Granulator Group – Pharmaceutical & Nutraceutical Powder Processing Equipment

High-Efficiency, GMP-Compliant Granulators for Tablets, Capsules, and Supplements in the Middle East

Why Choose Our High Shear Mixer Granulator ?

ALLPACK High shear mixer granulator is designed for pharmaceutical and nutraceutical powder processing, delivering consistent particle size, high efficiency, and reliable performance.

High Shear & Dry Options

Suitable for tablets, capsules, and supplement powders

GMP-Compliant Design

Ensures hygiene, safety, and regulatory compliance

Durable & Easy Maintenance

Stainless steel construction and CIP cleaning support

Flexible Integration

Can be combined with mixing, drying, and tablet press equipment for complete solid dosage lines

Various High Shear Mixer Granulators For Your Choice

FL Series Rotating High Shear Mixer Granulator for Wet Dry Granulation

AIPAK high shear mixer granulator has been widely used in the pharmaceutical industry for tablets, capsules, and low-sugar/no-sugar Chinese medicine granules, the food industry for cocoa, coffee, milk powder, juice granules, and flavorings, as well as other industries including pesticides, feed, chemical fertilizers, pigments, and dyestuffs. Made of SS316L stainless steel contact parts and designed to meet GMP hygiene standards, it ensures a clean production process and minimizes contamination risks.

Overload protection, simple maintenance

Free of oil lubrication and leakage

Reliable operation

GHL Series Pharmaceutical Wet Powder Granule High Shear Mixer Granulator

AIPAK high shear mixer granulator is a high-efficiency machine designed to uniformly mix powdered materials and produce granules in a single process, widely utilized across pharmaceutical, food, and chemical industries. With efficient mixing and controlled granulation, our machine can significantly reduce dust generation and material loss, improving production yield and lowering costs.

Adopt frequency speed adjustment

Easy to operate

Automatic lifting of the pan cover

GK Series Easy to Operate Industrial Horizontal High Shear Mixer Granulator

AIPAK high shear mixer granulator is manufactured to transform fine powder particles into larger, more uniform granules. As a newly designed equipment, the machine uses material’s crystallized water to convert powders into granules, featuring a robust structure, reliable performance, easy maintenance.

Adapts a practical horizontal cylinder structure

PLC Controls

Variable speed drive for main impeller & chopper

HLSG Series High Efficiency High Shear Mixer Granulator for Pharmaceutical Nutraceutical Food Chemical Industries

AIPAK high shear mixer granulator is a specially designed pharmaceutical granulation machine for evenly mixing powders and producing uniform wet granules. Our machine integrates consistent programmed technology with a main-machine interface as an optional feature to ensure stable quality and provides user-friendly manual controls for easy adjustment of technological parameters.

Mix evenly&Strong blending ability

Advanced design, reasonable layout

Reliable seal, convenient operation

KZL Series Stainless Steel High Shear Mixer Granulator for Powder

AIPAK high shear mixer granulator is extensively employed in pharmaceutical, chemical, and food industries, featuring a rationally designed sieve and linkage system that efficiently crushes blocks of brittle materials while maintaining operational reliability. Built with adjustable impeller and chopper speeds, our machine allows precise control over granule size and moisture content.

Compact&small in size

Light in weight, easy to operate

Low in noise and stable in operation

Model YK-160 High Speed High Shear Mixer Granulator with CE/ISO certification

AIPAK high shear mixer granulator can convert wet powdery materials into granules, crushes dry block materials, and enables rapid granulation, widely used in pharmaceutical, chemical, and food industries. Built with safety locks, easy-to-clean design, and global certifications (CE/ISO), our machine is safe, efficient, and reliable for pharmaceutical manufacturing.

Modular & Efficient Design

Fully Automatic Operation through Programmable

Uniform granules, higher output

Model ZL Industrial High Shear Mixer Granulator with GMP Compliant

AIPAK high shear mixer granulator is suitable for APIs, excipients, and sensitive powders, widely used in laboratory-scale and large-scale production. As an ideal choice for industries such as pharmaceuticals, food production, industrial dosage chemicals, and solid beverages, particularly for processing highly viscous materials, our machine can efficiently transform agitated materials into required granules.

Stable operation, low noise

Safety and reliability

Easy operation, convenient maintenance

ALLPACK High Shear Mixer Granulator Applications in Pharma & Nutraceutical Production

Tablets & Capsules

Accurate granulation ensures uniform dosage for tablets and capsules, reducing weight variation and improving production efficiency.

Protein & Supplement Powders

High shear granulation delivers consistent particle size, perfect for protein powders, vitamin blends, and herbal supplements.

Herbal & Vitamin Powders

Optimized wet or dry granulation process preserves active ingredients and improves compressibility.

Case Study – Middle East Vitamin Factory

A leading UAE-based nutraceutical manufacturer integrated our high shear granulator into their tablet production line.

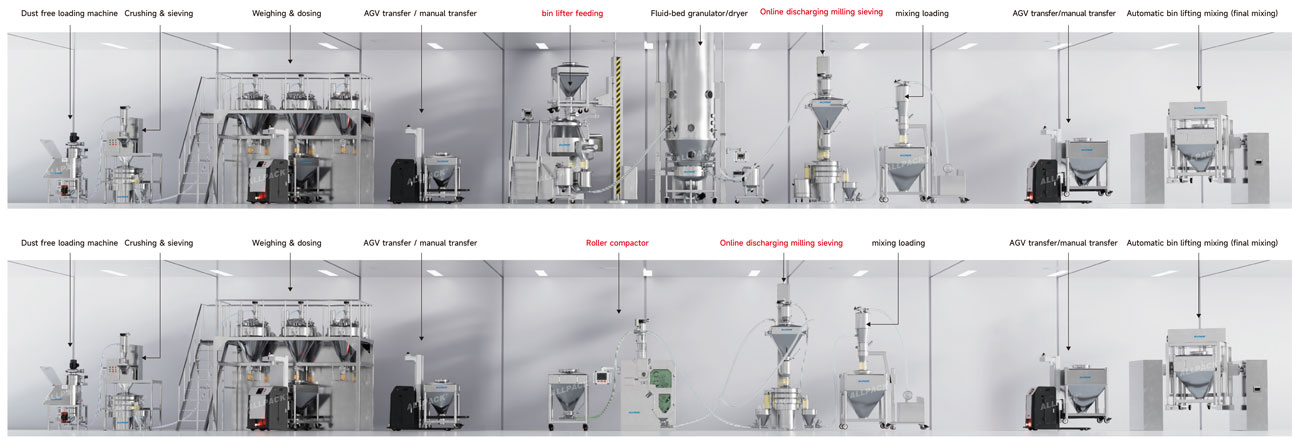

Granulation Line Integration – Turnkey Solutions

Our high shear mixer granulators can be integrated with mixing, drying, and tablet press equipment to form a complete solid dosage production line. Tailored turnkey solutions are available for pharmaceutical and nutraceutical manufacturers across Saudi Arabia, UAE, Egypt, and other Middle East markets.

Seamless Integration

Mixing → Granulation → Drying → Tablet Press → Coating

High Efficiency

Optimized workflow reduces production time and energy consumption

GMP Compliance

Ensures hygiene and regulatory compliance at every stage

Frequently Asked Questions – High Shear Mixer Granulator & Granulation Lines

Q: What types of granulators do you supply?

A: We provide high shear, dry, and fluid bed granulators suitable for pharmaceutical and nutraceutical powder processing, including tablets, capsules, and supplement powders.

Q: Can your granulators be integrated into a complete production line?

A: Yes. Our granulators can be combined with mixing, drying, tablet press, and coating equipment to form a turnkey solid dosage production line, fully customizable for different production capacities.

Q: Are your granulators GMP-compliant?

A: Absolutely. All our granulators are designed and manufactured according to GMP standards, with stainless steel construction, CIP cleaning, and dust-free operation.

Q: Do you provide installation and after-sales support in the Middle East?

A: Yes. We provide local installation guidance, training, spare parts supply, and maintenance support in Saudi Arabia, UAE, Egypt, and other GCC countries.

Q: Can your granulators handle both pharmaceutical and nutraceutical powders?

A: Yes. Our machines are suitable for a wide range of powders, including vitamins, herbal powders, protein powders, and tablet ingredients, ensuring consistent particle size and quality.

Q: What is the typical lead time for delivery?

A: Depending on the model and production line customization, lead times typically range from 6 to 12 weeks for Middle East deliveries.

Request a Free Granulator Quote

Talk to Our Middle East Equipment Specialist