seals it firmly.

Components

It comprised of vacuum cover, swing arm, pressure seal device, control panel, cellular type radiator and movable wheels.

Application

Its applicability is more in packaging of liquids and wet food. Vegetables, fruits, sauces or other similar things are mostly packed by this machine.

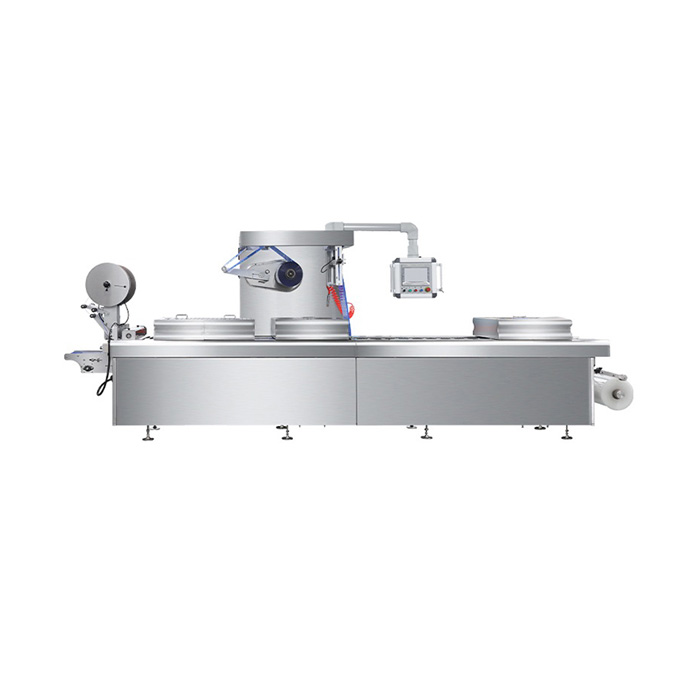

Thermoforming Vacuum Packaging Machine

This packaging machine is fully automatic and gives an amazing output in terms of efficiency. With advance components it contains the film roller for forming bottom and upper sealing of bag. It can be operated by pre heating film in chamber after which goods are manually poured into container. The bag then reached to cutting stage and the process ended. This machine has large production capacity.

Working Principles

It can be operated by pre heating film in chamber after which goods are manually poured into container. The bag then reached to cutting stage and the process ended.

Components

With advance components it contains the film roller for forming bottom and upper sealing of bag, conveyor belt, air suction device, sealing device, stand,

Application

Due to large production capacity this machine is ideal to perform the tasks of big manufacturers from pharmaceutical, food and chemical field.

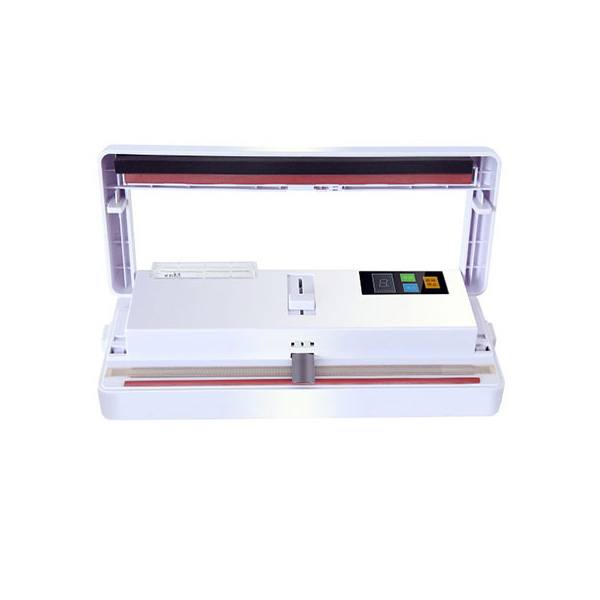

External Vacuum Sealer

External vacuum sealer is cost effective and suitable for domestic use. After extracting air and sealing bag it attaches the pack externally. Its sealing is not firm and left the residual air in container due to which it is not recommended for liquid or wet products. But this machine with its light duty performance is perfect for dry products and daily home use.

Working Principles

After extracting air and sealing bag it attaches the pack externally. The sealing material is used to close the bag’s opening.

Components

External vacuum packaging machine is compact mini design machine with simple components like releasing valve, air intake, lower and upper gasket, sealing strip and safety switch.

Application

With light duty performance this machine is perfect for dry products and daily home use. That’s why it is used in houses, small stores and grocery shops etc.

11.Differentiate Between Various Types Of Vacuum Packaging Machines?

How one machine is different from another under the same category is described below in detailed:

Automatic Vacuum Packaging Machine Vs Manual Vacuum Packaging Machine

| No | Factors | Automatic Vacuum Packaging Machine | Manual Vacuum Packaging machine |

| 1 | Definition | An automatic vacuum packaging machine pack various products through independent process without any error. | This machine of manual character can be used to vacuum pack numerous items through manual intervention of an operator. |

| 2 | Process | The machine works automatically after the fixation of parameters. | Timer for sucking air is settled untill desired level is achieved. |

| 3 | Speed | It is super fast as it does not require any timer rather functions through non stop process. | Compare to automatic vacuum packaging machine it is slow because of process breakage by user. |

| 4 | Application | This machine is best suitable for hard stable items and mostly utilized by large industries. | This equipment is best for soft products like muffins and is used by small scale factories. |

| 5 | Machine |  |

|

Chamber Vacuum Packaging Machine Vs External Vacuum Packaging Machine

| No | Factors | Chamber Vacuum Packaging Machine | External Vacuum Packaging machine |

| 1 | Definition | Chamber machine is used to preserve the food that is placed inside machine. | Unlike chamber machine, external vacuum sealer seal bags that are placed outside of machine. |

| 2 | Process | The loaded bag is kept over chamber and then sealed through heat pressure. | |

| 3 | Size & Sealing | Its size is big with many parts. Sealing achieved by this machine is stringent and strong. | This machine is highly portable with small compact structure. However, its sealing is sometimes weak which can cause product leakage. |

| 4 | Application | Many restaurants, food, chemical and medical industries are taking its services. | Its use is commonly found in houses or other small production areas. |

| 5 | Machine |  |

|

12.In Which Industries A Vacuum Packaging Machine Can Be Used?

With growing need for goods packaging the importance of a vacuum packaging machine can be traced in many areas among which few are considered below:

Restaurants

Restaurants are using this machine on large scale to satisfy their customers. They use it for the service of home delivery and keeping of vary perishable food items.

Food Industries

Large industrial firms who manufactures products like ketchup, pickle, freezing food, oil, glucose, candies etc look for the excellent performance of a vacuum packaging machine to enhance production as well as security level of their goods.

Household

It is a matter of common observation that most of the people buy food on weekly or monthly basis and some food is left over after eating in daily routine. For storing such food we have to cover them well so as to maintain their original taste along with freshness. In that case a vacuum packaging machine is ideally recommended.

Hardware and Chemical Industry

Presence of this machine can be seen in hardware and chemical industries where laboratory equipments and chemicals are packed in safe bags to reduce the risk of damage.

Textile industry

A vacuum packaging machine keeps the contamination of product free and decrease the product volume by light packaging which ultimately helps in the space saving and easy transportation. The ultra compact packaging keeps clothes dry and saves from insects as a result many textile industries have greater demand for this equipment.

Medical Industry

Vacuum packing is mandatory in medical industries for preserving the sterility of medicines. Different medical devices are wrapped with plastic film during transportation to isolate them from bacteria and restore safety.

13.What Are The Common Faults And Possible Solutions While Using A Vacuum Packaging Machine?

| Faults | Reasons | Solutions |

| Flatulence occurs and hot air left in vacuum bag | Less number of vent holes

Fast speed of conveyor belt |

Increase vent holes for quick air leakage from bag

Reduce the conveyor belt speed and increase machine temperature to assist air exclusion from film |

| The sealing line is weak and easily broken | Incorrect height of sealing line

Sealing tension is not uniform Short sealing time |

Adjust sealing line height by making it half of the height of packaging

Adjust horizontal position of sealing frame Extend sealing time until the process is completed |

| Surface of film is unclear and blurred | Too high temperature which result in film shrinkage

Low speed of conveyor belt |

Decrease temperature of machine

Enhance the speed of conveyor belt so the time for film to contact heat would be less |

| Cutting and sealing position error | Circulating wind direction, conveyor belt height and sealing frame are incorrect

Size of vacuum bag is too large |

Check them all and adjust to suitable position

Reduce the size of packaging film |

| Vacuum bag is sealed triangular at the corner | The vacuum bag length is big

Circulating wind and temperature of shrinking packaging machine is quite low |

Make the packaging bag smaller

Adjust the speed of temperature and circulating wind as well |

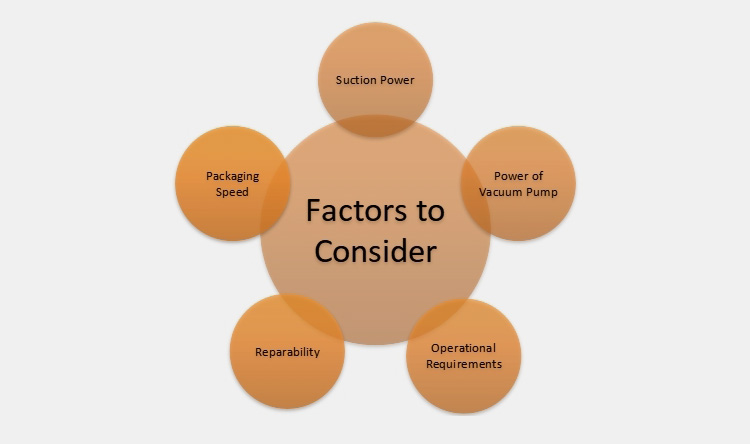

14.Factors That Should Be Considered Before Purchasing A Vacuum Packaging Machine?

Before buying a new vacuum packaging machine asks about few questions that would no doubt proved significant for your business:

Suction Power

One of your foremost considerations should be the suction power. The strong power suction can fastly remove oxygen and air from bag. Examine these features of machine and make sure whether or not the machine will provide successful packaging.

Packaging Speed

This aspect of a vacuum packaging machine is very essential to know if you are purchasing it for commercial use. Make sure that its capacity and efficiency of packaging is high. The quicker the machine seals the bags the more would be number of containers it can pack.

Reparability

Your next question should be about reparability. Ask for the easy maintenance, fixation of machine and the availability of parts in case of electrical error or part damage.

Power of Vacuum Pump

Among all other parts of machine vacuum pump is the heart. One should be aware of the power and quality of vacuum pump installed in a packaging machine. Its effective nature can ultimately enhance the production capacity of packaging.

Operational Requirements

The type of vacuum packaging machine would be definitely determined by the products you are going to pack. The size, nature and volume of materials play important role in the selection of suitable machine. For instance goods requiring more air to be removed need external vacuum sealer. While as, for sensitive items a chamber vacuum sealer is highly qualified.

Conclusion

Vacuum packaging machine has brought dramatic automation in the packaging industry due to which all consumers are looking for its extra ordinary performance. In this way, Allpack is recognized company that provides most economical, ultra fast vacuum packaging solutions to boost your production line while preserving food susceptibility. If you are eager to learn more please visit our site .

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours