Box Strapping Machine: The Complete Buying Guide In 2024

Box Strapping Machine: The Complete Buying Guide In 2024

Are you considering purchasing a box strapping machine for all your product strapping needs? If so, then you’re in the right place. Whether you are packaging materials for retail, delivery, or shipping purposes, then a box strapping machine is the best solution for you.

In this post, we’ll take you through everything you need to know about investing in a quality box strapping machine - from its various features and benefits, to the different types of box strapping machines that are available on the market today. Keep reading to learn more about this amazing device so as to make an informed decision on which type suits your needs.

1.What Is A Box Strapping Machine?

A box strapping machine is a type of automated packaging tool that is used to secure boxes with straps. This helps ensure the safe delivery of goods, as it prevents damage caused by items shifting during transit. Also, these machines are designed to quickly and securely fasten straps around boxes and other objects, making them ideal for high-volume packaging operations.

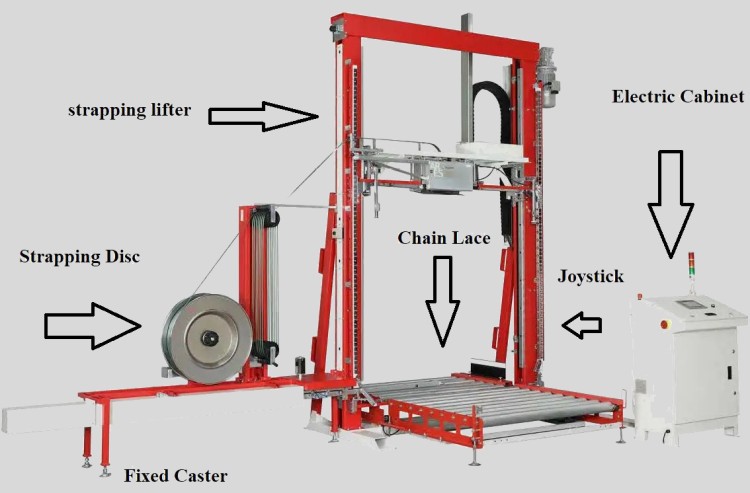

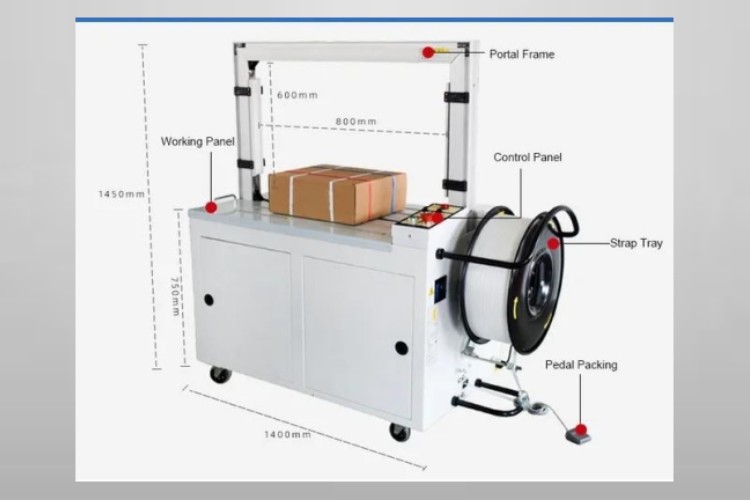

2.What Are The Components Of A Box Strapping Machine?

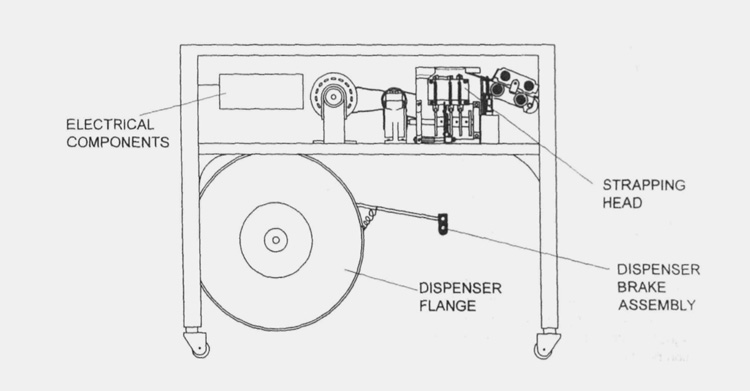

A box strapping machine is an automated packaging system that uses a variety of straps to bundle, secure, and compress multiple items together. The components of a box strapping machine include the strapping head, side and bottom belt drives, film perforator, tightener, weld jaw and sealer, strap dispenser, film roll holder, and tension control unit.

The Strapping Head

This is the main part of the machine, where the strap is attached and drawn through the items being packaged. It also helps guide the strap around the outer edges of the box.

The Side And Bottom Belt Drives

They provide the power needed to move the strapping head along,

The Film Perforator

This one help cut straps at specific lengths.

The Tightener And Weld Jaw & Sealer

These components apply heat to the strap, creating a strong bond that holds the items together securely.

The Strap Dispenser

This part of the machine feeds new straps into the strapping head, while

The Film Roll Holder

It stores extra rolls of the strapping material.

The Tension Control Unit

This component helps maintain a consistent level of force on each strap, ensuring the items stay secure.

3.What Are The Benefits Of Using A Box Strapping Machine?

Box strapping machines offer businesses many advantages.

Increased Productivity

Box strapping machines provide a faster and more efficient way of packaging materials than manual methods, resulting in significantly improved productivity levels.

Increased Precision

By using a box strapping machine, the accuracy of the packaging process is improved as it straps boxes with consistent tension for an even finish. This ensures that the box is tightly and securely sealed, ensuring reduced product damage during transportation and storage.

Improved Safety

Box strapping machines reduce the risk of injury to operators, as no manual labour is required and there is no need for dangerous handling of sharp tools. Furthermore, they can be programmed to be more secure than traditional manual methods.

Versatility

In terms of versatility, box strapping machines are designed to work with a variety of sizes, shapes, and materials. This allows for flexible packaging solutions to accommodate different products and customer needs.

4.What Are The Applications Of A Box Strapping Machine?

A box strapping machine can be used in a variety of industries, including:

Food Industry

A box strapping machine is used to secure boxes of food items for storage and transportation. This ensures that food products remain safe from contamination and spoilage due to changes in temperature or humidity.

Pharmaceuticals

Box strapping machines help keep drugs and medications secured during transport, preventing any tampering or mishandling.

Logistics

In the logistics industry, box strapping machines can be used to secure packages and items for safe delivery. The machines help reduce damage during shipping and ensure that items are properly secured.

Retail

Box strapping machines are often used in retail stores to bundle items together for sale or for display. Also, these machines can be used to create packages of items that are attractive and secure for customers.

Manufacturing Industry

When it comes to the manufacturing industry, box strapping machines are used to package parts and components securely for shipment, ensuring that the products arrive at their destination undamaged.

Beverage Industry

A box strapping machine is an essential part of the packaging process for many beverage companies. It can be used to securely strap boxes, bundles, and cases that contain beverages before they are shipped out for distribution.

Cosmetic Industry

In the cosmetic industry, a box strapping machine is used to package cosmetics and other beauty products. It's an effective way of ensuring that the products remain safe from damage and contamination during shipping and storage.

5.How Does A Box Strapping Machine Work?

A box strapping machine works by manually applying tension to the strap as it weaves through a series of buckles and secures it tightly around the box or carton.

The process begins when the feed system pulls the strap from a coil or spool and feeds it through to the strapping head. The strapping head then passes the strap through buckles which are attached to the box or carton being packaged.

Once the strap is securely in place, the tension rollers apply tension to the strap and pull it tightly around the box or carton. This ensures that it is firmly secured shut and will not come apart during transit.

6.What Are The Different Types Of Box Strapping Machines Available On The Market?

The different types of box strapping machines available on the market include:

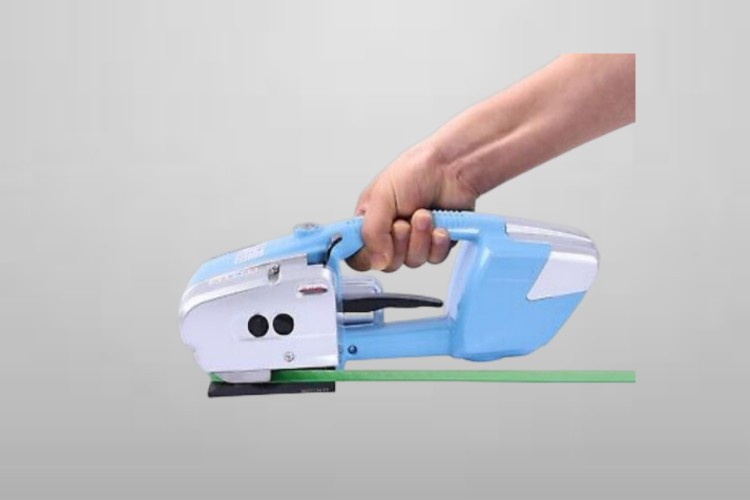

Manual Box Strapping Machine

Manual box strapping machines are the most basic type of box strapping machines available on the market. They are manually operated and don’t require any electricity to work. With manual box strapping machine, straps can be tensioned by hand and then sealed automatically through heat sealing. This type of box strapping machine is ideal for low-volume production jobs.

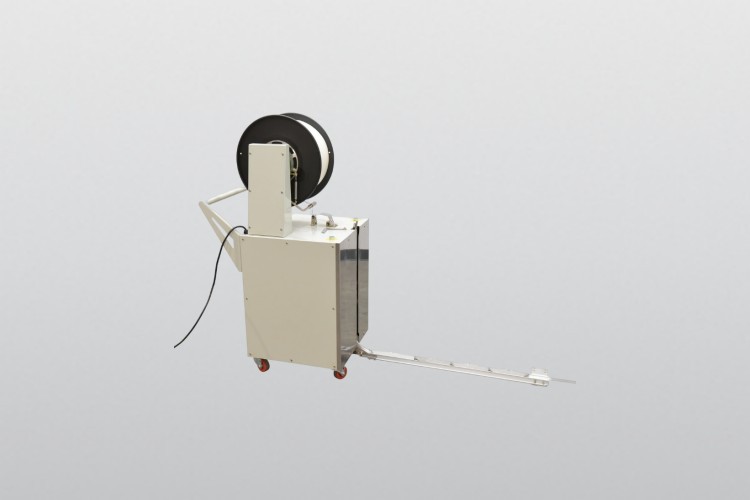

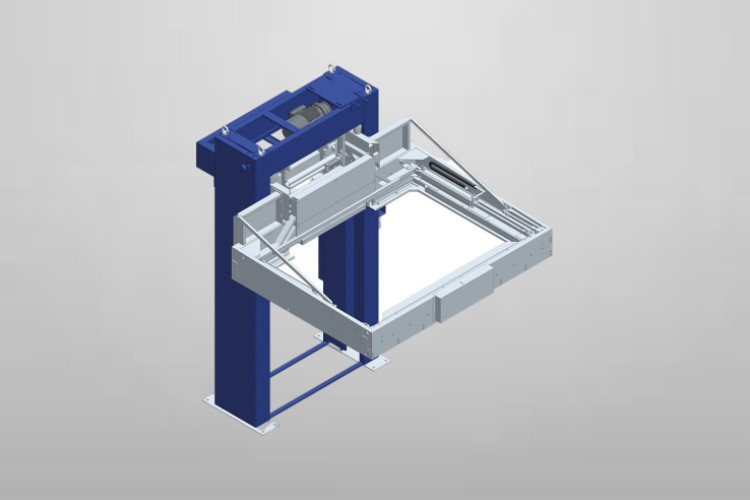

Semi-Automatic Box Strapping Machine

Semi-automatic box strapping machines are a step up from manual box strapping machines and feature some automated components. These machines require an electrical source to operate and use an electric motor to pull the straps and tension them.

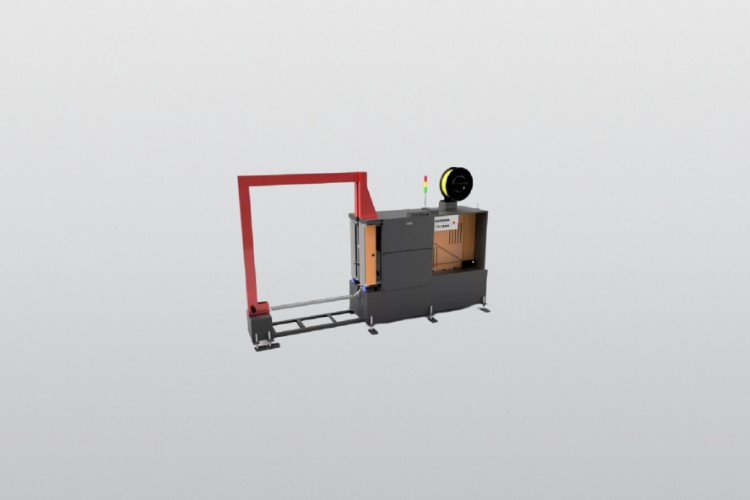

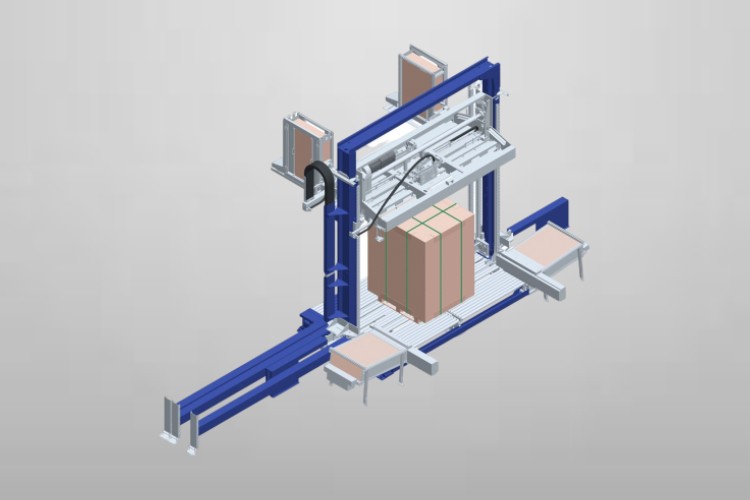

Automatic Box Strapping Machine

Automatic box strapping machines are the most advanced type of machine available on the market today. They feature fully automated components, and are powered by electricity. In addition, they can be used for high-volume production jobs as they can strap multiple boxes at once with a single pass of the machine.

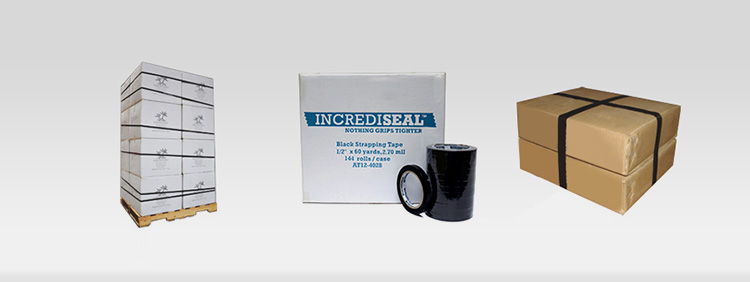

7.What Types Of Strapping Materials Are Compatible With A Box Strapping Machine?

The type of strapping material compatible with a box strapping machine will depend on the specific model and its features. Here are different types of straps that can be compatible with a box strapping machine:

Plastic Straps

Plastic straps are lightweight, durable, and cost-effective banding materials made of plastic. They are available in a range of widths and thicknesses, which allow for varying levels of tension and strength.

Steel Straps

Steel straps are heavy in weight and more durable than other straps. This nature makes them ideal for heavy-duty industrial applications and also because of their greater tensile strength they also be used to secure large boxes or pallets.

Polyester Straps

Polyester straps are strong, lightweight and have a high degree of flexibility. They are less prone to tearing or breaking than other types of strapping material and can be used in extreme temperature conditions.

Paper Straps

Paper straps are made of recyclable materials which are cost-effective and greater in tensile strength, making them an ideal choice for specifically light-duty uses. Their recyclable nature also makes them environmentally friendly thus an ideal choice for your applications.

8.What Factors Should You Consider When Choosing Strapping Material For Your Box Strapping Machines?

When choosing strapping material for box strapping machines, there are several factors to consider:

Strength and durability

Different types of strapping materials have different levels of strength, so it’s important to choose the one that is best suited for your particular packaging application. Strapping with high breaking strength and stretchability is best, as it will help to ensure the contents of your box stay secure during transport.

Durability

Not all strapping materials are resistant to wear and tear, so you should choose one that won’t become worn or frayed quickly. Look for an option with features like UV protection, resistance to moisture, and chemical resistance.

Ease of use

Your strapping material should not take much of your time using your box strapping machine. Some materials are easier to thread through the machine than others, so you should research different options and find the one that will fit and work best with your equipment.

Environmentally friendly

It’s quite important to consider whether or not the strapping material are made from sustainable materials.

Product dimensions

Finally, it’s important to select a strapping material that can wrap snugly around the product dimensions of your boxes. Strapping materials come in various sizes and widths, so you should measure the size of your products before selecting one. This will ensure that the strapping is secure and won’t slip or cause any issues during transport.

Shipping distance

You may want to choose a more durable material that can stand up to extreme weather conditions and rough handling more especially for longer distances.

Method of strapping

It’s also important to consider the method of strapping you will use with your box strapping machine. Some materials are better suited to manual or automated strapping, so be sure to research the pros and cons of each option before making a purchase.

9.What Is The Difference Between Banding Machines And Box Strapping Machines?

Banding machines are used to secure items together through the use of a flexible band wrapped around them, while box strapping machines are used to secure boxes with straps.

Box strapping machines use plastic or metal straps to hold boxes closed and secure the contents inside, while banding machines can be used to secure items of any size and shape.

Banding machines are typically smaller in size than box strapping machines, making them ideal for use in tight spaces or on specific products.

Box strapping machines provide more support and stability than banding machines, as they can secure larger objects with greater strength compared to a banding machine.

Box strapping machines are more expensive than banding machines due to the added cost of production, materials, and maintenance.

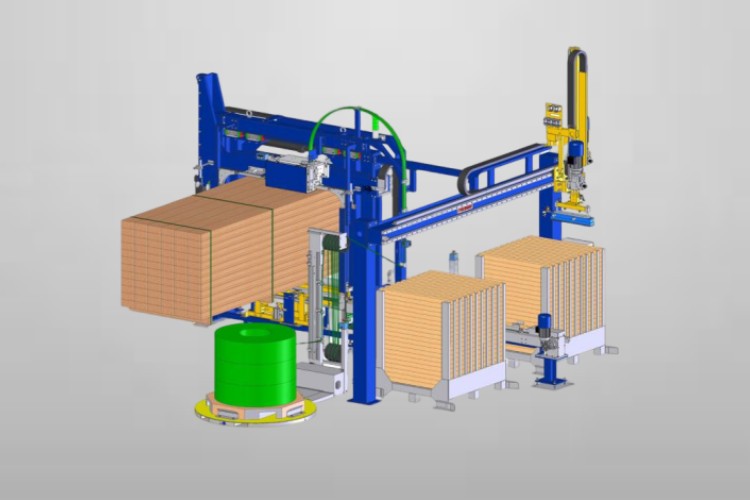

10.What Is The Difference Between pallet strapping Machines And Box Strapping Machines?

The primary difference between pallet strapping machines and box strapping machines is the size of the items they are used to strap. Pallet strapping machines are designed for bigger, heavier objects such as bales, pallets and crates. Box strapping machines, on the other hand, are designed for smaller items such as boxes and packages. These machines use more lightweight straps that can withstand less weight.

Pallet strapping machines come along with a variety of features such as automatic tensioning and adjustable strap widths making them ideal for large-scale industrial operations. Box strapping machines, on the other hand, are more suited to lighter packaging applications and usually have fewer features.

Another difference between pallet strapping machines and box strapping machines is their cost. Pallet strapping machines are relatively costly compared to box strapping machines due to their larger size and more powerful features they possess. Box strapping machines on the other side are usually much less expensive and can be purchased for a fraction of the cost of pallet strappers.

11.What Are The Considerations Before Purchasing A Box Strapping Machine?

Cost

Normally, the cost of a machine varies depending on its features and quality, so be sure to compare different models to get the best deal for your needs. Therefore, it’s important to consider the cost of the machine that can suite your needs.

Size and Capabilities

Some machines are designed to strap larger packages while others are meant for smaller packages. Consider this before buying a box strapping machine that can be an ideal choice for your business.

Maintenance

Be sure to find out how often your box strapping machine needs to be serviced, the type of maintenance required and whether there is a warranty provided with the purchase.

Safety

Look for a box strapping machines that come with safety features such as emergency stops, sensors for detecting overloads, and other protective features for this will ensure that the machine is being used safely and efficiently at all times.

Conclusion

The power of a box strapping machine is unrivaled! Whether you’re securely holding items together, protecting them from adverse conditions, or keeping them safe throughout their journey to the consumer, these machines are the perfect solution. Their speed and efficiency save you time and money while ensuring your products are packaged with care. With so much to benefit from, it's not surprising that countless businesses have chosen to invest in this reliable equipment. If you're ready to feel the same confidence and satisfaction when it comes to packaging, then contact Allpack today and take advantage of our comprehensive range of box strapping machines.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Box Strapping Machine: The Complete Buying Guide In 2024 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours