Premier Capsule Separating Machine

- Strict Process Control

- Disintegrator and Segregator

- Simulative Artificial Pulling Principle

Capsule Separating Machine

Allpack capsule separating machine is designed to automatically separate the filled capsules and retrieve powders, granules, pellets, or micro-tablets. It is designed and built to replace the conventional non-GMP method of milling, sieving and retrieving powder from filled capsules. It is ergonomically designed and suitable for all capsule sizes with applicable changeparts. It is easy to clean and maintain, low-noise, user-friendly, and meets the cGMP standard. There are safety functions and alarm devices built-in for maximum protection. The housing and capsule retrieving area are made of sanitary stainless steel to meet cGMP standard. It is mobile, compact, and easily wherever powder retrieving is needed. The entire working process is self-contained and isolated from operators to avoid product contamination.

Capsule Separating Machine

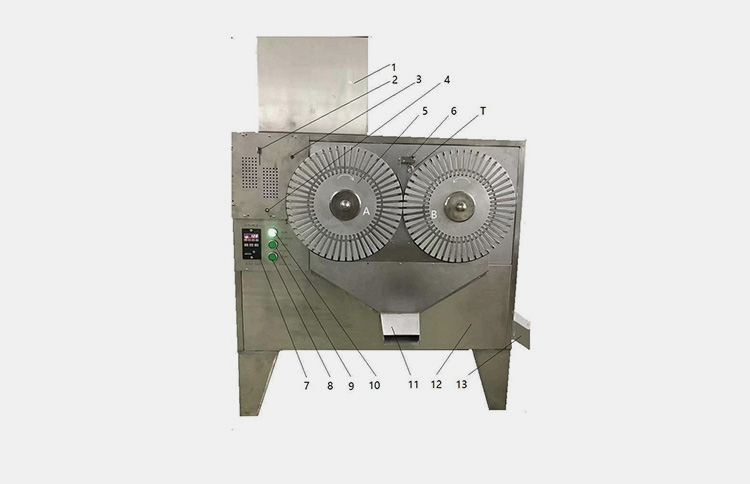

NQF-300B Automatic Capsule Separating Machine for gelatin vegetarian enteric empty capsules

Allpack NQF-300B capsule separating machine is suitable for 00#,0#,1#,2#,3# 4# capsule size and has the following advantages: quick separating speed, good effect, easy operation,easy maintenance. The machine is the best partner of capsule filling machine, and will be the best tool for recovery and reuse powder.

High work efficiency

Easy to clean and maintain

Simulative artificial pulling principle

NQF-600B Automatic Capsule Separating Machine for gelatin vegetarian enteric empty capsules

Allpack NQF-600B automatic capsule separating machine is a machine to separate the body and cap of capsule completely and re-use powder,granules.This machine replace the traditional way,it’s ergonomically designed. Suitable for powder are extremely expensive an strictly required by any capsule manufacturing plants.It is small in size,very easy to clean and repair.

Meet GMP standard &high efficient

Wide application range

Strict process control

NQF-800B Automatic Capsule Separating Machine for recycle medicine powder

Allpack automatic capsule separating machine can be also called automatic powder opening machine, is designed to automatically eliminate the cap and separate unqualified hard capsules with powders to recycle powders and particles.The machine is also built to replace the traditional way of milling, sieving and retrieving powder.It is first of its kind to separate and retrieve round pellets and micro-tablets.

Best capsule decapsulation machine

Provides disintegrator and segregator

Capsule powder recycle

The Buyer's Guide

Capsule Separating Machine: The Complete Buying Guide In 2025

Are you a producer of pharmaceuticals in need of an efficient and cost-effective method for separating capsules and other solid dosage forms for further use or storage? If so, then a capsule-separating machine could be the perfect solution.

By providing high-speed separation performance at relatively low capital and operational costs, these machines allow manufacturers to maximize productivity while still maintaining quality standards.

Here we’ll discuss the various benefits of investing in a reliable capsule separating machine and which features to consider when shopping for one that is right for your unique needs. Read on as we dive into the details of this exciting innovation!

1. What Is A Capsule Separating Machine?

A capsule separating machine is a device that is designed to automatically separate the filled capsules and retrieve powders, granules, pellets, or micro-tablets for use or storage. The capsule separating machine is a highly efficient and economical method for capsule separation that can be used in various industries, including pharmaceuticals, nutraceuticals, biotech, and food.

This equipment utilizes a mechanical sorting system in order to safely and quickly process the capsules. The capsule is placed into a hopper which then enters into a capsule sorting unit where the capsule is placed onto a conveyor belt. The capsule sorting system then separates the capsule into individual parts, allowing for easy retrieval of the capsule’s contents.

The capsule separating machine is capable of running at high speeds and can be used to process large quantities of capsules quickly and efficiently. Additionally, this machine is a fully automated process, eliminating the need for manual capsule sorting. This makes capsule separation more efficient and cost-effective, allowing businesses to save time and money in the capsule processing process.

2.What Are The Components Of Capsule Separating Machine?

Sorting Hopper

The sorting hopper is the first component of a capsule separating machine; it sorts capsule bottles by size and shape before they enter the capsule separator. This helps to ensure that only properly-sized capsules are accepted into the capsule separator.

Capsule Separator

The capsule separator is the main component of a capsule-separating machine. It uses a combination of mechanical and electronic components to separate capsule bottles into individual capsules.

Discharge Chute

The discharge chute is responsible for discharging sorted capsule bottles into an appropriate container, such as a capsule tray or capsule canister. This ensures that all capsule bottles are sorted and packaged correctly.

Control Panel

The control panel is the interface between the capsule separating the machine and the user. It provides information about capsule sorting, capsule discharge settings, capsule size settings, and other parameters that can help to ensure efficient capsule separation operations.

Vacuum Pump

The vacuum pump helps to ensure capsule bottles are properly loaded into the capsule separator. It also assists in removing capsule bottles from the capsule separator after capsule separation is complete.

Feed Chute

The feed chute is responsible for feeding capsule bottles into the separator. This ensures maximum efficiency during capsule separation operations.

Air Compressor

The air compressor supplies compressed air to the capsule separator, which is required for capsule separation operations. This helps to ensure capsule separation operations are completed quickly and safely.

Conveyor

The conveyor is responsible for transporting capsule bottles from the sorting hopper to the capsule separator and transporting capsule bottles from the capsule separator after capsule separation is complete. This ensures that capsule sorting and capsule separating operations are completed quickly and efficiently.

3.What Are The Advantages Of Capsule Separating Machines?

Enhanced Quality Control

Capsule separating machines feature a built in quality control mechanism that allows operators to check capsule integrity before filling. This ensures that only well-formed capsules are filled and improves overall capsule quality.

Increased Efficiency

Capsule separating machines offer improved capsule-filling efficiency compared to manual operations. They allow for higher capsule fill rates and can decrease the amount of time taken to separate individual capsules, resulting in increased production throughput.

Reduced Labor Requirements

Capsule separating machines drastically reduce the manual labor required for capsule separation, making it easier to scale up production operations without hiring additional labor.

Cost Savings

Capsule separating machines can help save money on capsule material costs by reducing wastage due to improper capsule formation or filling. This helps boost profit margins over time.

Re-Use of Power Supply

Capsule separating machines allow for the re-use of power supply, which helps to reduce waste and improve sustainability.

4.What Are The Applications Of A Capsule Separating Machine?

Pharmaceutical Industries

In the pharmaceutical industry, they are used for research and development processes, capsule filling and capsule sorting.

Nutraceutical Industries

In the nutraceutical industry, they are used to separate capsule shells from the content inside them and then fill them with different supplements or nutrients.

Food Industries

In food production, capsule separating machines provide an effective way of packaging products such as coffee beans or candy into capsule-like shapes. This can improve shelf life and appearance of products.

5.What Are The Working Principles Of A Capsule Separating Machine?

A capsule separating machine works by using force or vibration to shake the capsule, causing it to open and release its contents. The capsule contents are then collected in a specific container for further processing.

The capsule separating machine uses a number of mechanical and electrical components to achieve the desired results. The capsule is placed in a chamber that contains several rollers or plates which vibrate and move around, shaking the capsule and causing it to open. Once open, the capsule contents are collected by a vacuum system, which then passes them into a collection bin.

The capsule separating machine also uses sensors to detect capsule size and shape as well as capsule type. This helps to ensure that only the correct capsule types are separated and extracted from bulk supplies. In addition, the capsule separating machine can be set to separate capsules of different sizes or shapes for precise extraction results.

6.What Are The Different Types Of Capsule Separating Machines?

There are several different types of capsule separating machines available on the market, each with its own unique components.

a) Automatic Capsule Separating Machine

This capsule separating machine can automatically and quickly separate capsule parts. It uses vibrating technology to separate capsule shells from the capsule contents, allowing faster processing and less labor-intensive production.

Components

Hopper

This part of the automatic capsule separating machine is used to input the capsules for separation. It holds up to several hundred capsules at once and feeds them through the rest of the machine.

Drive Section

This component powers all other parts of the automatic capsule separating machine, allowing them to function as intended.

Capsule Pusher Plates

These plates move individual capsules forward so that they can be separated.

Separator Rollers

These rollers spin to separate the capsule components from each other.

A Separation Wall

This component separates the two halves of the capsules, allowing them to be collected separately.

Chutes

These channels allow for the automatic collection and transport of both halves of the capsules once they have been separated.

Air Blowers

This component blow air through all parts of the machine, keeping it running smoothly and efficiently.

Working Principles

An automatic capsule separating machine uses mechanical action to separate capsules from their shells. This can be done with various techniques, such as centrifugal force, air pressure, and vacuum suction. The capsules are placed into a hopper, separated from the container’s other components.

The automatic capsule separator then moves the capsules through a process of sorting and filtering that sorts out unwanted material while keeping the desired capsules intact. After this process, the automatic capsule separator will release the sorted capsules into a designated container for further processing or use.

Applications

Automatic capsule separating machines can be used in various industries. For instance, automatic capsule separating machines are essential for accurately measuring pills and tablets into regulated doses in the pharmaceutical industry. They also help ensure that filled capsules contain the exact dosage indicated on the label.

In addition to the pharmaceutical industry, automatic capsule separators are also being adopted by food manufacturers. These type of device can separate nuts and other large items from smaller ones to reduce waste or contamination. Additionally, automatic capsule separators can help with portion control of edible items such as candy or cereal pieces.

Automatic capsule separating machines also have potential applications in research facilities and labs, where they can be used to separate and analyze cells, tissues, and other biomaterials. By using automatic capsule separators in research laboratories, researchers can speed up the process of testing and analyzing chemical compounds.

The automatic capsule separating machines are also being utilized by cosmetic manufacturers who need to split ingredients into ideal proportions for manufacturing lipsticks and eye shadows.

b) Semi-Automatic Capsule Separating Machine

This type of machine allows for both automatic and manual operation. It uses a vacuum system to suck up capsules from one end and push them out from the other. The capsule can then be placed in a capsule-separating tray for easier separation.

Components

Feeder

The feeder holds and delivers the capsule to the separating machine. This component can be adjusted according to the size of the capsules for accurate delivery.

Separator Ring

The separator ring is at the bottom of the semi-automatic capsule separating machine. It is designed to separate the capsule and its shell.

Air Flow System

This component is responsible for controlling the amount of air that enters the semi-automatic capsule separating machine. It ensures a uniform airflow within the container, which helps to divide the capsules from each other efficiently.

Output Tray

The output tray is designed to collect the separated capsules and shells. It is usually made of stainless steel, allowing easy cleaning and maintenance.

Control Panel

The control panel controls the semi-automatic capsule separating the machine’s functions. It includes switches, knobs, levers, or buttons that allow users to adjust the machine’s speed, frequency, and other settings.

Power Source

The semi-automatic capsule separating machine requires a power source to operate. It can be powered by electricity, gas, or manual energy sources.

Safety Guard

A safety guard is included in semi-automatic capsule separating machines to protect users from accidental contact with moving parts. This component also helps to minimize the risk of injury or damage during operation.

Working Principles.

A semi-automatic capsule separating machine typically utilizes an automatic conveyor system to move the mixed capsules from an input point to its sorting compartment. The machine can then accurately and quickly sort the capsules into their compartments based on size, shape, or other factors. After the capsules are sorted, they are moved onto a designated outlet for collection.

Applications

This machine can be used in the pharmaceutical, food, and supplement industries. In pharmaceutical applications, semi-automatic capsule separating machines separate capsules filled with various active ingredients such as medication, vitamins, or supplements.

These machines are also used for food and supplement applications, where semi-automatic capsule separating machines can separate empty capsules from filled ones containing nutrients, flavoring agents, or dietary supplements.

Additionally, semi-automatic capsule separating machines can produce herbal medicines, where they can quickly and accurately differentiate herbs from one another.

c) Manual Capsule Separating Machine

This type of capsule separating machine requires manual operation. It has an adjustable speed control to adjust the speed at which the capsule parts are separated. The separation process involves pushing down on the capsule shell with a plunger, then releasing it, so the capsule content falls out.

Components

Sorting Plate

A manual capsule sorting plate is a device for separating empty capsules from filled and sealed ones. It consists of a flat-bottom tray on which an inclined surface is provided with grooves to separate the capsules according to their size and design.

Anticreepage Ring

The ant creeping ring is a device for manually separating empty capsules from filled and sealed ones. It is fitted around the manual capsule sorting plate to prevent the movement of the capsules from one chamber to another during operation.

Powder Hopper

The powder hopper fills the manual capsule separating machine with raw material or powder, which is then transferred to the manual capsule sorting plate.

Vacuum Mechanism

The vacuum machine creates a suction force, which helps extract empty capsules from the manual capsule separating machine. It also prevents powder leakage during operation.

Dust collection system

The dust collection system is a device for collecting dust particles during manual capsule separation. It consists of a vacuum chamber, filter bags, and an exhaust fan.

Electrical Control Panel

The electrical control panel is used to power the manual capsule separating machine and to monitor its performance. It consists of switches, buttons, indicators, and displays for controlling the various components of the manual capsule separating machine.

Battery Pack

When electricity is unavailable, a battery pack is required to operate the manual capsule separating machine.

Working Principle

A manual capsule separating machine uses centrifugal force to separate the two, with a rotating plate and multiple blades. The plate spins at high speed, and its blades cut through each capsule, pushing the filler material out of one compartment into another.

Due to the centrifugal force, the empty capsule shells are forced out of the machine into a receptacle while the filled capsules remain inside. This process allows for manual capsule separation and is an efficient way to separate thousands of capsules in a relatively short amount of time.

Applications

Manual capsule separating machines can be used in various industries, including the pharmaceutical, cosmetics, and food industries.

7.Is There Any Customization For Capsule Separating Machines?

The answer is yes! Capsule separating machines can be customized for a variety of applications. Depending on the size and type of capsule, there are various capsule separator models available to ensure optimal performance. For example, capsule sizes ranging from 0.5mm to 24mm can be separated with automatic capsule separating machines.

Furthermore, capsule separators can be customized to separate capsules of varying shapes and sizes. This includes capsule shapes such as oval, round, capsule-in-capsule, and capsule-on-plate. Additionally, capsule separators can be tailored to different types of capsule material such as gelatin or vegetable cellulose.

To ensure optimal performance for a specific application, many capsule separating machines can also be adjusted to separate capsule components such as capsule tops and bottoms. With this customized adjustment, capsule separating machine operators can increase their efficiency and accuracy in capsule separation.

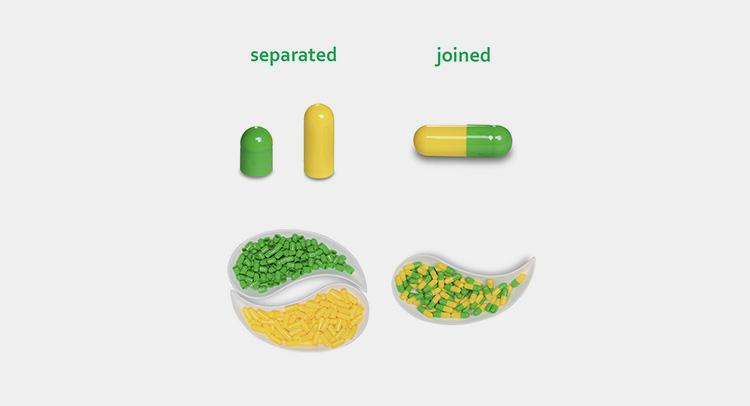

8.What Type Of Capsules Can Be Handled Using A Capsule Separating Machine?

Hard Gelatin Capsules

Hard gelatin capsules are the most common capsule type used in capsule separating machines. These capsules can be easily separated to retrieve their different components, such as powders and pellets.

Vegetable Capsules

Vegetable capsules are made from a variety of plant sources, including seaweed and cellulose derivatives. They are often used as a vegetarian alternative to hard gelatin capsules, and capsule separating machines can easily separate the capsule shell from its contents.

Multi-Part Capsules

Multi-part capsules are made of two or more capsule shells with different materials and colors, usually to provide additional protection for sensitive ingredients. These capsule types can be separated into their parts using capsule separating machines to retrieve their constituents.

9.What Materials Can Be Retrieved From Capsules Using A Capsule Separating Machine?

A capsule separating machine can be used to separate and retrieve various materials from capsules. These materials may include:

Granules

Capsule separating machines typically use a variety of techniques to separate out granules from capsules, such as shaking and vibrating.

Powder

Capsule separating machines can be used to extract powders from capsules by using centrifugal force or other methods.

Pellets

Capsule separating machines can be used to separate pellets from capsules by using mechanical force or other methods.

Micro-Tablets

Capsule separating machines can be used to separate micro-tablets from capsules by using air flow or other methods.

10.What Are The Safety Measures Taken When Using Capsule Separating Machines?

Wear Protective Gear

The capsule separating machine operator must always wear protective gear such as goggles, face shields and gloves. This will help protect their eyes and skin from any potential debris caused by the capsule separating machine’s operation.

Follow Safety Protocols

It is essential to adhere to safety protocols while operating a capsule separating machine, including reading and understanding the user manual before beginning work; following all in-house safety rules; only allowing authorized personnel near the machine; and reporting any defects or malfunctions immediately.

Use Proper Handling Techniques

Proper handling techniques are critical when using a capsule separating machine, such as firmly gripping parts with both hands for stability during operation; keeping fingers clear of moving parts; and moving slowly and steadily when positioning capsule parts.

Regular Maintenance

It is important to maintain regular maintenance on capsule separating machines in order to ensure their proper functioning and safety. This includes regularly lubricating the machine, cleaning away any dust, debris or liquid spills, and checking all electrical components for loose wires or exposed metal.

Perform Proper Shutdowns

After using a capsule separating machine, it is important to properly shut down the machine by pressing the emergency stop button and waiting for all moving parts to come to a complete halt before leaving the area. This helps prevent potential injury from occurring due to sudden movement of the machine’s parts.

11.What Are The Maintenance Procedures For A Capsule Separating Machine?

Testing

Before each use, it is essential to perform a thorough test of the capsule separating machine. This should include checking that all components are functioning properly and that there are no loose or damaged parts.

Cleaning

It is important to regularly clean the capsule separating machine by removing dirt, dust and other debris that may have accumulated on its surface. This will help ensure that it continues to operate efficiently and safely.

Lubrication

To ensure the capsule separating machine operates smoothly, all movable parts must be lubricated with a suitable lubricant at regular intervals in accordance with manufacturer’s instructions.

Inspection

The capsule containers should be inspected regularly for signs of wear or damage. Any cracked or broken capsule containers must be replaced immediately as they could cause capsule contamination which may result in improper function or even injury if not addressed promptly.

12.What Are The Problems Associated With Using Capsule Separating Machines And Their Possible Solutions?

Cross-Contamination

Capsule separating machines can cause cross-contamination of products, as capsule dust and micro-particles from one capsule can collect in another capsule. This is especially problematic with capsules that contain allergenic substances or sensitive ingredients.

Solutions

Using a capsule separating machine that has a closed capsule separator system, regular cleaning and maintenance to reduce capsule dust build-up, and using capsule type material that is less prone to generating capsule dust.

Jamming

Capsule separating machines can jam or become blocked due to capsule size, capsule material and capsule shape.

Solutions

Regularly checking capsule sizes, capsule materials and capsule shapes for compatibility with the capsule separator system and adjusting the settings of the capsule machine accordingly.

13.What Factors Should You Consider Before Purchasing A Capsule Separating Machine?

Here are some factors to consider before purchasing a capsule-separating machine.

Quality

Make sure the capsule separating machine you purchase is high quality and durable. A capsule-separating machine that breaks down often can cause significant downtime and result in lost profits.

Capacity

The capsule-separating machine must be able to accommodate your capsule size and quantity. Consider the speed at which the capsule separating machine can process different capsule sizes and its overall production rate for your business needs.

Efficiency

Check how efficient the capsule-separating machine is in terms of time, cost, and output. A high-efficiency capsule separating machine will ensure that you maximize profits while minimizing costs.

Maintenance

It’s important to have a capsule-separating machine with easy maintenance, 24-hour service options, and access to parts in case of failure. Doing so will help reduce unnecessary downtime due to breakdowns or repairs.

Warranty

Investing in a capsule separating machine with an extended warranty is always a good idea, as it ensures the longevity of your investment and provides peace of mind.

CONCLUSION

The process of retrieving materials from capsules is now an easy task, thanks to the capsule separating machine. This machine makes it easier for you to empty out your needed dosages without any hassle. Now that you know how a capsule separating machine works and its benefits, it’s time to start looking for a supplier. Allpack is a leading provider of high-quality machinery. Therefore, if you are interested in getting a capsule separating machine for your own purposes, then be sure to contact Allpack today!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours