Single Punch Tablet Machine:The Complete Buying Guide In 2024

Single Punch Tablet Machine:The Complete Buying Guide In 2024

Does your tablet production efficiency need to be increased? Are you trying to manufacture tablets with accuracy and uniformity in mind? Are you looking for a way to save costs without sacrificing quality? You are at the correct spot if you answered "yes" to any of these questions.

A single-punch tablet machine is an economical yet reliable and efficient equipment you should consider for your business, whether you own a pharmaceutical, food, or chemical production industry.

In this article, we will guide you through the complex world of tablet production equipment, enabling you to make wise choices at every turn. We will break down the important factors you should have in mind before making a purchase.

From understanding the basics about the single-punch tablet machine to assessing your needs and budget – we have got you covered. After going through this article, you will have all the necessary information and self-assurance to select an ideal single-punch tablet machine that complies with your needs and budget.

So, let’s dive into the topic together. Your ultimate solution of efficient and cost-effective tablet manufacturing is waiting for you!

1.What is a single-punch tablet machine?

AiPak Automatic Single Punch Tablet Machine

A single-punch tablet machine is an earlier innovation in tablet manufacturing. It is industrial equipment employed across various sectors for the formulation of tablets. With the technological growth, it has also evolved over the years.

The device is utilized in several industries offering a great number of benefits, particularly for small enterprises and laboratories. It has a simple structural design with fewer components and an easy operation of compressing granular or powdered matter into a compact structured tablet with uniform characteristics (shape, size, and weight).

It is a reliable, efficient, and economical solution for tablet manufacturing without degrading its quality and handling various materials. It is an indispensable device for a small-scale industry whether it is pharmaceuticals, food, or chemicals.

2.What are the industries that can utilize a single-punch tablet machine?

The single-punch tablet machine is a must-have device for many industries, boosting their production efficiency. It is employed across numerous industries for different purposes and items. Some of the industries that often utilize the single-punch tablet machine are;

Pharmaceuticals

Applications in the Pharmaceutical Industry – Picture Courtesy: IFLScience

If you run a small manufacturing industry and have a low to medium level of production capacity then a single-punch tablet machine can benefit you a lot.

A single-punch tablet machine can be employed in the pharmaceutical industry to produce a variety of tablets with uniform size, weight, and density.

Confectionery

Candy Tablets – Picture Courtesy: Candy Warehouse

The device can have several applications in the confectionery industry, as it can process different powdered food materials into compact elegant-looking tablet forms.

Nutraceuticals

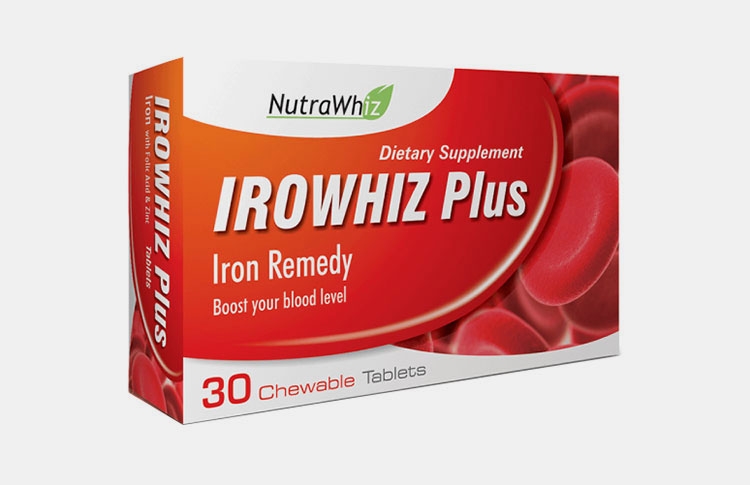

Applications in the Nutraceutical Industry – Picture Courtesy: Runner’s World

The single-punch tablet machine can also be employed in processing nutraceutical materials such as vitamins, minerals, and other dietary supplements into various forms of desired tablets.

Chemicals

Applications in the Chemical Industry

The production of various chemical tablets from powdered or granular materials in the laboratory or small-scale industry can be done using a single-punch tablet machine.

Cosmetics

Beauty Tablets – Picture Courtesy: Whole Store

In the cosmetic industry, certain materials need to be compressed into tablet form for better applications. For such purpose, a single-punch tablet machine can be employed which is an economical yet efficient and consistent device.

3.What are the benefits that one can have by investing in a single-punch tablet machine?

Are you wondering about the benefits that a single-punch tablet machine can offer to you? Don’t fret out! Here you will find how considering a single-punch tablet machine for your business can benefit you. So without any further delay, let’s go;

Small Size

Small Size Occupying Less Space

A single-punch tablet machine has a simple and compact design and occupies less space, which is beneficial for small-scale manufacturing.

Operational Ease

The Device is easy to Operate – Picture Courtesy: Lab Asia

With fewer components in its structure, a single-punch tablet machine has an easy operational procedure, requiring no trained personnel.

Low Noise

Low Noise Generation

The device has only a couple of moving parts, aiding in less production of noise.

Diverse Manufacturing

Manufacturing Versatility – Picture Courtesy: The Economic Times

One of the interesting advantages of a single-punch tablet machine is its flexibility in the fabrication of various shapes and sizes of pills. You need to change the tooling of the equipment to get the desired tablet’s form.

Efficiency

Efficient and Quality Production – Picture Courtesy: The FDA Group

The single-punch tablet machine is an efficient operational equipment, resulting in the efficient fabrication of tablets with consistent results. It can operate at a good speed and can produce 80 to 200 tablets each minute.

Cost-effective

Low Price, High Value Device – Picture Courtesy: Precision Machine Shop

If you want to boost your tablet production but the problem is your budget. Don’t worry, the single-punch tablet machine is comparatively a less expensive device and there are many variants available you can opt for based on your budget.

Maintenance Ease

Easy to Maintain – Picture Courtesy: YG Engineering Machinery

Being simpler in structure, a single-punch tablet machine can be maintained and cleaned easily with no complex structured component involved in the design.

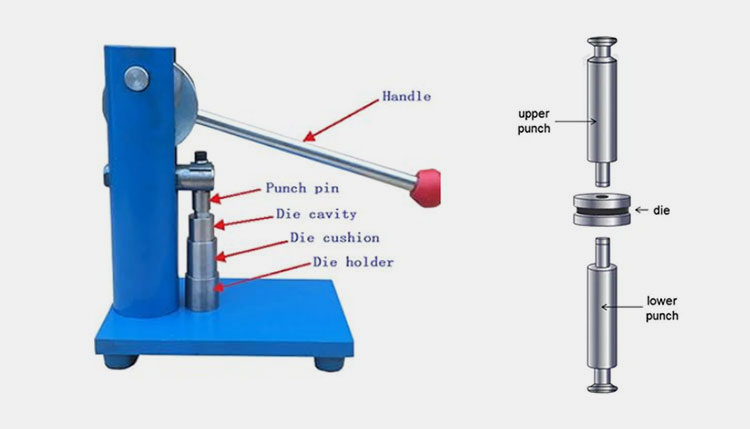

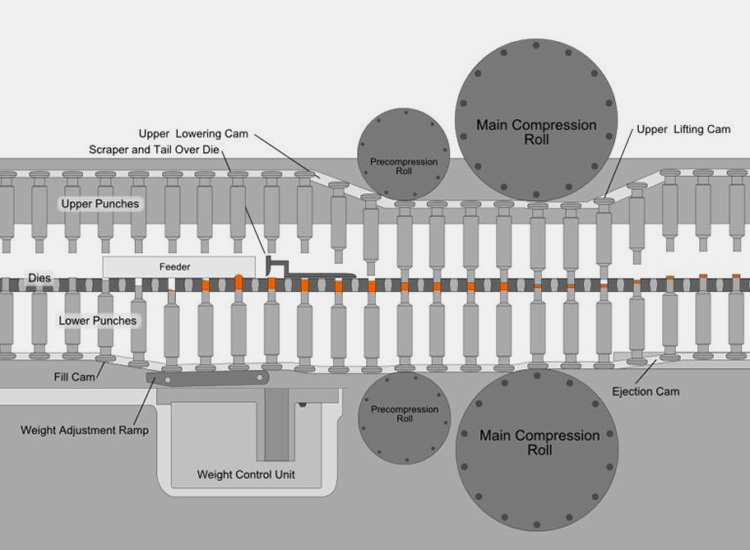

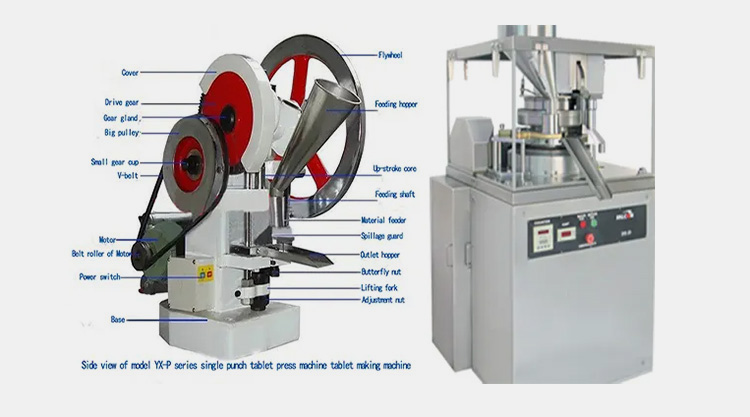

4.Describe the fundamental parts of a single-punch tablet machine.

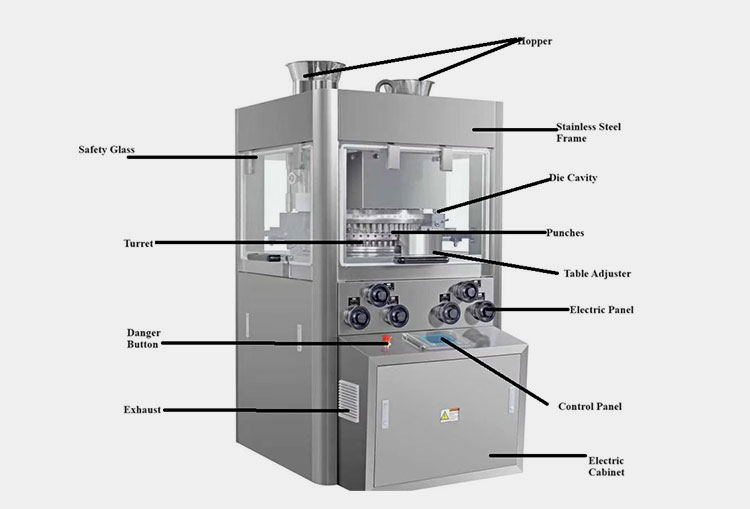

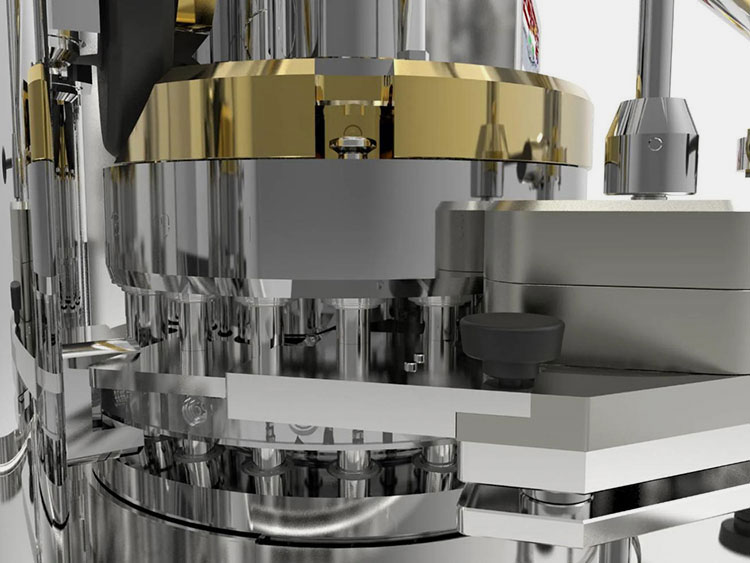

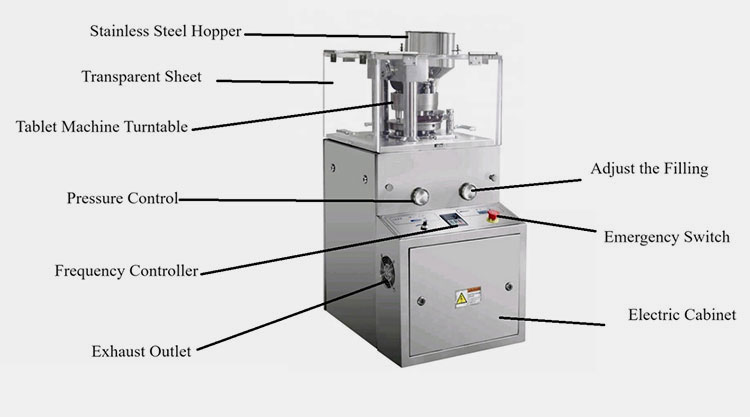

Parts of Single Punch Tablet Machine

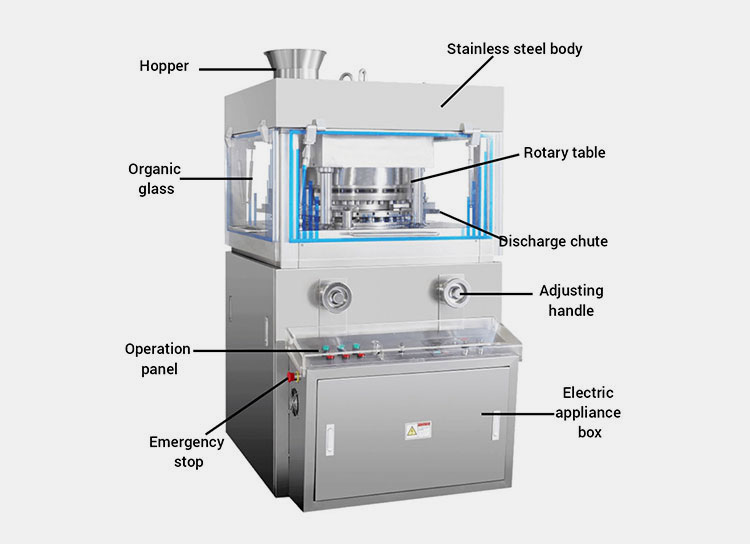

The single-punch tablet machine has a compact and simple structural design. It has fewer components working together to manufacture tablets. The basic components of a single-punch tablet machine are;

Hand Crank Handle

It is a manual control mechanism utilized to operate the process manually by applying force to the upper punch.

Loading Cup

It is also known as a feeding cup or hopper. It is the component from where the raw material is introduced into the machine. Its capacity depends on the design and size.

Feed Shoe

This is a connecting link between the die and hopper. It directs and regulates the material into the dies from the hopper.

Pressure Regulator

This component is used to regulate the exerting pressure by the upper punch on the material within the die pocket.

Eccentric Cam

It is the component that converts the spinning motion to the linear motion. It is connected to the hand crank handle and facilitates the downward movement of the upper punch.

Die Table

This part holds the die firm in place to withstand the punch pressure properly without any tumble.

Die

This is one of the core parts of the device. It contains a cavity known as the die pocket/cavity. The cavity comes in various shapes and depths. It provides the space for the material to be pressed by the punches.

Upper Punch

It is the component that exerts the necessary pressure on the powder mixture. It is the part that is responsible for compacting the powder into the desired tablet shape.

Lower Punch

It is another important tool, responsible for tablet thickness and ejection. It remains stationary during the compression phase.

Base

It is the bottom part of the device holding it firm and stable during the process.

Safety Mask

It is a protective cover that encloses the compression area, preventing any contact with the moving parts as well as the cross-contamination of the material.

Ejection Regulator

It facilitates the ejection of tablets after the compression.

Outlet

It offers an exit way for the manufactured tablets.

Motor

It provides the driving power to the machine for efficient processing.

Driving Belt

It connects the motor with the moving parts of the device.

Button

It is used to switch ON or OFF the device.

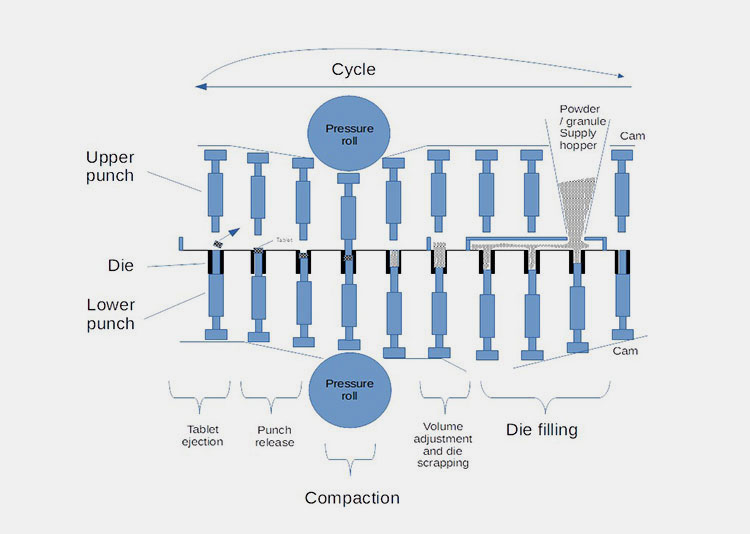

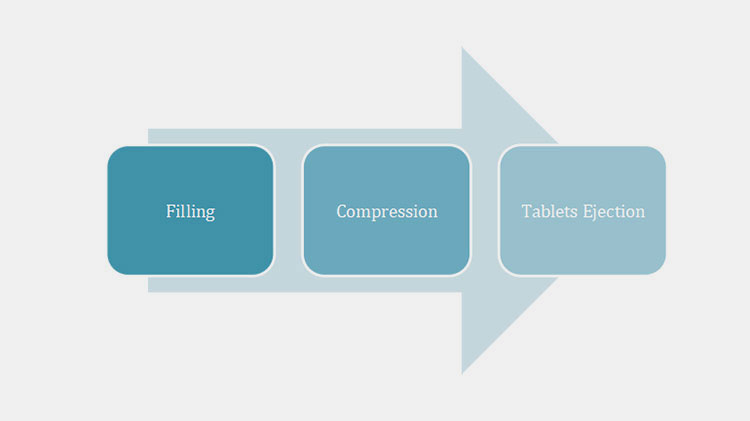

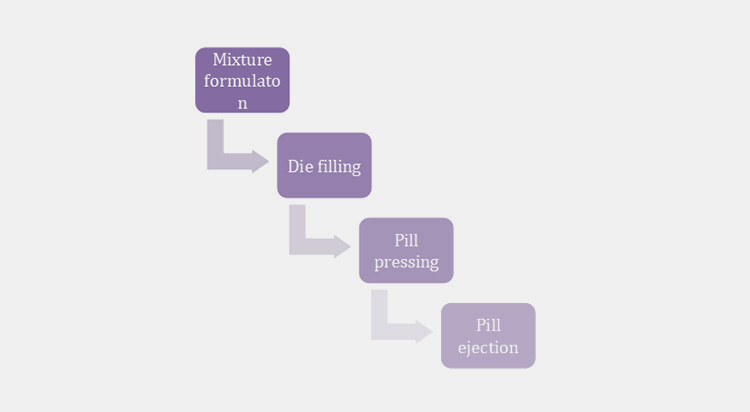

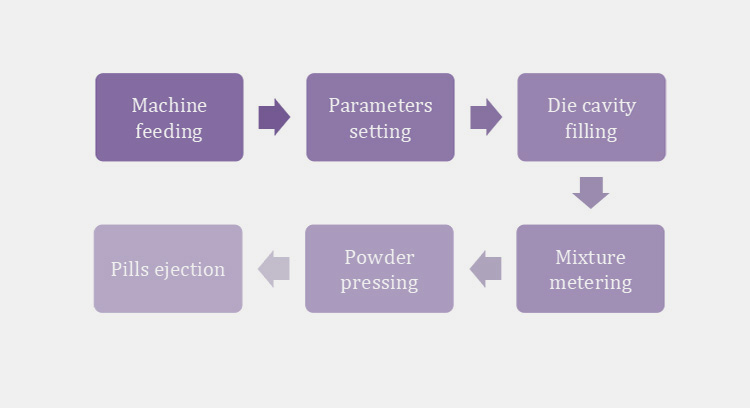

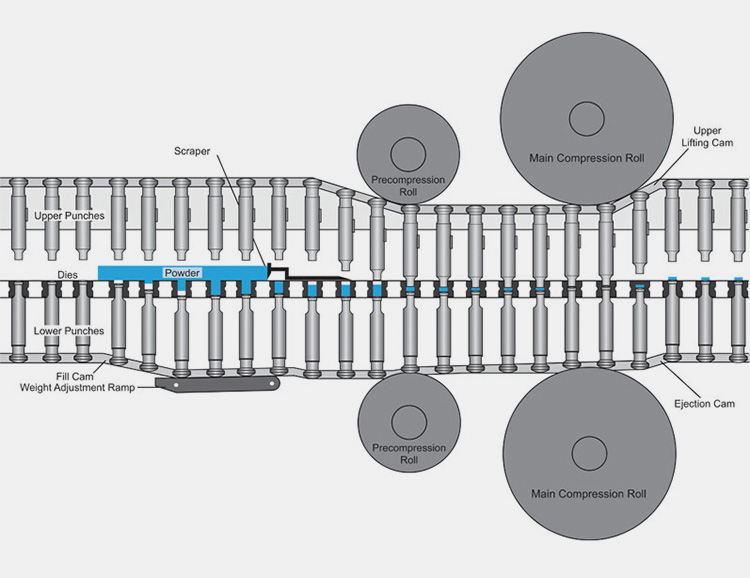

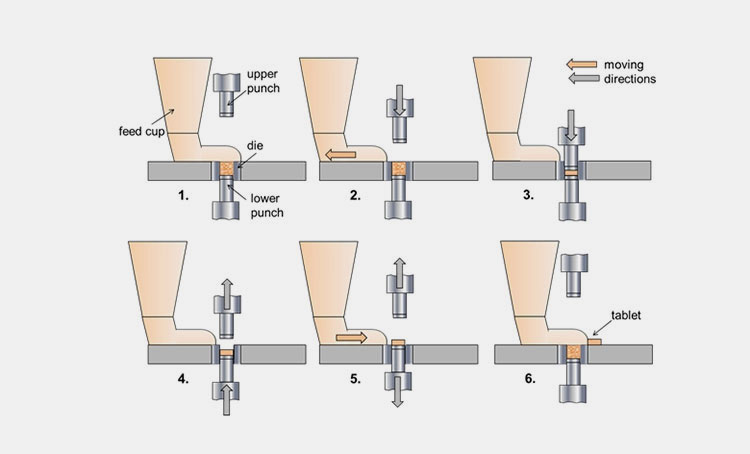

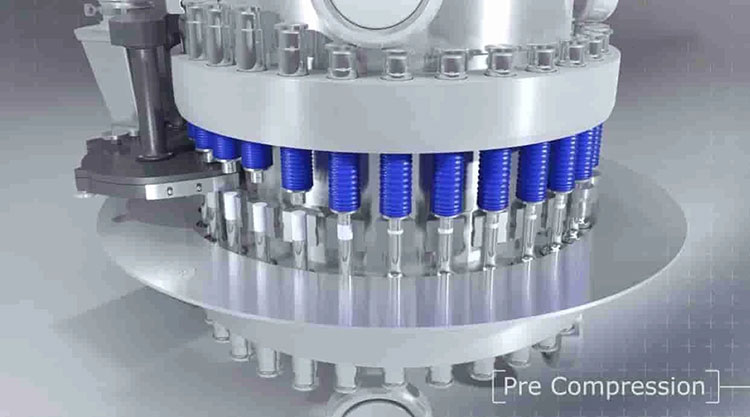

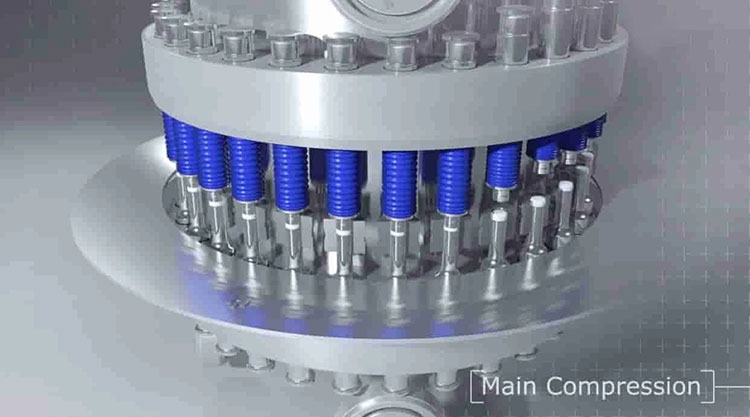

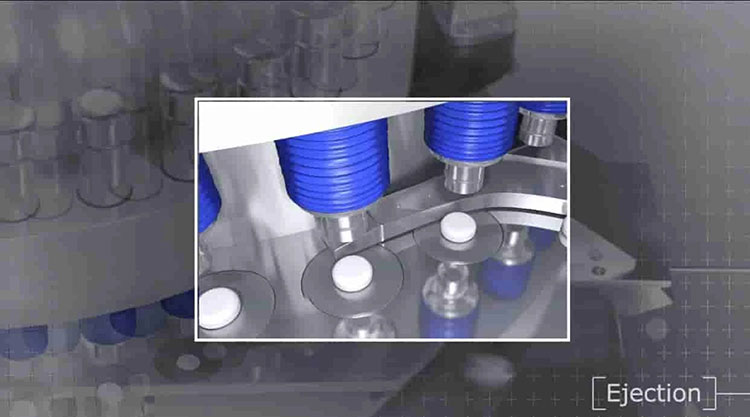

5.How does a single-punch tablet machine function?

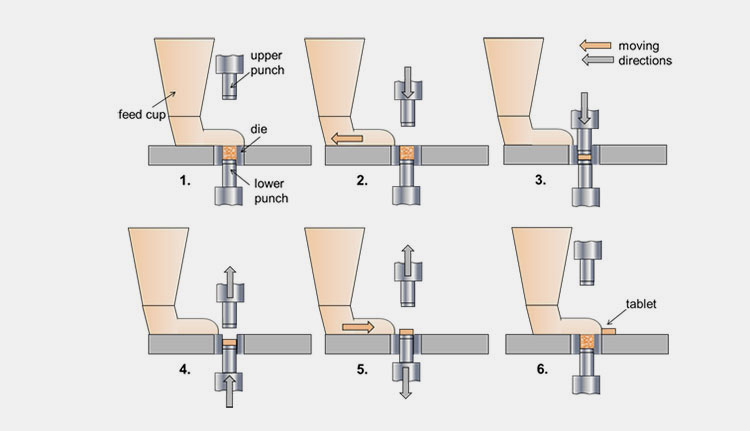

Working of Single Punch Tablet Machine – Picture Courtesy: SaintyCo

The elementary design of the single-punch tablet machine makes it easy to handle. The fundamental operational protocols of a single-punch tablet machine are stated below;

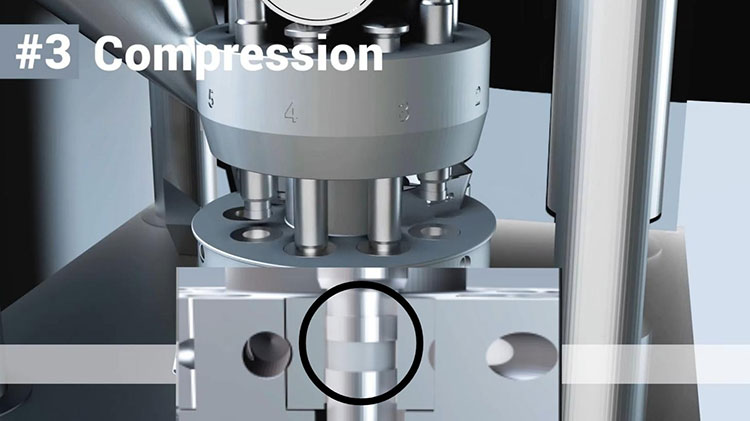

- A space is generated in the die by elevating and lowering the top and bottom punches, respectively.

- The gravity-driven raw mixture fills the die pocket to the brim from the loading cup.

- The upper punch then descends into the die pocket exerting the required compaction force to press the powder into the tablet and ensure that it attains uniformity.

- The thickness of the tablet depends on the distance between the punches. The closer they are placed, the harder and thinner will be the tablets produced.

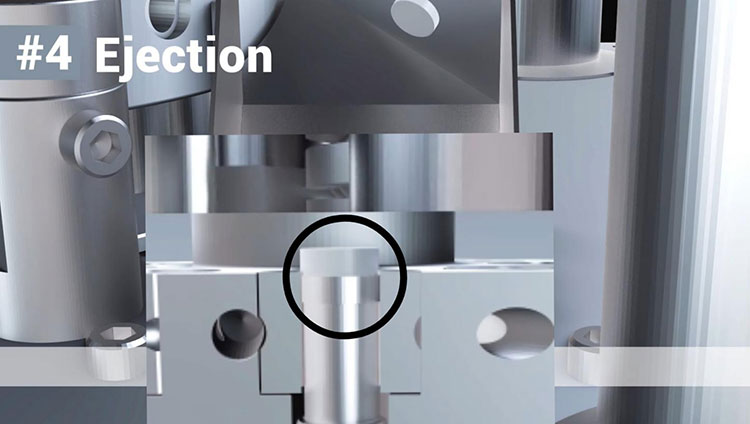

- The fabricated tablet gets ejected as a result of the simultaneous bottom punch uplifting and the top punch’s retraction.

- The entire process is continuously done until there is no more feeding material available.

- The working parameters can be regulated and monitored in the automatic variant of the device.

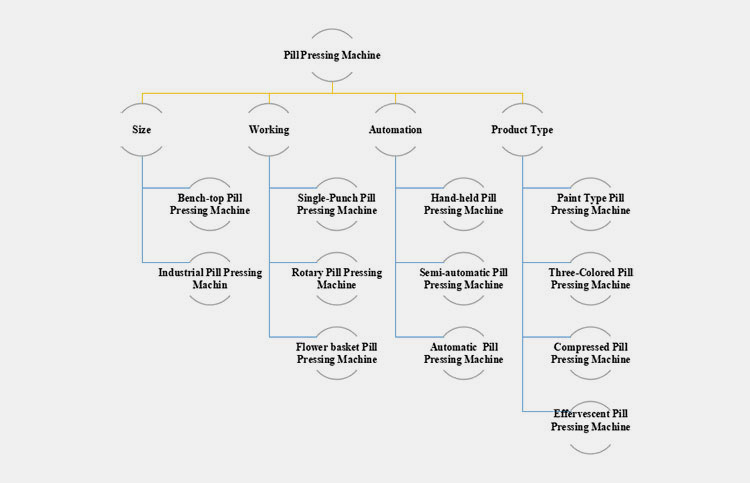

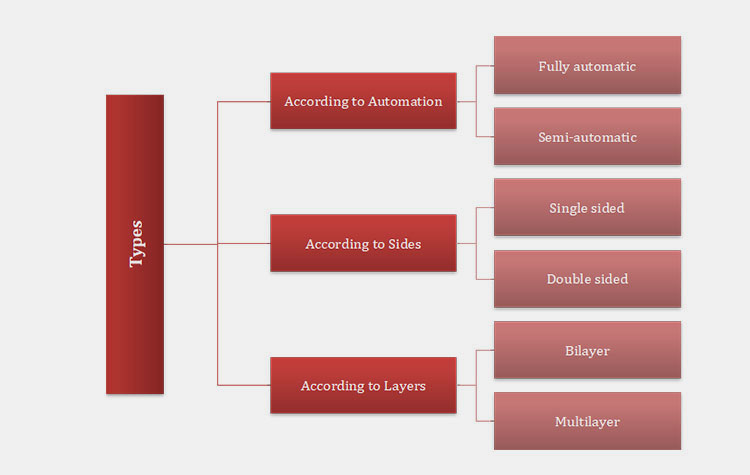

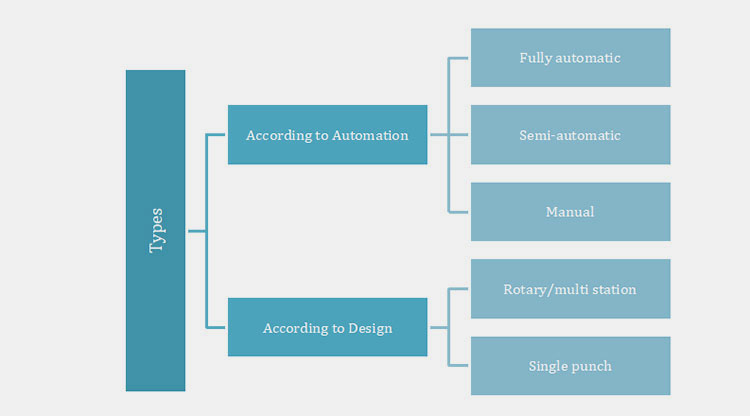

6.What are the kinds of models available for a single-punch tablet machine?

Based on the level of automation, a single-punch tablet machine can be categorized into 3 types, these are;

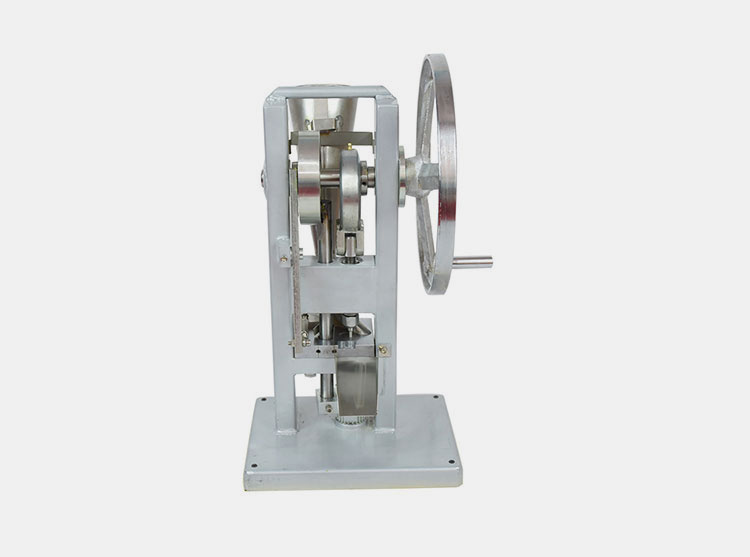

Manual Single Punch tablet Machine

Manual Single Punch Tablet Machine

It is a handheld operated model of single-punch tablet machine. It has the simplest design among all the tablet manufacturing equipment. It consists of a lever connected to the upper punch.

The material is poured into the die pocket by the operator. The lever is rotated which causes the upper punch to exert pressure on the material and transform it into tablet form. The tablet is then manually ejected from the cavity.

The production capacity of this equipment depends entirely on the operator.

Semi-Automatic Single Punch Tablet Machine

Semi-Automatic Single Punch Tablet Machine

In this type of machine, some of the operating steps are performed by the worker while the rest of the operation is done by the machine automatically.

They also have the facility of a hand crank wheel, which can be used for manual compression operation if the motor malfunctions.

Automatic Single Punch Tablet Machine

Automatic Single Punch Tablet Machine

These types of devices are equipped with automated mechanisms. The material to be compressed can be fed utilizing an automatic tool, compression is done, then the tablet gets ejected automatically.

In certain variants, a control panel is installed through which the process parameters can be monitored and controlled. The automatic single-punch tablet machine is an advanced form of device, having highest of the capacity and operating speed among single-punch tablet machine variants.

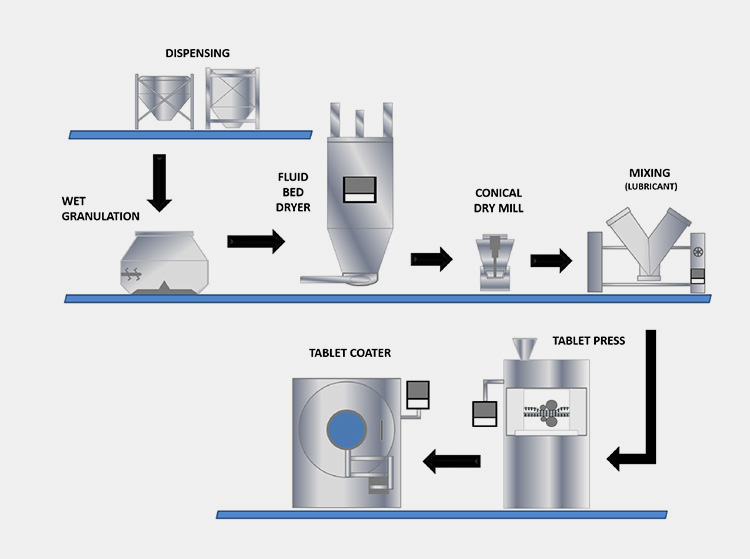

7.What kinds of materials can a single-punch tablet machine handle?

A single-punch tablet machine is a versatile device capable of handling a variety of materials and compressing them into a compact desired tablet form. Some of the materials that a single-punch tablet machine can handle are;

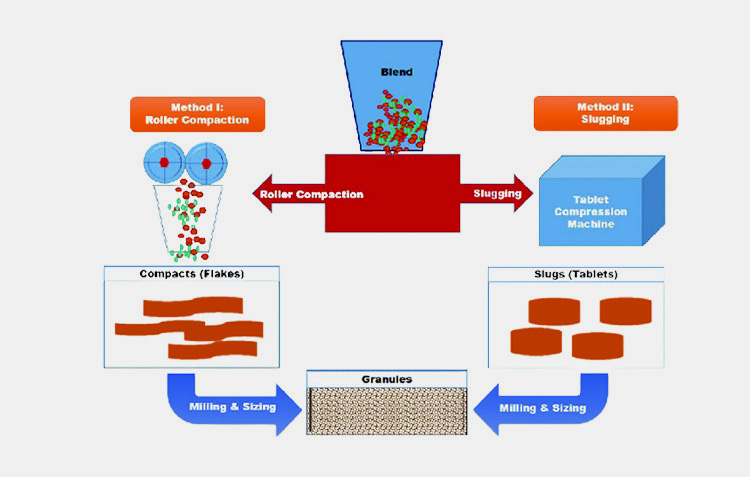

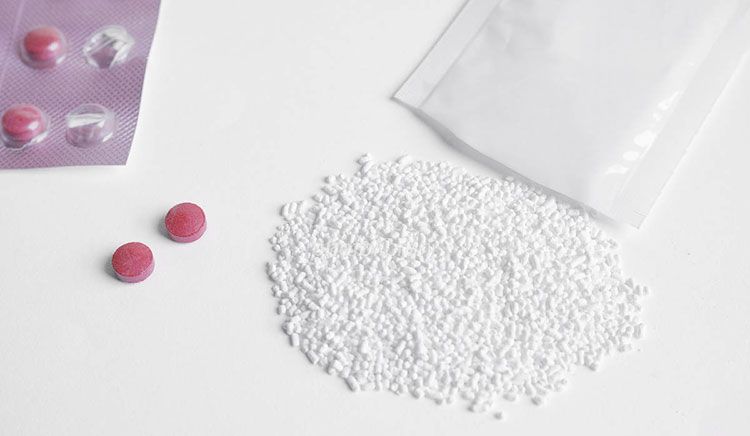

Granules

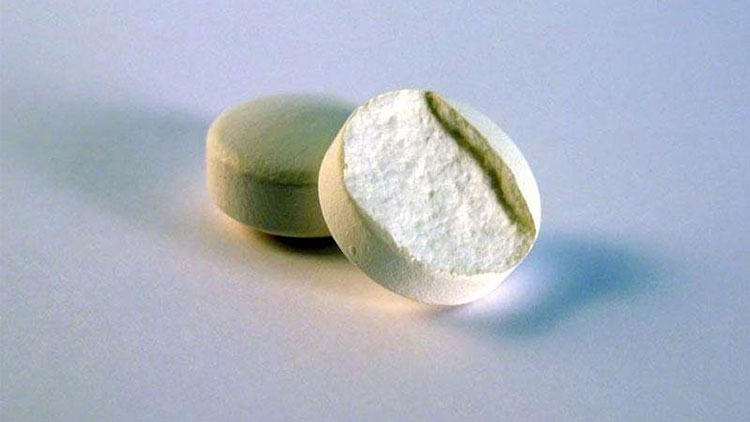

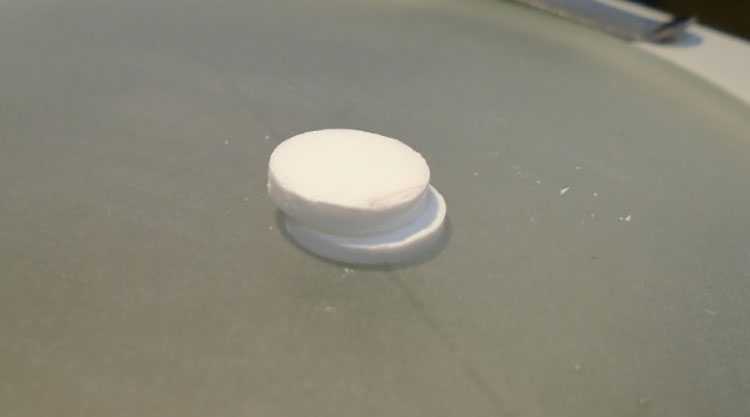

Tablet Formation from Granules

Granules are particles with consistent particle size. A single-punch tablet machine can handle all sorts of granular materials and compress them into a compact tablet structure.

Granulation of certain powders is done to improve their flow characteristics and facilitate the formulation of tablets.

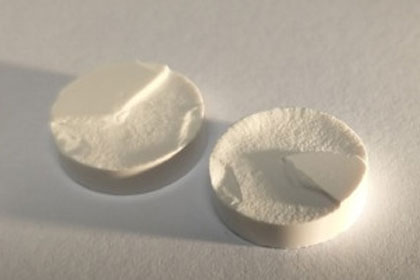

Powders

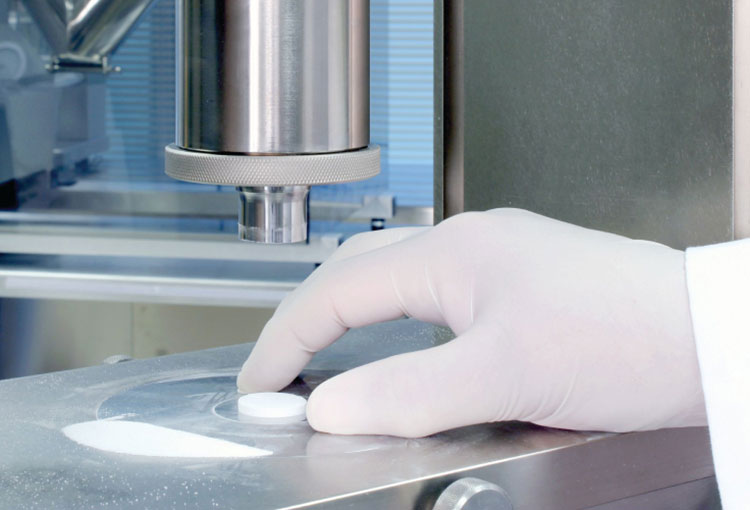

Tablets Formation from Powder – Picture Courtesy: Livestrong.com

Powders are finer particles with variable particle size. Dry powders can be compacted into tablets using a single-punch tablet machine.

8.What types of tablets can be manufactured by a single-punch tablet machine?

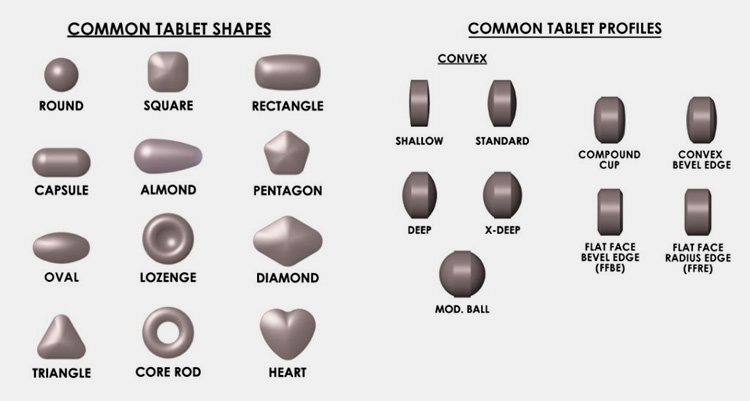

A single-punch tablet machine can manufacture various shapes of tablets. Some common are;

| Round Tablets

They are the most commonly manufactured tablets. They are circular with no edges. They can be easily produced. |

Round Tablets – Picture Courtesy: Amino Apps |

| Oval Tablets

They are elliptical-shaped tablets. They are usually bigger than round tablets. |

Oval Tablets |

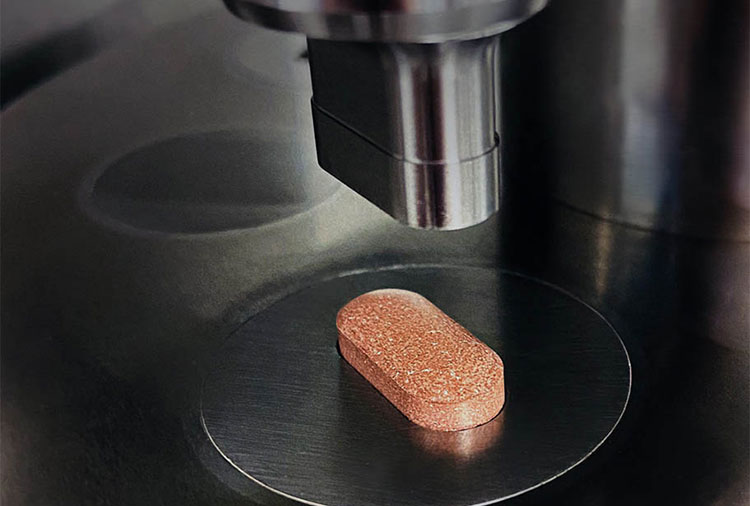

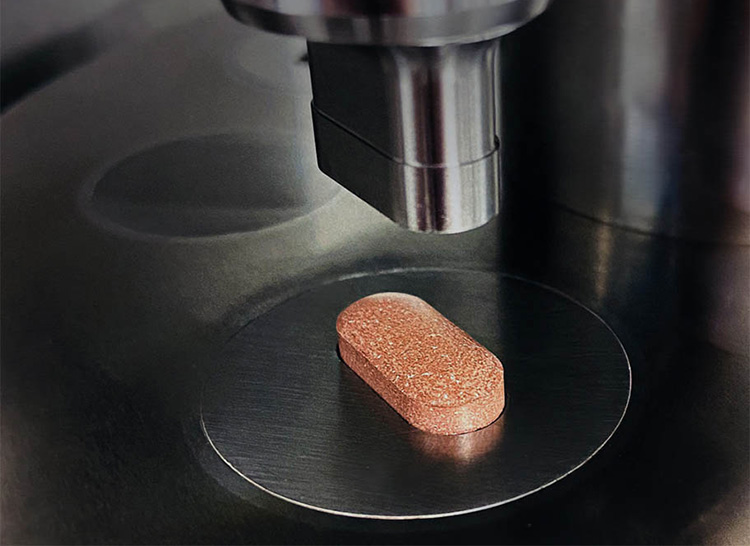

| Oblong Tablets

They are rounded-edged rectangular tablets. They are usually produced to carry large dosages of drugs, such as chewable tablets. |

Oblong Tablets – Picture Courtesy: PharmaTech |

| Triangular Tablets

They have three corners with distinct edges or round edges. |

Triangular Tablets |

| Square Tablets

They are four-cornered tablets. They usually have a flat surface. |

Square Tablets – Picture Courtesy: StudioNow |

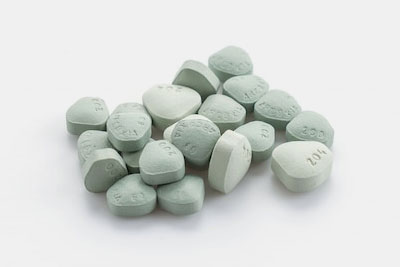

| Heart Tablets

They are heart-shaped and can be produced for many purposes in various industries, particularly in the confectionery industry. |

Heart Shaped Tablets |

| Core Rod Tablets

They have a round aperture in the center, mostly manufactured in the food industry. |

Core Rod Shaped Tablet – Picture Courtesy: navafresh.sg |

| Unique Tablets

There can be other unique tablet shapes, subject to the design of the punches. |

Different Unique Shaped Tablets – Picture Courtesy: Penglai Packaging |

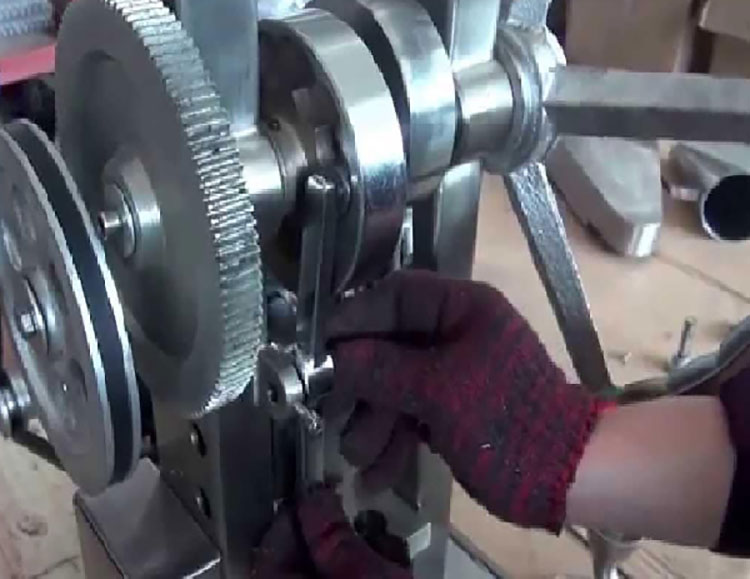

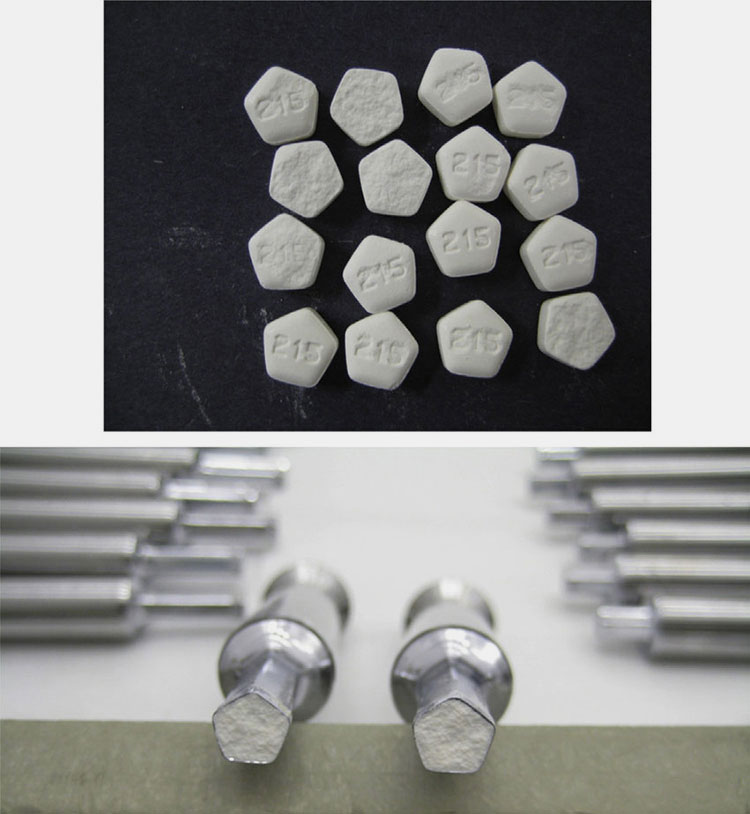

9.What role do tooling options play in a single-punch tablet machine?

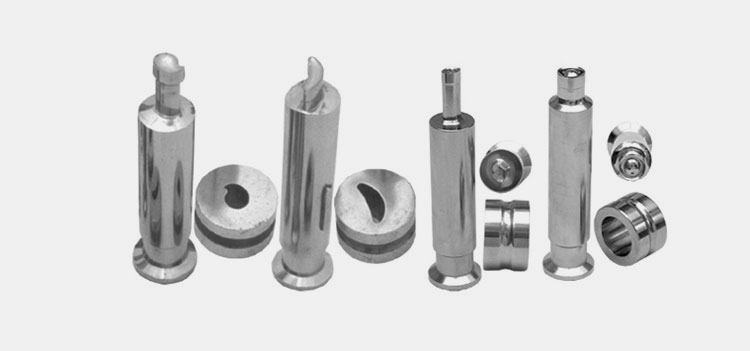

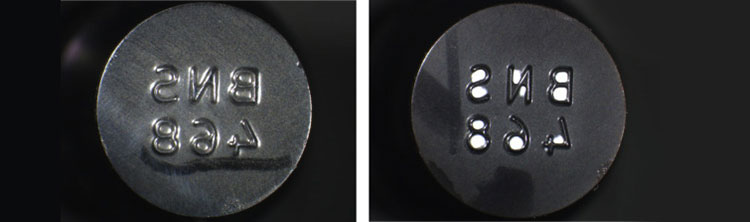

Variations in Tooling

The two fundamental components of the single-punch tablet machine that are punches and a die are collectively called tooling. The tooling is designed in various shapes and plays a major role in the device's versatility.

The tools are made to produce different kinds of tablets and are available in a range of sizes and shapes. The most typical shapes are oblong, diamond, oval, and round. Similar to this, certain instruments are designed to imprint symbols and shapes on tablets.

The dies and punches are typically made of a material that can withstand high-pressure force, such as stainless steel or Aluminum alloy.

Furthermore, differences in the thickness of the tablet are also caused by the depth of the die pockets. Because of the adaptability of the tooling, several production units stamp their industrial brand emblem on the tablets to deter counterfeiting.

10.What maintenance procedures should one develop to ensure the optimal performance of a single-punch tablet machine?

Maintenance of Single Punch Tablet Machine

You don’t need to worry about the maintenance of the machine as one of the benefits of a single-punch tablet machine is its easy maintenance. The device has a simple structural design and is easy to clean.

Maintenance is crucial for any industrial equipment as it aids in the machine's longevity and maintaining its best working condition. Here we are discussing the basic maintenance protocols of a single-punch tablet machine.

- Routine cleaning and dusting of the complete instrument must be done to guarantee the long life of the equipment without any decline in the quality of products.

- The tooling must be deeply cleaned to ensure the powder does not stick onto the surface or die pockets that may cause variations in the tablet’s consistency.

- Lubricate the moving components of the equipment to maintain efficient operation.

- A periodic inspection of all the parts should be done to observe any damage, rust, or tear.

- Repair or replace all the worn parts swiftly to prevent any loss of resources.

- The repaired tools should be measured for their dimensions to ensure the desired outcomes.

- The tooling can be polished properly without impacting their dimension to have a smooth finish.

11.What industrial standards you should be aware of when choosing a single-punch tablet machine?

Industrial equipment must adhere to the standard/criterion guidelines to certify the safe and efficacious formulation of tablets without compromising their quality.

The prime standards of quality an instrument needs to concur with are;

cGMP

The rules that provide the minimal requirements for proper designing, monitoring, lines of action, and provisions utilized in the product’s fabrication process are called the current good manufacturing practices (cGMP).

CE

The CE (Conformité Européenne/European Conformity) credential stipulates that the device satisfies certain authoritative conditions of the environment, safety, and health.

FDA

The approval of the FDA (Food and Drug Administration) implies that the product is safe and efficacious as per the legal guidelines.

ISO

The ISO (International Organization for Standardization) certification indicates the product’s safety, quality, and efficiency as per the standardized specifications.

12.What are the issues that one may face while using a single-punch tablet machine and what are the solutions to those issues?

Yes, it is! Suppose you are not following the working protocols. In that case, if the operators are not focused or making errors, the machine is continuously at work, the maintenance is not being regularly done, or any other reason then you may face certain problems in the final product.

Early assessment of the problem is important for a timely solution and for preventing any major loss in terms of the product resources or the machine.

Some of the common issues you may face while using a single-punch tablet machine are;

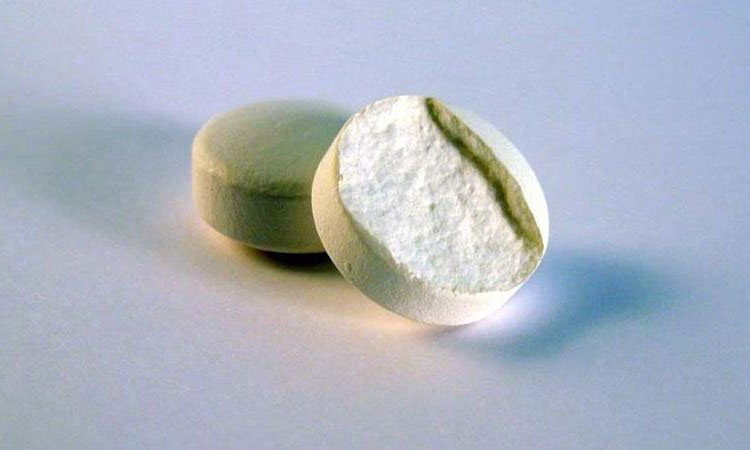

Lamination

Tablet Lamination – Picture Courtesy: Journal of Pharmaceutical Sciences

It refers to the layering of the tablet’s core structure.

It may be caused by over-pressing of powdered material, using worn tooling, or any formulation error.

Solution: Consider replacing the damaged tooling, increasing the binder level in the formulation, and operating the equipment under standard protocols.

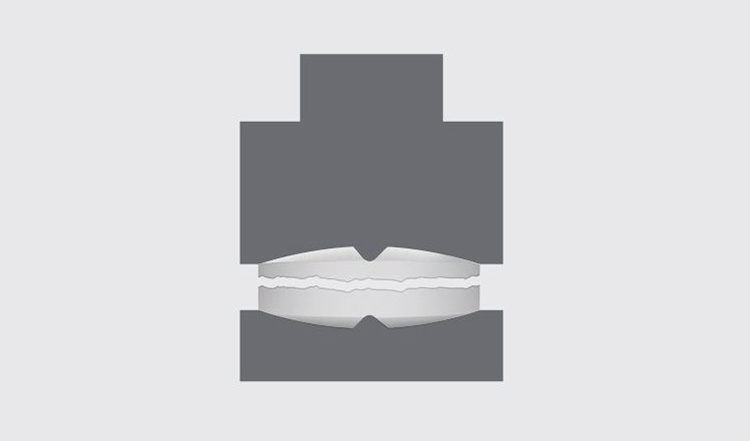

Capping

Tablet Capping – Picture Courtesy: Scientist Live

The removal of the upper or lower layer from the core of tablets is called capping.

The main reason is the air entrapment due to quick compression.

Solution: Adjust the compression speed and force

Sticking

Tablet Sticking – Picture Courtesy: Researchgate

The powder adhesion to the punches or die surface is called sticking.

It may occur due to the utilization of damaged punches or die, small letters or logos, less pressure force applied, or inadequate lubricant in the formulation.

Solution: Polish or replace the dies or punches, increase the lubricant level, increase the dimensions of logos, or adjust the pressing force.

Picking

Tablet Picking – Picture Courtesy: Researchgate

Picking is a more specific term used for material sticking inside the imprinting structures on the punches.

The causes are usually the same as sticking.

Double Impression

Tablet Double Impression – Picture Courtesy: Tech-publish

It refers to the dual imprinting on the tablets.

This issue typically arises with the punches having monograms. It can be caused by over-pressing of the material or by using damaged tooling.

Solution: Replace or repair the tooling or adjust the pressure force.

13.What are the limitations of a single-punch tablet machine?

Picture Courtesy: Adobe Stock

Apart from some incredible benefits of a single-punch tablet machine, there are a few limitations to the device. You must know about those limitations before investing in it so that you may not face any trouble in getting your desired outcomes from the device.

These limitations are;

- It cannot be employed in large production industries as it is designed for small to medium-scale production.

- Many variants of the single-punch tablet machine require manual operation, which can result in the operator’s fatigue and there is an increased chance of human errors

- The single-punch tablet machine offers limited automation, leading to a slower rate of production.

- The tooling changeover may take time and require adjustments manually.

- They may not provide a higher level of accuracy in the tablet’s properties.

14.What factors are necessary to be considered while shopping for a single-punch tablet machine?

There are various models of the single-punch tablet machine available on the market. These variants vary in many characteristics. Before investing in a single-punch tablet machine, you must consider certain factors to ensure buying the right equipment for your business.

Some common factors you should consider are;

Cost

You must assess your budget, considering not only the operational costs but also the maintenance cost, before selecting a particular single-punch tablet machine.

Opt for the equipment that offers the best performance in your available budget.

Capacity

It is an important factor to consider. Different models have different capacities to process the materials. You should select the variant by keeping in mind the present needs as well as the future objectives.

Regulatory Compliance

Safety and quality in the final product are crucial for your business. To ensure the quality of the product, you must consider the device which is designed and manufactured as per the standard specifications.

Maintenance

You should research or ask about the maintenance of the equipment considering its cost and protocols.

Processing Materials

Certain models of the device may not be able to handle some kinds of materials. Therefore, it is necessary to consider this factor and opt for the device that complies with your requirements.

Tablet Variations

Consider the equipment that is capable of producing different kinds of tablets with an easy changeover of the tools.

Safety Features

The safety features are important for a safe and efficient operation. Consider the device with proper safety features installed, such as an emergency alarm and guard locks, to prevent any incident.

CONCLUSION

Tablet manufacturing is a rapidly growing market due to the continuous demand and convenience of tablet dosage forms. A single-punch tablet machine stands as a pivotal tool in various industries, particularly the pharmaceutical industry, offering a versatile solution for the manufacturing of tablets. The device epitomizes efficiency, quality, and diversity, serving as an indispensable part of the tablet formulation. Selecting the right machine variant is crucial in obtaining the desired outcomes. So if you also want to get the incredible benefits of the single-punch tablet machine and considering investing in it, then you must contact the AllPack Team to learn more about the device.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Single Punch Tablet Machine:The Complete Buying Guide In 2024 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours