Can Sealer Machine: A Complete FAQ Guide In 2024

Can Sealer Machine: A Complete FAQ Guide In 2024

Sealing cans has never been easier with the introduction of can sealer machines. These machines are designed to seal cans of different shapes, sizes and materials with precision and efficiency. Whether you are a small business owner looking to expand your packaging capabilities or a large-scale manufacturer, finding the right can sealer machine can be a daunting task.

This buying guide will provide you with the essential information you need to make an informed decision and choose the right can sealer machine that meets your specific needs.

Let’s delve deeper and explore the world of can sealer machines:

1.What is a can sealer machine?

A can sealer machine is a device that seals the top of a can to preserve the contents and prevent contamination. It works by applying heat and pressure to the lid, melting and crimping it onto the can rim, creating an airtight seal. The machine is a crucial component in the packaging industry, ensuring the safe storage and transportation of various products in cans.

Imagine a summer day, and you have just made a pitcher of fresh lemonade. You want to keep it cold for later, and you need a container that will keep it fresh and fizzy. That’s where a can sealer machine comes in! It seals the lid onto the can with a strong bond that locks in the flavor, aroma, and carbonation of your lemonade.

2.What are the commercial applications of can sealer machine?

can sealer machines are widely used in a variety of commercial industries for sealing cans, bottles, and jars. These machines are designed to provide airtight and leak-proof seals, making them suitable for food and beverage packaging, as well as packaging of chemicals, and other products.

One popular application of can sealer machines is in the food and beverage industry, where they are used to package a wide range of products such as soups, sauces, juices, and drinks. The machines can be adjusted to accommodate different can sizes, and their speed and efficiency make them ideal for high-volume production environments.

Another application of can sealer machines is in the chemical industry, where they are used to package products such as paints, solvents, and adhesives. The machines provide a reliable seal that prevents leaks and spills, which can be dangerous in the handling and storage of these products.

3.Why is it crucial to use can sealer machine?

- Can sealer machines are crucial in packaging and preserving food and beverages. These machines help to maintain the freshness, flavor, and quality of the product by creating an airtight seal.

This is important because the presence of air and other contaminants can cause spoilage, leading to waste and a decrease in product quality. - These machines are capable of sealing cans at a high speed, which helps to increase productivity and reduce production time.

- The seals created by these machines are also highly durable and long-lasting, ensuring that the contents remain fresh and protected even under rough handling or shipping conditions.

- Another advantage of using a can sealer machine is that it helps to reduce waste and increase sustainability. By providing an airtight seal, the machine helps to prevent spoilage and reduce the need for excess packaging materials.

This can result in cost savings for the manufacturer and a reduction in environmental impact. - Furthermore, the machine can create consistent and uniform seals, giving the cans a professional and appealing look that can help to attract consumers and increase sales.

4.What are the various types of can sealer machines?

Some of the common types of can sealer machines include:

a)High Volume Fully Auto Round Can Sealer Machine

A high volume fully auto round can sealer machine is a type of sealing machine designed for high-volume production in the food and beverage industry. It is capable of sealing a large number of round cans quickly and efficiently, making it ideal for large-scale operations.

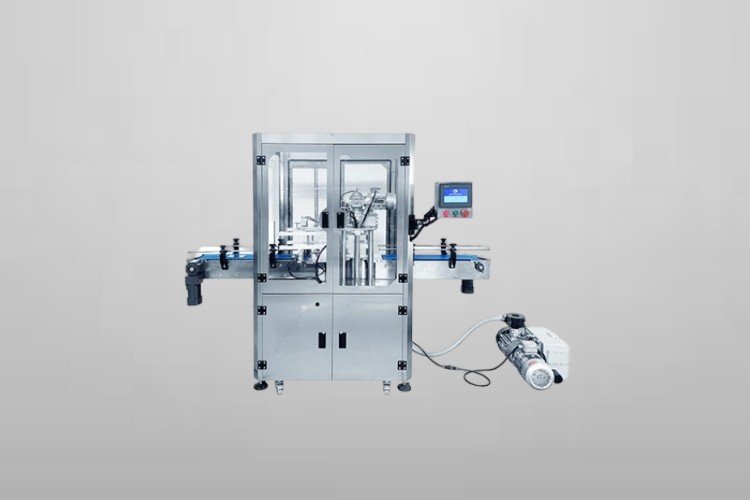

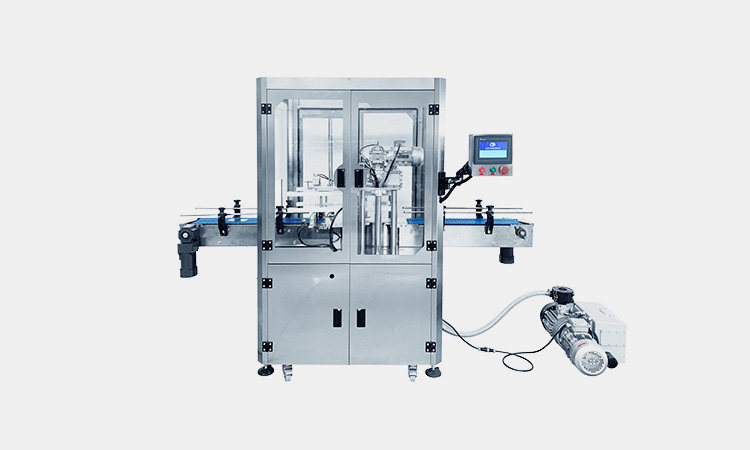

b)Servo Fixed Speed Can Sealer Machine

A servo fixed speed can sealer machine is a type of sealing machine used for packaging products in a variety of industries. It is characterized by its use of a servo motor to control the speed of the sealing process, which results in a more consistent and reliable seal.

This machine is often used for packaging products such as food, pharmaceuticals, and chemicals.

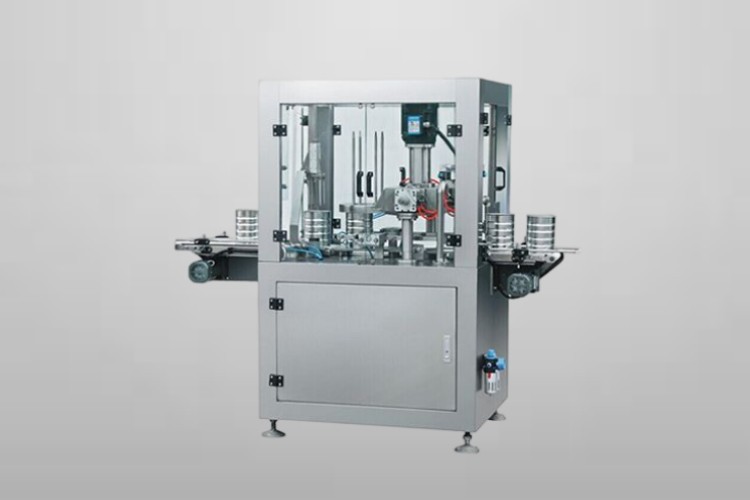

c)Fully Auto Nitrogen Filling Vacuum Sealing Machine

A fully auto nitrogen filling vacuum sealing machine is a machine used to fill and seal food products in containers. It is a fully automated process that utilizes nitrogen gas to preserve the freshness of the food product and extend its shelf life. This machine is widely used in the food and beverage industry, as well as in pharmaceuticals and chemical products.

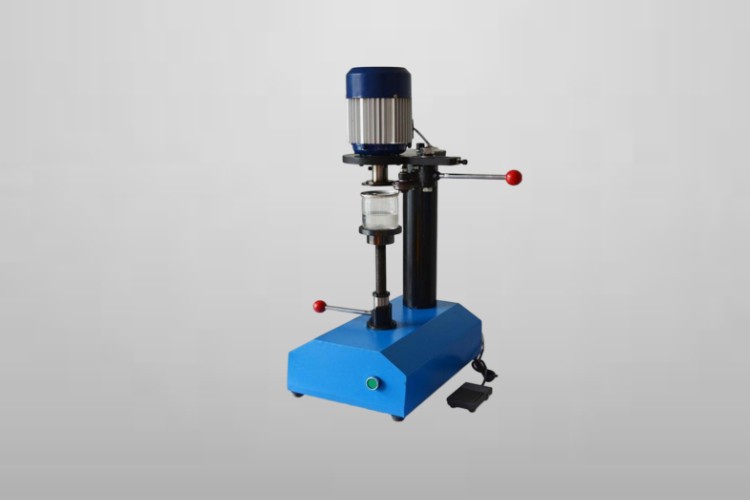

d)Semi Automatic Vacuum Can Sealer Machine

The semi automatic vacuum can sealer machine is a revolutionary kitchen gadget that will change the way you preserve and store food. This compact and versatile machine allows you to vacuum seal your food in an airtight and waterproof container, keeping it fresh for longer periods of time.

With its user-friendly design and semi-automatic operation, you can easily seal cans of any size and shape with just a touch of a button. Say goodbye to wasted food and hello to perfectly preserved meals, fruits, and snacks every time!

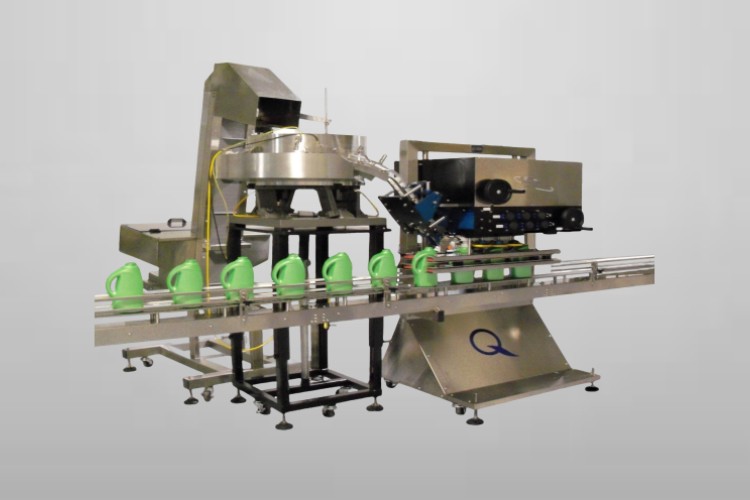

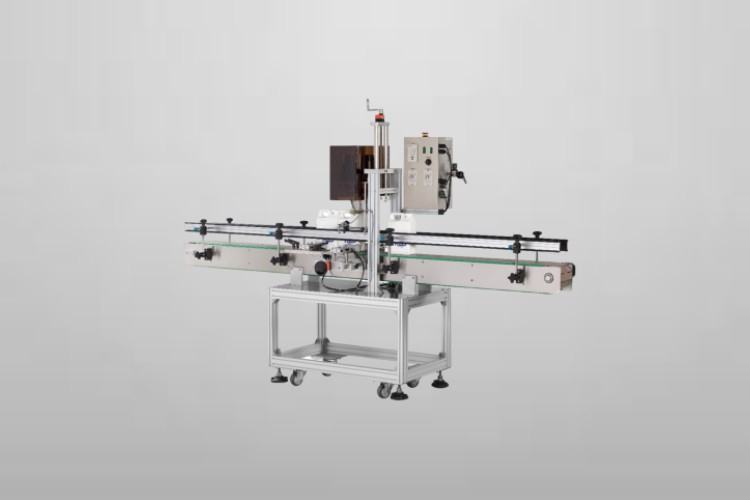

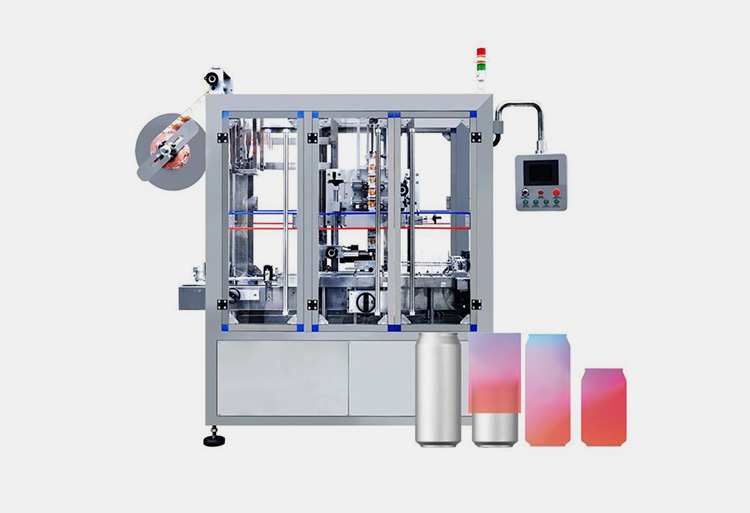

e)Automatic Can Sealer Machine

Automatic can sealer machine is a machine used for sealing the lid onto metal cans. It is widely used in the food and beverage industry for packing products such as juice, syrup, tomato paste, and more. The machine operates by first cleaning the rim of the can and then placing a lid on top, which is then tightened using a specialized sealing head.

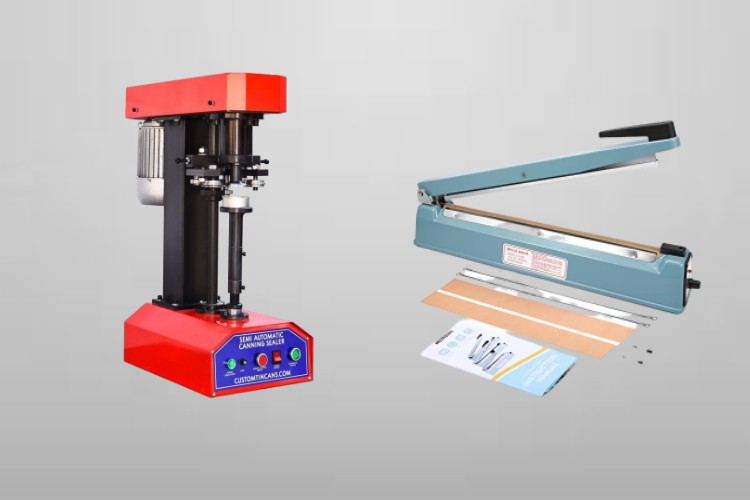

f)Semi Automatic Can Sealer Machine

Introducing the semi automatic can sealer machine, the perfect solution for all your canning needs! This versatile machine is designed to make the canning process effortless and efficient. With its innovative design and semi-automatic operation, you can seal cans of all sizes with ease.

With its user-friendly interface, you’ll be able to get started with canning in no time. Simply place your can in the designated area, pull down the lever to activate the sealing process, and voila! Your can is sealed and ready to store or sell. The machine’s powerful vacuum pump creates an airtight seal that will keep your food fresh for longer.

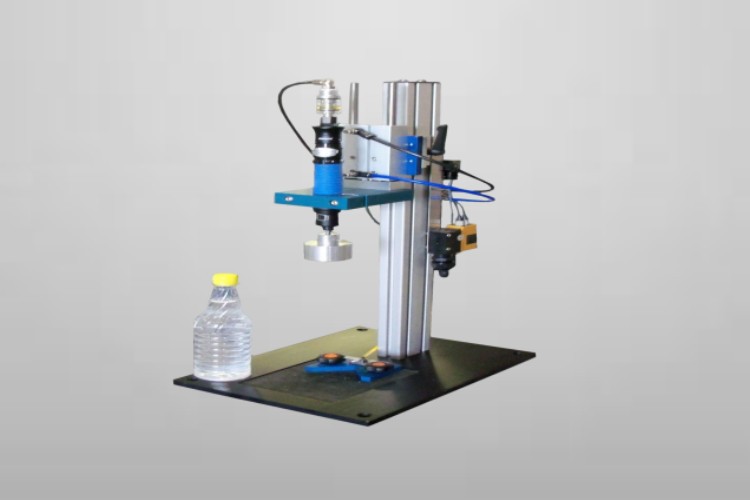

g)Hand Can Sealer Machine

The hand can sealer machine is a convenient and efficient packaging solution designed for sealing a range of containers, such as cans, jars, and tins.

The hand can sealer machine functions through thermal conduction, using electrical resistance to heat the sealing element and fuse the lid to the container. Its portable and lightweight design makes it a flexible solution for smaller-scale packaging needs, while its robust construction promises long-lasting durability.

h)Rotary Can Sealer Machine

A rotary can sealer machine is a high-performance packaging equipment designed for the efficient and precise sealing of cans. This machine is widely used in the food and beverage industry for canning and preserving products such as fruits, vegetables, sauces, and juices.

The compact design of the machine makes it easy to integrate into any production line, while the durable construction ensures long-lasting performance and reliability. The machine is capable of sealing cans of various sizes and materials, making it a versatile solution for businesses of different sizes and needs.

i)Aluminium Foil Induction Can Sealer Machine

The revolutionary aluminium foil induction can sealer machine offers a quick and efficient solution to seal your cans with precision and ease. The unique induction sealing technology uses electromagnetic energy to heat and melt the foil, creating an airtight and tamper-evident seal.

This machine ensures that your products stay fresh and protected for a longer period. So, upgrade your sealing game today and experience a new level of efficiency.

5.What are the differences between Can Sealer Machine and Can Capping Machine?

Differences Between Can Sealer and Can Capping Machines

Can sealer machine and can capping machine are both used in the packaging industry, but they serve different purposes. The main differences between the two are:

- Purpose: A can sealer machine is used to seal the lid onto the can body, creating a hermetic seal to preserve the contents inside. A can capping machine, on the other hand, is used to apply a cap onto the top of a bottle or a jar.

- Container type: Can sealer machines are specifically designed for sealing cans, while can capping machines can be used for a variety of container types, including bottles and jars.

- Sealing method: Can sealer machines typically use a heat sealing method to create an airtight seal on the can. Capping machines, on the other hand, can use a variety of methods, including screw-on caps, snap-on caps, and crimp-on caps, depending on the type of container and cap being used.

- Equipment type:Can sealer machines are typically larger and more heavy-duty, while can capping machines can be smaller and more compact, depending on the scale of the packaging operation.

- Operation: Can sealer machines usually require the can to be fed into the machine and rotated during the sealing process. Capping machines may have a conveyor system to transport bottles or jars through the machine, where the cap is automatically applied to each container.

These are some of the key differences between can sealer machines and can capping machines. Both types of equipment play important roles in the packaging process and are used by professionals in a variety of industries, including food and beverage, pharmaceuticals, and cosmetics.

6.What are the differences between Can Sealer Machine and Bag Sealer Machine?

Can Sealer vs Bag Sealer

Can sealer machine and bag sealer machine are both packaging machines that are used to seal containers to preserve and protect their contents. However, there are some key differences between the two that are worth considering:

Container Compatibility:

Can sealer machines are designed specifically to seal cylindrical cans, while Bag Sealer Machines can seal bags of various shapes and sizes, including flat, gusseted, and stand-up pouches.

- Sealing Method: Can sealer machines use a crimping mechanism to attach a lid to the top of the can, creating an airtight seal. On the other hand, Bag Sealer Machines typically use heat sealing to join the two sides of a bag together, creating an airtight seal.

- Seal Strength: Can sealer machines typically create a stronger and more secure seal than Bag Sealer Machines, as the crimping mechanism provides a solid, tamper-evident seal.Bag sealer machines can still provide a strong and secure seal, but it may not be as tamper-evident as a seal created by a can sealer machine.

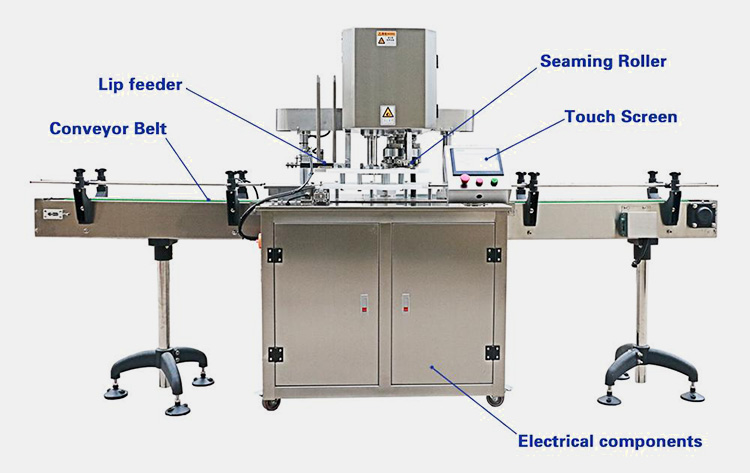

7.What are the main componentsof a Can Sealer Machine?

A can sealer machine typically consists of the following components:

Conveyor Belt: The conveyor belt is the backbone of the can sealermachine and helps to ensure that the cans are properly aligned and positioned for sealing. The conveyor belt typically runs on a series of rollers that are powered by the drive system.

Lid Placement Mechanism: The lid placement mechanism is responsible for placing the lid onto the top of the can before sealing. This mechanism typically consists of a series of mechanical arms and suction cups.

Sealing Head:The sealing head is the most critical component of the can sealer It is responsible for applying pressure and heat to the lid’s perimeter, creating a permanent, airtight seal that will keep the contents fresh. Some sealing heads may also include sensors and control systems to monitor and adjust the sealing process in real-time.

Drive System: The drive system is the motor and gears that power the conveyor belt and sealing head. This system is responsible for maintaining the proper speed and timing of the sealing process, and for controlling the amount of pressure and heat that is applied to the lid.

Safety Features: These features may include emergency stop buttons, protective guards, and interlocks that prevent the machine from operating if the lid placement mechanism is not in the correct position.

Cooling System: After sealing, the cans need to cool down before they can be removed. This system helps to ensure that the can and lid are properly set and that the contents of the can remain fresh and secure.

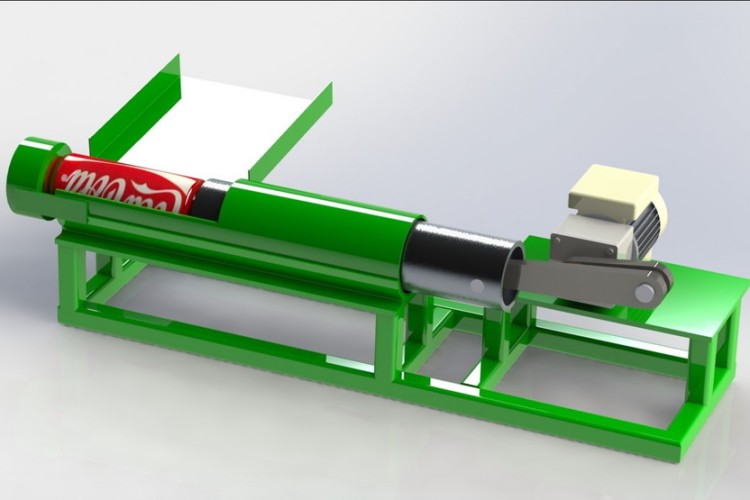

8.On what principles, a Can Sealer Machine works?

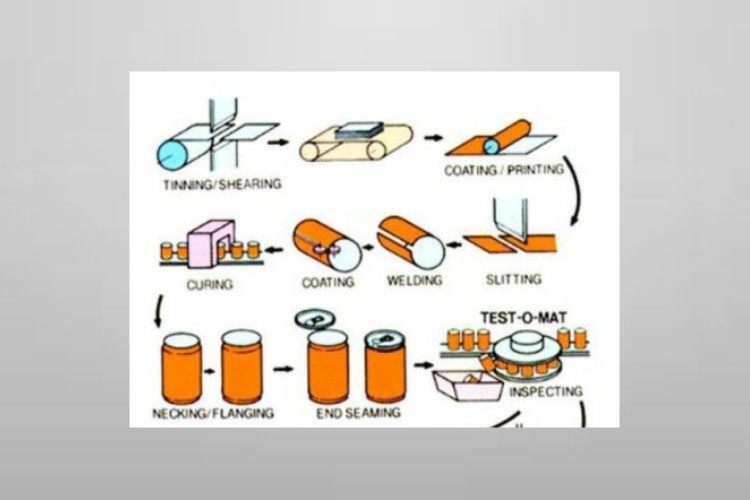

The can sealer machine works by crimping the end onto the can body, creating a double seam, trimming the excess metal, and finally inspecting the can for defects. It operates on the principle of creating an airtight seal on the top of a can. The following is a step-by-step explanation of how it works:

- Preparation: The first step is to prepare the can by cleaning it and making sure that it is free from any debris. The lid, known as the end, is also placed on top of the can.

- Seaming Roller: The next step is the seaming roller, which crimps the end onto the can body. The seaming roller is usually made up of two rollers, one stationary and one that rotates. The rotating roller is responsible for crimping the end onto the can body and creating a tight seal.

- Cutting and Folding: The next step is cutting and folding the end to create a double seam. This double seam is what creates a secure and airtight seal on the top of the can. The cutting and folding of the end are accomplished using a series of cutting blades and folding arms.

- Trimming: After the double seam has been created, the trimming process begins. The trimming process removes any excess metal from the top of the can, creating a smooth and polished finish.

- Inspection: The final step is inspection, where the can is checked for any defects or leaks. If the can passes inspection, it is then ready for use.

9.What materials is the Can Sealer Machine compatible with?

Can sealer machines can be used to seal various types of cans, including:

- Aluminium cans: These are the most common type of cans that are used for packaging food and beverages.

- Steel cans: Steel cans are often used for packaging canned goods such as soups, vegetables, and fruits.

- Tinplate cans: Tinplate cans are made of tin-coated steel and are often used for packaging tea, coffee, and spices.

- Composite cans: Composite cans are made of a combination of materials, such as aluminium and plastic, and are often used for packaging energy drinks and other beverages.

- Glass jars: Some can sealer machines are designed to seal glass jars, which are often used for packaging products such as pickles, sauces, and jams.

- Aerosol cans: Aerosol cans are used for packaging spray products such as deodorants, hair sprays, and air fresheners.

It’s important to note that not all can sealer machines are compatible with all types of cans, so it’s important to check the specifications of the machine before purchasing to ensure that it can seal the type of cans you need to use it for.

10.What are the troubleshooting during operation of a Can Sealer Machine?

Can sealer machines can face various issues during their operation. Some of the common problems and their solutions are as follows:

- Can jamming: Can jamming can occur due to improper can loading, damaged or worn out feeder gears, or worn out conveyor rollers.

Solution: Ensure proper can loading, replace damaged or worn out parts, and regularly maintain the machine. - Sealing problems: Can sealing problems can occur due to worn out sealing blades, damaged or clogged nozzles.

Solution: Replace worn out sealing blades, clean or replace damaged nozzles, and ensure proper air pressure. - Leaking cans:Leaking cans can be caused by improper sealing and damaged cans.

Solution: Ensure proper sealing, check for damaged cans, and clean or replace clogged nozzles. - Incomplete sealing: Incomplete sealing can be caused by worn out sealing blades.

Solution: Replace worn out sealing blades and ensure proper air pressure.

11.How to Select the Satisfactory Can Sealer Machine?

When choosing a can sealer machine, there are several key factors to consider to ensure that you select the most suitable one for your needs:

- Can Size: Make sure the machine can accommodate the size of cans you will be sealing.

- Type of machine: Choose between a manual, semi-automatic, or automatic sealing machine based on your needs and level of automation desired.And consider the machine’s speed and capacity, to ensure it meets your production requirements.

- Durability: The machine should be able to withstand frequent use and perform well over a long period of time, reducing the need for maintenance and downtime.

- Price: Determine your budget and compare prices between different models to find the best value.

- Brand Reputation: Choose a supplier that has good reputation and provides technical support and training to ensure you can effectively operate and maintain the machine.The most important thing is that it should have a warranty

- Compliance with industry standards:The machine should meet relevant industry standards and regulations, such as food safety standards, to ensure product quality and protect consumer health.

Taking the time to choose the right can sealer machine can help ensure that your investment provides the desired results and enhances the efficiency and quality of your production processes.

Conclusion

In conclusion, a can sealer machine can be a game-changer for your business or personal canning needs. With the right machine, you can save time and money while ensuring that your cans are sealed securely and efficiently. Whether you are a small business owner, a home canner, or just someone who enjoys preserving food, a can sealer machine is a valuable investment that will pay for itself in no time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Can Sealer Machine: A Complete FAQ Guide In 2024 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

A vegetable canning machine typically has several major components, including:

A vegetable canning machine typically has several major components, including:

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours