Why Choose Our Shampoo Filling Machine?

High Viscosity Compatibility

Equipped with piston or servo pump system, it easily handles thick products like shampoo, cream, or hair conditioner without clogging or foaming.

No-Leak & Make Clean Filling

Anti-drip nozzles and precise filling heads keep your production line spotless — ideal for cosmetic-grade packaging standards.

Adjustable&Wide Filling Range

Customizable filling volume from 10ml to 30L bottles, compatible with various bottle shapes and sizes, best solutions to meet your production line.

Easy Operation & Maintenance

Touchscreen control, quick parameter adjustment, and tool-free cleaning make it easy for operators of all skill levels.

Stainless Steel Construction

Built with SUS304 / SUS316L stainless steel, ensuring durability and corrosion resistance in long-term production.

Various Shampoo Filling Machine Production Lines For Your Choice

Allpack 10-100ML High Speed Daily Chemical Shampoo Filling Machine for Bottles & Cans

Allpack 10-100ml high-speed shampoo filling machine is engineered for bottles and cans of various sizes, seamlessly handling daily‑chemical liquids including shampoos, liquid soaps, conditioners and detergents. The machine is built with a durable 304‑grade stainless steel frame, PLC & touchscreen HMI control, and multi‑head servo drive filling system, it delivers stable high‑speed operation, precise fill volumes and low product loss. It is ideal for manufacturers scaling up their production.

High Filling Precision

Wide Capacity Range

Handles High-Viscosity Liquids

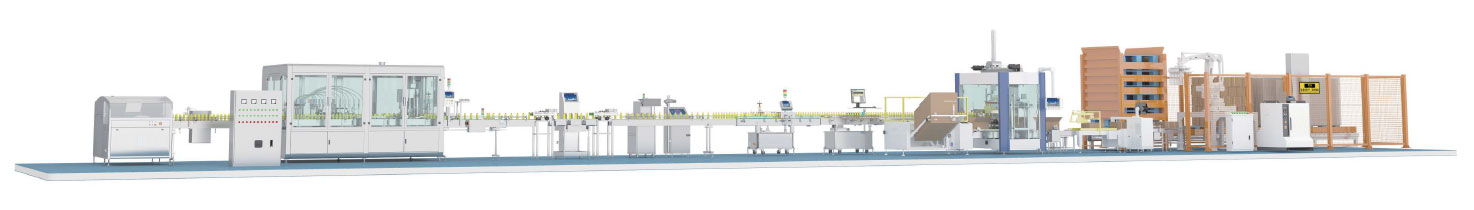

Allpack 50-1000ML Standard Shampoo Filling Machine for Medium Volume Production

Allpack 50-1000ml standard shampoo filling machine is designed for small to mid‑scale manufacturers, specially catered to thicker shampoos, conditioners and other viscous or mildly corrosive daily‑chemical liquids. It features anti‑corrosion material construction, independent control cabinets, and an automatic motor‑driven lifting system for the filling heads—providing high precision and reliability even under demanding fluid conditions. Operators simply load containers and initiate the process—filling becomes fast, consistent and easy to manage.

PLC Touchscreen Control

Automatic Bottle Feeding & Capping

Anti-Foam & Anti-Drip Design

Allpack 1-5L Bullet Train Daily Chemical Shampoo Filling Machine for Bulk Packaging

Allpack 1-5L bullet train shampoo filling machine handles drums, pails and jerrycans efficiently. Using a piston‑pressure filling system, motor‑driven lifting, and PLC‑controlled interface, it enables operators to adjust parameters quickly and maintain consistent fill levels. Its strong corrosion‑resistance and ease of cleaning make it a top choice for shampoo, hand‑sanitizer, detergent and other daily‑chemical production lines.

Explosion-Proof Options

High Production Efficiency

Stainless Steel Construction

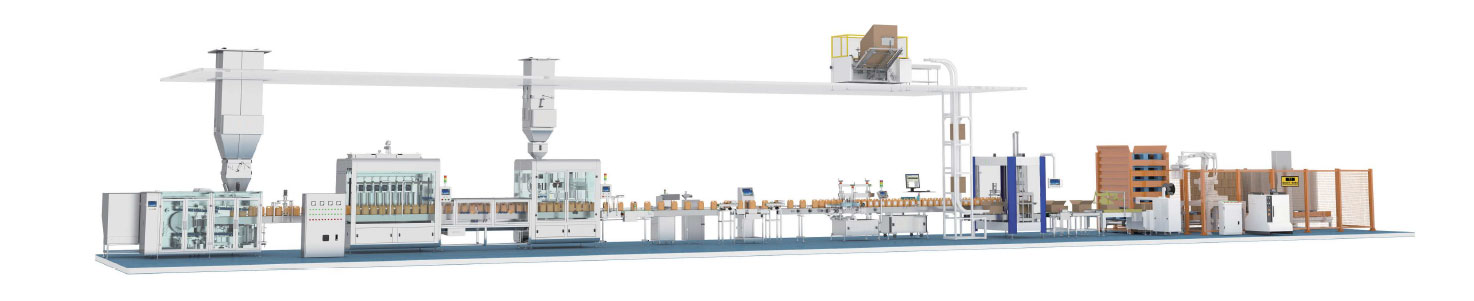

Allpack 5-30L Daily Chemical Shampoo Filling Machine for Bottled Production Lines

Allpack 5-30L shampoo filling machine is engineered for high‑throughput bottle filling of shampoos and personal‑care liquids, this production line features a compact and ergonomic structure, fluent automation and high precision filling with advanced nozzles. It supports quick format change‑overs, minimises downtime and facilitates easy maintenance. The whole production line is ideal for cosmetic brands expanding their lineup of bottled products with consistent quality and efficient operations

Flexible Container Compatibility

Smart Error Detection System

Energy-Efficient Operation

ALLPACK Shampoo Filling Machine Applications

Shampoo

Conditioner

Hair Oil

Body Wash

Shower Gel

Lotion

Serving the Middle East Cosmetic Industry

Trusted by manufacturers in Dubai, Riyadh, Cairo, Doha, and Istanbul, our shampoo filling machines help cosmetic brands scale up production with consistent quality and fast ROI.

Allpack Shampoo Filling Machine FAQ

Q1: Can this machine handle both shampoo and conditioner?

Yes. The piston or servo filling system is designed for various viscosities, suitable for both liquid and semi-viscous products.

Q2: What is the filling speed?

Depending on the model, from 20–60 bottles/min, fully adjustable based on bottle size and volume.

Q3: Is it suitable for foamy liquids?

Yes, we offer foam control nozzles and bottom-up filling options to reduce bubbles during filling.

Q4: Can the machine integrate with labeling or capping systems?

Absolutely. We provide complete packaging lines including filling, capping, and labeling.

Q5: Do you provide installation and training in the Middle East?

Yes. Our engineers can assist with on-site installation, online support, and full operator training.

Upgrade your shampoo production line today.

Contact us to get a customized quote for your factory in UAE, Saudi Arabia, or Egypt.