Why Choose Our Pesticide Filling Machine?

High-Precision Filling

Servo-driven or piston pump systems guarantee ±0.2% filling accuracy.

Handles highly corrosive or viscous liquids without overflow or spillage.

Corrosion-Resistant & Durable

All liquid-contact parts made from SUS316L stainless steel or PTFE.

Resistant to acids, alkalis, and chemical solvents.

Automatic & Flexible Operation

Filling volumes from 10ml to 1000L

Compatible with bottles, jerry cans, and drums

Optional auto capping and labeling integration

Safe & Clean

Anti-drip nozzles and enclosed filling area reduce chemical exposure.

Optional explosion-proof design for flammable agrochemicals.

Easy Operation & Maintenance

Intuitive PLC touchscreen interface for simple batch setting.

Quick-disassembly components for fast cleaning and maintenance.

Various Pesticide Filling Machine Production Line For Your Choice

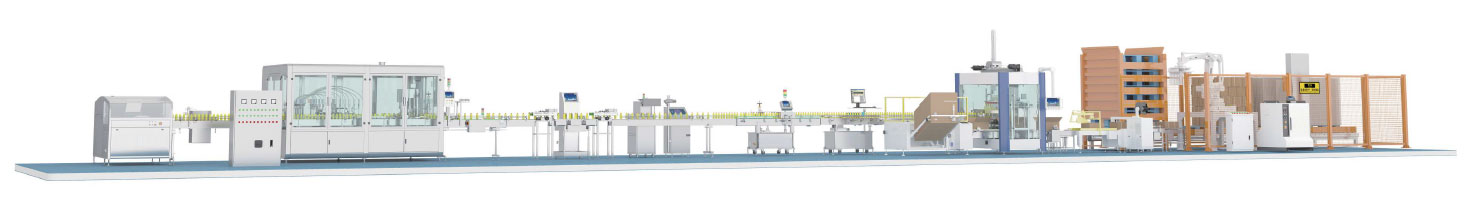

Allpack 50-1000ML Pesticide Filling Machine With High Filling Precision

Allpack 50-1000ml pesticide filling machine integrates bottle unscrambling, filling, capping, and optional labeling for seamless pesticide packaging. It supports various bottle sizes and viscosities, features PLC control, corrosion-resistant materials, and explosion-proof options. The whole production line is perfect for manufacturers aiming to improve productivity, ensure safety, and maintain compliance with environmental and safety regulations.

Explosion-Proof Options

High Production Efficiency

Adjustable Filling Speed & Volume

Allpack 1-5L Pesticide Filling Machine for High-Viscosity Liquids

Allpack 1-5L pesticide filling machine is designed to handle thick liquid pesticides, herbicides, and liquid fertilizers efficiently. The machine features corrosion-resistant stainless steel construction, adjustable filling speed, and anti-drip nozzles, it ensures precise filling from small bottles to large drums, reduces chemical waste, and improves operator safety. Ideal for medium-to-large agrochemical production lines.

Smart Error Detection System

Low Product Loss & Waste

Flexible Container Compatibility

Allpack 5-30L Pesticide Filling Machine for High-Volume Production

Allpack 5-30L pesticide filling machine is equipped with multiple filling heads and PLC control, it allows simultaneous filling of several bottles or containers. Accurate flow-meter and piston pump technology ensures consistent volume and minimal product loss. The whole production line is best built for large-scale agrochemical manufacturers who require speed, reliability, and safety compliance.

High Durability & Industrial Construction

GMP & CE Compliant

Easy Integration into Production Lines

Allpack 200L Pesticide Filling Machine for Drums & Containers

Allpack 200L pesticide filling machine is designed specifically for corrosive agrochemicals, it uses stainless steel and chemical-resistant materials to protect the equipment. Adjustable nozzle height, real-time weight feedback, and automatic stop features guarantee precise filling of 20–200 L drums, reducing spillage and ensuring worker safety.

Quick Format Changeover

Energy-Efficient Design

Safe & Ergonomic Operation

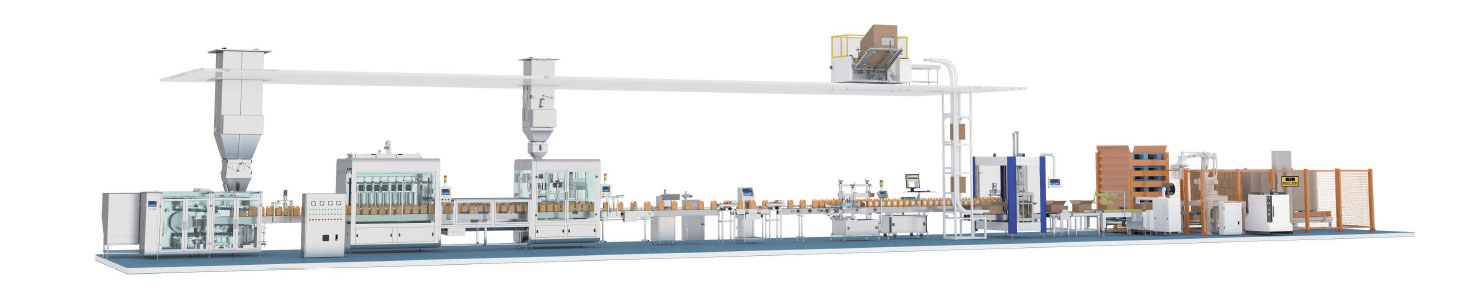

Allpack Ton Drum Pesticide Filling Machine for Flexible Production

Allpack ton drum pesticide filling machine integrates bottle feeding, filling, capping, and optional labeling for pesticides, herbicides, and liquid fertilizers. It has the feature PLC control, explosion-proof options, and corrosion-resistant materials, providing high throughput, precise filling, and compliance with safety and environmental standards. The whole production line is perfect for modern agrochemical factories.

Flexible Container Compatibility

High Durability & Industrial Construction

Easy Integration into Production Lines

Trusted by Middle Eastern Agrochemical Producers

Used by manufacturers and distributors in UAE, Saudi Arabia, Egypt, Oman, Turkey, and Iran, our pesticide filling machines ensure accurate dosing, reliable operation, and reduced chemical waste, helping clients maintain safety and efficiency.

ALLPACK Pesticide Filling Machine FAQ

Q1: Can this machine handle highly corrosive pesticides?

Yes. All liquid-contact parts use corrosion-resistant stainless steel (SS316L) or PTFE, suitable for acids, alkalis, and chemical solvents.

Q2: What container sizes can it fill?

It supports small bottles (100ml) up to large drums (1000L), with customizable nozzle configurations.

Q3: Is it safe for flammable liquids?

Yes. Explosion-proof options are available to ensure safe operation with flammable agrochemicals.

Q4: Can it integrate with capping and labeling systems?

Absolutely. We provide fully automated production lines including filling, capping, labeling, and conveyors.

Q5: Do you provide support in the Middle East?

Yes. We offer on-site installation, operator training, and remote technical support across all key Middle Eastern countries.

Boost Your Agricultural Production Efficiency Today

Contact us for a customized pesticide filling solution for your factory in UAE, Saudi Arabia, Egypt, or Oman.