Your Ideal Band Sealer

- Powerful Copper Motor

- Wheel Pressure Adjustment

- Photoelectric Sensor

Allpack Band Sealer

Allpack continuous band sealers can be used for sealing plastic films and are suitable for continuously sealing all kinds of heat-sealed packages, such as PE bags, aluminum foil bags, kraft paper bags, electrostatic bags, and Yin-Yang bags. They are widely used in food, pharmaceutical, chemical, agriculture, lubricating oil industries,etc. This continuous band sealer can be applied in a place where there is a restriction on space, such as a small factory, monopolization shop, workshop, etc. Allpack band sealer adopts electronic constant temperature control and an automatic conveying device. The band sealers can control different shapes of plastic film bags and can be used in all kinds of packaging lines, and the seal length is not limited. Allpack provides horizontal band sealer and vertical band sealer, to meet different sealing demands.

Band Sealer

FRM-980I High Speed Continuous Soild-ink Band Coding Sealer

FRM-980I high-speed continuous solid-ink band coding sealer is able to print at high speed with instant dry and highly legible letters that have good adhesion properties. The solid-ink band sealer can seal all kinds of heat-sealable materials, which adopt a constant temperature control system and step-less speed-adjusting transmission mechanism. Temperature is adjustable to accommodate a wide range of applications. You can select various colors.

Fine Copper Motor

Suitable For Solid And Liquid

Electronic Constant Temperature

FRM-980II High Quality Continuous Band Sealer Coding Sealer

FRM-980II high-quality coding band sealer adopts an enclosed 100w connected turbine motor. The core is made of high-quality fine copper conductive wire, with strong conductivity and strong power. The coding band sealer works with a solid-ink coder to print the colored labels while sealing. The printing wheel in the machine can be used for both R arrange and T arrange types. There are four modes for your choice. This high-quality band sealer can be used continuously in an assembly line.

Closed Gearbox

High Precision Gear

High Powder Fine Copper Motor

FRM-980III Continuous Band Coding Printing Sealer For Plastic Bags

FRM-980III continuous band coding printing sealer adopts a constant temperature control system and step-less speed adjusting transmission with adjustable temperature to accommodate a wide range of applications. For types in R arrange, the machine can print two lines in font size two(18PT) or three lines in font size five (10.5PT). The counting device is optional. There are four models for your choice in this FRM series. This band sealer can be used continuously in an assembly line.

Adjustable Platform

Heating And Cooling Fine Copper Block

Sealing And Printing One-shot Lettering

FBH-42 Automatic Continuous Band Sealer For Heavy Duty Bag

FBH series is the largest heavy-duty continuous band sealer of Allpack for handling and sealing extra large or extra heavy bags. This continuous band sealer is equipped with two pairs of brass heating bars and one pair of brass cooling bars with a forced air cooling system. FBH series continuous band sealer can be applied for sealing thick bags with filling materials of food, grains, pellets, etc.

One Pair Of Brass Cooling Bar

Two Pairs Of Brass Heating Bars

Specially Designed For Heavy-duty Bag Sealing

FR-770I Stepless Speed Continuous Band Sealer For Small Plastic Bags

FR-770I stepless speed band sealers are applied for sealing small packages. These band sealers also adopt a constant temperature control system and stepless speed regulation mechanism. FR-770I band sealer can seal plastic films made from various materials continuously. You can choose to equip the embossing wheel and counting device. There are three modes in the FR-770 series.

Three Models Applicable

Stepless Speed Regulation

Constant Temperature Control System

FR-770II Automatic Continuous Band Sealer For Plastic Bags

FR-770II automatic continuous plastic bag band sealer is suitable for sealing small packages and can continuously seal plastic films made from various materials. This band sealer applied constant temperature control, making the temperature easy to control and adjust. The FR-770II type is designed with a vertical structure for your control and handling. With its compact structure, this band sealer is simple and easy for you to control and operate.

Vertical Structure Design

Easy Control and Operation

Constant Temperature Control

FR-770III Vertical Automatic Continuous Plastic Bag Band Sealer

FR-770III vertical automatic band sealer is one of the types from the FR-770 series that are console designed that are easy for you to adjust the working table. When sealing the packaging, this plastic bag band sealer can constantly outputting the temperature. Because of the step-less speed regulation mechanism, you can easily operate this machine with your mind without any concern.

Console Design

Adjustable Working Table

Stepless Speed Regulation

FRB-710I Continuous Band Sealer With Digital Temperature Controller For Plastic Films Bags

FRB-710I continuous band sealers can seal plastic films made from various materials continuously. These band sealers are equipped with an embossing printing device and a counting device. The FRB-710I continuous band sealers are updated with a new temperature controller compared with the old types. Now Allpack new FRB-710I bander sealers offer a new type of digital temperature controller for highly accurate temperature control.

New Digital Temperature Controller

High-accurate Temperature Control

Suitable For Wide Voltage Range: AC 86-240V

FRB-770III Adjustable Vertical Continuous Band Sealer For Plastic Bags

FRB-770III adjustable vertical band sealer is new type of sealing equipment that adopts advanced components, it is equipped with a deformed base and a coupling shaft. It is designed with an adjustable platform and a more reasonable transmission mechanism. With precise temperature control, this band seal can provide the perfect sealing effect. Meanwhile, it has high efficiency and high accuracy, can seal products continuously.

High-quality Thick Conveyor Belt

Elaborating On Every Circuit Inside

Security Guard, Anti-pinch Hand, Anti-preventing

FRS-1010I Heat Sealing Ribbon Printing Band Sealer With Colorful Labels

FRS-10101 heat sealing ribbon printing band sealer is suitable for sealing any heat-sealing materials and is able to print the colorful label while sealing at high speed and with adhesive properties. A color-adapted ribbon printing device is adopted to print the colored label on the bag while sealing. If necessary, a counting device can be equipped as well. Besides sealing and printing, model FRSC-1010III has the function of air suction.

Stepless Speed Regulation

Constant Temperature Control

Adopt Novel Design Ideas And Advanced Manufacturing Technology

FRS-1010II Ribbon Printing Coding Band Sealer For Food Plastic Bag

FRS-1010II ribbon printing coding band sealers for food plastic bags are used to print clear words or letters with various selectable colors. They are applied to print the colorful label while sealing in high speed and adhesive property. The FRS-1010II types are able to print at high speed with instant dry and highly legible letters that have a good adhesion property.

Adjustable Temperature

Stepless Speed Regulation

Constant Temperature Control

FRS-1010III Ribbon Printing Coding Band Sealers For All Kinds Of Heat-sealable Materials

FRS-1010III ribbon printing coding band sealers can seal all kinds of heat-sealable materials by adopting a constant temperature control system and a step-less speed-adjusting transmission mechanism. The temperature can be adjusted for accommodating a wide range of applications. The band sealer works with a color ribbon printer to print colored labels while sealing.

Optional Counting Device

Selectable Printing Colors

Four Models For Your Choices

FRS-1120W Horizontal Color Ribbon Printing Band Label Sealer

FRS-1120W color ribbon printing band sealers are horizontally designed for your colorful label sealing in high speed and adhesive properties. They are able to seal all kinds of heat-sealable materials with constant and adjustable temperatures. If necessary, a counting device can be equipped as well. These color ribbon sealers are all types from the FRS series. There are counting devices for your optional choices if it is necessary for your packaging needs. With the color ribbon printing device, you can get clear and stable printing words for your need.

Optional Counting Device

Stepless Speed Regulation

Color Ribbon Printing Device

FRSC-1010III Color Ribbon Plastic Bag Printing Band Sealer

FRSC-1010III color ribbon plastic bag printing band sealer applies the both R arrange and T arrange printing types. For the type "R arrange", the machine can print two lines in a font size two(18PT) or three lines in font size five (10.5PT). These coding band sealers can print at high speed with instant dry and highly legible letters that have good adhesion properties with various colors for your selection. With the constant temperature control system, it is easy for you to control and adjust the sealing temperature for your needs.

Horizontally Designed

Stepless Speed Regulation

Constant Temperature Control System

The Buyer's Guide

Band Sealer: The Complete Buying Guide In 2025

In the modern world, manufacturers have increased their production capacity to meet global demand. Machines like band sealers are highly important to fulfill their requirements. A band sealer provides continuous sealing of materials like plastic, bags, foils, polythene, etc. They are used where high-capacity sealing is done with precision.

Perhaps you will say that you are unfamiliar with band sealers, don’t worry, this article is to help you understand this machine is a deeper degree. Keep on reading this article, you will know the machine in many aspects, such as the definition, types, advantages, working principle, applications, etc, If you are interested in band sealer, please continue to read.

1. What Is A Band Sealer?

A band sealer is a device that can seal the mouth of bags that are made of thermoplastic material through heat sealing, it can seal bags continuously since it is equipped with a conveyor belt, and this machine is always used for high production volumes. Band sealers are usually present in the pharmaceutical Industry, food manufacturing industry, chemical industry, agriculture industry, and so on.

2. What Are Different Types Of Band Sealers Available For Consumers?

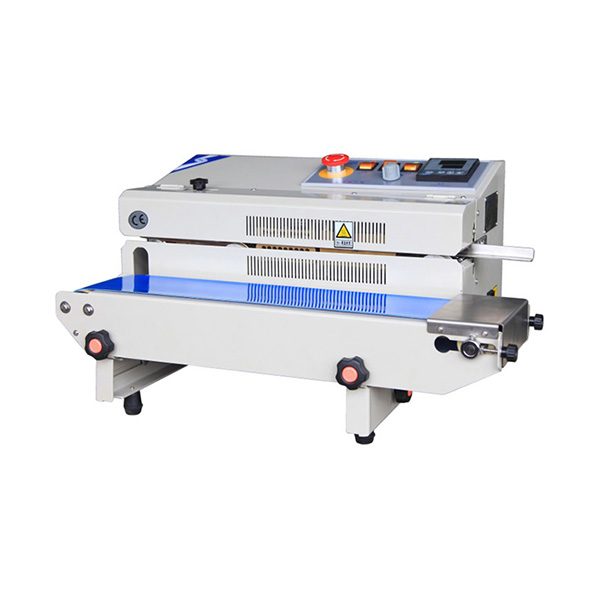

In terms of different heights and sealing directions, the band sealers can be divided into vertical band sealers and horizontal band sealers.

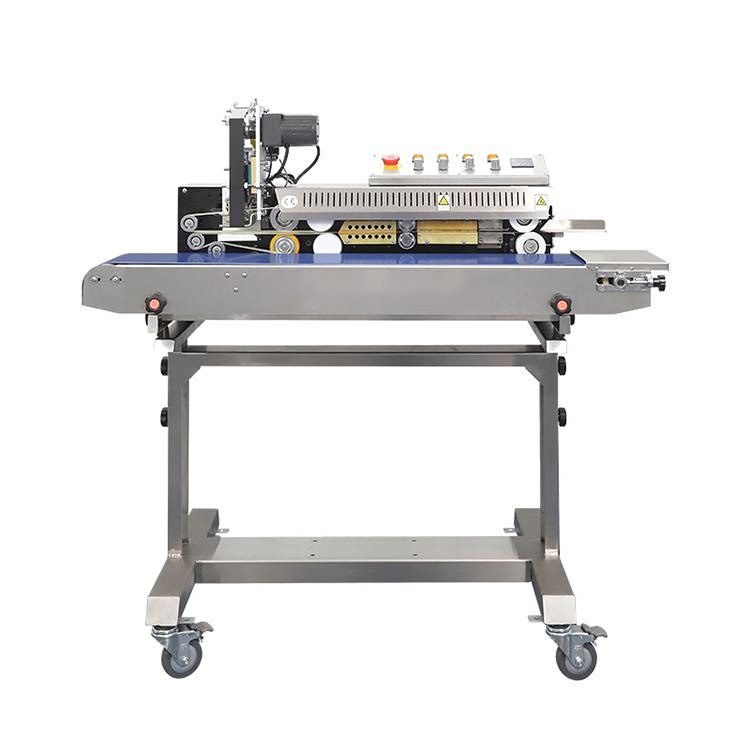

Vertical Band Sealer

Vertical band sealer, as the name shows, the bags are sealed by this machine in a vertical direction. This type of band sealer is equipped with an adjustable stand, so the height of the machine can be adjusted, which makes it more suitable for all kinds of bags that are different in size.

Horizontal Band Sealer

Different from vertical band sealer, the movement of bags in horizontal band sealer is in a horizontal direction, it is more suitable for sealing small bags, for instance, snack bags. But, the oblique angle and the height of the horizontal band sealer are adjustable, so this machine can also seal a large range of bags.

Band Sealers With Nitrogen Flush

The working principle of this type of band sealer is a little different from the other two types, it is to fill nitrogen gas into the bags and then do the sealing operation. This type of band sealer can have a good effect in protecting the freshness of the products inside the bag, so it is suitable for sealing food bags.

3. What Are The Differences Between Vertical Band Sealer And Horizontal Band Sealers?

Even though the purpose, components, and working principle of vertical band sealer and horizontal band sealer are the same, the two types of band sealers also have many differences in other aspects, which will be explained in detail.

| Aspect | Vertical Band Sealer | Horizontal Band Sealer |

| Appearance |  |

|

| Direction | The bags which are sealed by vertical band sealer is in a vertical direction. | The bags are sealed by horizontal band sealer in a horizontal direction. |

| Suitable bags | The vertical band sealer is more suitable for sealing stand-up pouches. It can seal bags that pack small products such as powder, grains, coffee, and liquid products. | Compared with vertical band sealer, the horizontal band sealer is more suitable for bags whose thicknesses are low because they are laying flat when they are sealed. And the horizontal band sealer is not suitable for sealing liquid products. |

| Height | The vertical band sealer is higher than the horizontal band sealer because it is equipped with an adjustable rise-and-down stand. | Comparatively, the horizontal band sealer is lower than the vertical band sealer. |

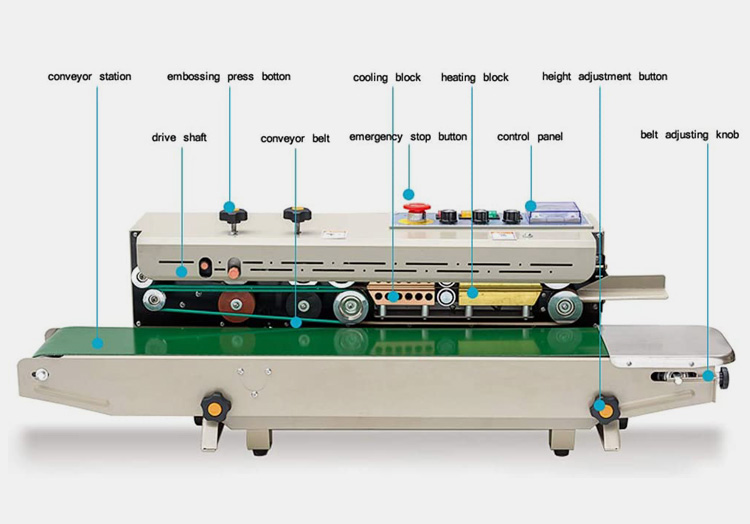

4. What Are The Functional Parts Of Band Sealer?

No matter whether vertical band sealer or horizontal band sealer, they have similar structures, and their components of them are almost the same. Next, you will learn about the functional parts of a band sealer, which are shown in the picture below.

Control Panel

The control panel contains a power switch, heat switch, temperature controller, and conveyor speed adjustment. The function of the control panel is to let the operator turn on and turn off the machine, besides, setting up all the parameters such as temperature and speed.

Heating Block

The heating block is the component that heats the mouth of bags, to let them realize thermal deformation.

Cooling Block

The cooling block is to let the bag cool down, when the bag totally gets cool, the sealing operation is finished.

Emergency Stop

If the operation occurs an error that leads to a high temperature, you can click the emergency stop button to end the working press of the machine, this component can ensure the safety of both the machine and the operator.

Conveyor Belt

The purpose of the conveyor belt is to deliver the bags depending on their constant movement of itself.

Drive Shaft

This part is of vital importance, it consists of a driving shaft and driven shaft, and it helps the conveyor belt move so all the working steps can smoothly go on.

Height Adjustment Button

It is used to adjust the height of the machine, to let it suitable for sealing different kinds of bags.

Belt Adjusting Knob

The belt adjusting knob is to adjust the angle of the conveyor, the purpose of this operation is the same as that of the height adjustment button.

Embossing Press Button

As the name shows, this component is to add embossing to the mouth of bags.

5. What Is The Working Principle Of Band Sealer?

As mentioned band sealer seals bags through heat sealing, but do you know why? Do you know what is the working principle of this machine?

To be honest, the working principle of band sealer is simple, when the temperature is high enough, the mouth of the bag begins to heat distortion, and when it is cooled down, the mouth of the bag will be coagulated and the sealing process is completed.

In the beginning, the conveyor belt delivers the bag to the heating blocks, which will constantly heat it to let the temperature rise to the melting point, when the heating process is finished, the bag is moved to the cooling block, here, the temperature drops and the heat dissipates, the mouth of bag begins to congeal, and then the is the embossing operation, until now the sealing operation is realized, then this bag is moved away, the next bag is delivered and the above process will be repeated.

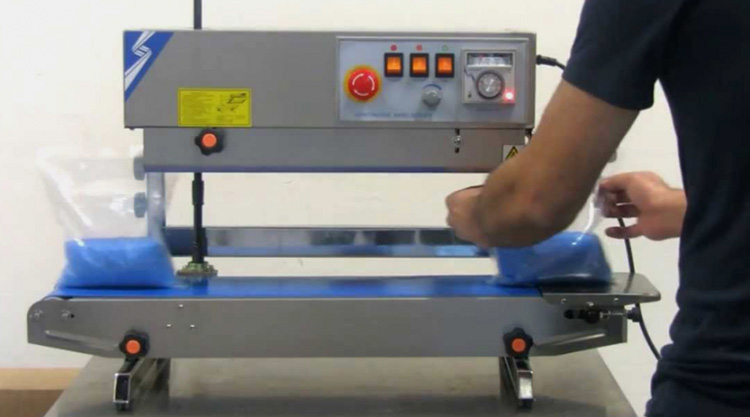

6. What Is The Operation Process Of A Band Sealer?

After learning the structure and working principle of band sealer, but actually, you still don’t know how to operate this machine, read the next part to learn the operation steps.

In the beginning, turn on the power, and wait for a short time, to let the machine enter the preheating stage.

Then, adjust the height and angle of the conveyor, to let it fit the size and thickness of the bags which need to be sealed.

Adjust the conveyor speed and adjust the temperature controller button, the temperature is determined by the materials you need to seal.

Adjust the embossing press button, this is based on the thickness of the bags which are going to be sealed.

Next is the bag feeding operation, put the bag on the conveyor and let the machine pull your bag, and then the machine will do the heating operations.

When the heating process is at the end, turn off the heating switch, and the bag is moved to the cooling block, to let the bag cool down. Until now, the sealing process is finished.

And after that is the next cycle, repeat the operations from the bag feeding step, and keep so on, to achieve continuous sealing.

7. What Are The Strengths Of A Band Sealer?

Whenever you decide to purchase the equipment you look for the strengths of a particular type of machine. Band sealers are used worldwide due to their highly efficient and precise sealing. Some of the strengths of band sealers are

| S. No | Features | Description |

| 1 | Precision | Band sealers replace the traditional sealing method has high precision to produce quality products. Packets, bags, and pouches are sealed with fine finishing that makes every product look even in formation. |

| 2 | Easy Operation | Band sealers are highly automated, and no special training is required for the operator. It has easy handling options, and every individual can easily understand the process. |

| 3 | Cost Efficient | The prices of band sealers are in a reasonable range, and the machine will not consume too much power or other materials. Using a band sealer, can have a large-scale production with little investment. |

| 4 | Durable | Stainless steel construction makes band sealers highly durable that the body does not corrode easily and can last for a longer period. The body is chemically resistive and no external factor can harm the shell. |

| 5 | High Speed | Speed is one of the main advantages of a band sealer. Depending upon the usage and worker efficiency more than 20-25 bags can easily be sealed in a minute which makes a bigger count while having large production domains. The speed can also be varied by regulating the motion of the conveyor. |

| 6 | Easy Maintenance | Band sealers are easy to understand and require less and more efficient maintenance. The materials are also easily available and can be replaced in no time when needed |

| 7 | Multifunctional | One of the most important strengths that we can get from a band sealer is that we can seal different sizes of bags, pouches, and films. A single can be used for all products lying between a specific width. |

8. What Are The Applications Of Band Sealers?

A band sealer is used worldwide in industries where a high volume of sealing is carried out. Industries like food, cosmetics, and pharmaceutical mostly use these sealing options to save their product and allow them to last long. Some of the applications of band sealer are:

| S. No | Application | Detail |

| 1 | Packaging Industry | Band sealers are mostly used in the packaging industry because of the excess traveling and shipment of products. This type of sealing provides safety to the products and allows them to reach their destination in a safer manner. |

| 2 | Food Industry | Food products like pre-baked goods, grains, dry fruits, chocolates, etc. require special protection to not be contaminated. These band sealers are used in the food industry to keep the food items preserved and have a decent exterior look. |

| 3 | Pharmaceutical Industry | Pharmaceutics is also another important place where the sealing of products is carried out by these band sealers. The pouches of milk, calcium supplements, and others necessary to be sealed properly before they are delivered to the customer. |

| 4 | Chemical Industry | Chemical products like mortars, powders, and dyes require proper sealing of their pouches and bags. Therefore, band sealer is also having an application in this industry. |

| 5 | Agricultural Industry | Seeds, hemp, pet foods, and bird seeds are some of the examples that are sealed using a band sealer in the agricultural sector. Band sealer allows these products to remain safe and can be used at any time without any chemical changes. |

9. What Kind of Bags Can You Seal By Using A Band Sealer?

Perhaps, most people do not know what kinds of bags can be sealed with a band sealer, they just call these bags plastic bags, but actually, bags that are made of different materials also have different features, in the next part, you will know about some heat sealed bags.

Poly Bags

Flat poly bags, flat bags on rolls, and reclosable poly bags, these are all belong to poly bags, which are made of polyethylene, polyethylene, and polypropylene, these bags are usually used to pack food,all kinds of poly bags can be heat sealed.

Freezer Bags

Freezer bags are used to pack frozen products, so they are made of thick bags, to prevent the products from environmental elements.

Anti-Static Bags

Anti-static bags contains a special additive that can prevent static, so this type of bag can be used to pack electric elements, and these bags are sealable.

Vacuum Bags

The diverse vacuum bags can also be sealed by band sealers, after the air inside the bags is extracted, they can be heat sealed.

Laminated Bags

Laminated bags, or you can say stand-up bags, these bags are made of various types of materials, and they have a certain degree of functionality.

10. How To Maintain A Band Sealer?

No matter how good the machine is, it needs to be maintained well to extend its service life, the band sealer is not an exception, so you need to learn some points about how to do the maintenance.

- The basic point is to check your band sealer regularly, to check its temperature and the functional parts.

- Every time before you use the band sealer, check whether the screws are loose.

- Clean the surface and grooves of the machine, don’t let dust hide in any corner of the machine.

- Swipe lubricating oil on the driving devices regularly, to prevent them from the risk of being worn, which can extend the service life of the machine.

- When you need to wash the machine, remember that the electric components of it can not contact with water, if they are wet, there may be a risk of damaging the machine.

- When you need to clean the machine or replace some components, don’t forget to check whether the power is on, if it is, turn it off.

- The conveyor belt is a type of consumable, you need to change regularly, to avoid it breaking suddenly while the machine is working.

11. What Are The Malfunctions And Solutions Of A Band Sealer?

It is normal for the machine to have problems in the process of working, when this situation occurs, just take it easy and try to solve the problem by yourself. Next, you will learn the common malfunctions and how to resolve them.

| Problems | Causes | Solutions |

| The conveyor belt is off track | The driving shaft isn’t in accord with the driven shaft | Click the conveyor belt adjustment button to adjust it |

| The motor can not be controlled which results in high speed | The speed controller occurs a problem | Replace the speed controller |

| Temperature can not rise or be controlled | ①Heat switch occurs error ②Temperature controller occurs error |

①Replace heat switch ②Replace temperature controlled conveyor |

| Conveyor belt does not move at the same speed as sealing belt | The conveyor belt doesn’t have enough tension tighten | Tighten the conveyor belt embossing |

| Embossing is unclear | The embossing press roller is damaged | Replace the embossing press roller sealing |

| Sealing effect isn’t good | The temperature isn’t proper, it is too high or too low | Click the temperature controller to adjust the temperature |

| Sealing belt breaks | ①The tension is too high ②The sealing belt escapes track ③There are creases on the sealing belt ④There are remained film on the sealing belt |

①Adjust the screw which is on the driven shaft to reduce the tension ②The same as the last paragraph ③Install the sealing belt again and ensure there is no crease ④Clean the surface of the sealing belt |

| The machine does not work | ①The connection is broken ②The speed regulating board is faulty |

①To tight the connecting screws ②Replace the speed regulating board |

12. What Factors Should You Keep In Mind When Choose A Band Sealer?

If you want to choose a band sealer, there are some factors that are necessary for you to consider, which will be listed below.

Model Of Band Sealer

First, you need to consider which model of band sealer should you choose, in the above text, the vertical band sealer and horizontal band sealer have been compared form different aspects, which can give you a reference. You need to think carefully, choose the model according to your demand, and what kinds of bags do you need to seal.

Packaging Bags

And you need to consider the bags which you need to seal by using a band sealer, the material and thickness of the bags, these factors also influence your choice.

Durability Of Band Sealer

The durability of band sealer,or in other words,the quality of the band sealer,it is matter-of-course that you want a machine with a long service life.However,a machine can not tell you that whether it is durable,so you need to consider the brand,the reputations of different brands.

In fact, the most effective method is to look for various brands of band sealers and research their reviews of them, the reviews will provide you with direct using experience from customers.

Determine A Budget

Another important factor is your budget, it is not necessary to invest a large amount of money in a band sealer, you need to determine a budget before you purchase this machine. Referring to the market price of the band sealer, the budget should not be above too much of the market average price.

13. Band Sealer VS Hand Sealer-Which One Is Right For You?

When it goes to bag sealing machines, the most common types are band sealers and hand sealers, as is well-known that the two machines are all based on the heat sealing principle. But, what are the differences between them? Which one is right for you?

In terms of size

You can directly observe that the size of the band sealer and hand sealer has a large difference, the hand sealer is much smaller than the band sealer, and it looks like a book sewer. As a result, the hand sealer is very portable and convenient to be carried. Therefore, if you regard size as an important factor in choosing a bag-sealing machine, you can choose a hand sealer.

In terms of speed

There is no doubt that the band sealer is better than the hand sealer in terms of speed because the band sealer is operated automatically while the hand sealer is operated manually. On the other hand, the band sealer is equipped with a conveyor belt, which makes it realize continuous bag sealing, but hand sealer seals bags by hand, so the speed of it is slow.

So, if you need a high-speed bag-sealing machine, the band sealer is a better choice for you.

In terms of production capacity

To a certain degree, production capacity is directly proportional to the production speed, the faster the speed is, the larger the capacity is. As mentioned in the last paragraph, the band sealer is faster than the hand sealer because it can seal the bag constantly. So, the production capacity of band sealer is much larger than that of hand sealer.

If you have a demand for large-scale production, you can choose a band sealer, but if you only need to seal a small scale of bags, for instance, just for family or restaurant demands, you can choose a hand sealer.

In terms of cost

In most cases, the price of band sealer is higher than hand sealer, and its consumption of power is also higher than hand sealer. As a consequence, the cost of using a band sealer is higher than using a hand sealer, if you want a low cost, you can buy a hand sealer.

Conclusion

Band sealers provide high-quality sealing options to industries and allow the customer to get a decent and effective look. Many industries are now preferring band sealers to increase their productivity and meet global demand. This article in detail explains all about band sealers but still, if you find any difficulty we are here to guide you 24/7. Feel free to ask any question at any time.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply to you ASAP within 24 hours

Tell us your material or budget, we'll reply to you ASAP within 24 hours